Method to remove an agent using a magnetic carrier

A magnetic carrier and reagent technology, applied in the field of process systems, can solve problems such as no substantive results, achieve considerable economic advantages, improve functions, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

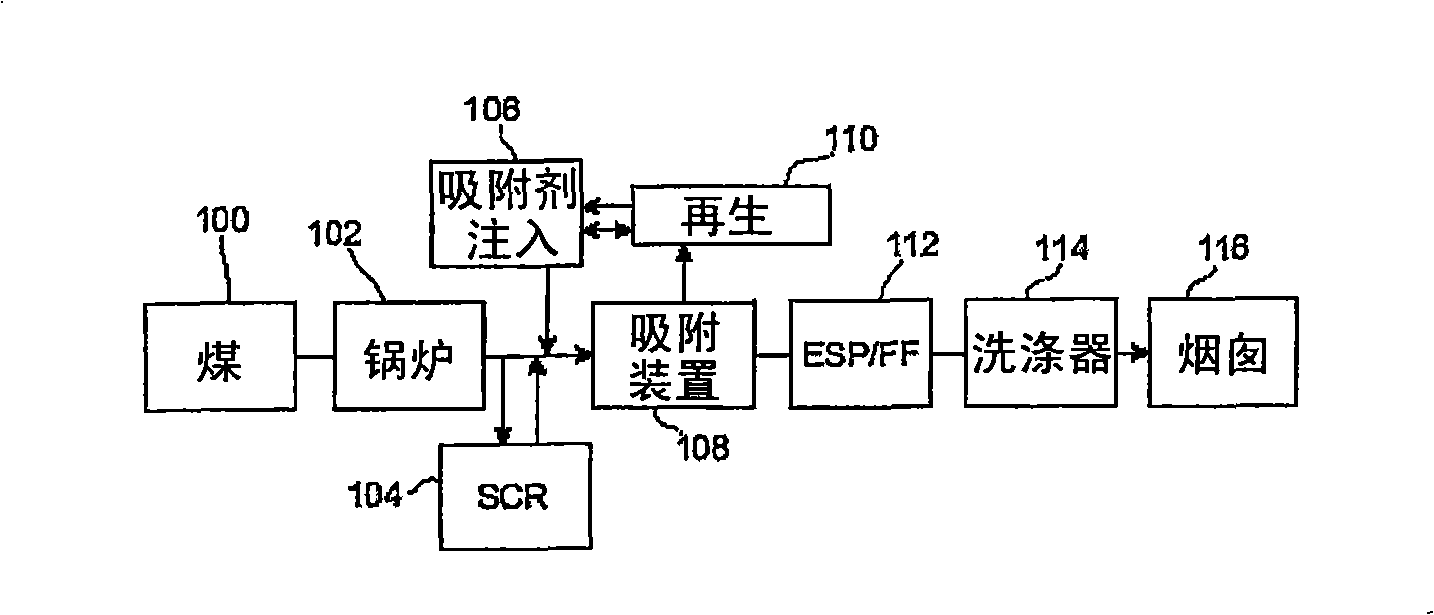

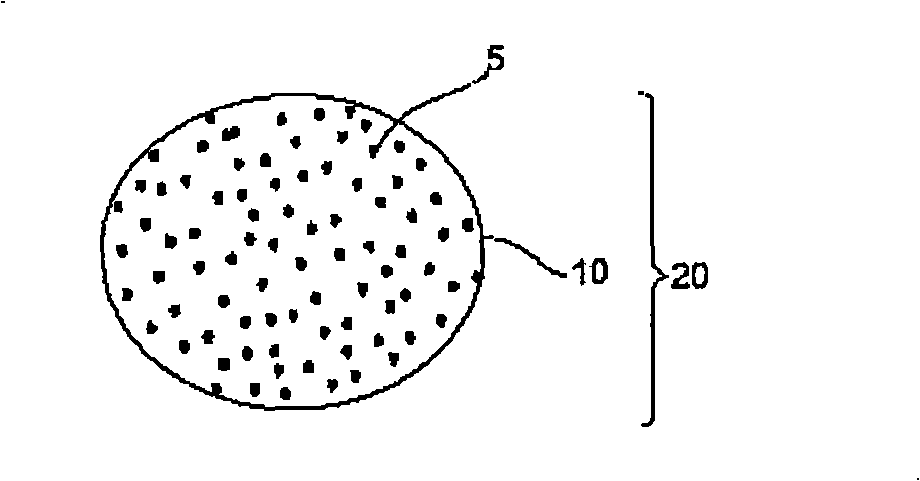

[0021] On a technical level, the present invention looks at the removal of mercury from effluents from fossil fuel power generation systems. In the prior art, mercury has been removed from sewage using adsorbents bound to a solid phase, such as activated carbon, plates or channels. These prior art methods are not entirely satisfactory in removing mercury because conventional sorbents such as activated carbon, sulfur and elemental gold have specific problems including cost, polluting fly ash, and performance issues High efficiency in removing mercury from gas streams. The main reason seems to be that a particular sorbent works or works best with mercury in its oxidized state and does not work well with mercury in its non-oxidized or elemental vapor state. This problem is solved by using magnetic carriers of sufficiently small size suspended in the exhaust gas. The magnetic carrier is functionalized to bind mercury. An advantage over the prior art is that it can be reused. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com