Electrochemical upgrading method for bio-oil

An electrochemical and bio-oil technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of poor thermal stability of bio-oil, difficult reactions, and reduced upgrading efficiency, and achieves no coking, carbon deposits, acid The effect of content reduction, suitability for transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment specifically includes the following steps:

[0044] (a) first add 0.1mol / L LiCl supporting electrolyte to methanol, then mix bio-oil and methanol at a mass ratio of 4:1, and the mixed liquid is used as catholyte for standby;

[0045] (b) configuration concentration is the dilute sulfuric acid solution of 0.5mol / L as anolyte standby;

[0046] (c) Assembly of electrochemical reactor: prepare H-type electrolytic cell, separate it with Nafion-117 cation exchange membrane in the middle, put catholyte and anolyte into both sides of H-type electrolytic cell respectively, and insert platinum in catholyte A sheet electrode, a platinum sheet electrode is inserted in the anolyte, and the electrode is connected with a constant current meter;

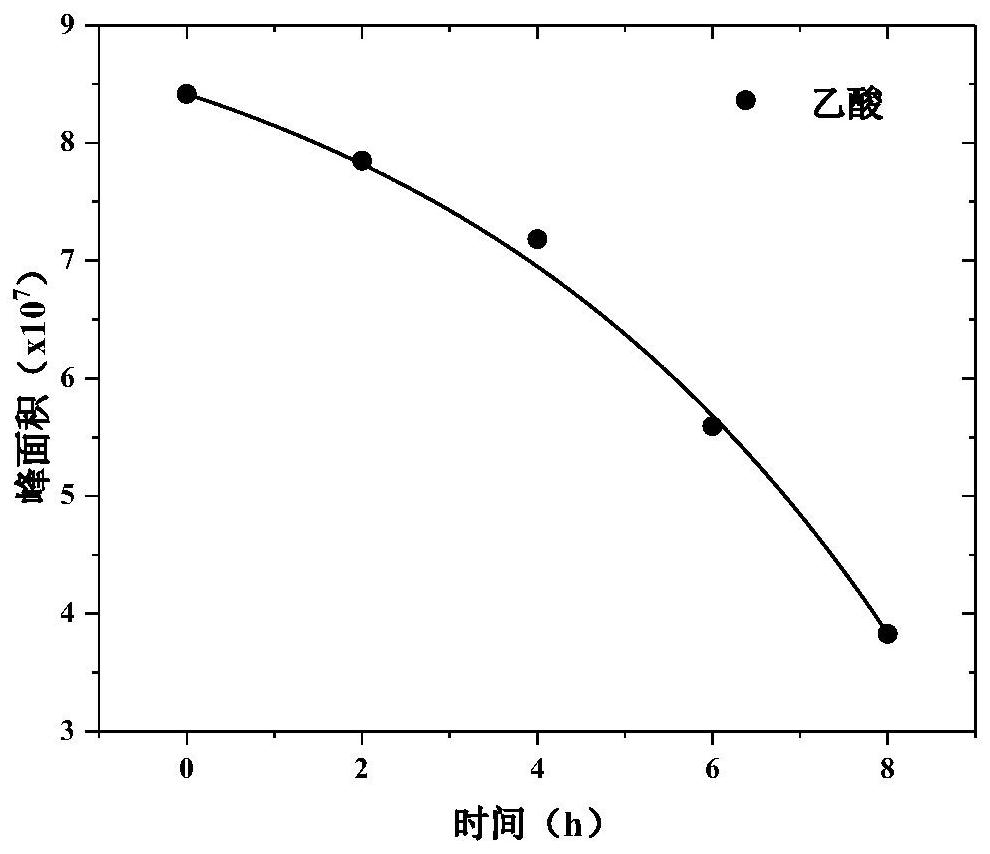

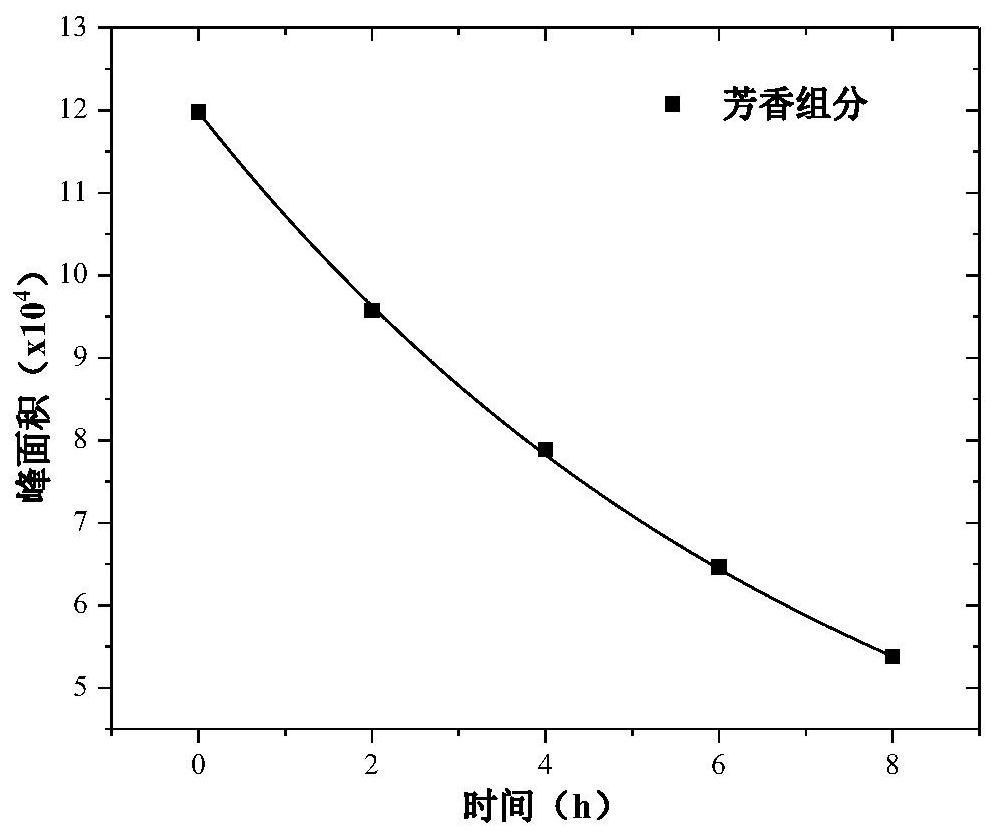

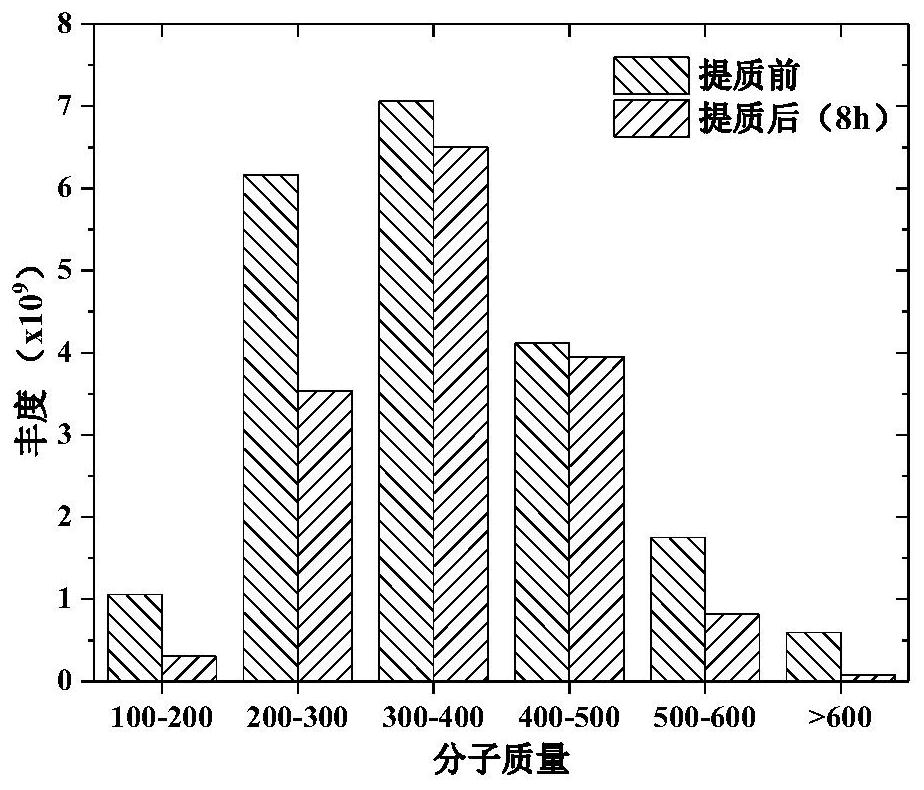

[0047] (d) After 15 minutes of passing nitrogen gas into the catholyte side, turn on the power supply, set a constant current of 50 mA, a reaction temperature of 20° C., and a reaction time of 8 hours to realize bio-oil upgra...

Embodiment 2

[0052] The concentration of dilute sulfuric acid in the anolyte used in this embodiment is 0.2 mol / L, and other conditions are the same as those in Embodiment 1. After upgrading for 8 hours, the content of acetic acid in bio-oil decreased by 26.7%, the content of aromatic components decreased by 34.1%, and the molecular weight of bio-oil decreased.

Embodiment 3

[0054] This embodiment specifically includes the following steps:

[0055] (a) First add 0.1mol / L Bu to methanol 4 NBF 4 supporting electrolyte, and then mix bio-oil and methanol at a mass ratio of 6:1, and the mixed liquid is used as catholyte for standby;

[0056] (b) configuration concentration is the dilute sulfuric acid solution of 0.5mol / L as anolyte standby;

[0057] (c) Assembly of electrochemical reactor: prepare H-type electrolytic cell, separate it with Nafion-117 cation exchange membrane in the middle, put catholyte and anolyte into both sides of H-type electrolytic cell respectively, insert carbon into catholyte For the ruthenium-based electrode, a platinum sheet electrode is inserted into the anolyte, and the electrodes are connected by a galvanostat; the carbon-based ruthenium electrode is prepared by electroplating (the specific process of the electroplating method can directly refer to relevant prior art).

[0058] (d) After feeding nitrogen into the cathol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com