Method for preparing quality-improved biomass pyrolytic oil based on emulsification system electro-catalysis and obtained quality-improved biomass pyrolytic oil

A biomass pyrolysis oil and emulsification system technology, applied in the field of biomass energy utilization, can solve the problems of reducing the upgrading efficiency, deactivating the catalyst, increasing the risk, etc. High phenolic content and the effect of avoiding carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

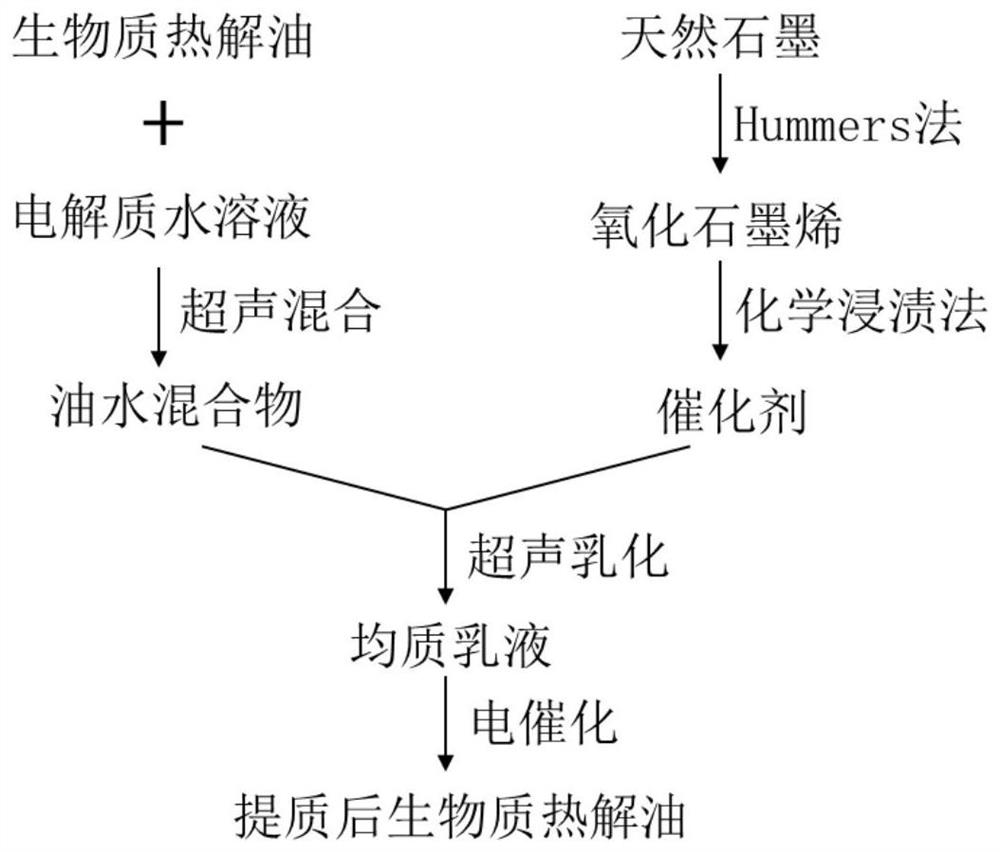

[0046] (a) Use 30g of ground rice powder to rapidly pyrolyze biomass at 700°C with a heating rate of 200°C / s to obtain biomass pyrolysis oil. Combine the collected biomass pyrolysis oil with 50mmol / L sodium chloride The solution was ultrasonically mixed for 5 minutes, and the prepared oil-water mixture was allowed to stand at room temperature for 5 hours;

[0047] (b) using the Hummers method to oxidize and modify natural graphite to prepare graphene oxide;

[0048] (c) using chemical impregnation method to load platinum on graphene oxide to obtain the required catalyst, the load is 1wt.%;

[0049] (d) Ultrasonic emulsification of 10 g of oil-water mixture with 0.2 g of catalyst for 10 min to prepare an emulsion with uniformly dispersed droplets;

[0050] (e) Take 20mL of the emulsion in a continuous flow electrolysis cell, control the current at 200mA, and perform electrolysis for 0.5h to obtain the upgraded biomass pyrolysis oil.

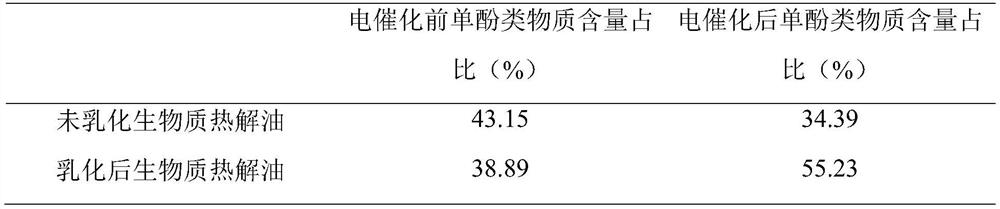

[0051] Table 1 shows the change in propor...

Embodiment 2

[0057] (a) Use 30g of ground rice powder to rapidly pyrolyze biomass at 800°C with a heating rate of 150°C / s to obtain biomass pyrolysis oil. Combine the collected biomass pyrolysis oil with 40mmol / L potassium chloride The solution was ultrasonically mixed for 4 minutes, and the prepared oil-water mixture was allowed to stand at room temperature for 4 hours;

[0058] (b) using the Hummers method to oxidize and modify natural graphite to prepare graphene oxide;

[0059] (c) using a sol-gel method to load ruthenium on graphene oxide to obtain the required catalyst, and the loading amount is 1wt.%;

[0060] (d) Ultrasonic emulsification of 10 g of oil-water mixture with 0.01 g of catalyst for 9 min to prepare an emulsion with uniformly dispersed droplets;

[0061] (e) Take 20mL of the emulsion in an undivided electrolytic cell, control the current at 150mA, and electrolyze for 1h to obtain the upgraded biomass pyrolysis oil.

Embodiment 3

[0063] (a) Use 30g of ground soybean shell powder to rapidly pyrolyze biomass pyrolysis oil at 500°C with a heating rate of 100°C / s to obtain biomass pyrolysis oil, and combine the collected biomass pyrolysis oil with 30mmol / L chlorinated The lithium solution was ultrasonically mixed for 3 minutes, and the prepared oil-water mixture was allowed to stand at room temperature for 3 hours;

[0064] (b) using the Brodie method to oxidize and modify natural graphite to prepare graphene oxide;

[0065] (c) palladium is supported on graphene oxide by vapor deposition method to obtain the required catalyst, and the loading capacity is 1wt.%;

[0066] (d) Ultrasonic emulsification of 10 g of oil-water mixture with 1 g of catalyst for 8 min to prepare an emulsion with uniformly dispersed droplets;

[0067] (e) Take 20mL of the emulsion in a continuous flow electrolysis cell, control the current at 100mA, and perform electrolysis for 1.5h to obtain the upgraded biomass pyrolysis oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com