Raw material stirring extraction mechanism with filter apparatus

A technology for filtering devices and raw materials, which is applied to mixers with rotary stirring devices, accessories of mixers, filter screens, etc., can solve the problems of poor sealing performance, reduced product quality, disadvantages, etc., to increase service life and reduce high power output. , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

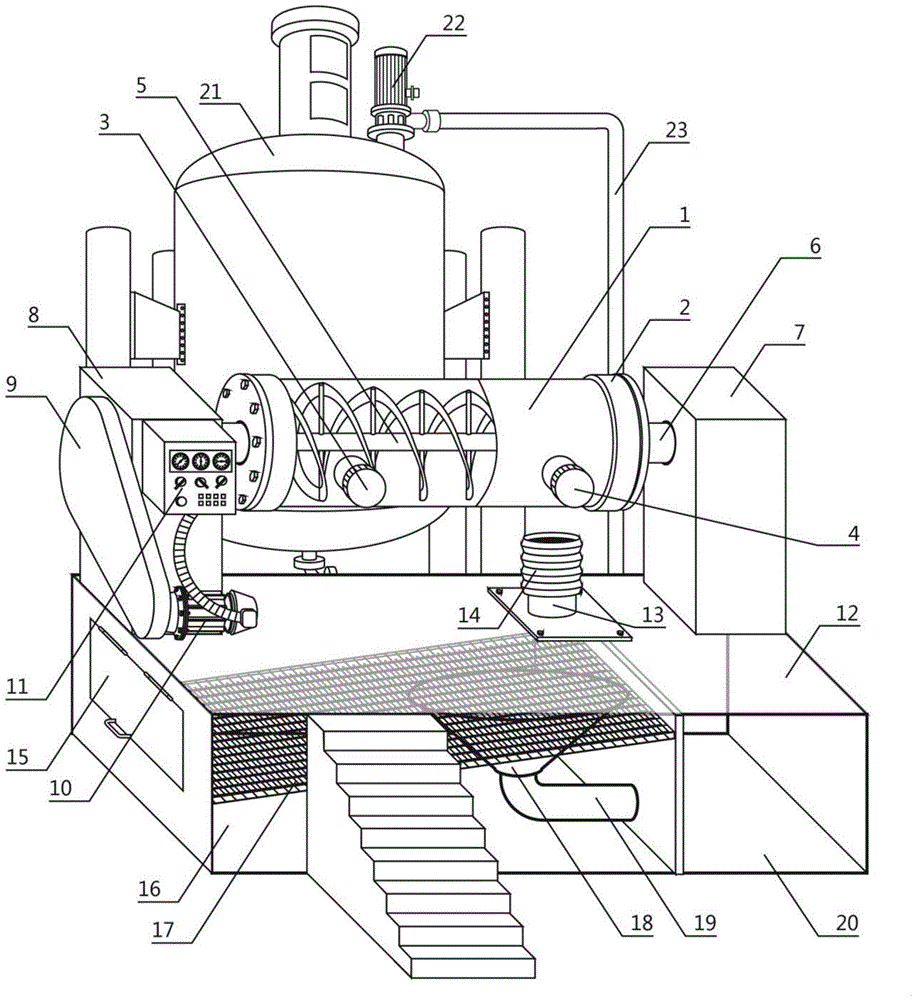

[0024] Such as figure 1A raw material stirring and extracting mechanism with a filtering device is shown, which is characterized in that it includes a stirring tank 1, a rotating shaft 6, a support frame 7, a driving device 8, a transmission belt 9, a motor 10, a control box 11, and a sieve storage cabin 12 and a storage tank 21, the stirred tank 1 is also provided with a power-assisted rotating bearing 2, a feed port 3, a discharge port 4 and a stirring rod 5, and the described power-assisted rotating bearing 2 is located on one side of the stirred tank 1, so The power-assisted rotating bearing 2 is fixedly connected with the stirring tank 1, the feed port 3 is located at one side of the stir tank 1, the feed port 3 is fixedly connected with the stir tank 1, and the discharge port 4 is located at the feeding One side of the mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com