Synthesis method of long-carbon-chain semi-aromatic nylon

A synthesis method and long carbon chain technology, applied in the field of semi-aromatic nylon synthesis, can solve the problems of molar ratio imbalance, side reactions, easy blockage of pipes, etc., and achieve an increase in the proportion of active end groups, an increase in the number of effective collisions, and an increase in the number of effective collisions. The effect of end-group activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

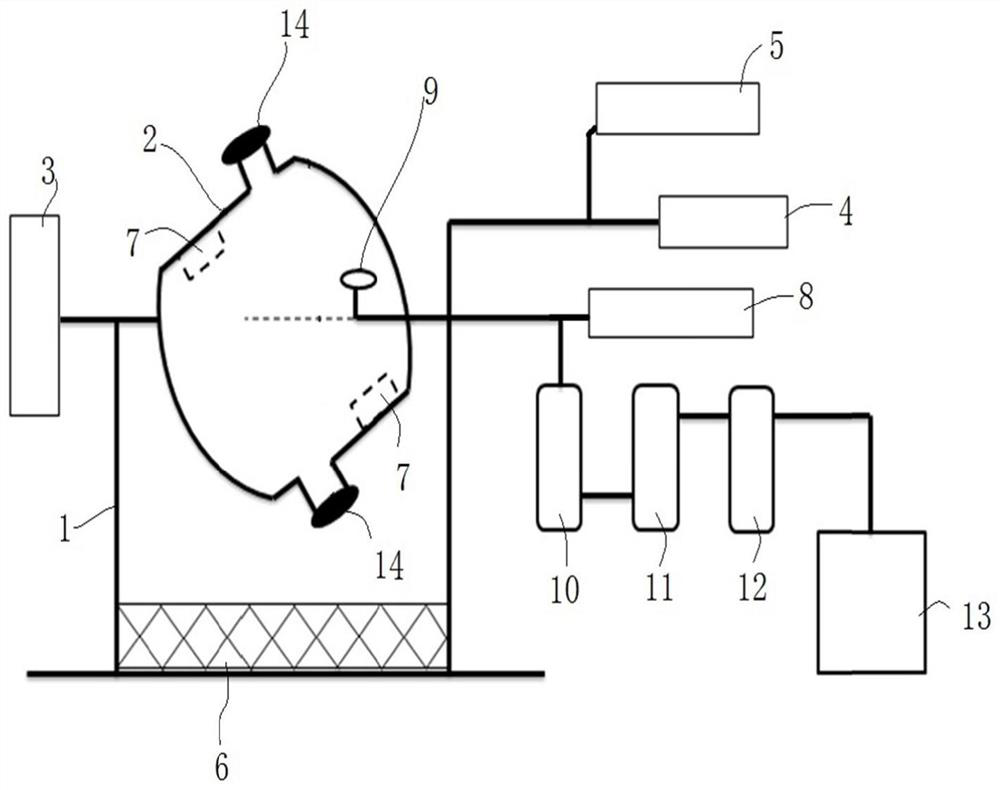

[0051] The synthetic method of the long carbon chain semi-aromatic nylon of the present embodiment comprises the following steps:

[0052] 1) Add 15kg of pure water to the salt-forming kettle, add 2.76kg of dodecyl diamine and 2.27kg of terephthalic acid (the molar ratio is 1.01:1), seal it, and use N 2 Replace the gas three times to keep the pressure in the kettle at 0.01MPa. Turn on the stirring motor and adjust the stirring speed to 150r / min. Heating, when the temperature in the kettle rises to 140°C, the pH value of the test is 7.2, and the temperature is maintained for 1 hour. Cool down to obtain a mixed solution of nylon PA12T salt. The mixed liquor was dehydrated to obtain wet powder nylon PA12T salt with a water content of 10 wt%.

[0053] 2) Weigh 4kg of the wet powder nylon PA12T salt obtained in step 1), 12g of catalyst phosphorous acid, 8g of antioxidant SH120, 20g of surfactant heavy alkylbenzene sulfonate and 50 pieces of polyetheretherketone with a diameter o...

Embodiment 2

[0055] The synthetic method of the long carbon chain semi-aromatic nylon of the present embodiment comprises the following steps:

[0056] 1) Add 15kg of pure water to the salt-forming kettle, add 2.57kg of decanediamine and 2.46kg of terephthalic acid (the molar ratio is 1.01:1), seal it, and use CO 2 Replace the gas three times to keep the pressure in the kettle at 0.01MPa. Turn on the stirring motor and adjust the stirring speed to 200r / min. Heating, when the temperature in the kettle rises to 140°C, the test pH value is 7.5, and the temperature is maintained for 1 hour. Cool down to obtain a mixed solution of nylon PA10T salt. The mixed liquor was dehydrated to obtain wet powdered nylon PA10T salt with a water content of 10 wt%.

[0057] 2) Weigh 4kg of wet powdered nylon PA10T salt obtained in step 1), 12g of catalyst sodium hypophosphite, 8g of antioxidant s9228, 20g of surfactant fatty alcohol polyoxyethylene ether sodium sulfate and 40 pieces of stainless steel with...

Embodiment 3

[0059] The synthetic method of the long carbon chain semi-aromatic nylon of the present embodiment comprises the following steps:

[0060] 1) Add 15kg of pure water to the salt-forming kettle, add 2.92kg of tetradecanediamine and 2.11kg of terephthalic acid (the molar ratio is 1.01:1), seal and use N 2 Replace the gas three times to keep the pressure in the kettle at 0.01MPa. Turn on the stirring motor and adjust the stirring speed to 100r / min. Heating, when the temperature in the kettle rises to 140°C, the test pH value is 6.7; add 36g of tetradecanediamine, test the pH value to 7.2, and keep it for 1 hour. Cool down to obtain a mixed solution of nylon PA14T salt. The mixed liquor was dehydrated to obtain wet powder nylon PA14T salt with a water content of 10 wt%.

[0061] 2) Weigh 4kg of wet powdered nylon PA14T salt obtained in step (1), 12g of catalyst H10, 8g of antioxidant B215, 20g of surfactant (para) linear sodium dodecylbenzenesulfonate and 50 diameter Put 35mm p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com