Conveying control method for pneumatic conveying system

A pneumatic conveying system and conveying control technology, applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as uncontrollable air volume, difficulty in diagnosis and maintenance of intake valve faults, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

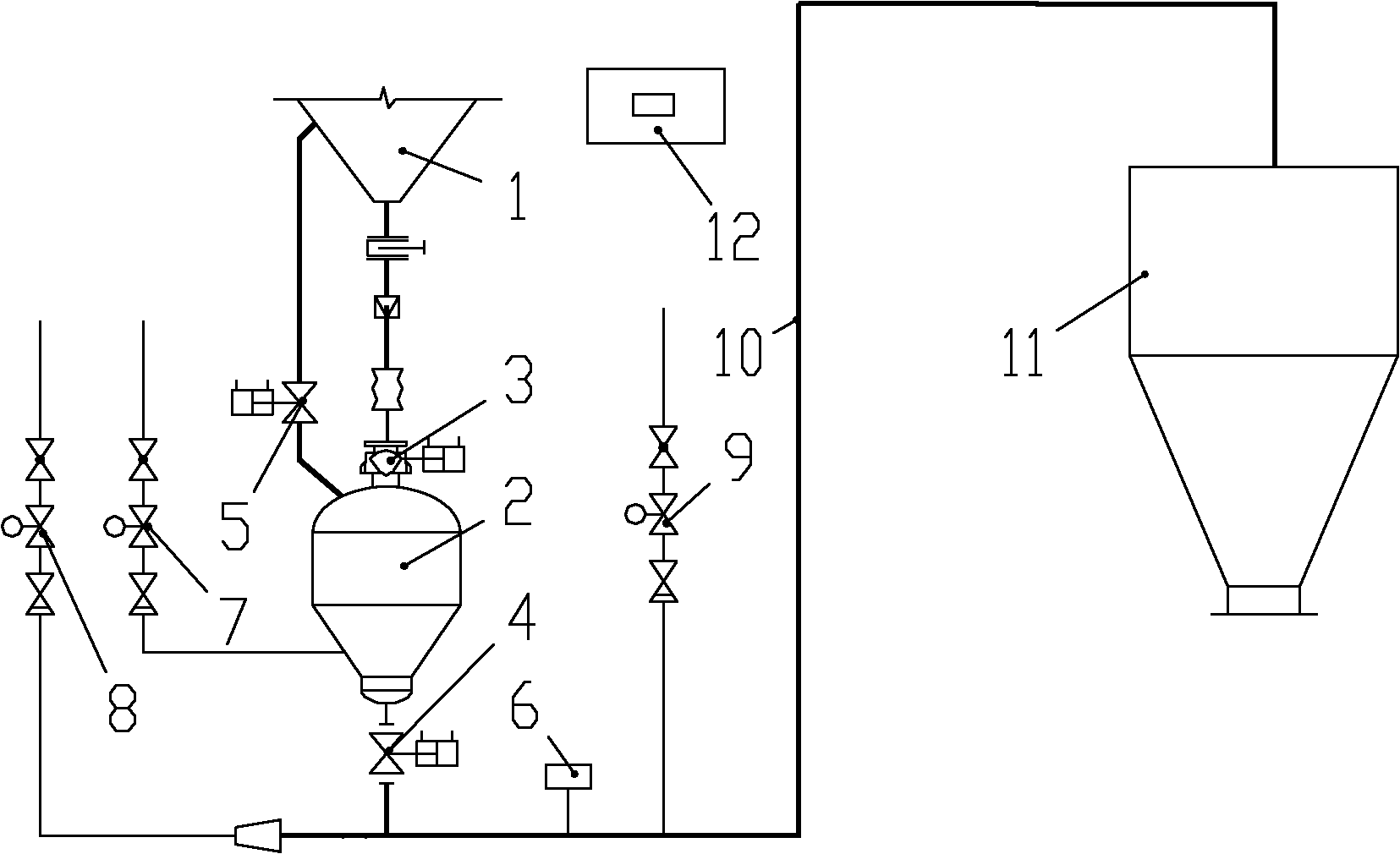

[0020] Please refer to figure 1 , figure 1 It is a schematic diagram of the composition of a conventional pneumatic conveying system. The upper end of the transmitter 2 is connected to the silo 1 through the feed valve 3 and the balance valve 5, and the material enters the transmitter 2 from the silo 1 to be transported; the lower end of the transmitter 2 passes through the discharge valve 4 through the delivery pipeline 10 and the terminal silo 11, the material is transported by the transmitter 2 to the terminal warehouse 11 through the conveying pipeline 10. One end of the air delivery valve 8 is connected to the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com