Submerged pipeline air guide sleeve and its production and fixing method

A technology for submarine pipelines and fixing methods, which is applied in the directions of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of high requirements on corrosion resistance of porous layer materials, reduce the possibility and delay the release of vortices. , the effect of enhancing the suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

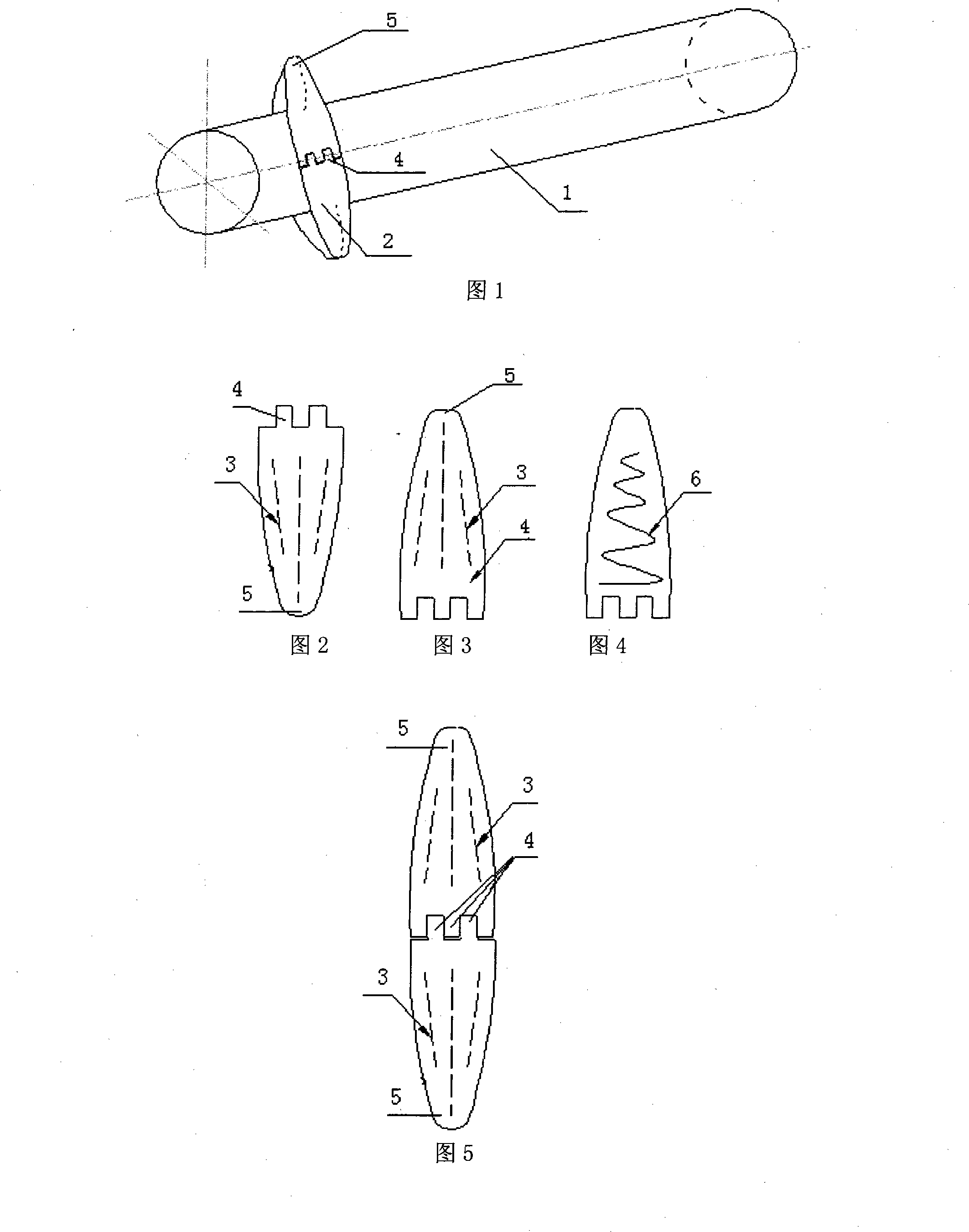

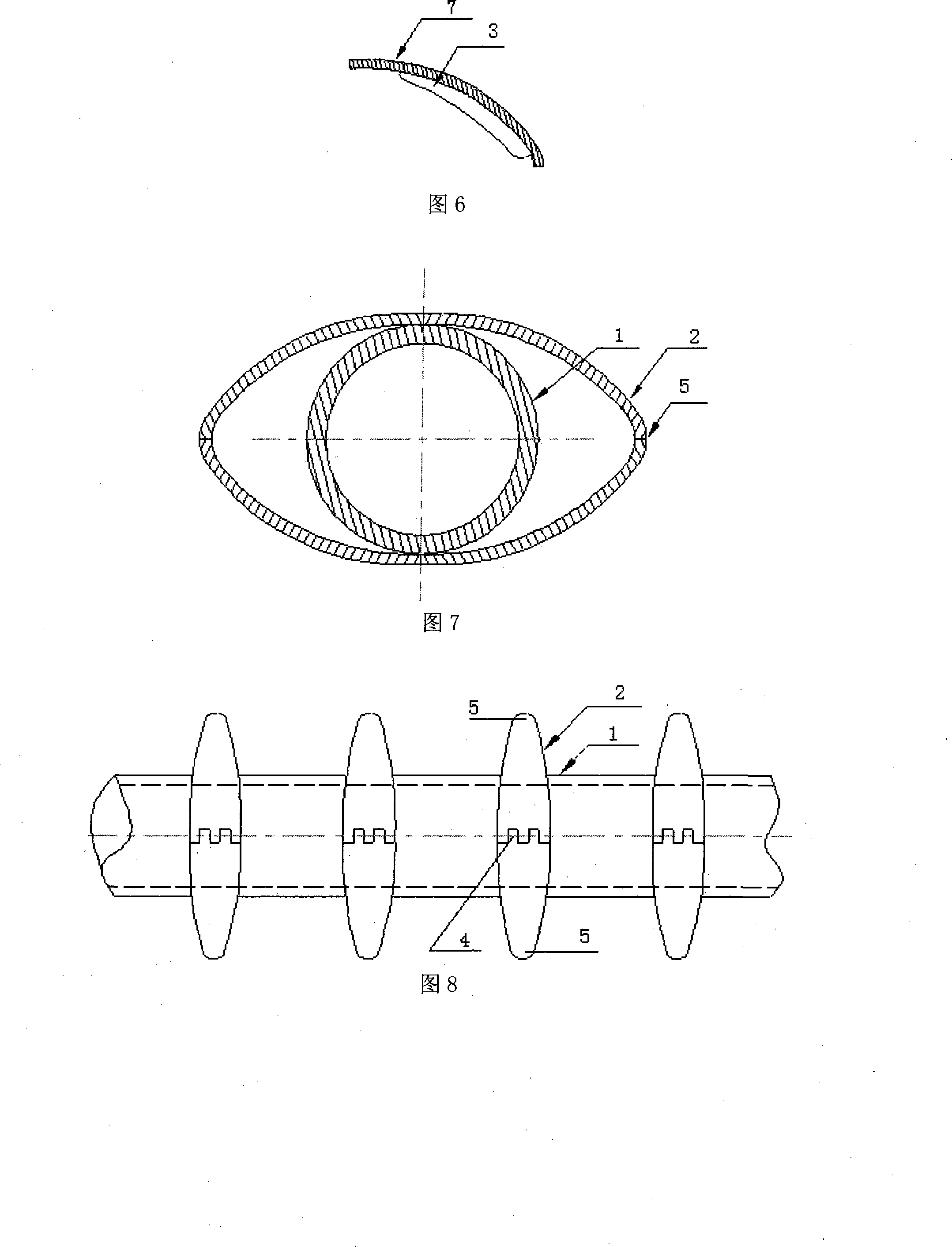

[0030] A three-dimensional view of a wind deflector after being assembled and fixed on the pipeline is shown in Figure 1. The wind deflector of the present invention is a central protrusion formed by splicing four tongue-shaped deflectors 7 with the same size and curvature. A symmetrical shell with two top ends 5 connected. After installation, the inner wall of the raised part in the middle is tangent to the pipe 1 with the bottom edge 4 of the butt-connected deflector 7 as the tangent, and is welded on the pipe 1 . The positions where the tops 5 of the four deflectors 7 are connected are also welded together. Each deflector 7 is made of steel plate or other corrosion-resistant plate with certain strength after cutting and bending.

[0031] The shape of each deflector 7 is a curved tongue, similar to an isosceles triangle cut from a cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com