Dispersion nanometer reinforced 690 steel and manufacturing method thereof

A manufacturing method and nanotechnology, applied in the field of 690 steel marine engineering equipment, can solve problems such as low stress corrosion resistance, high environmental fracture sensitivity, and restricted application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0057] The melting, casting and melting process of the sample steel: The chemical composition of the sample steel is shown in Table 1. It is smelted and poured in a 150Kg vacuum induction furnace, cut out the shrinkage cavity, and forged into a billet of 100mm×100mm×120mm. The billet was reheated to 1250°C for 2h, and rolled in 7 passes on a laboratory 450nm two-roll reversible hot-rolling experimental mill, with a final plate thickness of about 12mm. The 12mm thick steel plate was placed in a box-type resistance furnace at 1250°C for 72h, so that the carbides were completely dissolved in the matrix as much as possible, and then quenched to room temperature. A standard thermal simulation sample with a diameter of 8mm and a length of 15mm was cut from the treated steel plate.

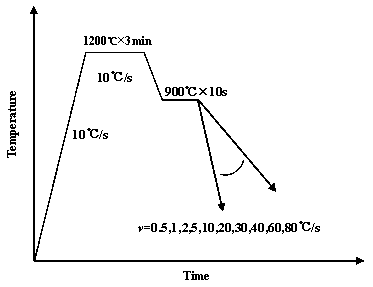

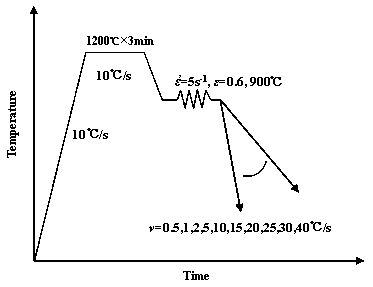

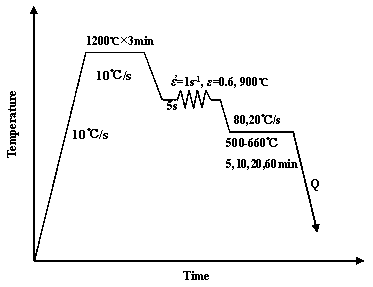

[0058] Determination of static continuous cooling transformation curve of sample steel (static CCT): carried out on MMS-300 thermal simulation testing machine, such as figure 1 The sample was heated to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com