Electric heater for pipeline

A pipeline electric heater and electric heater technology, applied in pipeline heating/cooling, pipeline systems, pipes/pipe joints/fittings, etc., can solve problems such as uneven heating temperature, low thermal efficiency, and low thermal conductivity of tiles. Achieve the effect of ensuring normal production, large heat conduction area and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

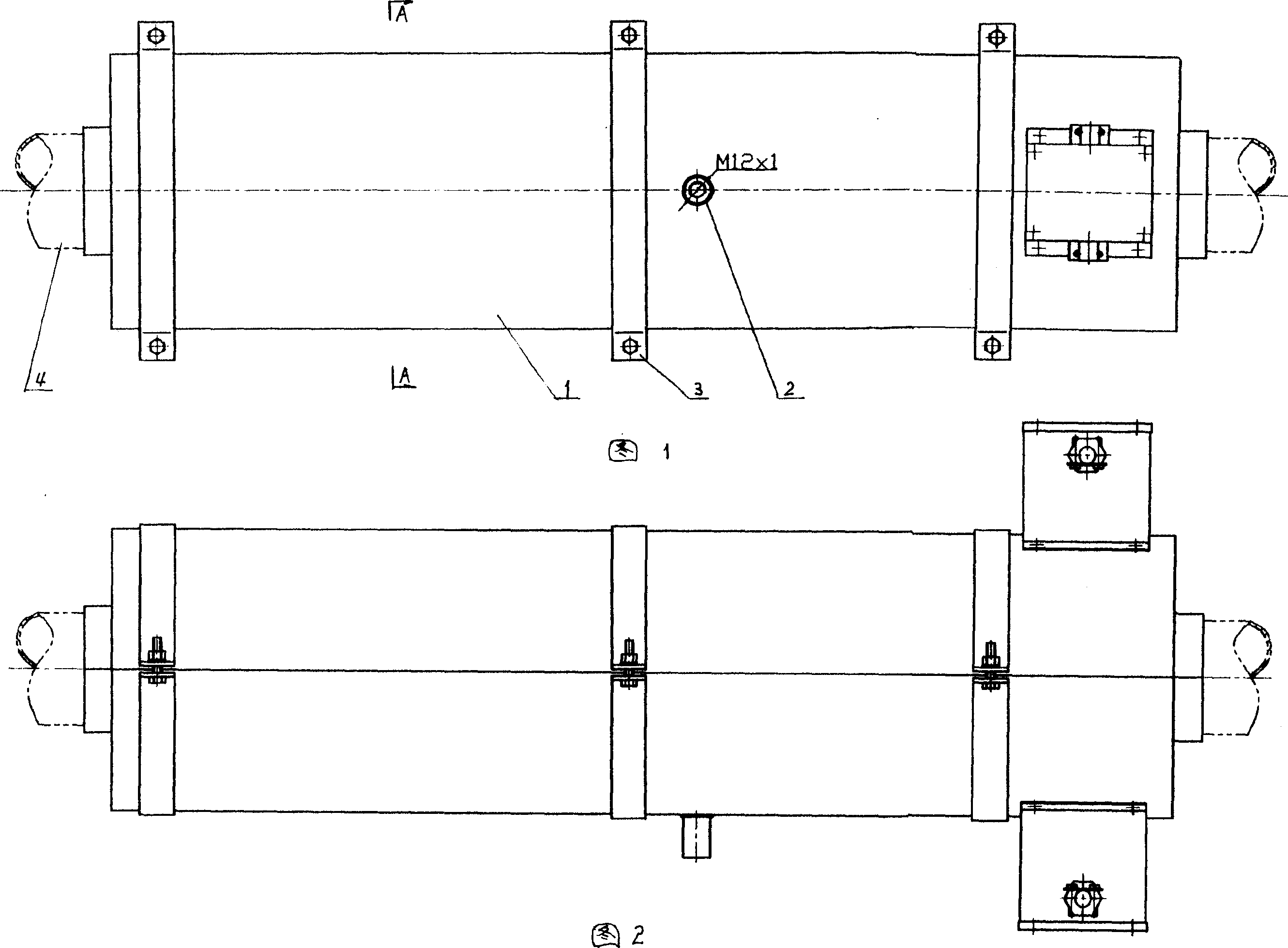

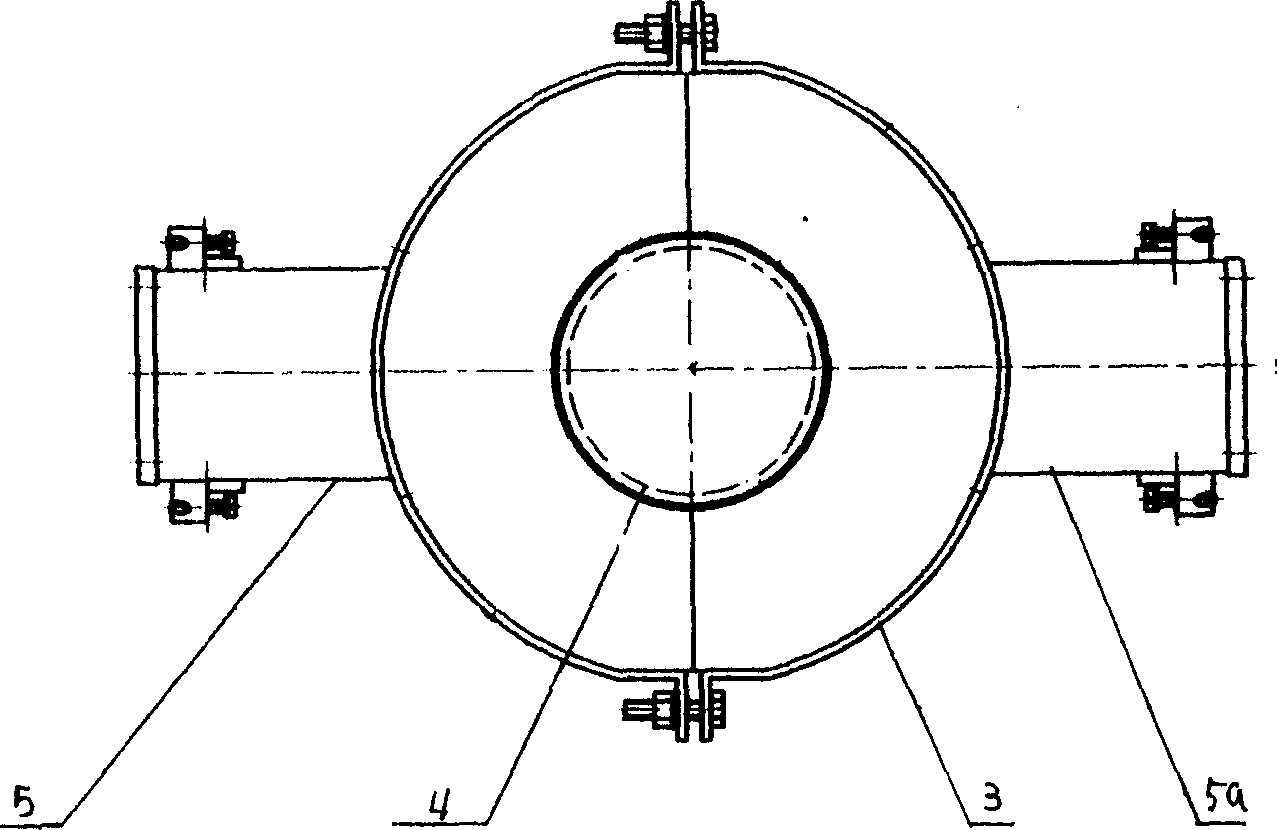

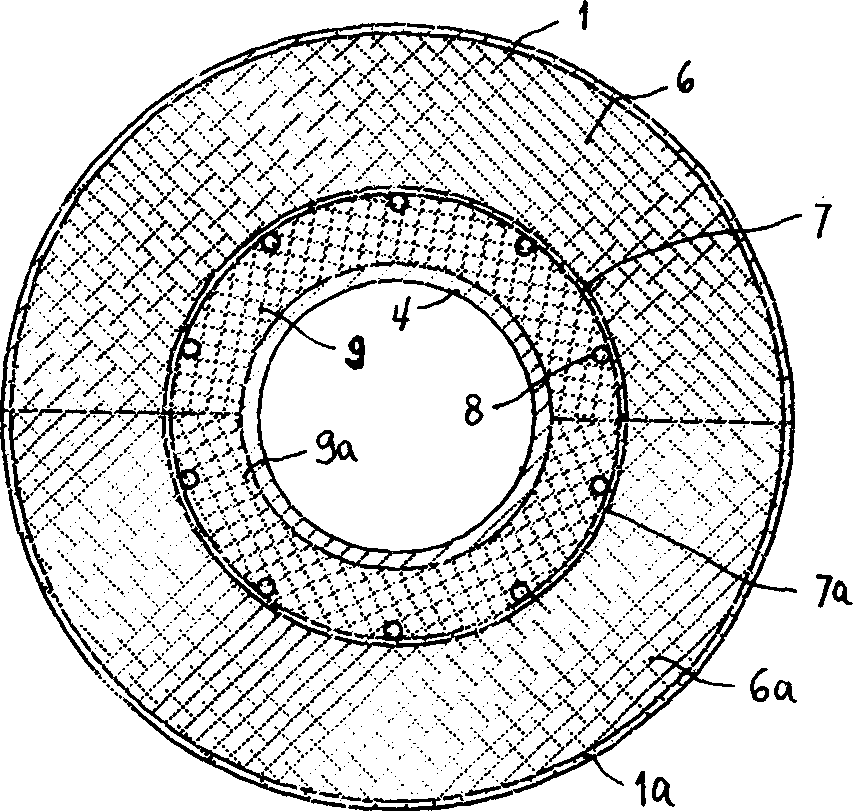

[0018] Figure 4 It is shown that the two bush-shaped heat-conducting layers 9, 9a are made of high-efficiency heat-conducting materials (for example, the temperature range is 500°C, the insulation resistance is above 300MΩ, and the thermal conductivity is 0.9W / M°C); the two bush-shaped metal inner shells 7, An electric heating tube 8 is respectively fixed on the inner wall of 7a, and the electric heating tube 8 is coiled and evenly distributed back and forth along the axial direction parallel to the metal inner shell (see Figure 5 ); two bearing pad-shaped forming insulation layers 6, 6a are made of light aluminum silicate material, and the outer surface of the forming insulation layer is provided with two bearing pad-shaped shells 1, 1a, and the shells 1, 1a are stainless steel plates (such as thick 1.5 mm); the above-mentioned formed heat pipes 9, 9a, metal inner shells 7, 7a with electric heating pipes, formed heat insulating layers 6, 6a and outer shells 1, 1a have the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com