A Lightweight Machine Tool Beam Reinforced by Arched Ribs

A light-weight, cross-beam technology, applied in the field of machine tools, can solve problems that do not conform to the force characteristics of the cross-beam, reduce the dynamic response of the cross-beam, and affect the dynamic characteristics of the machine tool, so as to improve the dynamic response characteristics, reduce the possibility, and increase the rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

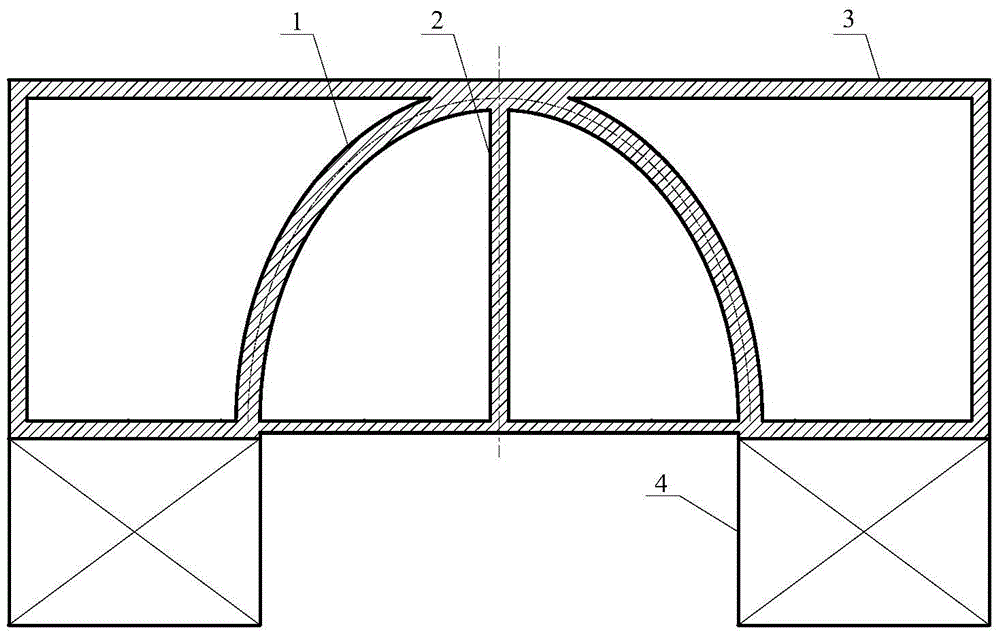

[0027] A light-weight machine tool beam reinforced by arch ribs, such as image 3 As shown, the chord-to-height ratio of the arch axis of the arched ribbed plate inside the beam is 1:1, and the arched ribbed plate has a strong bearing capacity. Only one longitudinal diaphragm is distributed in the center of the beam to improve the overall stiffness of the beam. At the same time, the weight of the beam is reduced, and the static and dynamic characteristics of the beam are improved.

Embodiment 2

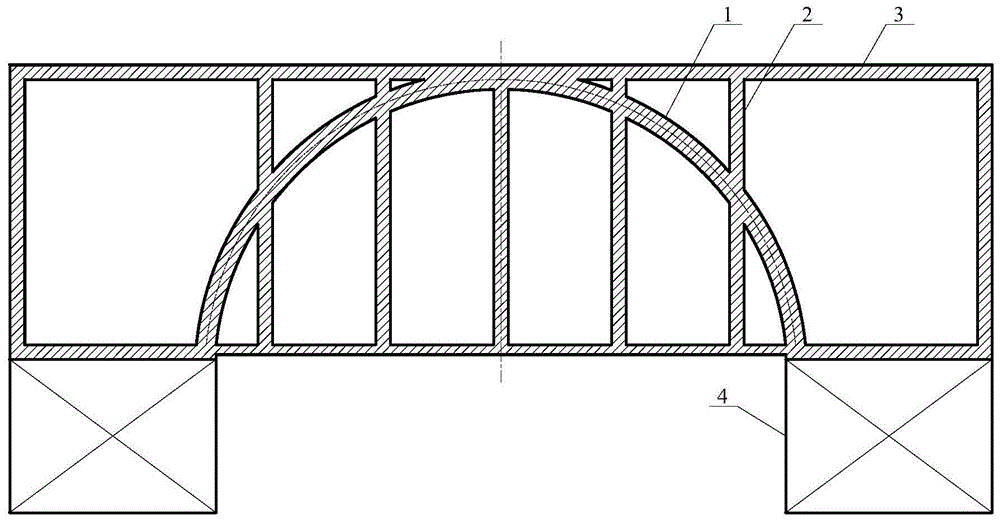

[0029] A light-weight machine tool beam reinforced by arch ribs, such as Figure 4 As shown, the chord-to-height ratio of the arch axis of the arched ribbed plate inside the beam is 2:1, and the arched ribbed plate has a strong load-carrying capacity. The three longitudinal diaphragms are distributed symmetrically on the basis, which can increase the overall stiffness of the beam, reduce the weight of the beam, and improve the static and dynamic characteristics of the beam.

Embodiment 3

[0031] A light-weight machine tool beam reinforced by arch ribs, such as Figure 5 As shown, the chord-to-height ratio of the arch axis of the arched stiffener plate inside the beam is 5:1, and nine longitudinal diaphragms need to be symmetrically distributed in the center of the beam with the mid-plane as the reference, so as to improve the overall stiffness of the beam and reduce the weight of the beam at the same time. Improve the static and dynamic characteristics of the beam.

[0032] The present invention compares the static characteristics of the cross ribbed beam and the arched ribbed beam, see Table 1 for details; see Table 2 for the comparison of dynamic characteristics.

[0033] Table 1 Comparison of static characteristics

[0034]

[0035] Table 2 Comparison of dynamic characteristics

[0036]

[0037] From Table 1 and Table 2, compared with cross-rib plate beams, it can be seen that the arched rib plate beams have the following performance improvements: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com