Formwork-stripping device

A technology for removing templates and templates, applied in the direction of formwork/formwork/work frame, mold, formwork/formwork/work frame connectors, etc., can solve problems such as high cost, falling, increased cost and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

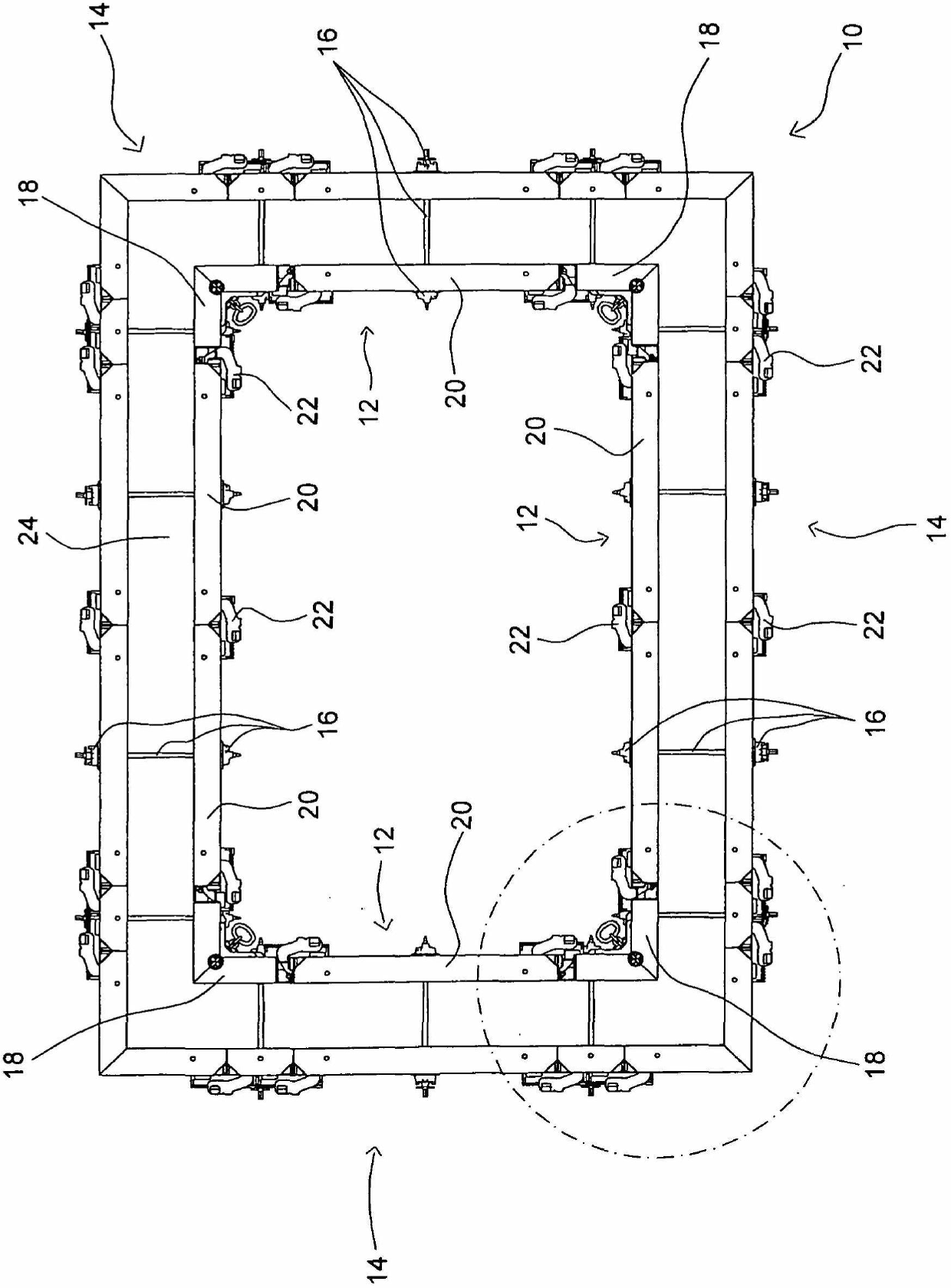

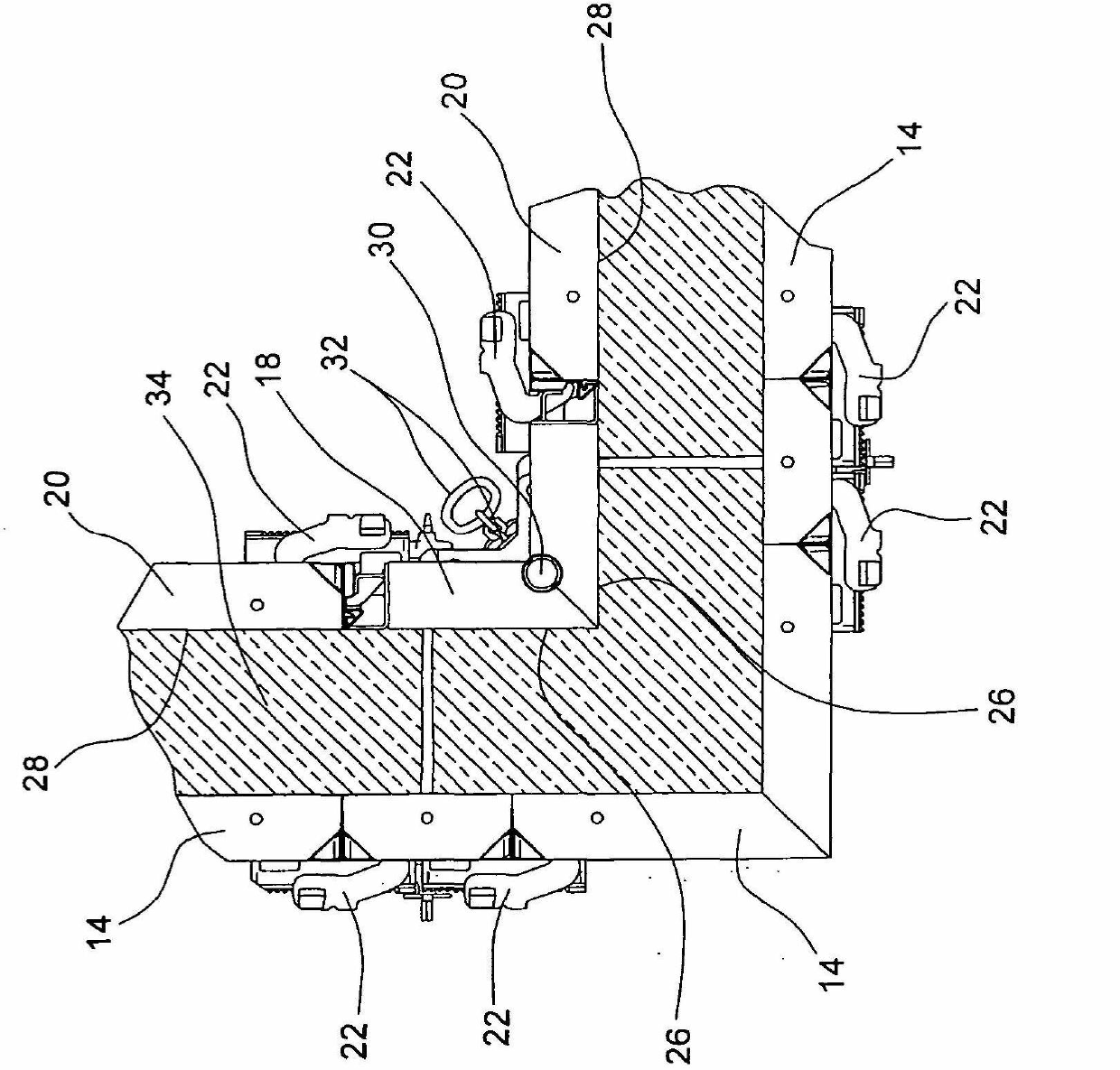

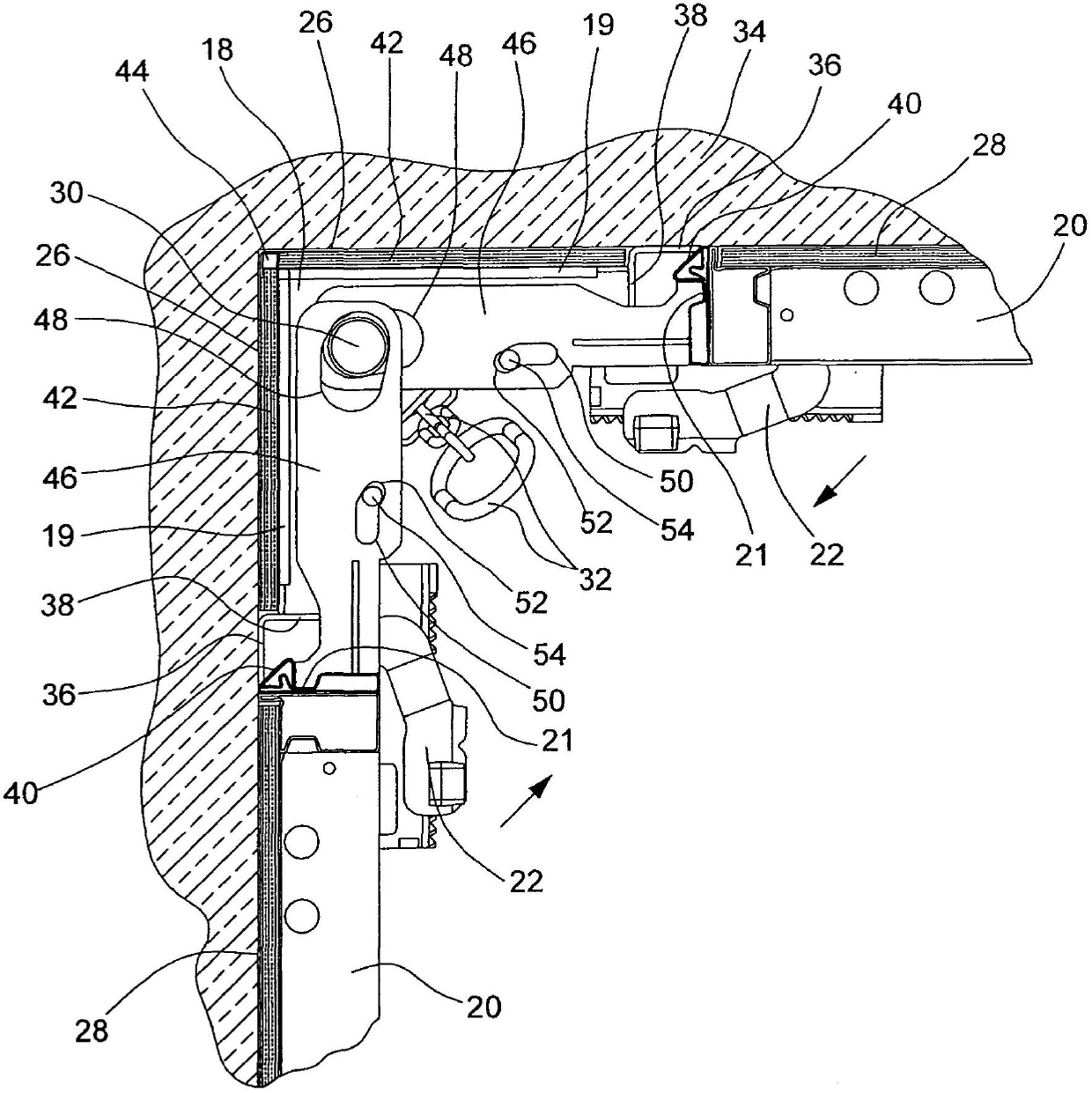

[0029] figure 1 A top view of the hoistway template 10 according to the present invention is shown. The hoistway template is composed of an inner hoistway template 12 and an outer hoistway template 14. The inner hoistway template 12 and the outer hoistway template 14 are connected to each other by a plurality of template anchor bolts 16.

[0030] The hoistway template 10 has a substantially rectangular shape, wherein the inner hoistway template 12 and the outer hoistway template 14 are respectively composed of a plurality of corner template elements and a plurality of other template elements extending along a plane. The inner hoistway template 12, which is essential in the scope of the present invention, is composed of a total of four corner template elements 18, on both sides of which are adjacent to other template elements 20 extending along the plane. The formwork elements 18, 20 adjacent to each other are connected to each other by means of suitable coupling devices 22.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com