Solar greenhouse suitable for facility cherry cultivation

A technology for solar greenhouses and cherries, which is applied in the field of solar greenhouses and can solve the problems of advancing cherry germination, reducing system performance and efficiency, and increasing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

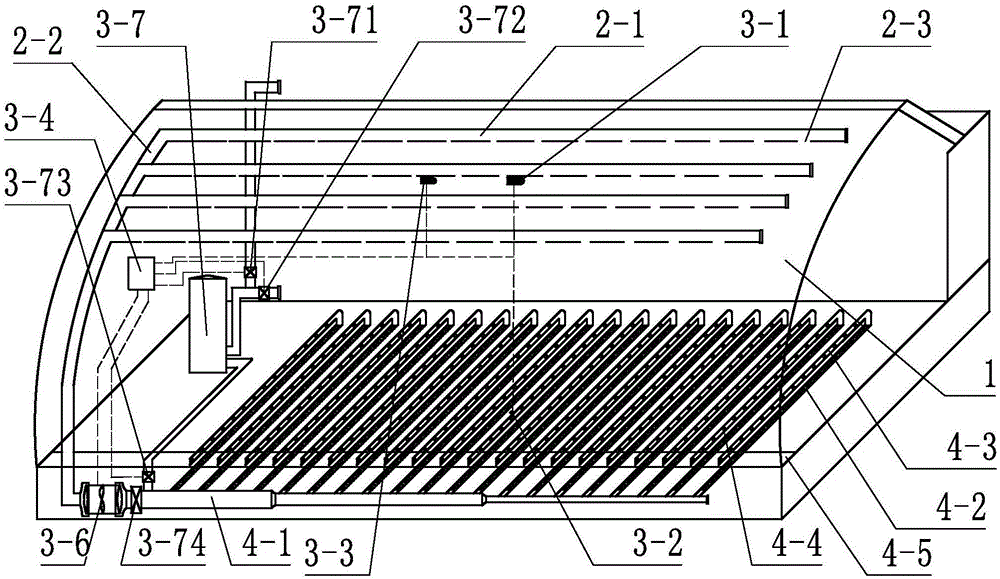

[0047] Embodiment 1: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the present invention includes a shed post and a light-transmitting layer 1, which is characterized in that: the shed post and the light-transmitting layer 1 enclose a solar shed, and is characterized in that: a heat collection device is arranged on the light-transmitting layer 1, and the sunlight The shed is equipped with a uniform air intake device, an automatic control device and a heat dissipation device;

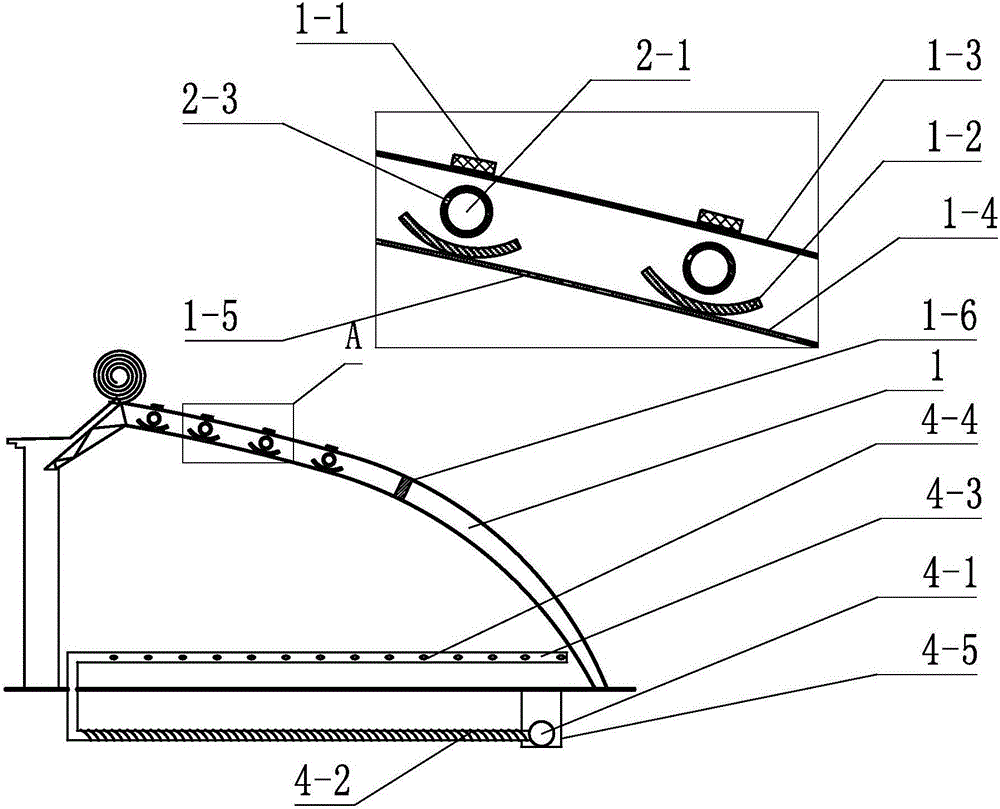

[0048] The heat collecting device comprises a heat absorbing plate 1-1, a reflective plate 1-2, an outer light-transmitting layer 1-3 and an inner light-transmitting layer 1-4, and the outer light-transmitting layer 1-3 and the inner light-transmitting layer 1 -4 is a hollow cavity in the middle, and a reflector 1-2 and a blocking block 1-6 are arranged in the hollow cavity, and the reflector 1-2 is arranged on the inner light-transmitting layer 1-4, and the heat-ab...

Embodiment 2

[0076] Embodiment 2: refer to figure 2 : Compared with Embodiment 1, the difference of this embodiment is: the corrugated heat dissipation pipe 4-2 and the air outlet pipe 4-3 can be provided with multiple groups, and the spacing can be set to 1m, and the corrugated heat dissipation pipe 4-2 The south end is installed at a soil depth of 40cm, the north end of the corrugated heat dissipation pipe 4-2 is installed at a soil depth of 45cm, and the air outlet pipe 4-3 is 10cm higher than the ground.

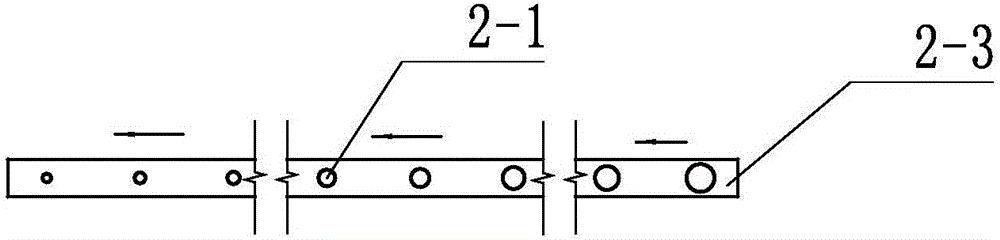

[0077] In actual use: setting more than two groups of air inlet ducts 2-1, heat absorbing panels 1-1 and reflector panels 1-2 can improve the circulation efficiency of cold and hot air and improve the utilization rate of solar energy. High and low in the north, which can effectively prevent pipeline blockage; the air outlet 4-4 on the air outlet pipe 4-3 is set to have a certain angle with the ground, which can effectively prevent the outlet air from spraying directly to the cherry,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com