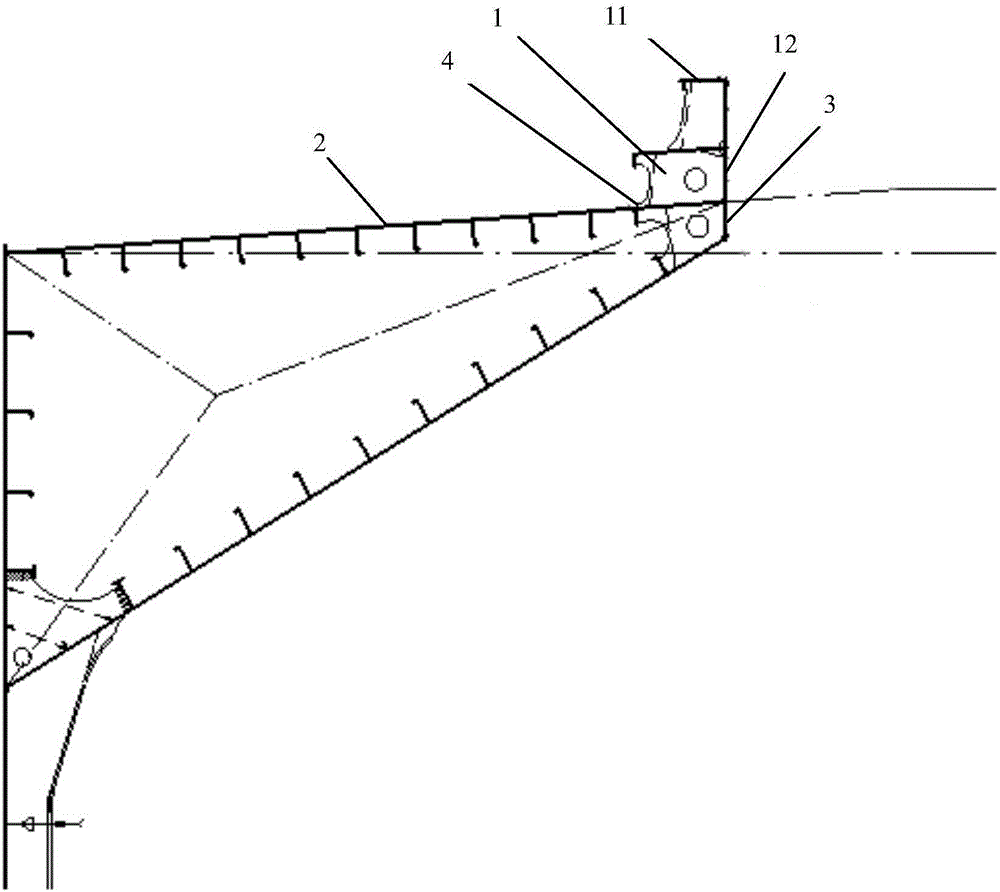

Hatch coaming partially numbered in total strength and hatchway stringer for bulk cargo ship

A coaming and strength technology, which is applied in the field of hatch coaming, can solve the problems that cannot be included in the overall longitudinal strength of the hull girder, discontinuous structure type, hatch coaming danger, etc., achieve weight reduction, improve fatigue life, and enhance The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

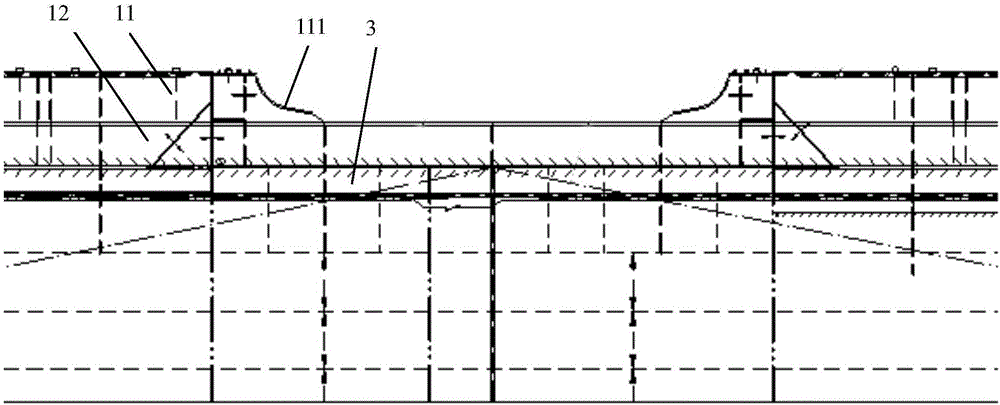

[0024] In further embodiments of the present invention, please continue to refer to figure 2 As shown, the side shape of the cross-section of the upper coaming plate 11 at the disconnection at the transverse bulkhead is a soft toe structure 111 with a circular arc (ie, a transverse "S" shape).

[0025] In a further embodiment of the present invention, since the lower coaming 12 is continuous along the length of the ship, the lower coaming 12 is included in the overall strength, and the upper coaming 11 is disconnected at the transverse bulkhead, so the upper coaming 11 is not included in the overall strength.

[0026] In a further embodiment of the present invention, the selection of the height of the lower coaming 12 needs to comprehensively consider the layout of the cable piping system, the requirements of the construction space, the requirements of personnel passage and the requirements of the arrangement of mooring equipment.

[0027] In a further embodiment of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com