Pneumatic vehicle tyre

A technology for pneumatic tires and vehicles, applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve the problems of long R&D time and high R&D costs, and achieve the effect of high durable kilometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

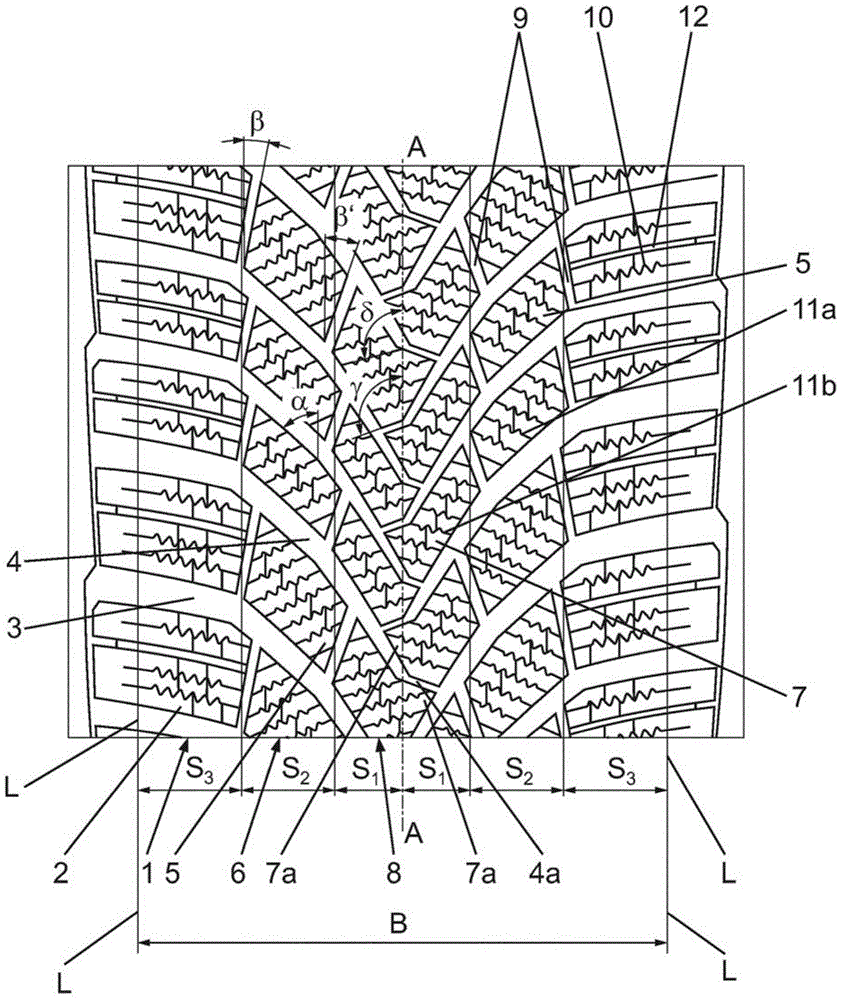

[0010] figure 1 The tread shown in is intended for vehicle pneumatic tires for passenger cars of radial construction, in particular for use in winter driving conditions, and preferably has an outer contour with a tread radius of 300 mm to 400 mm. However, the invention is not limited to winter tyres, but can also be applied to summer tyres. Furthermore, the exemplary tread has a pattern that is implemented in a direction-dependent manner. The invention is not limited to this tread pattern, but can be applied to all kinds of tread patterns.

[0011] exist figure 1 A-A is used to describe the equator of the tire, whereby the tread of the vehicle pneumatic tire is divided into two halves. This tread has two shoulder block rows 1, the blocks 2 of which are separated from each other by a plurality of transverse grooves 3, which are substantially in the transverse direction of the tread or in the order of 5° to 7° It extends obliquely in the transverse direction of the tread und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com