Parallel bearingless co-rotating standing wave type linear ultrasonic motor

An ultrasonic motor, co-rotation technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of complex structure design and difficulty in realizing co-rotation , to achieve the effect of compact motor structure, high output and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

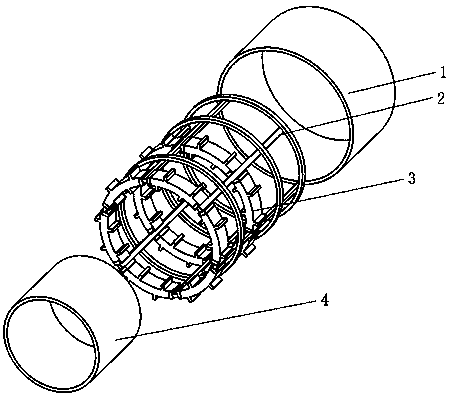

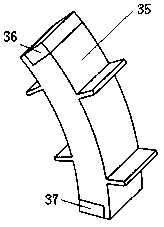

[0044] A parallel bearingless co-rotating standing wave linear ultrasonic motor, such as figure 1 , including a stator and a rotor, the rotor includes an inner rotor 4 and an outer rotor 1, the inner rotor 4 and the outer rotor 1 are fixed together, the stator is arranged between the inner rotor 4 and the outer rotor 1, and the stator includes a stator unit 3 and a squirrel-cage fixed structure 2. The stator unit 3 includes an elastic body 35, a piezoelectric ceramic at the left end 36 and a piezoelectric ceramic at the right end 37. The elastic body adopts an arc-shaped structure. The two ends of the body are respectively provided with a left end piezoelectric ceramic 36 and a right end piezoelectric ceramic 37, and the left end piezoelectric ceramic 36 and the right end piezoelectric ceramic 37 respectively adopt piezoelectric ceramics polarized in the radial direction; In the electric field, the ceramic torsional vibration mode is used to excite the stator elastic body to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com