Reduced weight aircraft tire

A technology of pneumatic tires and carcass, which is applied to aircraft tires, tire parts, reinforcement layers of pneumatic tires, etc., and can solve the problem that tires cannot carry heavy loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

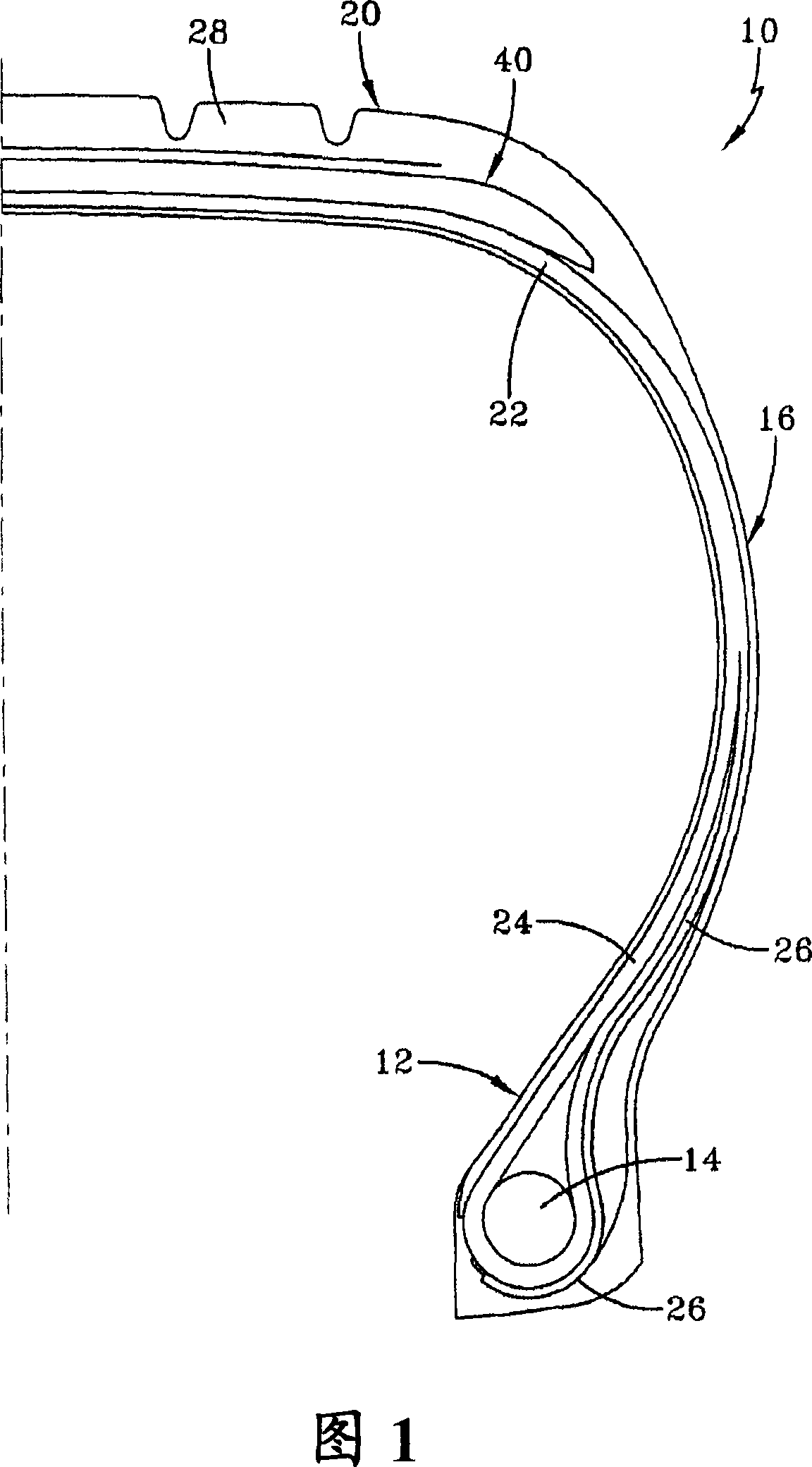

[0022] FIG. 1 shows an example of a radial aircraft tire 10 . As shown, the aircraft tire includes a pair of bead sections 12, each containing a bead core 14 embedded therein. One example of a bead core suitable for use in an aircraft tire is shown in US Patent No. 6,571,847. Those skilled in the art will understand that other bead cores may also be utilized. The aircraft tire comprises sidewall portions 16 extending generally outwardly in the radial direction of the tire from each bead portion 12 and a generally cylindrical tread portion 20 extending between the radially outer ends of these sidewall portions 16 . In addition, the tire 10 is reinforced with a carcass 22 extending annularly from one of the bead portions 12 to the other bead portion 12 . The carcass 22 includes an inner carcass layer 24 and an outer carcass layer 26 . In these carcass layers, generally four inner layers 24 are wound around the bead core 14 from the inner side of the tire toward its outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com