Method for reducing CO2-crude oil minimum miscible pressure and CO2 oil displacement method

A technology of miscible pressure and oil displacement method, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of large adsorption loss of surfactants, difficult injection, low efficiency, etc., and reduce the minimum miscible pressure. , the effect of improving the recovery rate and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

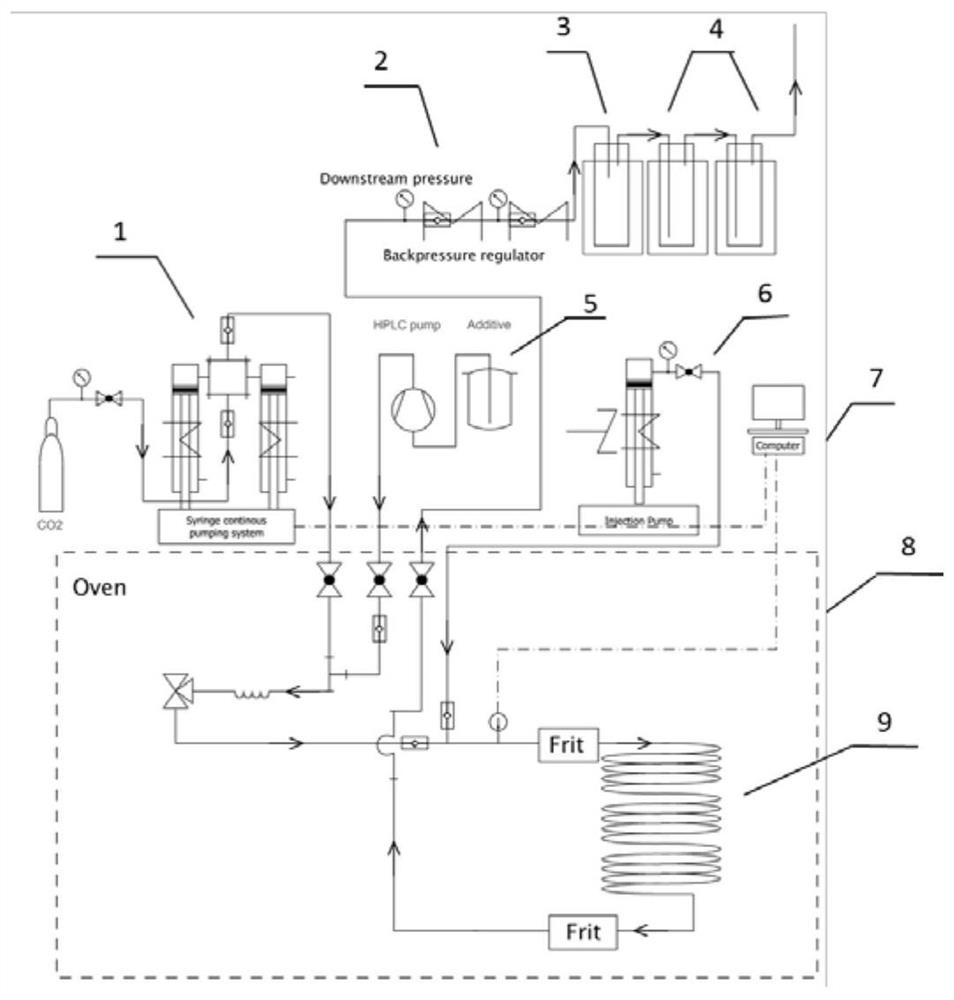

Method used

Image

Examples

Embodiment 1

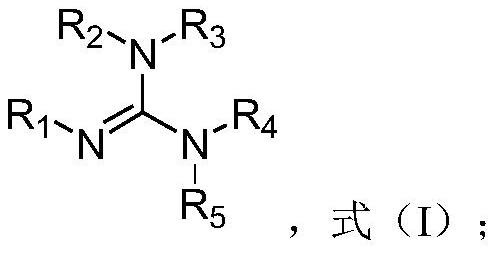

[0031] Reduce the components and content of the minimum miscible pressure chemical agent:

[0032] Surfactant A (R 1 =-C 16 h 33 ; 2 =-CH 3 ; 3 =-CH 3 ; 4 =-CH 3 ; 5 =-CH 3 ): 100;

[0033] Use concentration: 1.0% (chemical agent in CO 2 mass concentration in);

[0034] Crude oil: provided by Shengli Oilfield.

Embodiment 2

[0036] Components and contents of miscible pressure chemicals:

[0037] Surfactant A (R 1 =-C 16 h 33 ; 2 =-CH 3 ; 3 =-CH 3 ; 4 =-CH 3 ; 5 =-CH 3 ):100;

[0038] Use concentration: 1.5% (chemical agent in CO 2 mass concentration in);

[0039] Crude oil: provided by Shengli Oilfield.

Embodiment 3

[0041] Components and contents of miscible pressure chemicals:

[0042] Surfactant B (R 1 =-C 12 h 25 ; 2 =-CH 3 ; 3 =-CH 3 ; 4 =-CH 3 ; 5 =-CH 3 ):100;

[0043] Use concentration: 1.0% (chemical agent in CO 2 mass concentration in);

[0044] Crude oil: provided by Shengli Oilfield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com