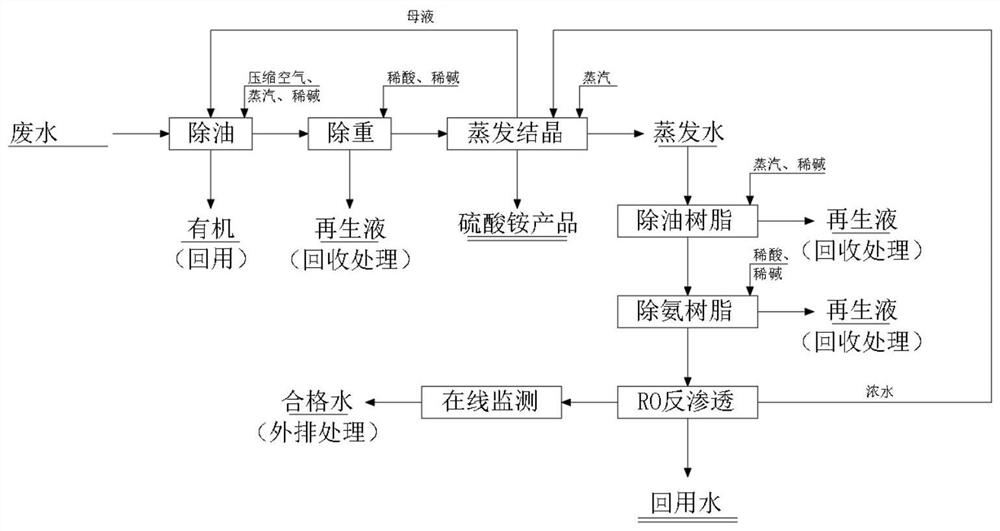

Treatment process of high-salinity wastewater

A treatment process and high salinity technology, applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve equipment scaling and corrosion, affect heat transfer effect, and threaten ecological environment safety To achieve the effect of improving the quality of pure water, increasing water solubility, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

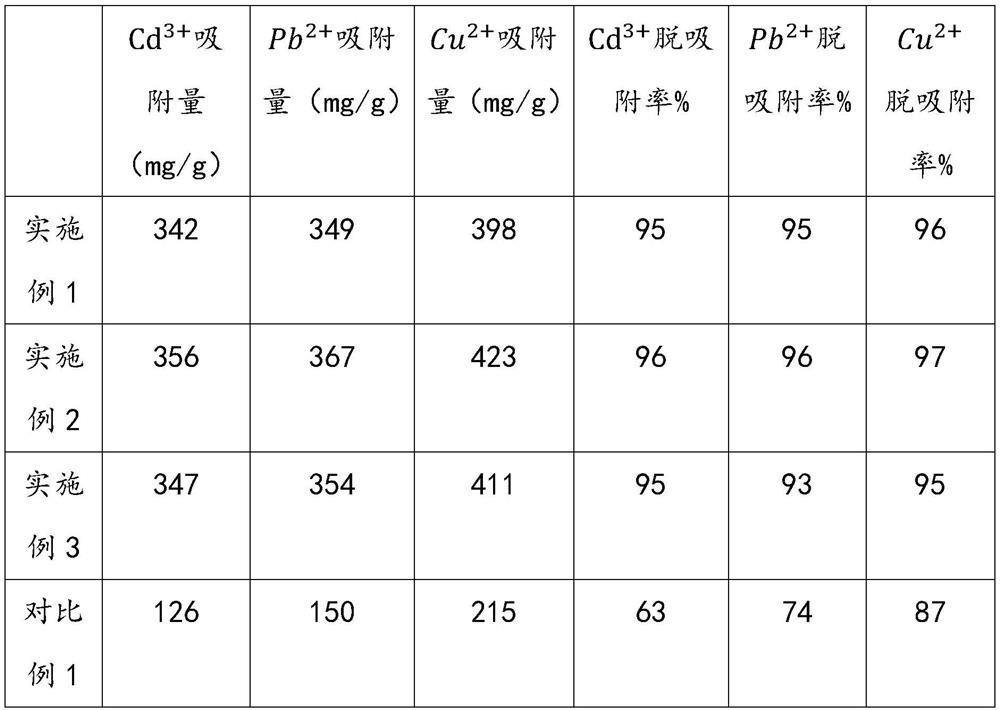

Embodiment 1

[0029] Preparation of metal ion exchange resin:

[0030] SS1: Swell chlorine balls in toluene, add ethylenediamine solution, heat up to 148°C and stir for reflux reaction for 4 hours, filter after the reaction, wash with deionized water and absolute ethanol for 3 times, dry dry to obtain Intermediate A;

[0031] SS2: Swell intermediate A in nitrobenzene, let it stand for 12 hours, add ferric chloride under nitrogen, control the temperature at 180°C and stir and reflux for 1 hour, slowly raise the temperature to 233°C and continue to stir and reflux for 4 hours, and cool to room temperature , washed with deionized water until neutral, then extracted with absolute ethanol for 10 h, dried to obtain intermediate B;

[0032] SS3: Add di-tert-butyl dicarbonate into the tetrahydrofuran solution, add intermediate B, then add sodium hydroxide aqueous solution, then add p-chlorotoluene, stir well, then slowly add triethylamine dropwise, continue stirring after the dropwise addition Af...

Embodiment 2

[0038] Preparation of metal ion exchange resin:

[0039]SS1: Swell chlorine balls in toluene, add ethylenediamine solution, heat up to 150°C and stir for reflux reaction for 6 hours, filter after the reaction, wash with deionized water and absolute ethanol for 4 times, dry dry to obtain Intermediate A;

[0040] SS2: Swell intermediate A in nitrobenzene, let it stand for 13 hours, add ferric chloride under nitrogen, control the temperature at 182°C and stir and reflux for 1.3 hours, slowly raise the temperature to 234°C, continue to stir and reflux for 5 hours, and cool to At room temperature, wash with deionized water until neutral, then extract with absolute ethanol for 11 hours, and dry to obtain intermediate B;

[0041] SS3: Add di-tert-butyl dicarbonate into the tetrahydrofuran solution, add intermediate B, then add sodium hydroxide aqueous solution, then add p-chlorotoluene, stir well, then slowly add triethylamine dropwise, continue stirring after the dropwise addition ...

Embodiment 3

[0047] Preparation of metal ion exchange resin:

[0048] SS1: Swell chlorine balls in toluene, add ethylenediamine solution, heat up to 153°C and stir for reflux reaction for 8 hours, filter after the reaction, wash with deionized water and absolute ethanol for 5 times, and dry dry to obtain Intermediate A;

[0049] SS2: Swell intermediate A in nitrobenzene, let it stand for 15 hours, add ferric chloride under nitrogen, control the temperature at 183°C and stir and reflux for 1.5 hours, slowly raise the temperature to 235°C and continue to stir and reflux for 6 hours, and cool to At room temperature, wash with deionized water until neutral, then extract with absolute ethanol for 12 hours, and dry to obtain intermediate B;

[0050] SS3: Add di-tert-butyl dicarbonate into the tetrahydrofuran solution, add intermediate B, then add sodium hydroxide aqueous solution, then add p-chlorotoluene, stir well, then slowly add triethylamine dropwise, continue stirring after the dropwise a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com