Bidirectional trough type conveyor

A technology of trough conveyors and troughs, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effect of a good sealing state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

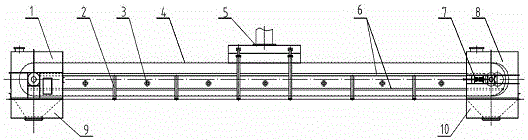

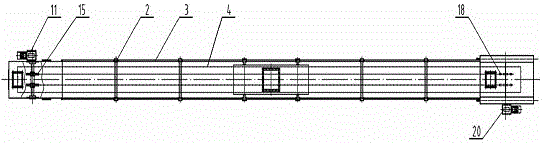

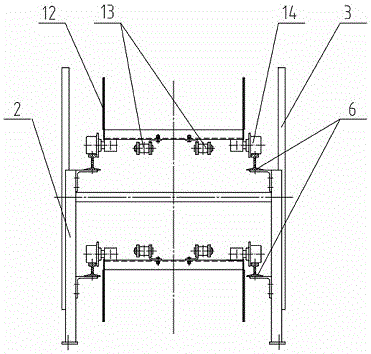

[0017] As shown in the figure, at both ends of the bracket 2 are provided a head device 1 composed of a drive sprocket set and a tail device 8 composed of a reversing sprocket set. The head device 1 and the tail device 8 are respectively provided with a head The bottom discharge port 9 and the tail discharge port 10; the support 2 is provided with an upper and lower double-layer track 6, and a trough 12 is provided on the track 6, and the bottom of the trough 12 is provided with rollers 14 on both sides to cooperate with the track 6, and the bottom of the trough 12 Two chains 13 are also provided to cooperate with the driving sprocket 15 of the head device 1 and the reversing sprocket 18 of the tail device; the support 2 is provided with a feed port 5 with a dust cover, and the feed port 5 is in the trough 12 Above.

[0018] The running part 4 (including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com