Streamline tunnel type turbocharger

A turbocharger and tunnel-type technology, applied in the direction of non-variable pumps, machines/engines, pumping devices for elastic fluids, etc., can solve the problem of streamline tunnels that are not deep and have no application examples In order to achieve the effects of controlling weight, widening the range of material selection, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

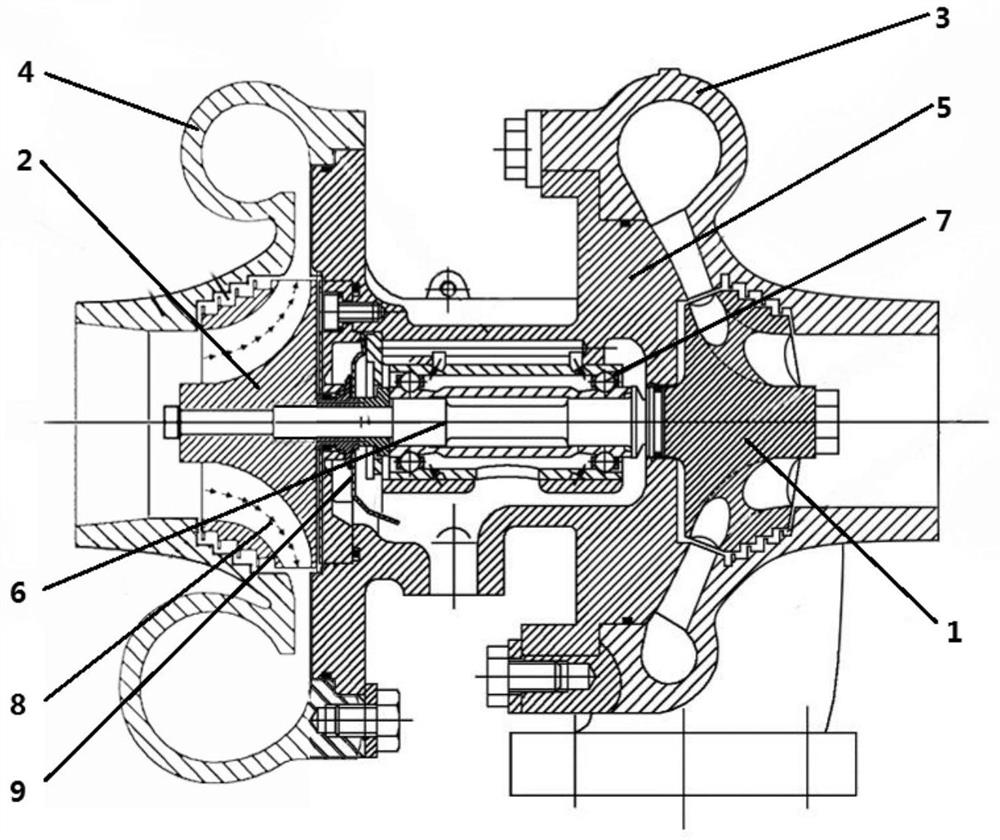

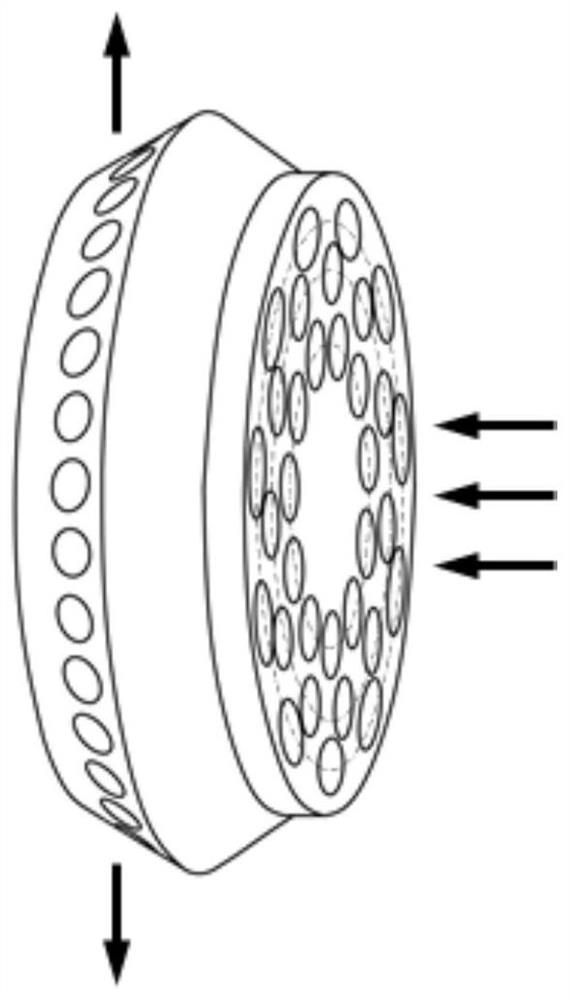

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. A streamline tunnel turbocharger provided by the present invention comprises: a streamline tunnel turbine 1, a streamline tunnel compressor wheel 2, a turbine shell 3, a compressor shell 4, an intermediate shell 5 and a rotating shaft 6; The linear tunnel type turbine 1 and the streamline tunnel type compressor wheel 2 are respectively mounted on both ends of the rotating shaft 6 to form a supercharger rotor; the rear side of the streamline tunnel type compressor wheel 2 is provided with an oil thrust rotary bearing assembly 9 .

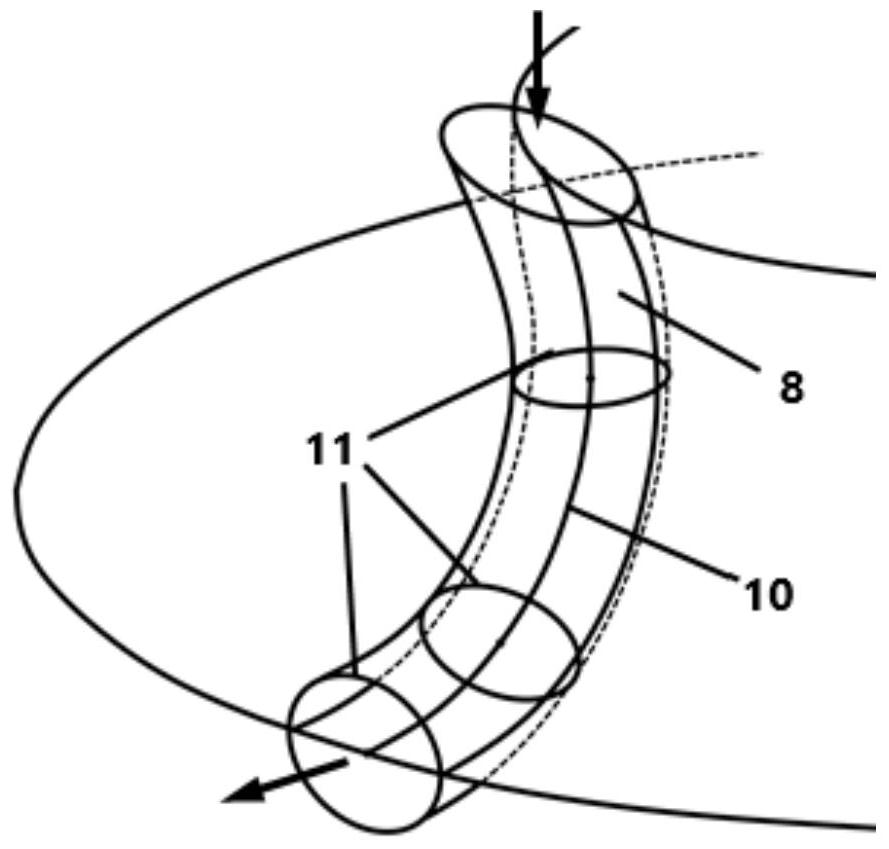

[0029] Further, the streamline tunnel turbine 1 and the streamline tunnel compressor wheel 2 are closed rotating mechanical structures; and the structures of the two can be exactly the same; the streamline tunnel turbine 1 and the streamline tunnel compressor wheel 2 have A pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com