Check valve special for ammonia gas

A check valve, ammonia technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of long-term use that cannot meet the working conditions, poor sealing performance, short service life, etc., to achieve superior effect, check Good effect and tight sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

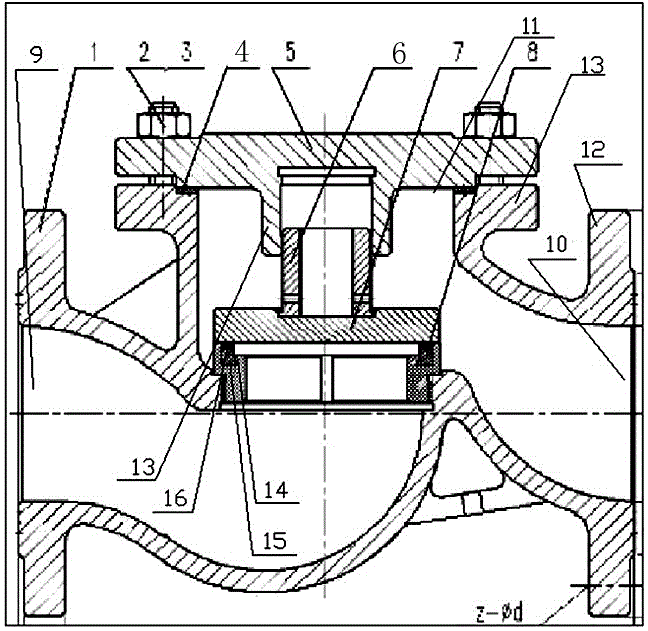

[0013] like figure 1 As shown, the special check valve for ammonia includes a valve body 1, a valve cover 5, a valve seat 8, and a valve disc 7. The valve seat 8 is fixed in the valve body 1, and the valve body 1 includes an inlet 9, an outlet 10, and a middle connection Port 11, the inlet and outlet 9, 10 are respectively provided with interface flange 12, and the middle connection port 11 is provided with a connecting flange 13, the inlet and outlet 9, 10 are located on the same axis, and the middle connection port 11 is located in the direction of the inlet and outlet Vertical direction; the bonnet 5 is sealed and fixed by a plurality of bolts and nuts and the connecting flange 12, and a sealing gasket 4 is arranged between the bonnet 5 and the connecting flange 12; The center of one end face of the disc 7 is fixedly connected to the disc rod 6, the disc rod 6 fits in the guide sleeve 13, the other end face of the valve disc 7 is in close contact with the valve seat 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com