Method for preparing nattokinase through solid-state fermentation

A technology of nattokinase and solid-state fermentation, applied in the field of microbial fermentation engineering, can solve the problem that nattokinase has not been reported, and achieve the effects of high nattokinase activity, increased added value, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The concrete process that present embodiment prepares nattokinase is:

[0019] (1) Preparation of medium: Mix agar 15g / L, peptone 10g / L, beef powder 3g / L and sodium chloride 5g / L, and then sterilize at 121°C for 20 minutes to obtain a slant medium with a pH of 7.1 to 7.5 ; Mix peptone 10g / L, beef extract 5g / L, sodium chloride 3g / L, glucose 10g / L and yeast extract 5g / L, and then sterilize at 121°C for 20min to obtain a seed liquid medium; peanut meal, Wash the bran, soybean meal, oats, and soybeans with clean water and soak them in water three times the total weight, then mix them in a weight ratio of 6:1:1:1:1, and add peanut meal, bran, soybean meal, oats and A nutrient salt composed of a mixture of 1.5% sucrose, 0.21% magnesium sulfate, and 0.27% calcium chloride of the total weight of soybeans, mixed evenly and sterilized at 121° C. for 20 minutes to obtain a fermentation medium;

[0020] (2) Preparation of Bacillus natto seed solution: in a sterile environment, pic...

Embodiment 2

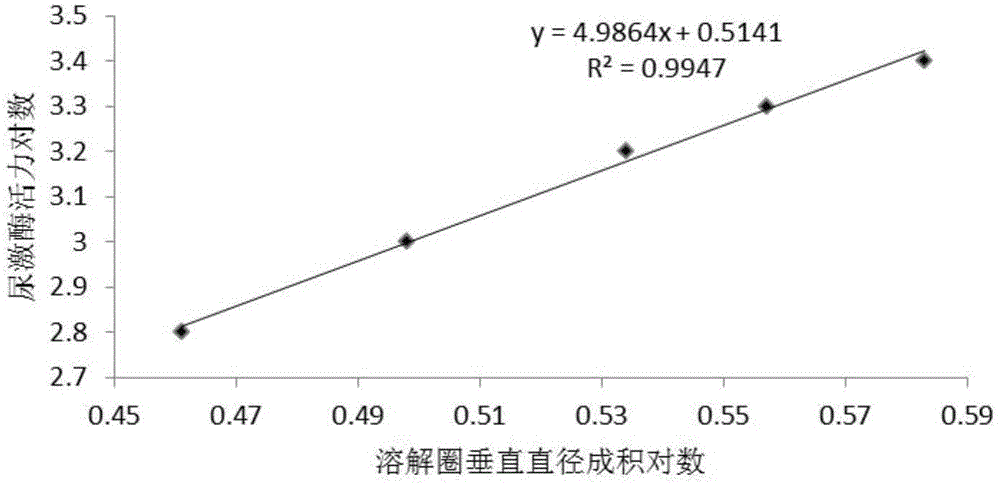

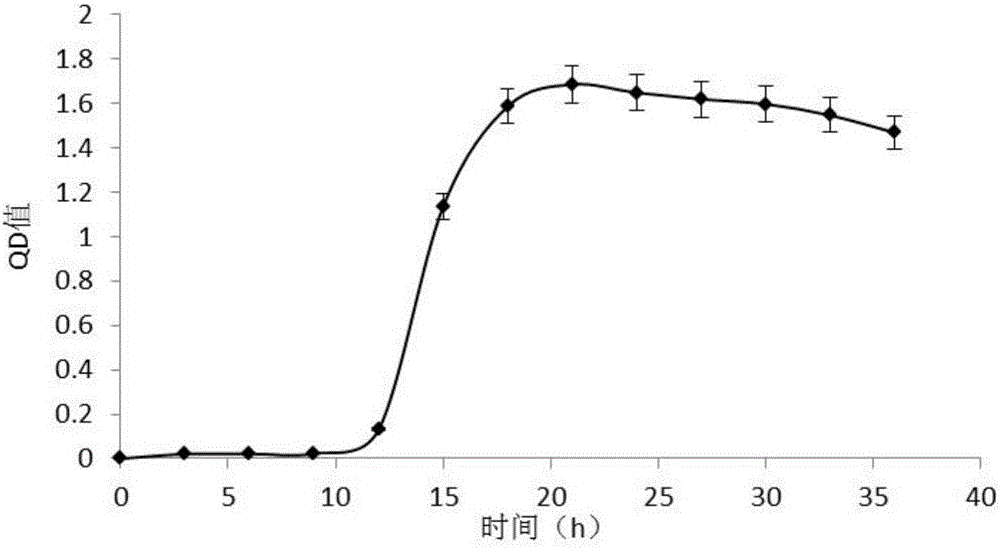

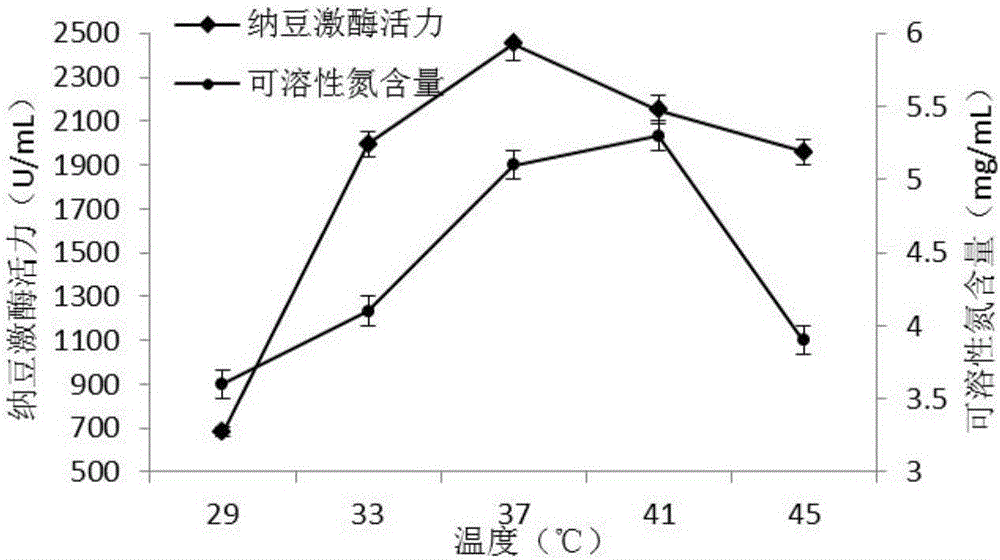

[0023] In this embodiment, the fermented seed solution prepared in step (2) of Example 1 is sampled every 3 hours, and the OD value at 660 nm is measured, and the growth of Bacillus natto is plotted with the seed culture solution not inoculated with Bacillus natto as a blank control curve (eg figure 1 shown), determine the seed age of the access fermentation medium; and change the fermentation temperature, inoculum size (spraying amount of fermented seed liquid), fermentation time, material-liquid ratio (fermentation medium and the Water weight ratio) and the nutrient salt in the step (1), measure the influence of single factor on nattokinase activity and soluble nitrogen content respectively, fermentation temperature is respectively 29,33,37,41,45 ℃; Inoculum size is respectively 1, 2, 3, 4, 5mL; the fermentation time is 12, 18, 24, 30, 36h; the ratio of solid to liquid is 1:0.2, 1:0.3, 1:0.4, 1:0.5, 1:0.6 The measurement results are as image 3 , 4 , 5, and 6; Nutrient sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com