Concrete wet spraying machine chassis and concrete wet spraying machine

A concrete and wet spraying machine technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of wet spraying machine inoperability, poor climbing ability, large turning radius, etc., and achieve superior passability and cross-country performance , Improve stability and safety, and stabilize torque force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] A concrete wet spraying machine, comprising a concrete wet spraying locomotive body and the concrete wet spraying machine chassis described in Embodiment 1, wherein the concrete wet spraying machine chassis is mounted on the lower part of the concrete wet spraying locomotive body;

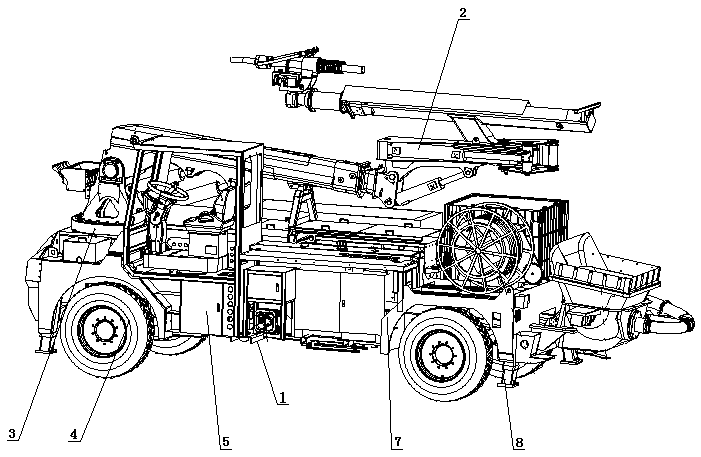

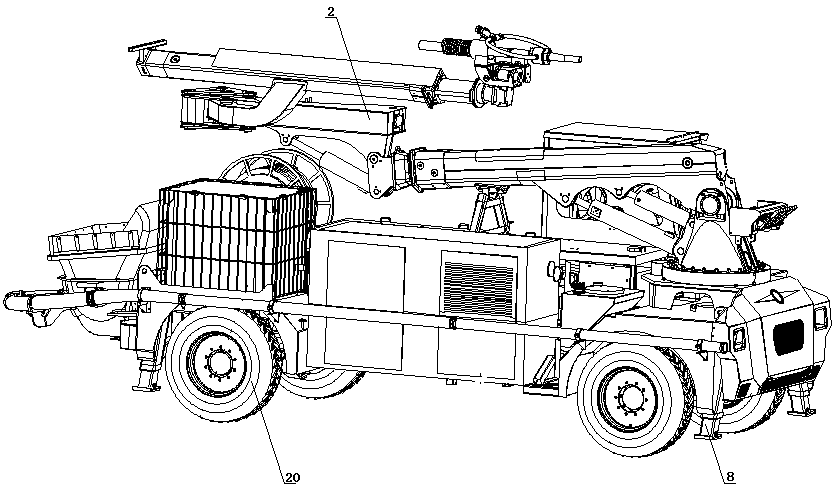

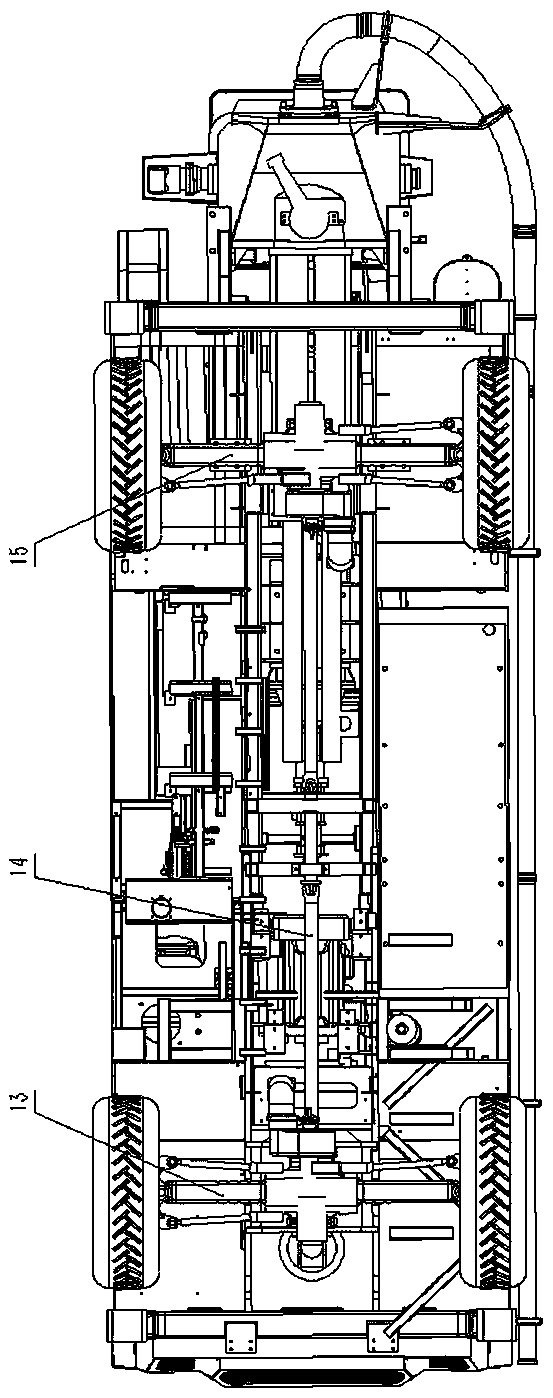

[0044] It also includes a boom system 2, a slewing bearing 3, an air compressor and a high-pressure water pump system 5. The high-pressure water pump system 5 is installed below the vehicle frame 7, and the air compressor is installed above the vehicle frame 7. The spraying operation is performed in the case of an external air compressor. The boom system 2 is installed above the frame 7 through the slewing bearing 3, and the slewing bearing 3 drives the boom system 2 to rotate 270°. The boom in this embodiment is The system 2 includes a big arm 16, a middle arm 17 and a small arm 18. A telescopic oil cylinder is installed inside the big arm 16. The big arm 16 and the middle arm 17 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com