Three-way reversing check valve

A check valve, valve body technology, applied in multi-port valves, valve details, control valves, etc., can solve problems such as must be replaced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

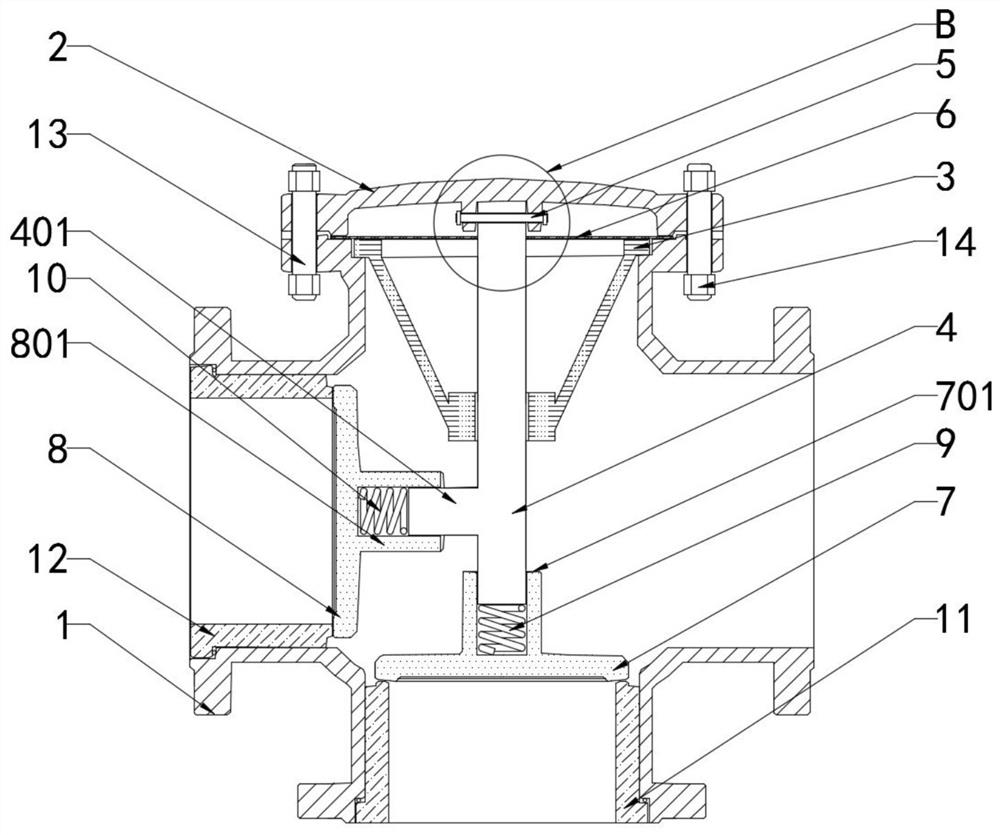

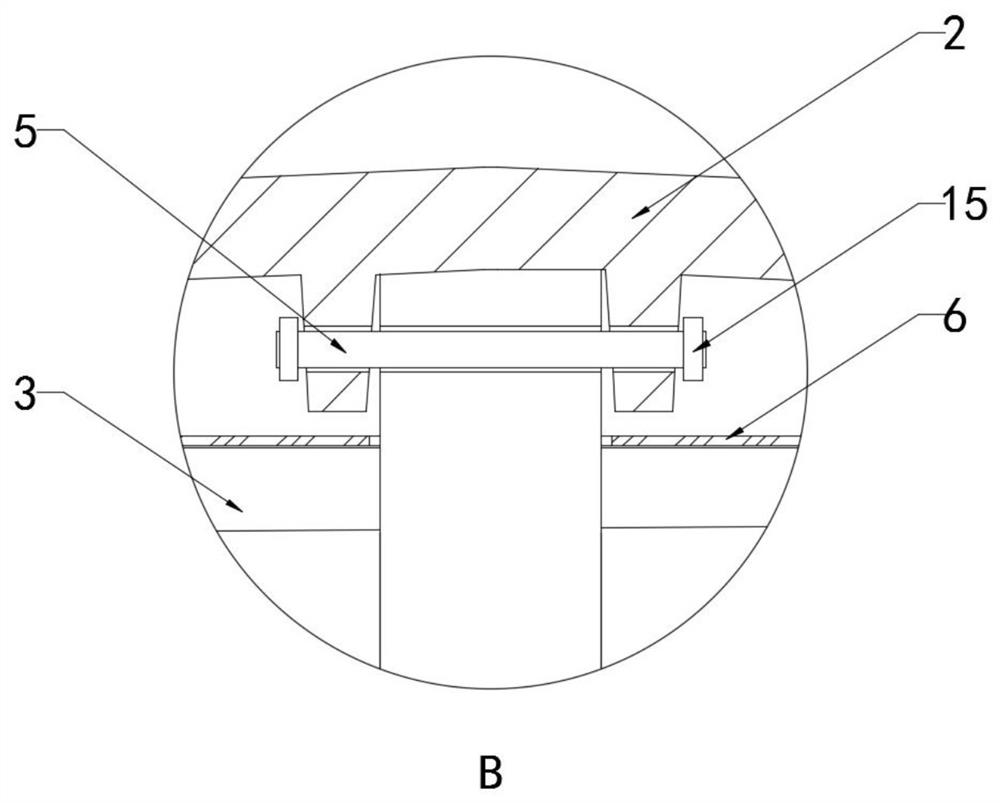

[0024] see Figure 1-2 , including the valve body 1, the shape of the valve body 1 is set in a cross shape, and the top end of the valve body 1 is fixedly connected with the bonnet 2 through the stud 13 and the nut 14, and the lower end surface of the bonnet 2 has a cylindrical The fixed seat and the main valve rod 4 arranged in the vertical direction are fixedly connected to the fixed seat through the insertion rod 5. The main valve rod 4 is sleeved with a fixing part 3 fixedly connected to the valve body 1, and the fixing part 3 has a valve Body 1 and bonnet 2 sandwich the pressure plate 6, the pressure plate 6 is a circular component, and at the same time, after the pressure plate 6 is made of sealing material, the pressure plate 6 is used as a sealing member between the valve cover 2 and the valve body 1, the main valve stem 4 is fixed with an auxiliary valve rod 401 coaxial with the inlet and outlet of the valve body 1, and the end of the main valve rod 4 is provided with...

Embodiment 2

[0026] see Figure 1-2 , the fixing part 3 is a frustum-shaped member, and the bottom end of the fixing part 3 is excessively matched with the main valve stem 4, and the top end of the fixing part 3 has a ring flange, and the flange is engaged with the valve body 1, through the pressure plate 6, the fixing part 3 is firmly installed inside the valve body 1. The valve cavity of the valve body 1 has a circular valve port in the horizontal direction and the vertical direction, the valve port at the top is connected to the valve cover 2, and the first valve disc 7 corresponds to the inlet and has a first valve seat 11 inside it. The two valve discs 8 correspond to the inlet and have a second valve seat 12 inside, so that the valve is a three-way valve. Both the first valve seat 11 and the second valve seat 12 have flanges that engage with the valve body 1 There is an annular sealing member at the position where the flanges of the first valve seat 11 and the second valve seat 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com