High-density molding device and high-density molding method for mixed powder

a high-density molding and mixed powder technology, applied in the direction of shaping presses, manufacturing tools, presses, etc., can solve the problems of insufficient mechanical strength of green compact, deterioration of the quality of green compact obtained by press molding, and deterioration of the magnetic properties of green compact, so as to reduce production costs, produce high-quality green compact smoothly, and produce high-density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

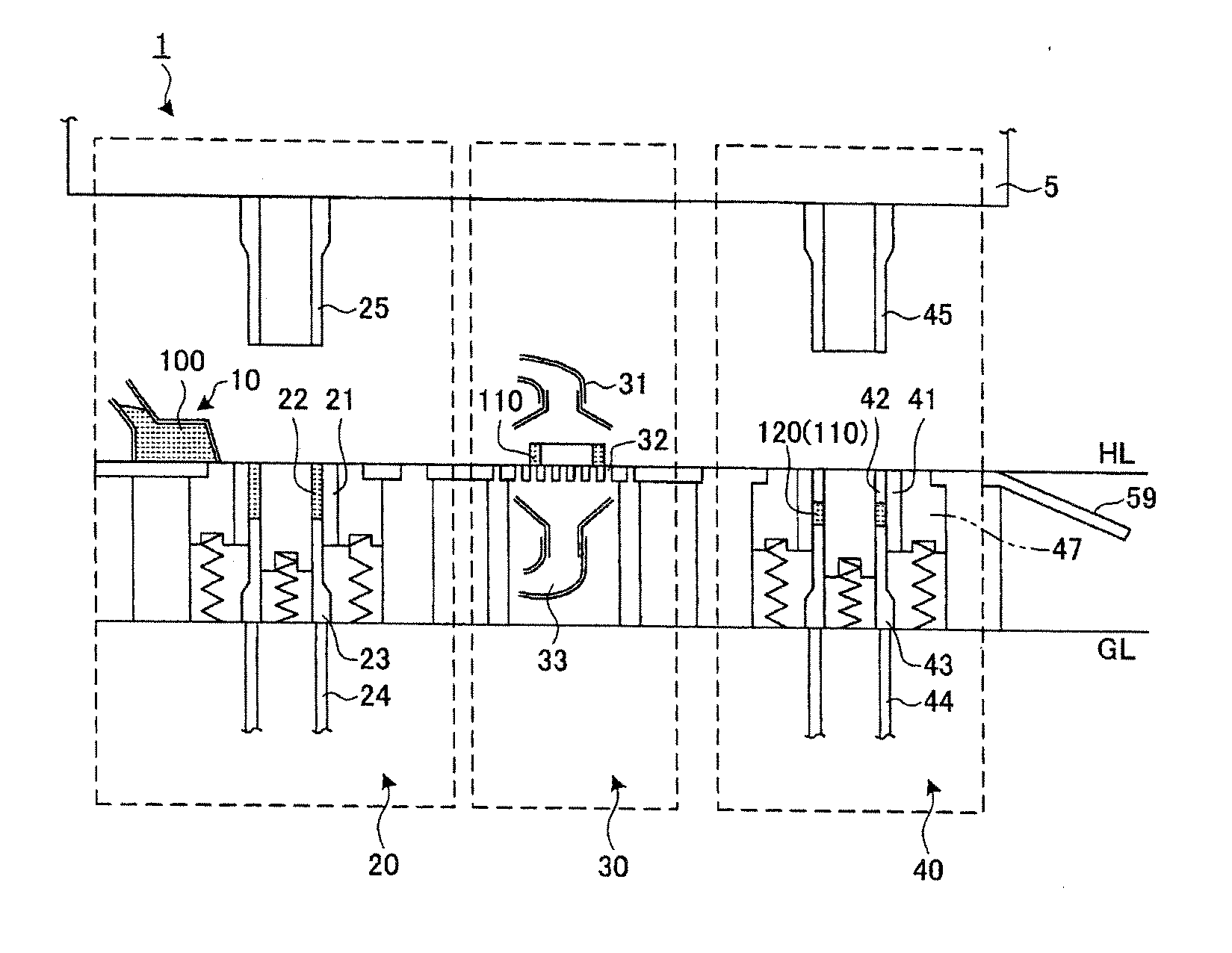

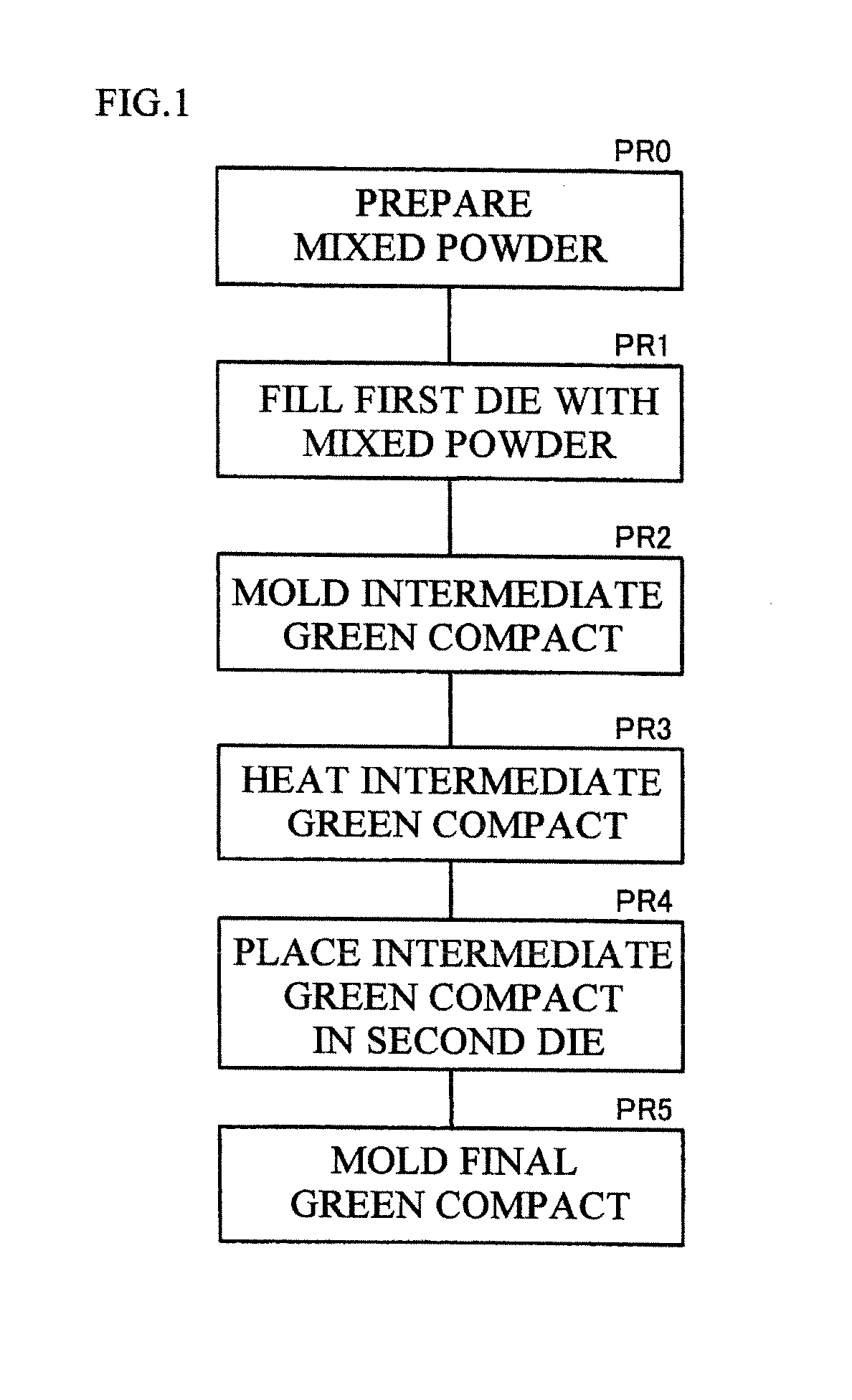

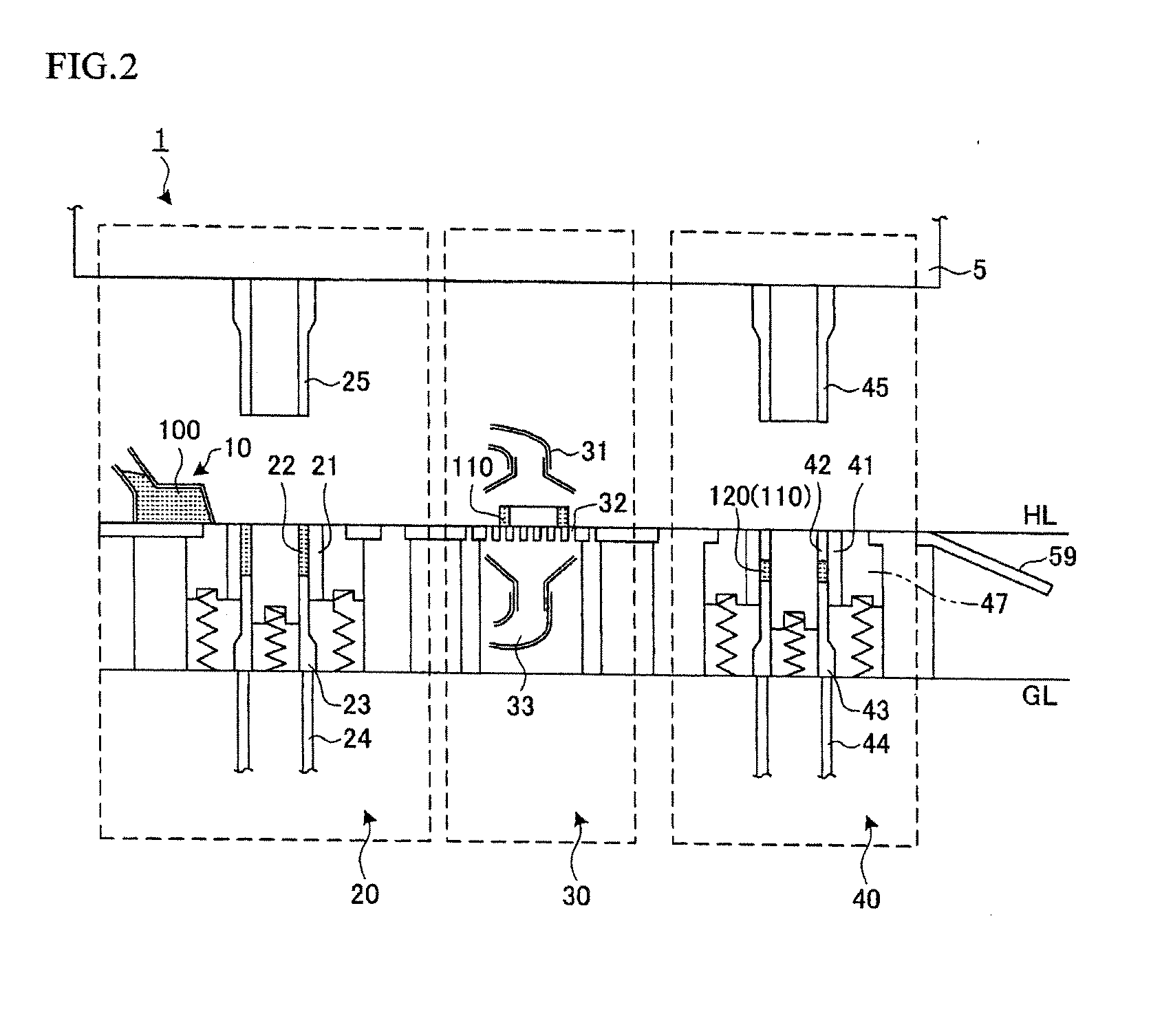

[0063]As illustrated in FIGS. 1 to 8, a mixed powder high-density molding system 1 includes a mixed powder feeding device 10, a first press molding device 20, a heating device 30, and a second press molding device 40, and stably and reliably implements a mixed powder high-density molding method that includes a mixed powder-filling step (PR1) that fills a first die (lower die 21) with a mixed powder 100 that is prepared by mixing a low-melting-point lubricant powder with a basic metal powder, an intermediate green compact-forming step (PR2) that applies a first pressure (P1) to the mixed powder 100 in the first die (lower die 21) using an upper die 25 attached to a slide 1 of a press molding device 20 to form a mixed powder intermediate compressed body (hereinafter may be referred to as “intermediate green compact 110”) having a protrusion 110A, a heating step (PR3) that heats the intermediate green compact 110 removed from the first die (lower die 21) to the melting point of the lub...

second embodiment

[0152]FIG. 10 illustrates a second embodiment of the invention. The second embodiment is identical with the first embodiment as to the mixed powder feeding device 10 and the first press molding device 20, but differs from the first embodiment in that the heating device 30 and the second press molding device 40 are integrally formed.

[0153]Specifically, a high-density molding system 1 according to the second embodiment includes a heating / press molding device 70 that has the function of the heating device 30 and the function of the second press molding device 40 (see the first embodiment). The heating / press molding device 70 includes a plurality of (e.g., two) heating / press molding sub-devices 70A and 70B. The heating / press molding sub-devices 70A and 70B are selectively (sequentially) operated by a control device (not illustrated in the drawings) in a production cycle.

[0154]The heating / press molding sub-devices 70A and 70B have a basic structure similar to that of the second press mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com