Urea hydrolytic and pyrolytic compound ammonia preparation system for denitration in thermal power plant

A technology of urea hydrolysis and thermal power plant, which is applied in the field of ammonia production system, can solve the problems of increased energy consumption, corrosion of product pipelines, agglomeration of furnace impurities, etc., and achieve the effect of avoiding whole-process heat tracing, avoiding blockage of pipelines, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

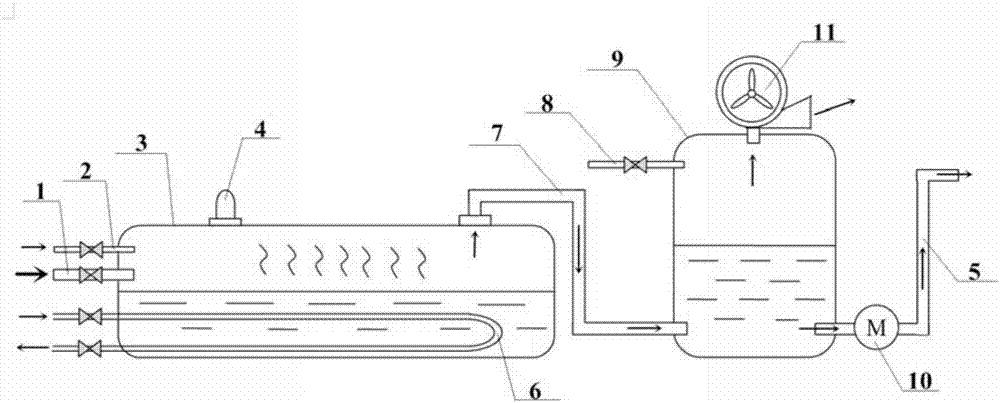

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] refer to figure 1 , the urea hydrolysis pyrolysis composite ammonia production system for denitrification in a thermal power plant according to the present invention comprises a urea solution inlet pipe 1, a hydrolysis reactor 3, a carbon removal tank 9, a demineralized water pipe 8 and an exhaust fan 11; a urea solution inlet pipe 1 Be communicated with the inlet of hydrolysis reactor 3 sides, the bottom of hydrolysis reactor 3 is provided with the steam heater 6 that is used for heating the urea solution in the hydrolysis reactor 3, the top outlet of hydrolysis reactor 3 and the carbon removal tank 9 The bottom inlet is connected, the desalted water inlet on the side of the carbon removal tank 9 is connected to the desalinated water pipe 8, the exhaust fan 11 is located at the top opening of the carbon removal tank 9, and the ammonia water pipe 5 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com