Composite micro-electrolysis filler as well as preparation method and application thereof

A micro-electrolysis and composite technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy passivation and hardening, and achieve strong mechanical strength and treatment efficiency. The effect of high and large potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

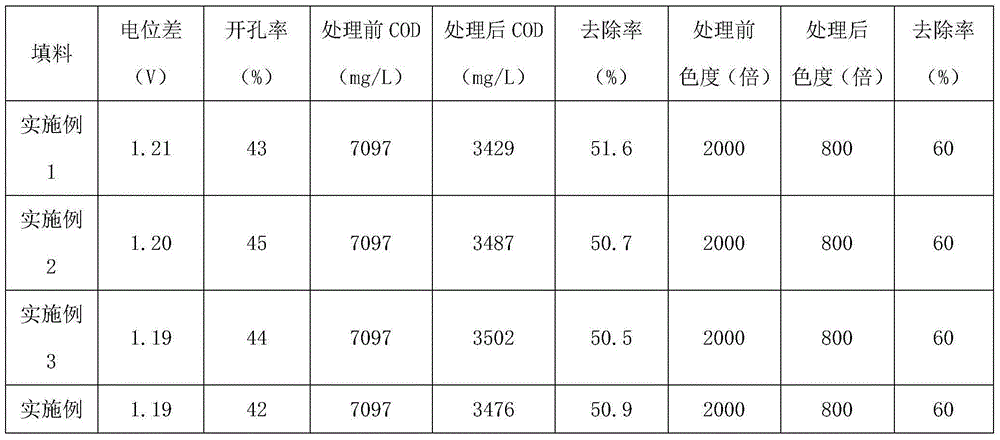

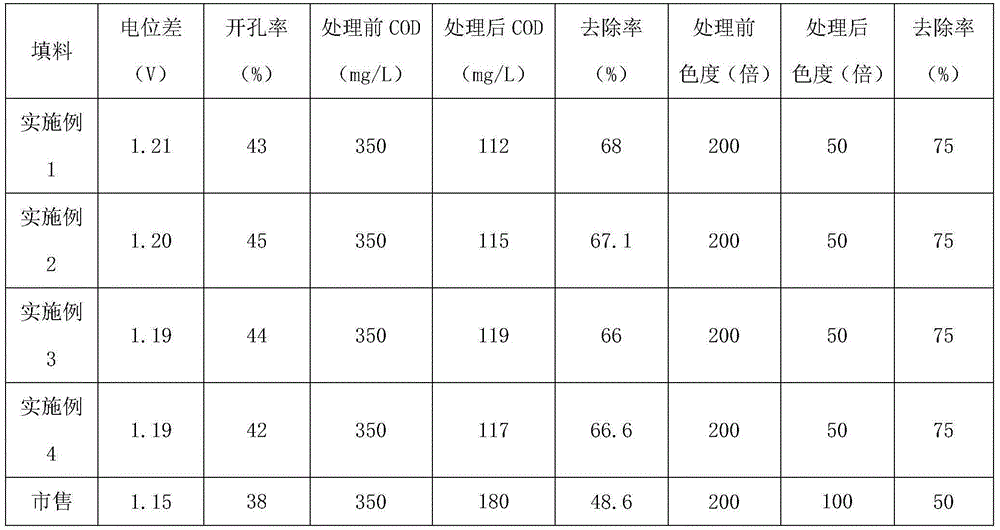

[0056] Embodiment 1: Preparation of composite micro-electrolytic filler

[0057] Screen and weigh 42kg of iron powder, 30kg of activated carbon powder, 6kg of sodium borate, 4kg of sodium carbonate, 2kg of alumina, 3kg of sodium silicate, 1kg of clay, 1kg of bentonite, 3kg of copper powder, 1kg of molybdenum powder, and 2kg of calcium oxide. Add the above raw materials into the mixer, mix them evenly, add 5.5kg of water, stir and age for 1.0 hours, put them into a roller press, and press at a pressure of 700-800kg / cm 2 , press the elliptical semi-finished product with a long diameter of 8-10cm and a short diameter of 3-5cm and place it in an oven at a drying temperature of 80-120°C. After drying for 16 hours, put it into a high-temperature sintering furnace, fill it with nitrogen to prevent oxidation, and gradually Raise the temperature to 800-1000°C, and after sintering for 5 hours, place it in the furnace to cool naturally to below 200°C, take it out and put it in a ventilat...

Embodiment 2

[0058] Embodiment 2: Preparation of composite micro-electrolytic filler

[0059] Screen and weigh 42kg of iron powder, 30kg of activated carbon powder, 6kg of sodium borate, 6kg of sodium carbonate, 3kg of sodium silicate, 2kg of clay, 2kg of copper powder, 2kg of molybdenum powder, and 2kg of calcium oxide. In the mixer, add 5.0kg of water after mixing evenly, stir and age for 0.5 hours, put it into a roller press, and press at a pressure of 700-800kg / cm 2 , press the oval semi-finished product with a long diameter of 8-10cm and a short diameter of 3-5cm and place it in an oven at a drying temperature of 80-120°C. After drying for 12 hours, put it into a high-temperature sintering furnace, fill it with nitrogen to prevent oxidation, and gradually Raise the temperature to 800-1000°C, and after sintering for 4 hours, place it in the furnace to cool naturally to below 200°C, take it out and put it in a ventilated place to continue cooling to room temperature, and then the compos...

Embodiment 3

[0060] Embodiment 3: Preparation of composite micro-electrolytic filler

[0061]Screen and weigh 45kg of iron powder, 35kg of activated carbon powder, 6kg of sodium borate, 6kg of alumina, 3kg of sodium silicate, 2kg of bentonite, 2kg of copper powder, 2kg of molybdenum powder, and 1kg of calcium oxide. In the mixer, add 6.2kg of water after mixing evenly, stir and age for 1.0 hours, put it into a roller press, and press at a pressure of 700-800kg / cm 2 , press the elliptical semi-finished product with a long diameter of 8-10cm and a short diameter of 3-5cm and place it in an oven at a drying temperature of 80-120°C. After drying for 14 hours, put it into a high-temperature sintering furnace, fill it with nitrogen to prevent oxidation, and gradually Raise the temperature to 800-1000°C, and after sintering for 5 hours, place it in the furnace to cool naturally to below 200°C, take it out and put it in a ventilated place to continue cooling to room temperature, and then the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com