Continuous sounding pipe installation method and device for detecting concrete filling pile

An acoustic tube, uninterrupted technology, applied in the testing of infrastructure, construction, infrastructure engineering and other directions, can solve problems such as increased labor costs, great construction period pressure, material waste, etc., to reduce construction costs and improve work efficiency. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

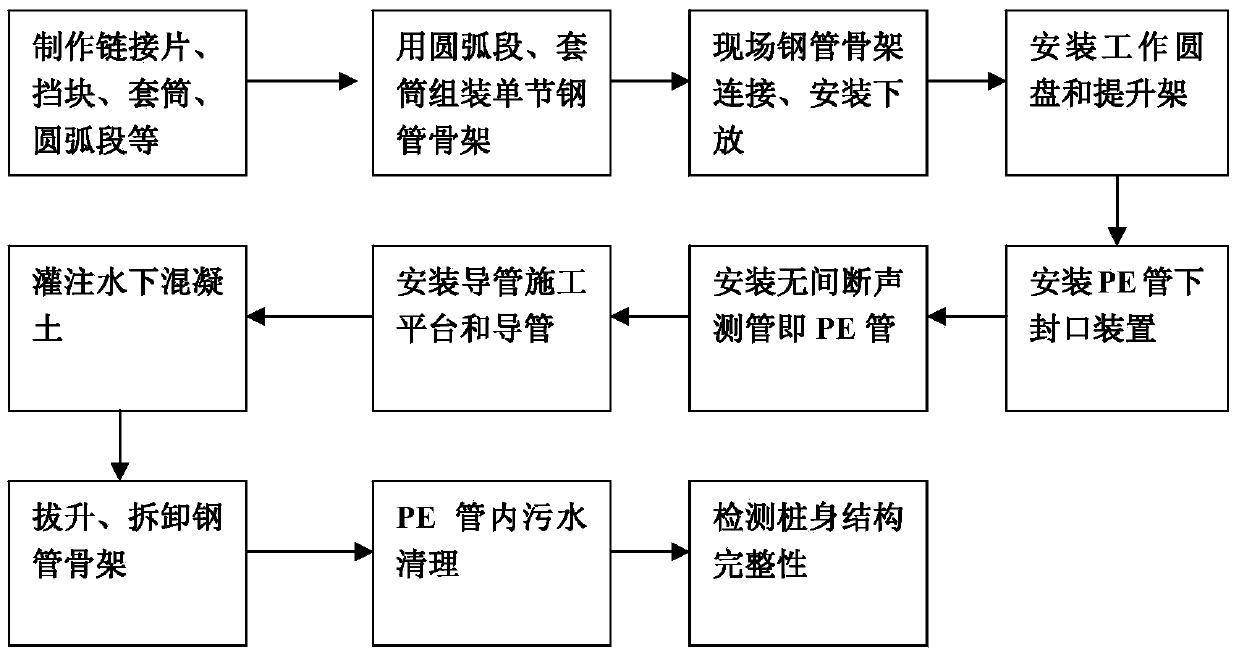

Method used

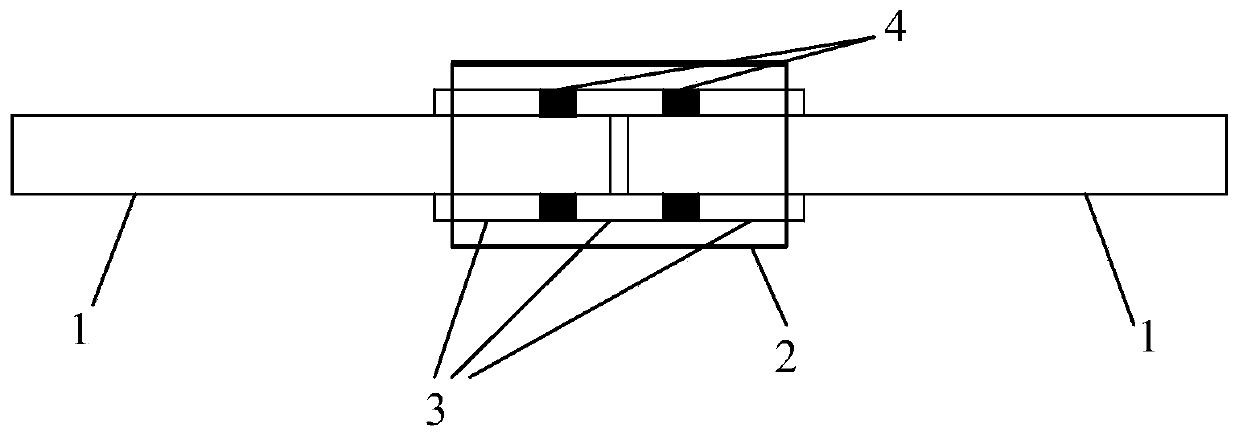

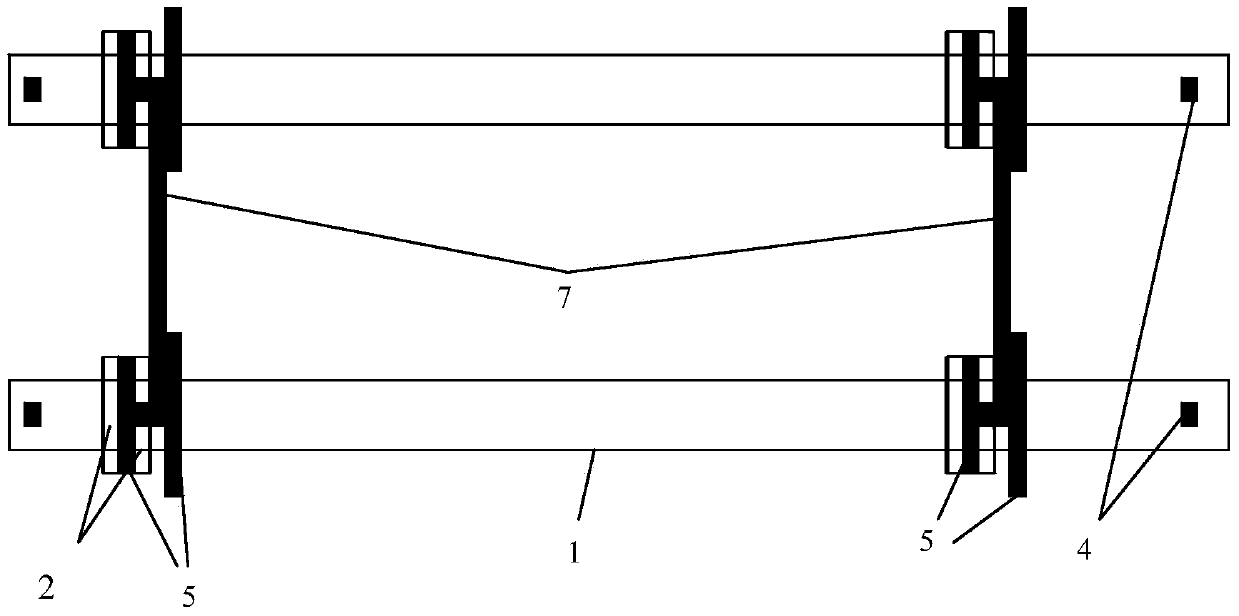

Image

Examples

Embodiment

[0036] First, the material selection of the continuous acoustic tube

[0037]For the sound wave transmission method, the uninterrupted sound measuring tube should choose PE round tube (polyethylene resin) and give up the steel tube. The size of the PE pipe is φ40 and the thickness is 3mm. Reasons for choosing PE pipe: PE pipe has good sound permeability and high strength, and the circular pipe has a large ability to resist lateral pressure, which can meet the lateral pressure of concrete at the bottom of the cast-in-situ pile; PE pipe has good toughness, and the finished product can be rolled into a disc, and the unfolded length is several From ten meters to hundreds of meters, one-time ruling can be made according to the working length, which is also the main reason to ensure the uninterrupted sound pipe; the price of PE pipe is low, which is 25% of the current price of $57×3 steel pipe.

[0038] 2. Fabrication of uninterrupted acoustic tube skeleton

[0039] Since PE pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com