Flying saucer spacecraft

A spacecraft and flying saucer technology, applied in the field of flying saucer spacecraft, can solve the problems of high cost of space activities, low payload, and high manufacturing cost, and achieve the effects of increasing thrust, reducing payload, and reducing gravity and payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

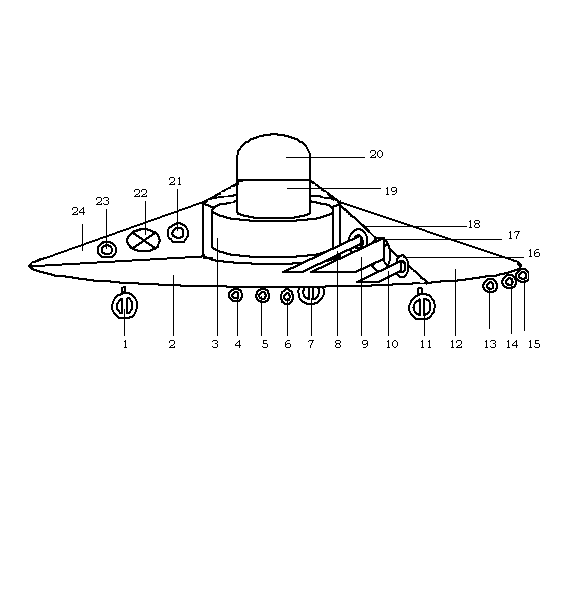

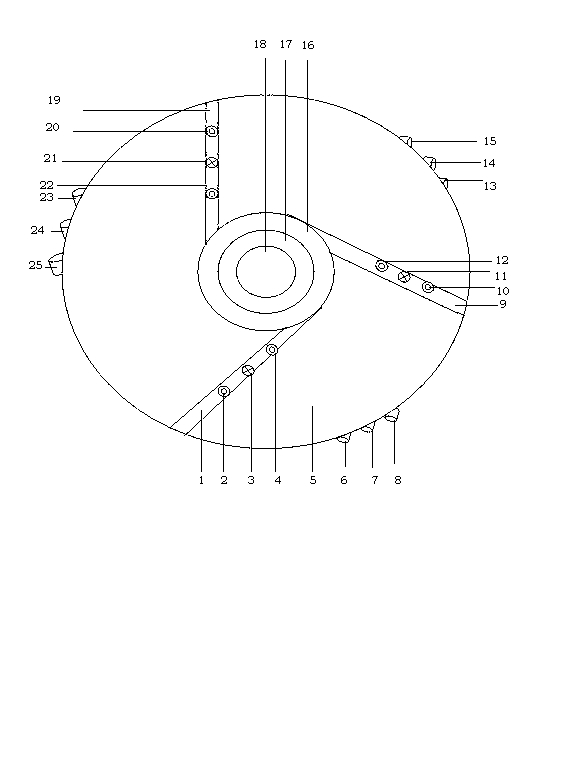

[0015] exist figure 1 In the shown embodiment, the flying saucer spacecraft is shaped like a flying saucer. The fuel tank (3) is installed in the lower part of the center of the flying saucer spacecraft, the control system (19) of the flying saucer spacecraft is installed in the middle, and the launch chamber (satellite warehouse, missile warehouse) is installed in the upper part. , spaceship warehouse) (20); the upper layer of the flying saucer spacecraft is provided with a group A rocket engine air inlet (17), A group No. 1 air duct air inlet (18), A group No. 2 air duct air inlet ( 16), Group C rocket engine inlet (22), Group C No. 1 air duct inlet (21), Group C No. 2 air duct inlet (23); the middle layer of the flying saucer spacecraft is provided with Group A rocket Engine (9), Group A Air Duct No. 1 (8), Group A No. 2 Air Duct (10); Group C Air Duct Air Inlet and Rocket Engine Air Inlet Mounting Bracket (24) for connecting Group C Air Duct and rocket engines. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com