Method for reducing CO2 flooding minimum miscible pressure by using microbial hydrocarbon degrading bacteria

A technology of miscible pressure and hydrocarbon-reducing bacteria is applied in the field of reducing the minimum miscible pressure of CO2 flooding by using microbial hydrocarbon-reducing bacteria. Easy to apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

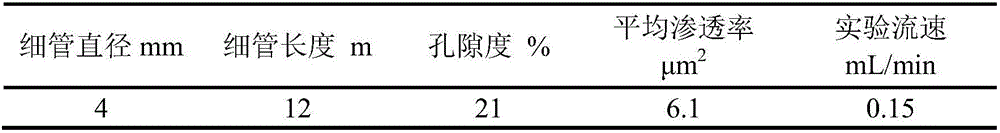

Examples

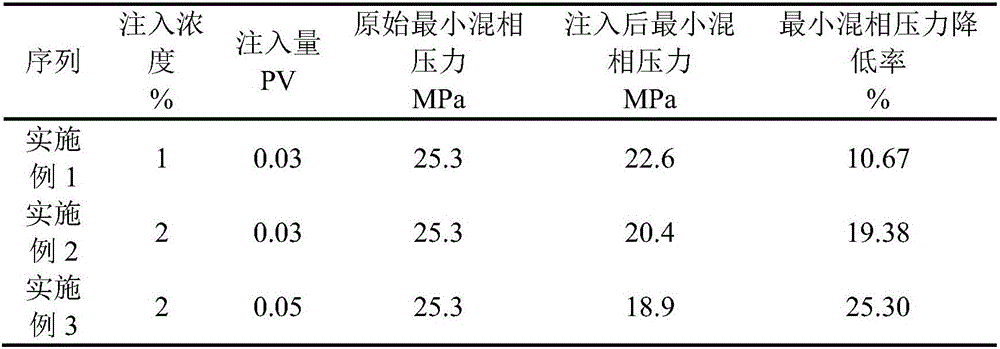

Embodiment 1

[0038] 1) First, cultivate the seeds of YM8 depressant bacteria in a small seed bottle. The specific conditions are: culture in a shaker at a temperature of 35°C and a rotation speed of 120 rpm for about 18 hours; then in a large seed bottle The specific conditions are: culture in a shaker at a temperature of 35°C and a rotation speed of 75 rpm, and the culture time is about 16 hours;

[0039] Among them, the medium (g / L) in the small seed bottle and the large seed bottle: sucrose 10.0, corn steep liquor 5.0, disodium hydrogen phosphate 1.0, potassium dihydrogen phosphate 0.25, sodium nitrate 1.5, magnesium sulfate 0.5, sodium chloride 3.0 , pH 7.2;

[0040] 2) Then, use the pressure difference to insert the seeds into the first-level seed tank for fermentation. The specific conditions are: the temperature is 35°C, the stirring speed is 150 rpm, and the cultivation time is about 24 hours to reach the required index; Put the seeds into the secondary seed tank for fermentation,...

Embodiment 2

[0045] 1) First, cultivate the seeds of YM8 depressant bacteria in a small seed bottle. The specific conditions are: culture in a shaker at a temperature of 34°C and a rotation speed of 110 rpm for about 19 hours; then in a large seed bottle The specific conditions are as follows: culture in a shaker at a temperature of 34°C and a rotation speed of 70 rpm, and the culture time is about 15 hours;

[0046] Among them, the medium (g / L) in the small seed bottle and the large seed bottle: sucrose 15.0, corn steep liquor 7.0, disodium hydrogen phosphate 0.7, potassium dihydrogen phosphate 0.4, sodium nitrate 2.0, magnesium sulfate 0.2, sodium chloride 4.0 , pH 7.3;

[0047] 2) Then, use the pressure difference to insert the seeds into the first-level seed tank for fermentation. The specific conditions are: the temperature is 34°C, the stirring speed is 160 rpm, and the cultivation time is about 23 hours to reach the required index; Put the seeds into the secondary seed tank for fer...

Embodiment 3

[0052] 1) First, cultivate the seeds of YM8 depressant bacteria in a small seed bottle. The specific conditions are: culture in a shaker at a temperature of 36°C and a rotation speed of 130 rpm for about 20 hours; then in a large seed bottle The specific conditions are as follows: culture in a shaker at a temperature of 36°C and a rotation speed of 80 rpm, and the culture time is about 17 hours;

[0053] Among them, the medium (g / L) in the small seed bottle and the large seed bottle: sucrose 12.0, corn steep liquor 10.0, disodium hydrogen phosphate 0.5, potassium dihydrogen phosphate 0.5, sodium nitrate 1.8, magnesium sulfate 0.3, sodium chloride 5.0 , pH 7.4;

[0054] 2) Then, use the pressure difference to insert the seeds into the first-level seed tank for fermentation. The specific conditions are: the temperature is 36°C, the stirring speed is 140 rpm, and the cultivation time is about 25 hours to reach the required index; Put the seeds into the secondary seed tank for fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com