Airbag grout-block valve pipe assembly for conveniently perforating and slip casting construction

A drilling grouting and grouting technology, which is applied in the field of engineering grouting, can solve the problems of low grouting pressure, slow speed, bending rigidity and easy reverse bending of the grouting bowl, and discount of grouting effect, etc. Slurry speed and slurry pressure, filling effect of dense slurry, and effect of good slurry non-return performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

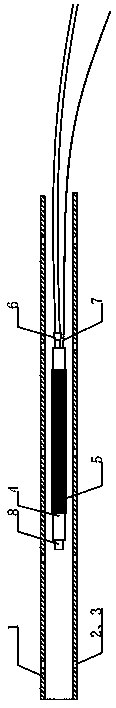

[0022] Attached below Figure 1-5 , to further describe the embodiments of the present invention.

[0023] The present invention is an air bag grout stop valve pipe assembly that is convenient for drilling and grouting construction, such as figure 1 As shown, it includes a grouting drill pipe 1 and an airbag grouting valve tube body 4 . The body of the grouting drill pipe 1 is provided with a grouting hole 3 and a one-way grouting valve 2; the front end of the airbag grouting valve pipe body 4 is a grouting gun mouth 8, the pipe body is wrapped by a grouting airbag 5, and the tail is connected with a grouting Pipe 6 and air bag inflating pipe 7.

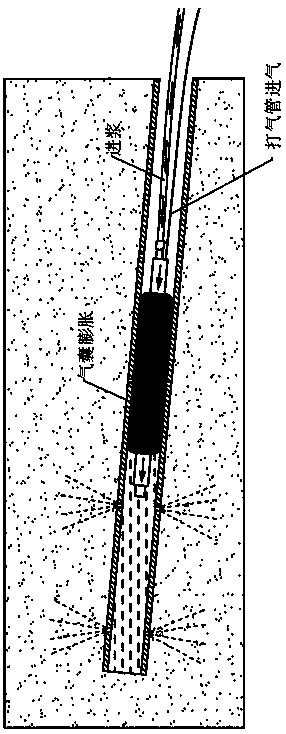

[0024] Before grouting, a sufficient amount of outside air is first pumped into the grout-stop air bag 5 through the air pump 7 to make it expand at high pressure to fill the gap between the drill pipe and the valve pipe body to achieve the function of efficiently plugging the grout, such as figure 2 shown.

[0025] The high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com