Frame structure of motor bicycle

A technology for motorized two-wheeled vehicles and car bodies, which is applied to motor vehicles, bicycle brackets, motorcycles, etc., and can solve problems such as increased weight, larger frames, and larger pivot plates, and achieve the effect of reducing weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

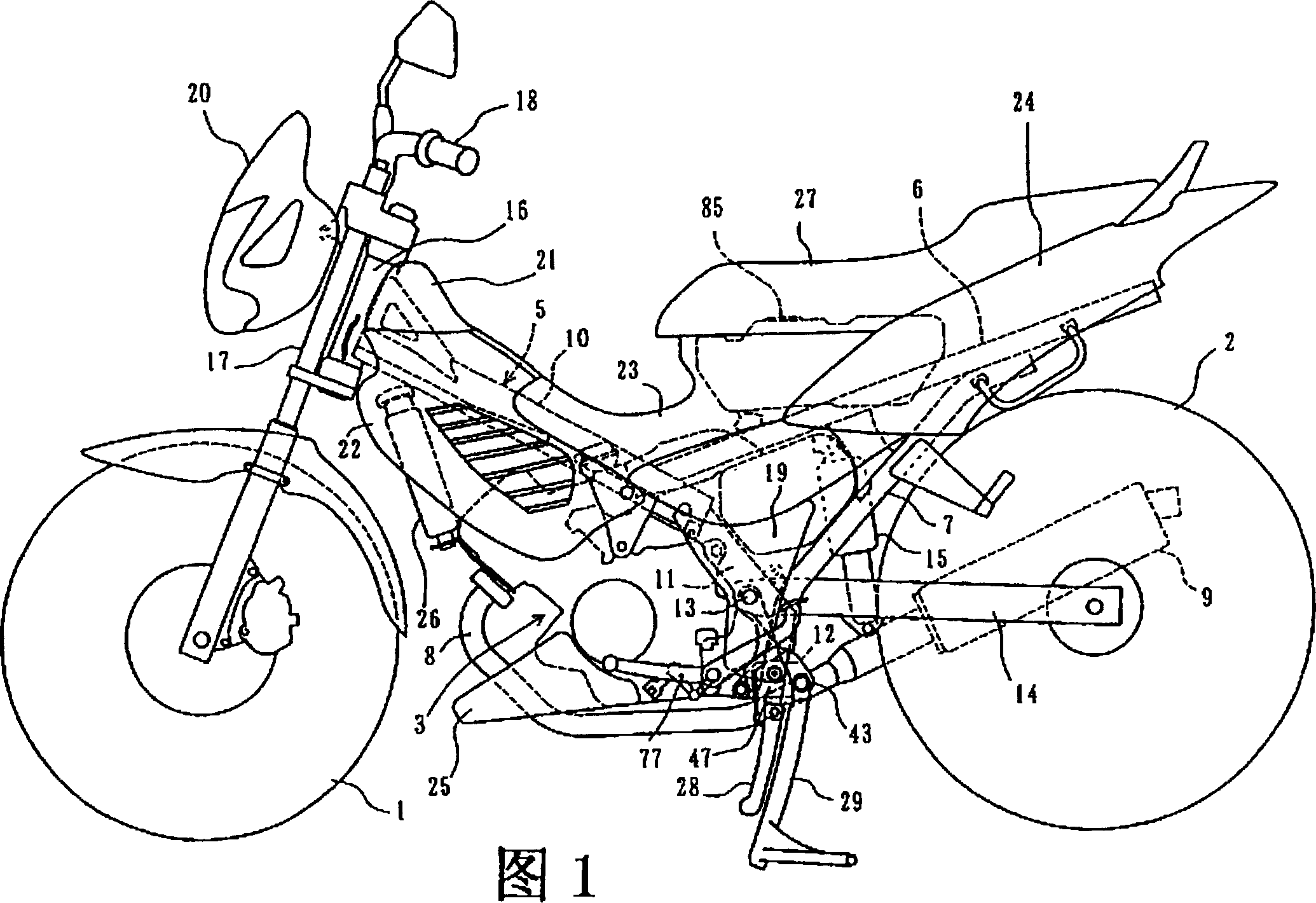

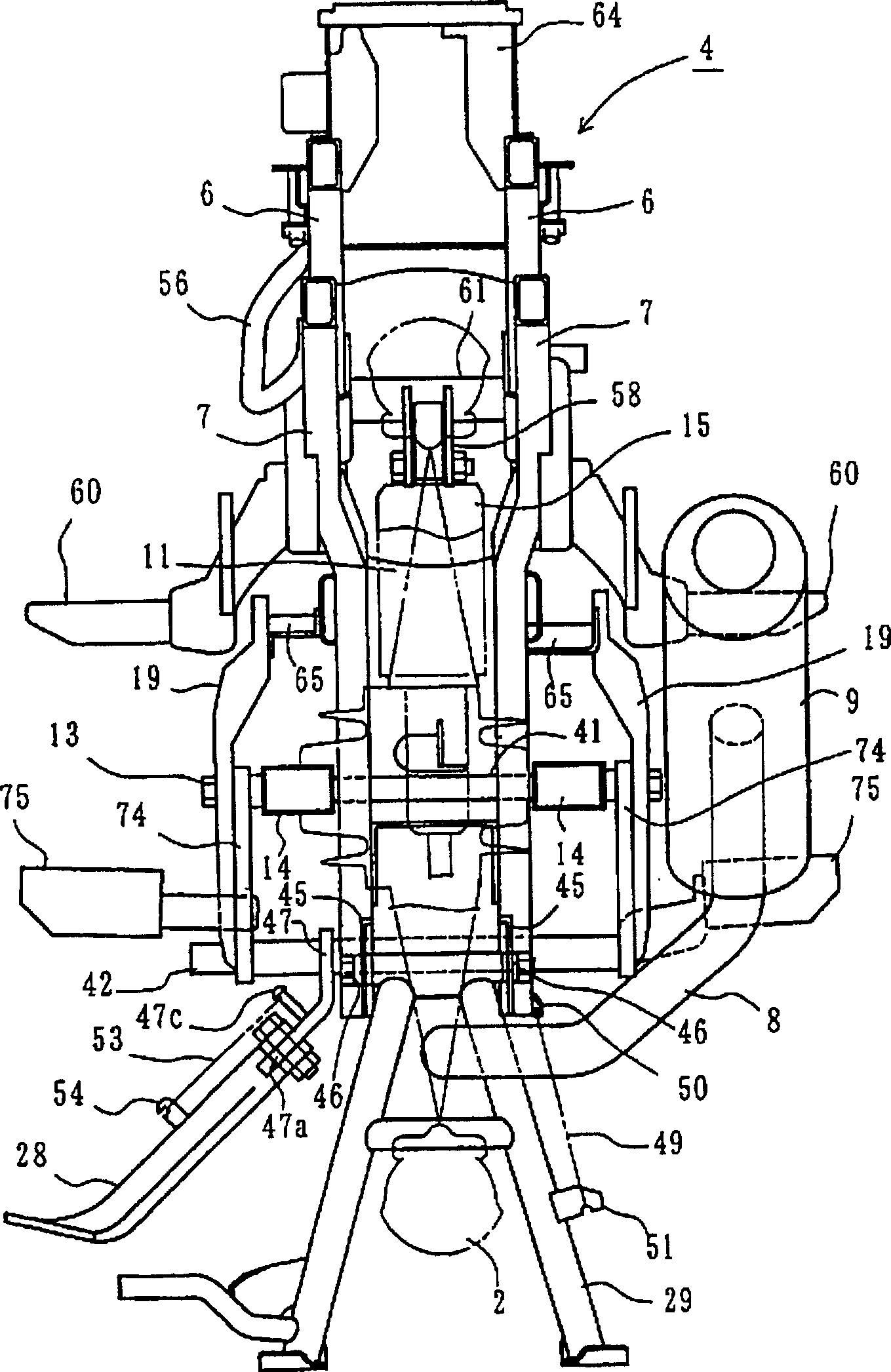

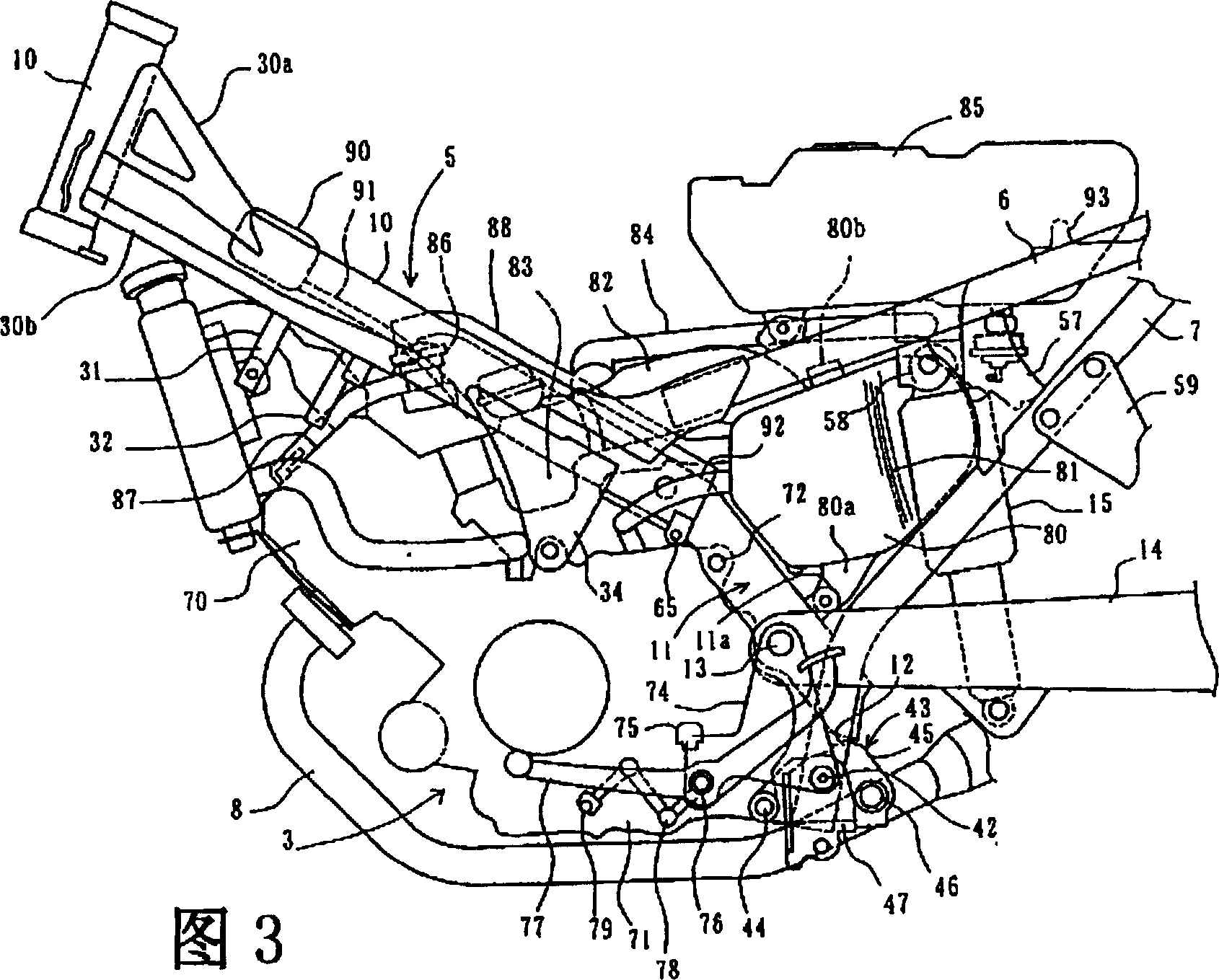

[0023] Next, an embodiment applicable to an off-road motorcycle will be described with reference to the drawings. Fig. 1-Fig. 9 shows embodiment, and Fig. 1 is the side view of vehicle body whole, figure 2 It is a rear view, Fig. 3 is an enlarged side view of the main part of the frame, Fig. 4 is a side view of the whole frame, and Fig. 5 is a plan view thereof, Image 6 for its back view, Figure 7 It is the enlarged cross-sectional view of line 7-7 in Fig. 4, Figure 8 It is an enlarged side view of the lower end of the lower frame, and Fig. 9 is its bottom view.

[0024] First, the general structure of the entire vehicle body will be described with reference to FIGS. 1 to 3 . The vehicle frame 4 (Fig. 4) supporting the water-cooled four-stroke engine 3 arranged between the front wheel 1 and the rear wheel 2 is diamond-shaped, and is composed of a main frame 5, a seat rail 6, and a lower frame 7. The engine 3 functions as part of the frame 4.

[0025] The main frame 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com