Drying and gasification process

A technology for hot gas and synthesis gas, which is applied in the manufacture of combustible gas, petroleum industry, combined combustion mitigation, etc., and can solve the problems of low power output, high investment cost of gas engines, and expensive transportation of central power plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

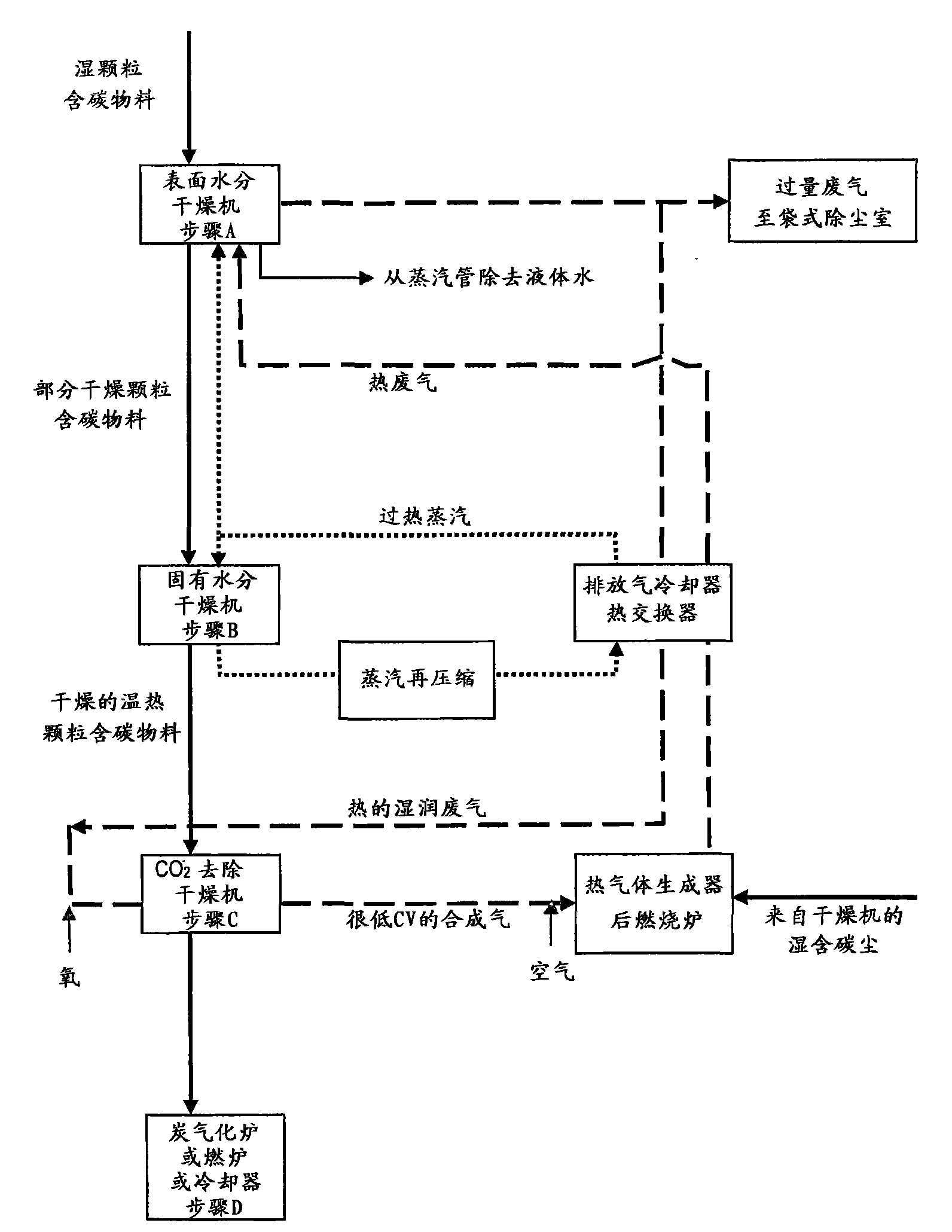

[0091] Example 1 is a plant for the production of thermal biochar as a feed to a conventional coal power plant. see image 3 , which shows a process flow diagram according to one embodiment of the present invention. As can be seen in the figure, the carbonaceous material goes through three process steps, resulting in low-grade syngas.

[0092] In a first step a), the carbonaceous material enters a surface moisture dryer where it comes into contact with hot gas at temperatures between 115°C and 400°C. According to this embodiment, the hot gas is exhaust gas from a power station. In addition to direct contact with the hot gas, surface moisture dryers place the carbonaceous material in indirect contact with the steam flowing through the steam piping inside the dryer. The effect of steam indirect contact with carbonaceous material is to slowly heat carbonaceous material to between 100°C and 140°C, causing the steam to condense and be removed from the surface moisture dryer as l...

Embodiment 2

[0106] In the following examples, fresh leaves and twigs were mechanically picked from the ground. The average collection rate throughout the year is 1.25 tons per hour. This biomass material is sent to a small centralized station where the wood is shredded. The power plant is within 25km of a farm that sustainably provides wood production. The composition of the fuel is:

[0107] Total humidity 50.00% w.b.

[0108] Ash 10.80%d.b.

[0109] Carbon 46.10%d.b.

[0110] Hydrogen 5.90%d.b.

[0111] Nitrogen 0.60% d.b.

[0112] Sulfur 0.20%d.b.

[0113] Oxygen 36.40%d.b.

[0114] Specific energy 18.10MJ / kg d.b (gross number)

[0115] Such biomass, with the composition listed, would typically produce about 0.46MW if it were used in an open cycle power plant e (gross) electricity. This means an overall conversion efficiency of 15%. This is below the economies of scale of an open cycle power plant.

[0116] However, if the same biomass is used as in the process flow diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com