High-strength heat radiation type hardware backboard and production technology thereof

A heat-dissipating, high-strength technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve problems such as insufficient strength and no heat dissipation function of the backplane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

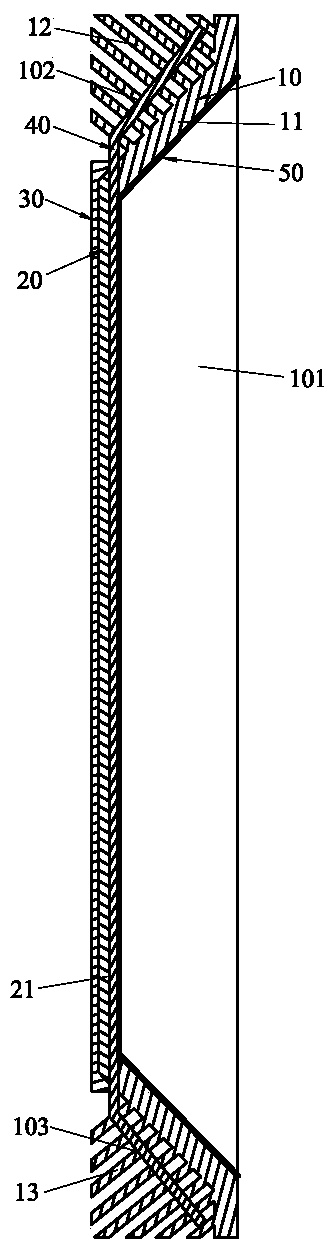

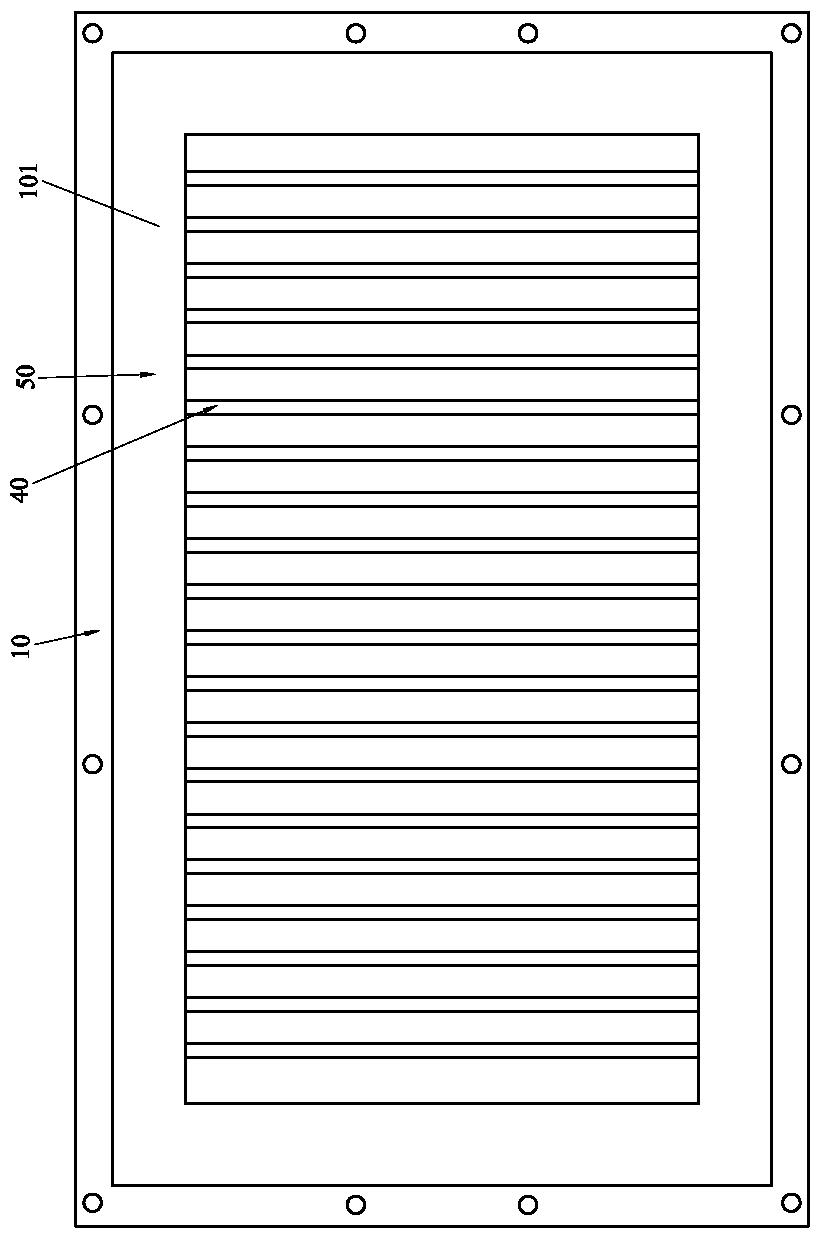

[0028] Please refer to figure 1 with figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a heat dissipation frame 10 , a heat dissipation cover 20 , a reinforcement cover 30 and a plurality of heat pipes 40 .

[0029] The heat dissipation frame 10 is made of aluminum alloy, and includes a main frame 11, which is in the shape of a hollow truncated cone, and has a truncated cone-shaped accommodation space 101. Radiating fin group 12, the upper cooling fin group 12 is provided with a plurality of horizontally arranged upper jacks 102, the upper side of the upper cooling fin group 12 is flush with the upper side of the main frame 11, and the upper cooling fin group The rear side of the group 12 is flush with the rear side of the reinforced cover plate 30 to make full use of the space; the bottom inclined surface of the main body frame 11 extends integrally with a lower cooling fin group 13, and the lower cooling fin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com