360-degree combing assembly of waste processor

A technology of waste disposer and assembly, applied in grain processing, cocoa, food science, etc., can solve the problems of low food waste crushing ability, food waste filtration, blockage of sewage pipes, etc., so as to avoid the increase of cleaning cycle and increase the internal Space, avoid the effect of blocking the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

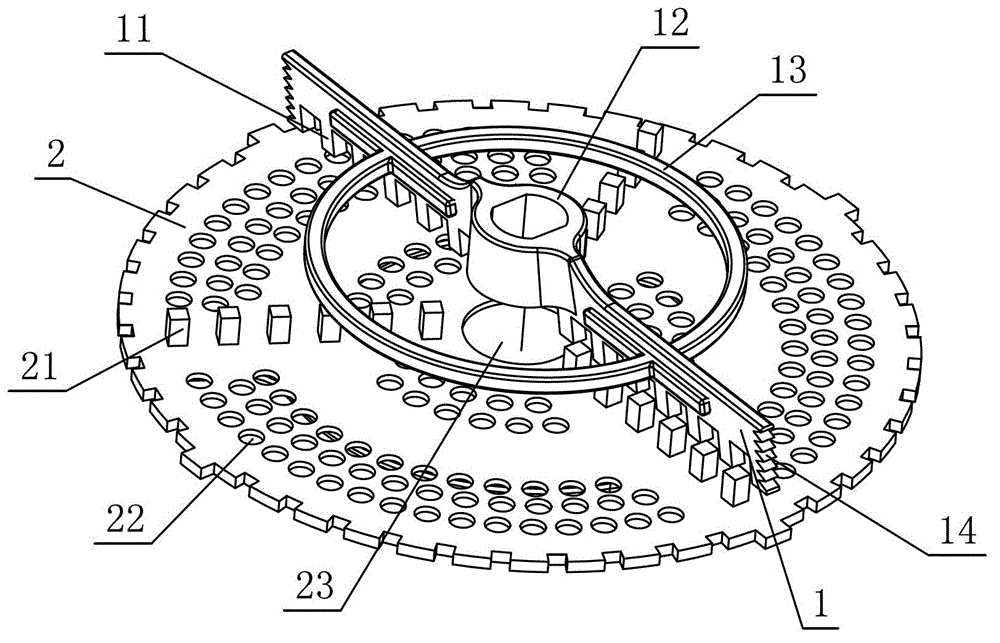

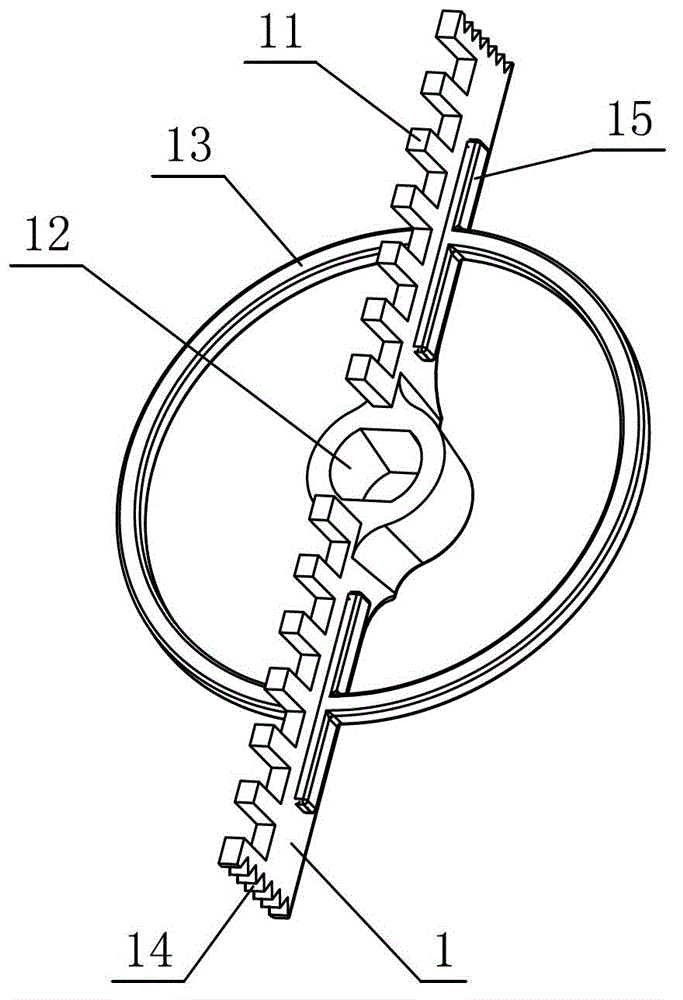

[0029] Such as Figure 1 to Figure 6 As shown, the 360-degree comb assembly of the garbage disposer includes a filter chassis 2 and a stirring paddle 1. The filter chassis 2 is fixedly arranged in the garbage disposer, and the stirring paddle 1 is rotated and arranged above the filter chassis 2. The surface of the filter chassis 2 Several filter holes 22 are provided, upper comb teeth 21 are arranged radially on the top surface, and lower comb teeth 11 are arranged on the bottom surface of the stirring paddle 1, and the teeth of the lower comb teeth 11 and the teeth of the upper comb teeth 21 are staggered from each other.

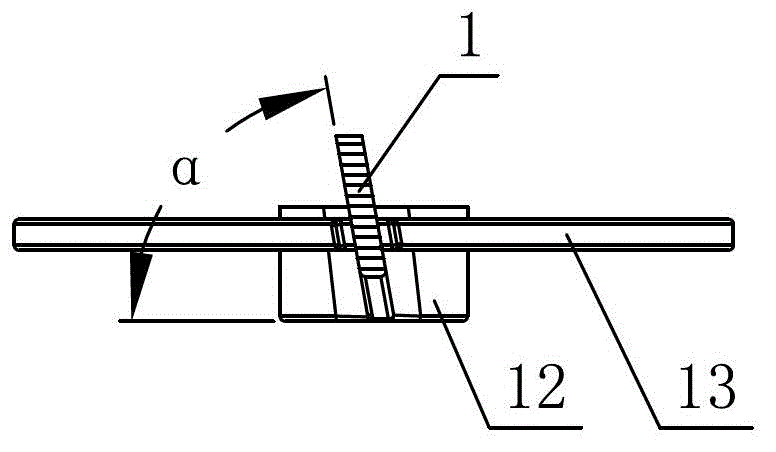

[0030] The stirring paddle 1 is arranged obliquely relative to the horizontal plane, and the inclination angle α is 75° to 85°.

[0031] The stirring paddle 1 is provided with two pieces, which are evenly distributed on the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com