Concrete transfer device

A transfer device and concrete technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low safety and difficult construction, and achieve the effect of convenient operation, avoiding pipe blockage and less disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

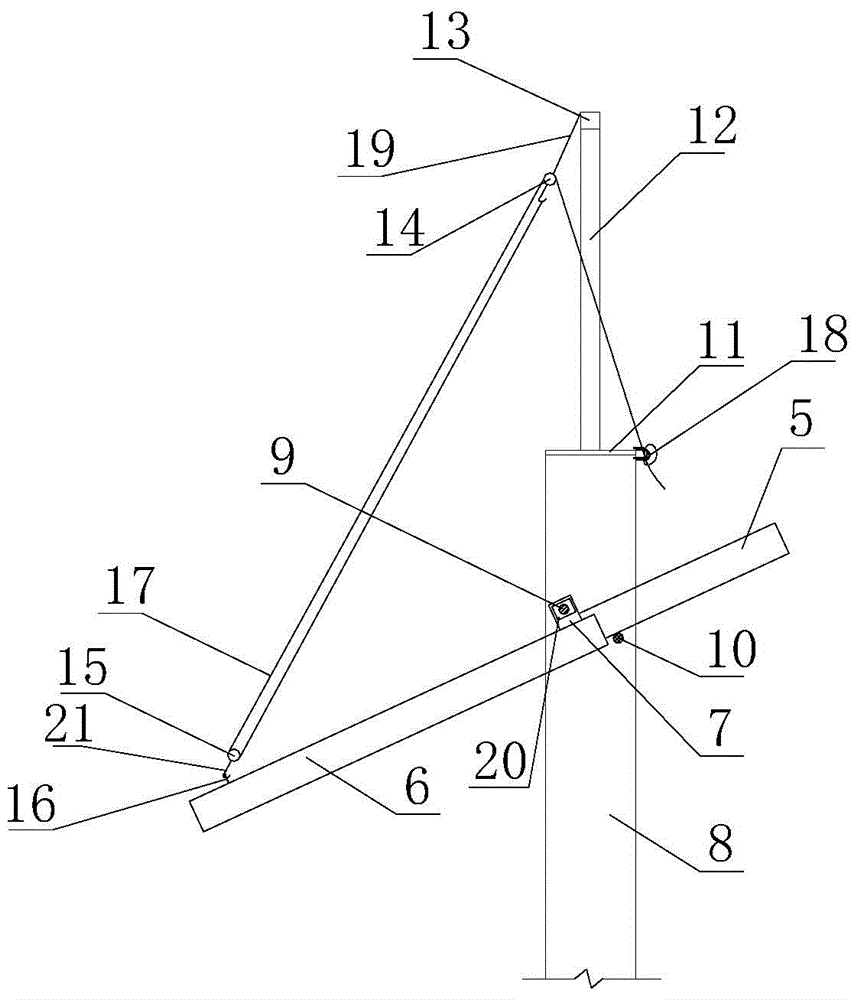

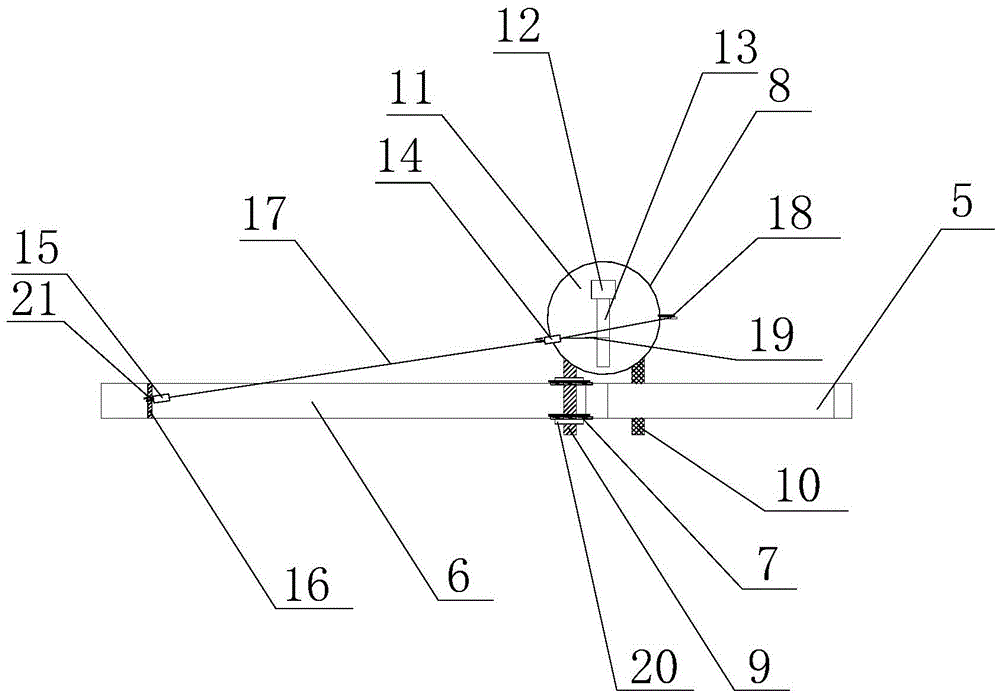

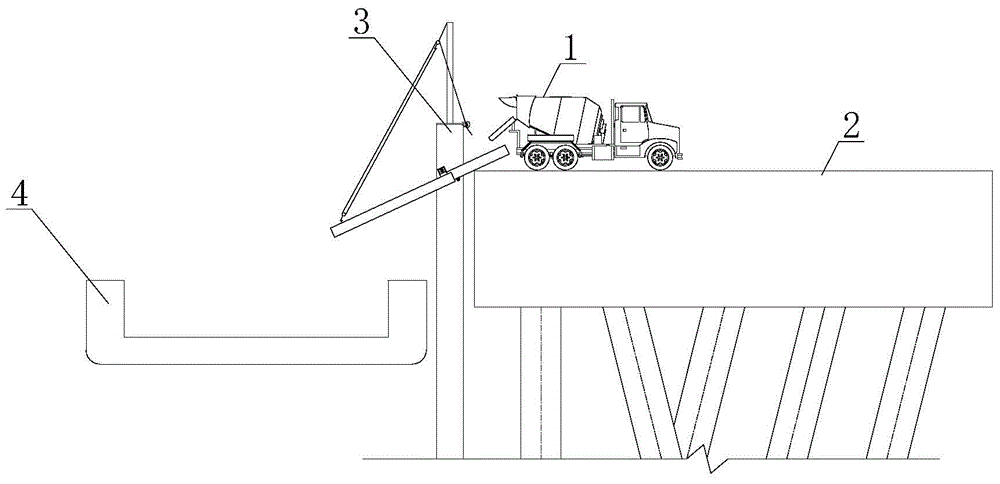

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] refer to figure 1 and figure 2 , a concrete transfer device of the present embodiment mainly includes steel pipe piles 8 and chutes, the steel pipe piles 8 are arranged outside the edge of the wharf 2, steel cover plates 11 are welded on the top surface of the steel pipe piles 8, and the uprights 12 are welded On the steel cover plate 11, the cross bar 13 is welded on the column 12. The chute of the present embodiment comprises an upper section chute 5 and a lower section chute 6 that are all semicircular steel pipes. On the support rod 10 below the platform, through the joint action of the support rod 10 and the corners of the wharf, the upper section chute 5 forms a fixed inclination angle; the lower end of the upper section chute 5 is docked with the upper end of the lower section chute 6. Just below the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com