Production line for flexibly machining workpieces

A technology for processing workpieces and production lines, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

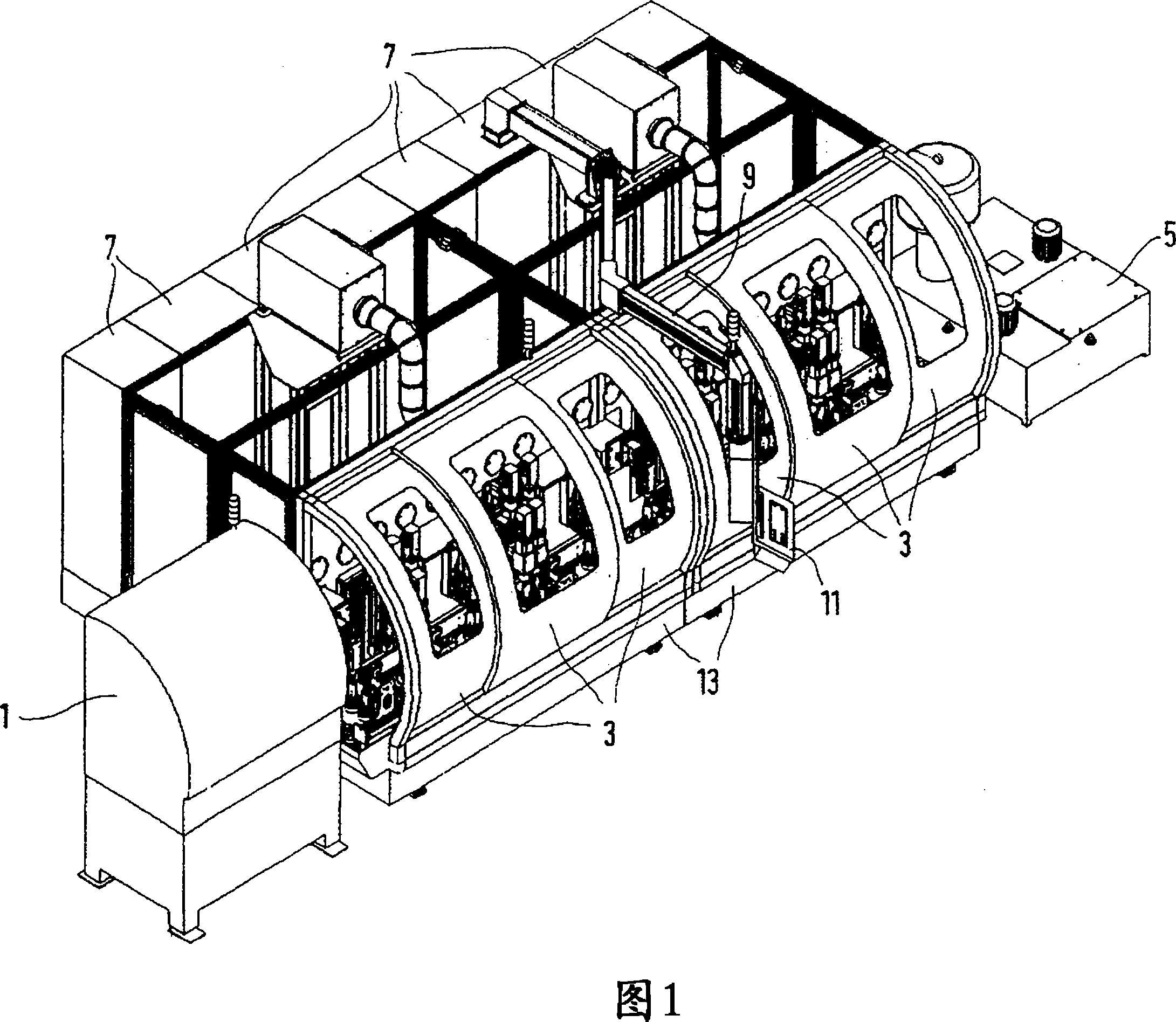

[0032] Figure 1 shows an embodiment of a production line according to the invention. On the left side of the production line according to the invention there is an automatic loader 1 with which workpieces are loaded in the production line according to the invention. On the right end of Fig. 1 production line, be provided with washing unit 5.

[0033] At the front of the production line in FIG. 1 and behind the splash guard 3, a plurality of processing units (without reference numerals) are arranged side by side in a row. Different control cabinets 7 are arranged side by side at the rear end of the production line in FIG. 1 . In this respect, each control cabinet is used to control the processing units located in front of it. It goes without saying that superordinate control devices can also be used, which network the different processing units of the production line according to the invention and control them in a coordinated manner.

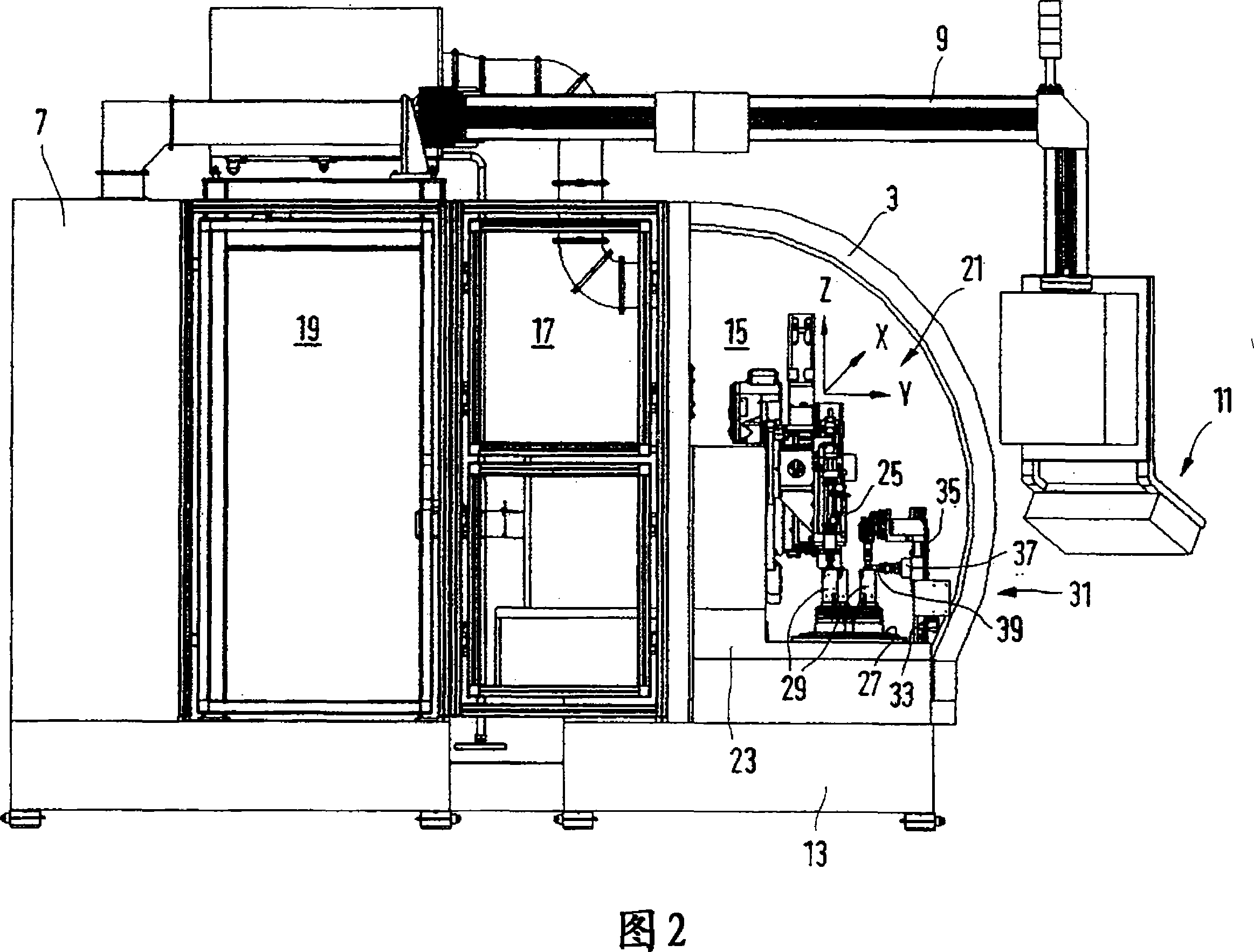

[0034] The console 11 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com