Self-compacting concrete for concrete repairing and preparation method of self-compacting concrete for concrete repairing

A self-compacting concrete and concrete technology, which is applied in the field of cement to achieve the effects of wide repair applicability, reduction of construction risks and good economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

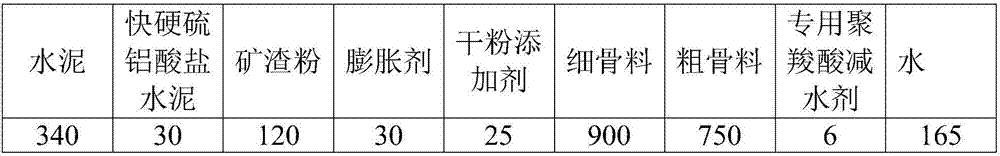

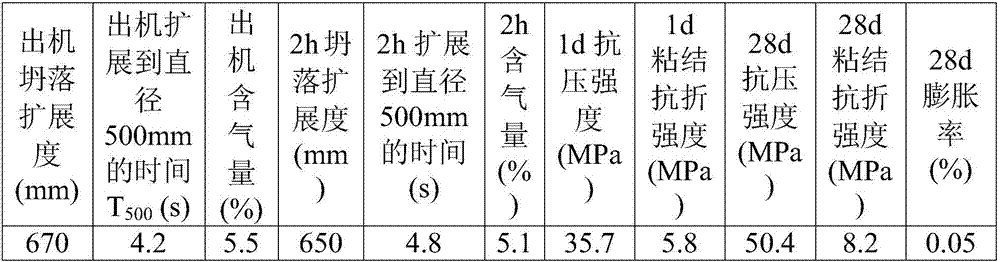

Embodiment 1

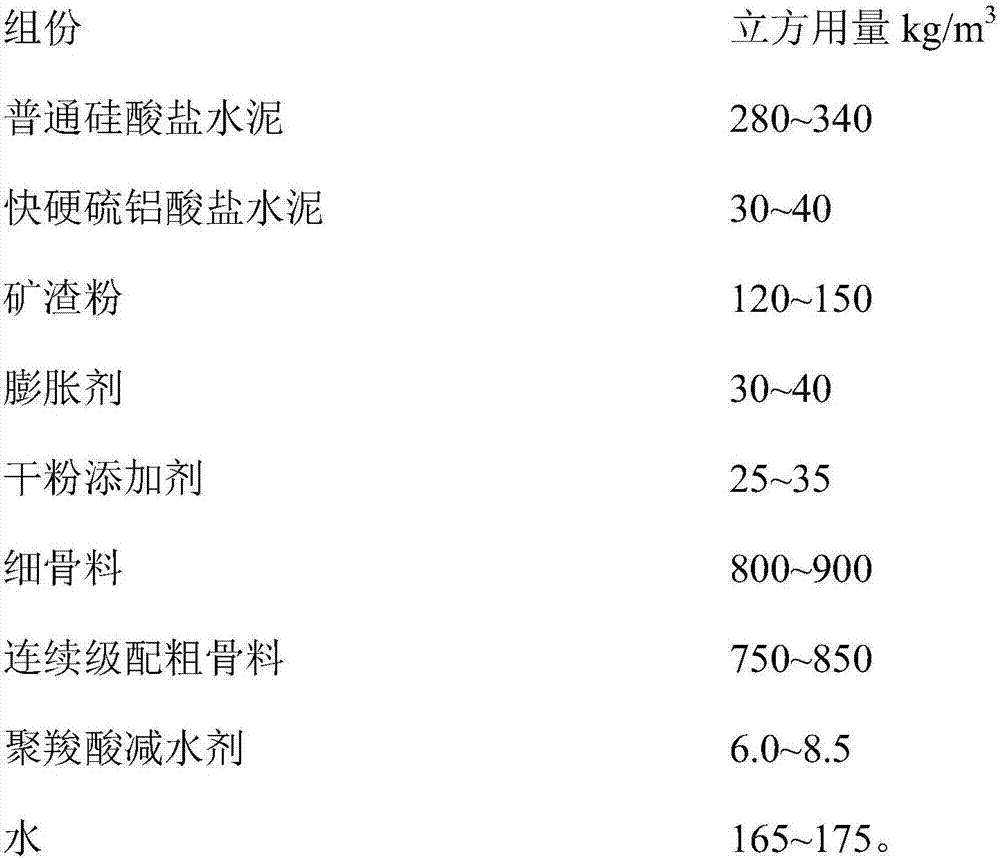

[0031] Prepare ingredients:

[0032] Cement: P.O 42.5 grade ordinary portland cement; rapid hardening sulfoaluminate cement: 42.5 grade; slag powder: S95 grade slag powder; expansion agent: calcium sulfoaluminate expansion agent; dry powder additive: composed of vinyl acetate and ethylene Copolymerized rubber powder, lithium carbonate, polypropylene fiber, and xanthan gum are uniformly mixed and stirred according to the mass ratio of 100:10:10:1; fine aggregate: river sand with a fineness modulus of 2.7; coarse aggregate: 5~ 20mm continuous graded crushed stone; water: tap water.

[0033] In order to prevent sticking to the pot, first weigh an appropriate amount of materials in proportion, mix the concrete, pour out the mixed concrete after the inner wall of the mixer is stained with cement mortar, and then add ordinary portland cement, rapid hardening sulphoaluminate cement, slag powder, expansion Put agent, dry powder additive, fine aggregate, and coarse aggregate into the ...

Embodiment 2

[0040] Prepare ingredients:

[0041] Cement: P.O 42.5 grade ordinary portland cement; rapid hardening sulfoaluminate cement: 42.5 grade; slag powder: S105 grade granulated blast furnace slag powder; expansion agent: calcium oxide expansion agent; dry powder additive: vinyl acetate homopolymer Rubber powder, aluminum sulfate, polyvinyl alcohol fiber, and hydroxypropyl guar gum are mixed and stirred evenly according to the mass ratio of 100:10:10:1; fine aggregate: machine-made sand with a fineness modulus of 2.4; coarse aggregate : 5 ~ 16mm continuously graded crushed stone; water: tap water.

[0042] In order to prevent sticking to the pot, first weigh an appropriate amount of materials in proportion, mix the concrete, and pour out the mixed concrete after the inner wall of the mixer is stained with cement mortar. Put ordinary Portland cement, rapid-hardening sulfoaluminate cement, slag powder, expansion agent, dry powder additive, fine aggregate, and coarse aggregate into th...

Embodiment 3

[0049] Prepare ingredients:

[0050] Cement: P.O 42.5 grade ordinary Portland cement; rapid hardening sulfoaluminate cement: 42.5 grade; slag powder: S95 grade granulated blast furnace slag powder; expansion agent: calcium sulfoaluminate-calcium oxide expansion agent; dry powder additives: Styrene and butadiene copolymer powder, lithium carbonate, polyacrylonitrile fiber, and hydroxyethyl cellulose are uniformly mixed and stirred at a mass ratio of 100:10:10:1; fine aggregate: fineness modulus of 2.6 River sand; coarse aggregate: 10-16mm continuously graded crushed stone; water: tap water.

[0051] In order to prevent sticking to the pot, first weigh an appropriate amount of materials in proportion, mix the concrete, and pour out the mixed concrete after the inner wall of the mixer is stained with cement mortar. Put ordinary Portland cement, fast-hardening sulfoaluminate cement, slag powder, expansion agent, dry powder additive, fine aggregate, and coarse aggregate into the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com