Coal tar catalytic upgrading method

A coal tar and coal coking technology, which is applied in the fields of hydrocarbon oil cracking and petroleum industry, can solve the problems of excessive heat, difficulty in catalytic cracking, consumption, etc., and achieve the goals of saving heat energy, increasing tar utilization efficiency, good application prospects and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific examples.

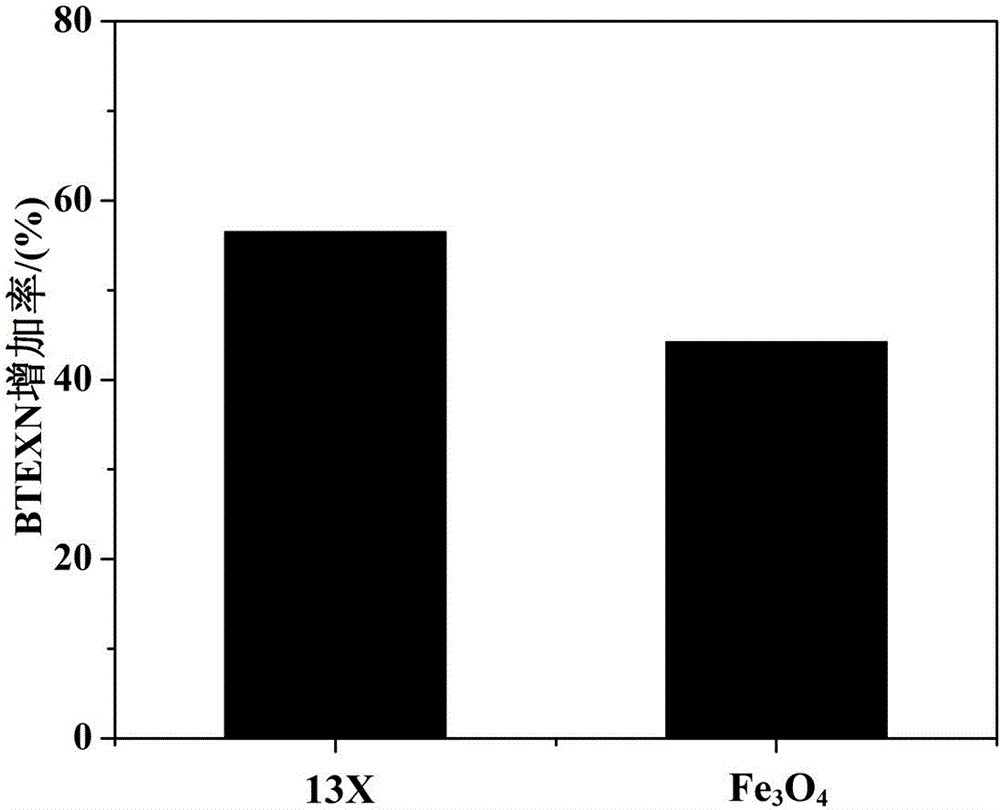

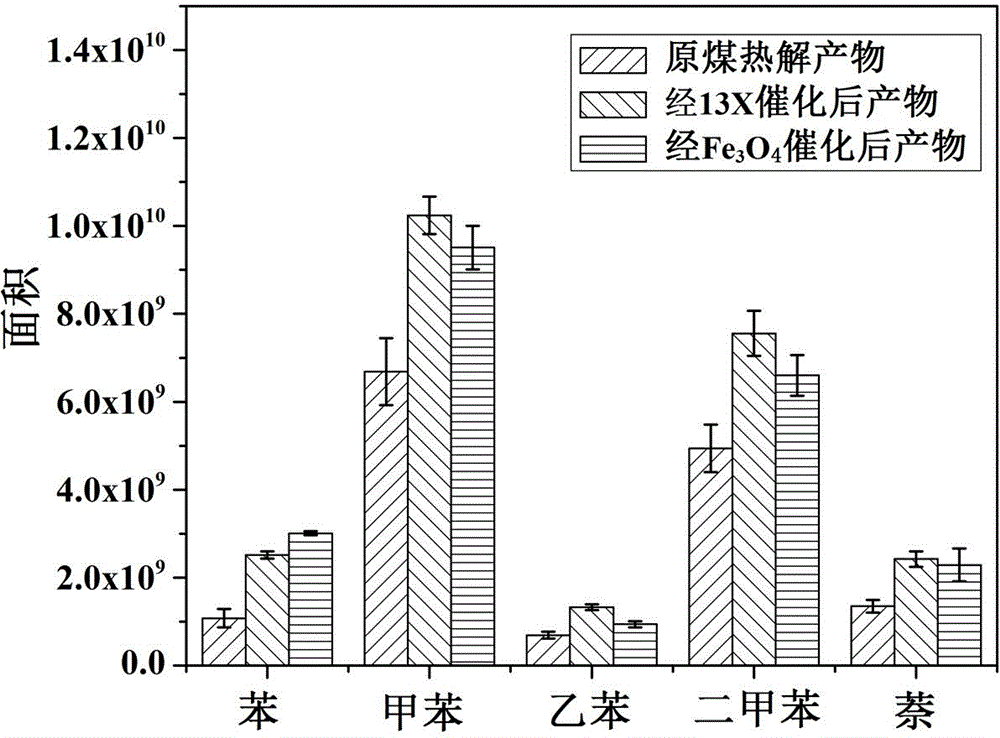

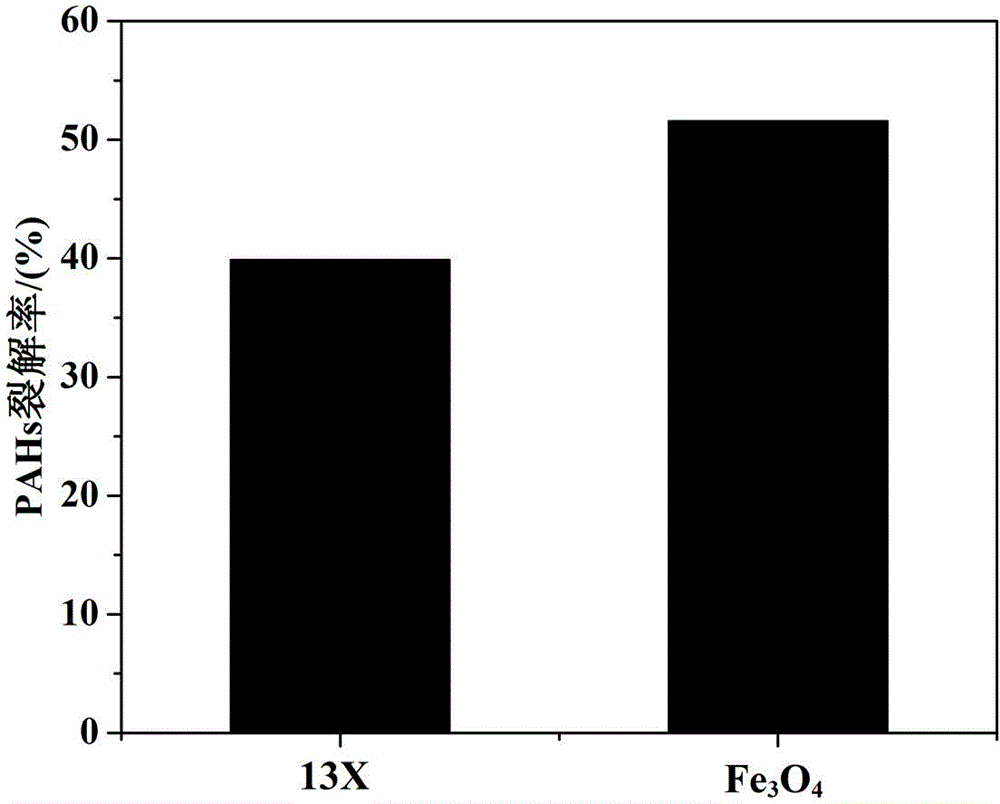

[0020] In order to verify the feasibility of the present invention, select coking coal as the research object, carry out the pyrolysis and catalysis experiment of coking coal in fast pyrolysis instrument, the volatile matter gained from pyrolysis is separated by gas chromatography and mass spectrometry respectively before and after catalysis, to determine its Composition and content of each component. By comparing the difference between the products before and after the catalysis, the feasibility of the present invention can be judged.

[0021] Sampling by quartering method, after crushing, grinding and sieving Fenxi coking coal, select 60-100 mesh coking coal samples. 13X molecular sieve and Fe 3 o 4 Separately crush, grind and sieve, select 13X molecular sieve and Fe 3 o 4 as a catalyst.

[0022] Add a quartz column to the quartz cracking tube of the fast pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com