AOD converter side blowing gun pipeline system flow control method

A technology of side blowing guns and pipeline systems, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., to achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The steps and principle of the flow control method of the AOD converter side blowing gun pipeline system of the present invention will be described in detail below according to the drawings and specific embodiments. In order to illustrate the essence of the present invention more clearly, conventional methods and devices in the present invention are only briefly described, and in the drawings, the same components are represented by the same reference numerals.

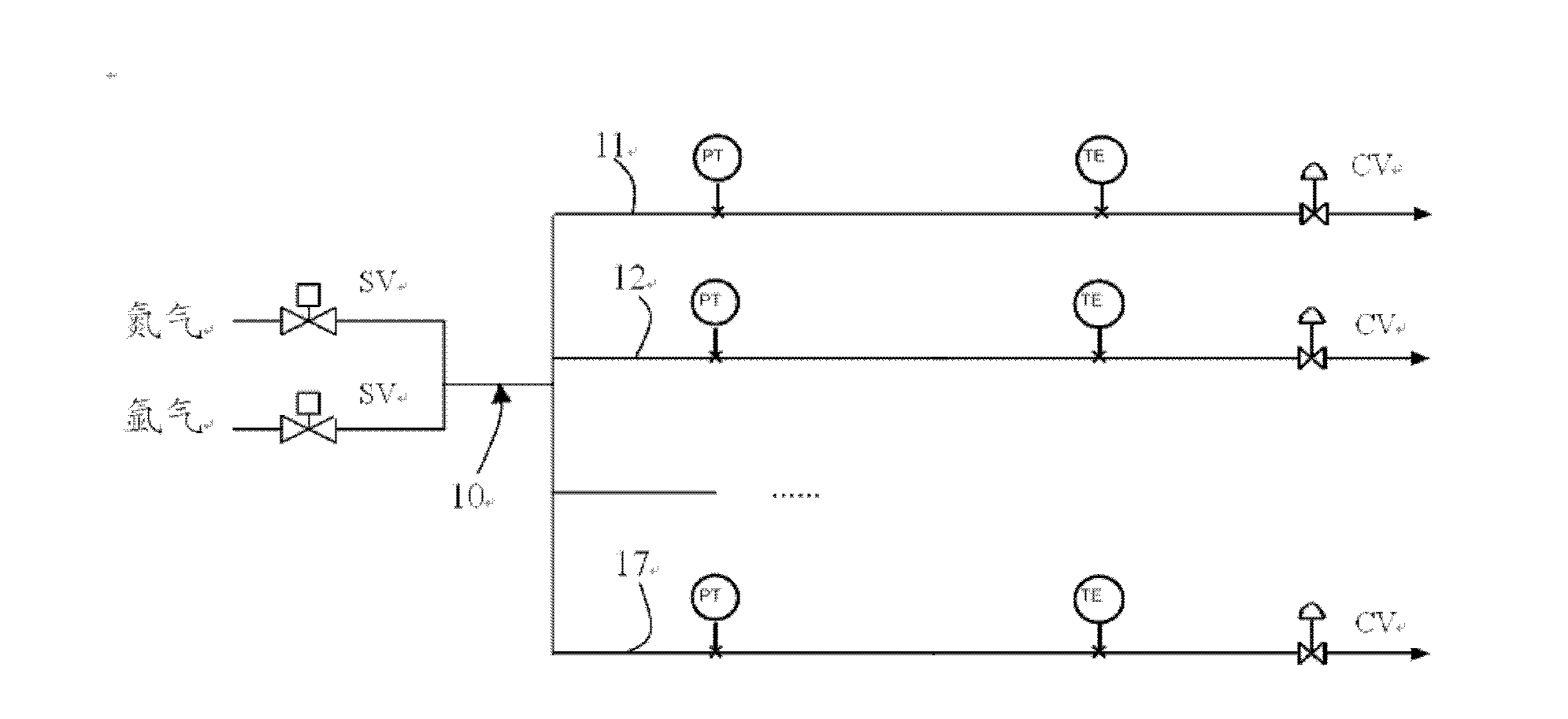

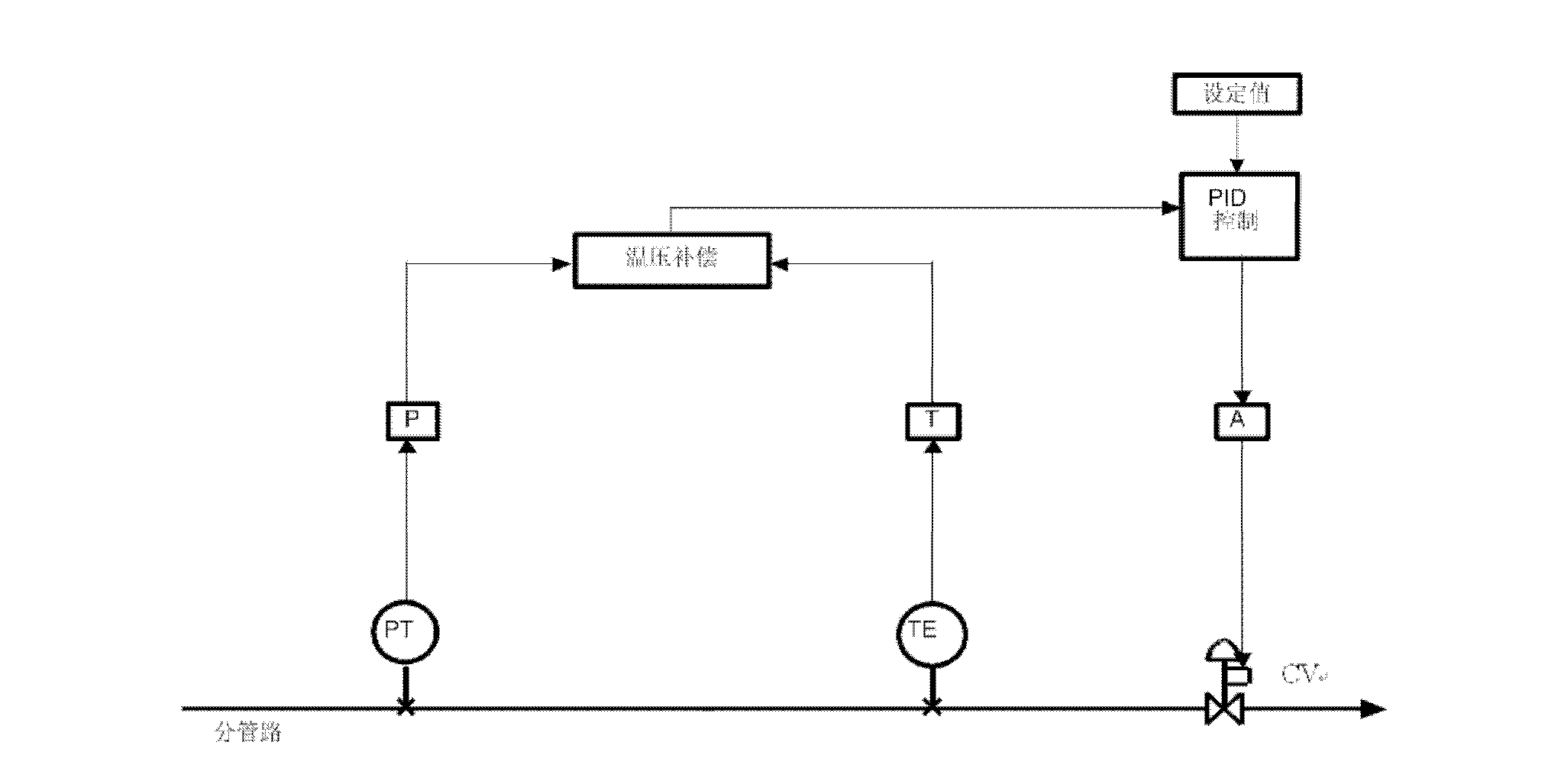

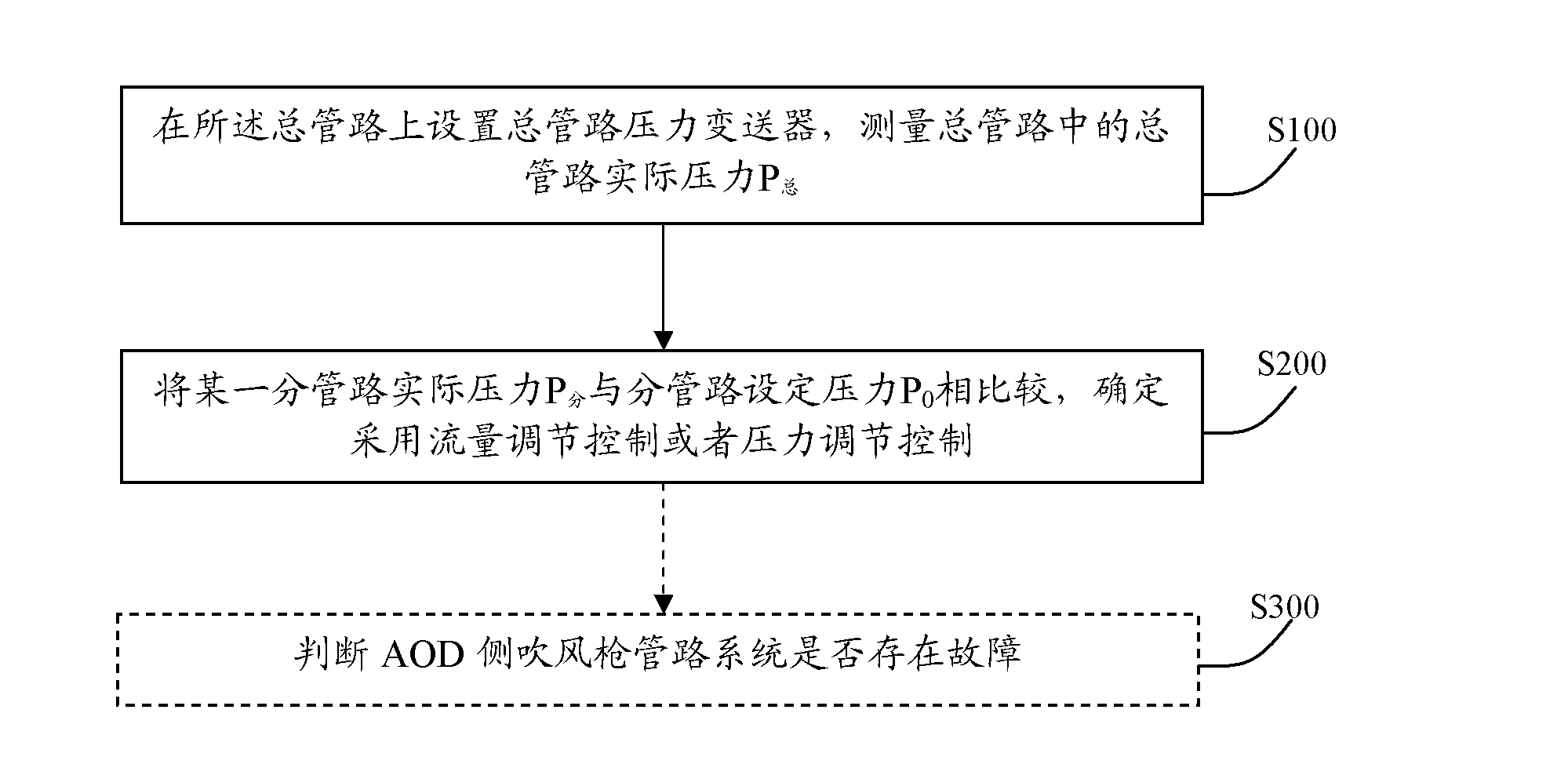

[0037] First refer to figure 1 , Figure 5 with Figure 7 , the flow control method of the AOD converter side blowing gun pipeline system of the present invention is used to control and adjust the gas flow of each pipeline in the AOD converter side blowing gun pipeline system, and the above-mentioned figure 1 The description in is similar, the AOD converter side blow gun pipeline system includes a main pipeline 10 and a plurality of sub-pipelines connected with the main pipeline (the number of sub-pipelines in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com