Pipeline air tightness detection device

A technology of air tightness detection and pipeline, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, etc., which can solve the problems of inability to detect the air tightness of pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

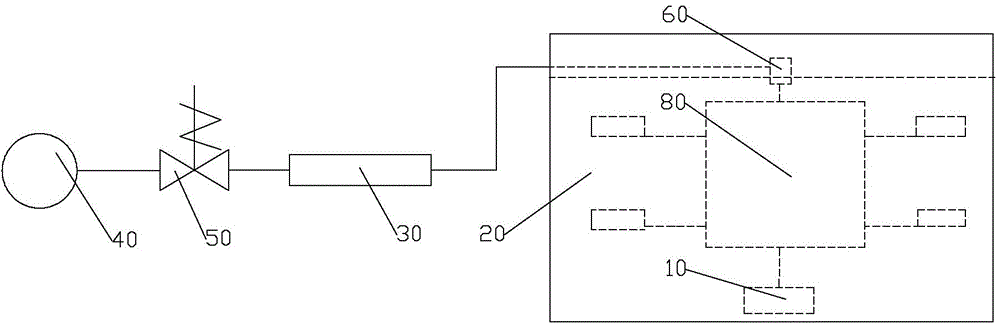

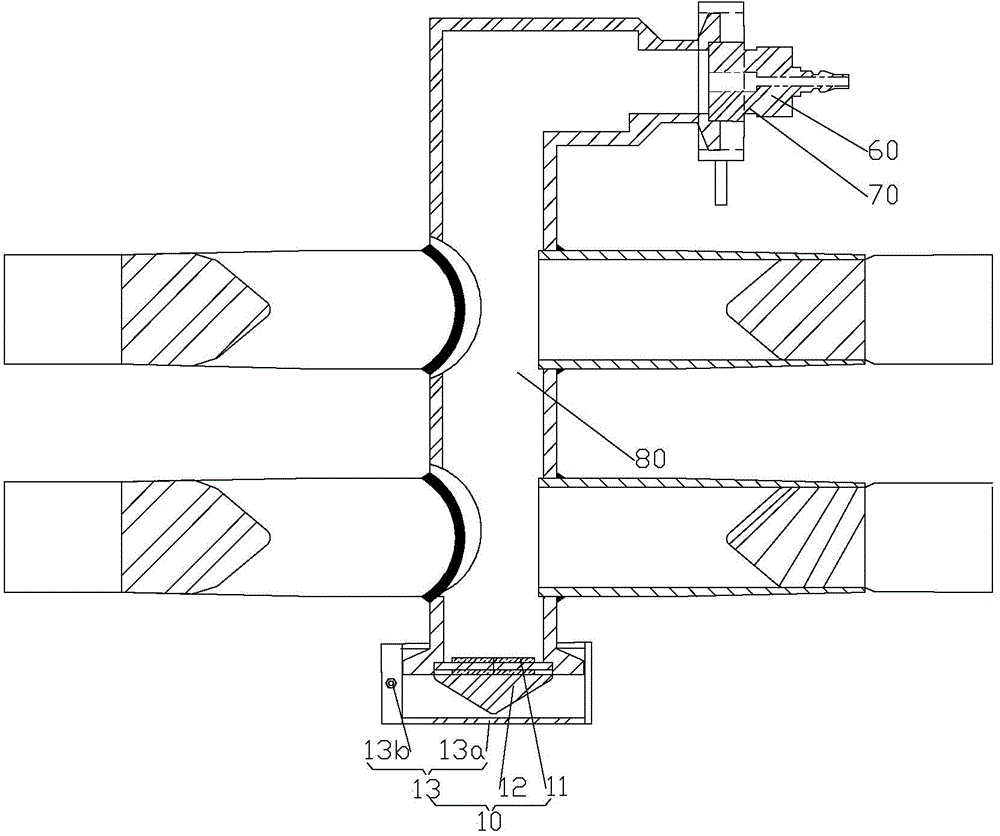

[0021] The invention provides a pipeline air tightness detection device. Such as figure 1 and figure 2 As shown, the pipeline air tightness detection device includes a plugging part 10, a water tank 20 and an air inlet pipe 30. The plugging part 10 is used to seal the air outlet of the detected pipeline 80, and the plugging part 10 and the detected pipeline 80 are located at Below the liquid level in the water tank 20 , the air inlet pipe 30 communicates with the air inlet of the detected pipeline 80 . When using the pipeline airtightness detection device in the present invention, the worker needs to pass gas into the pipeline 80 to be tested through the air inlet pipe 30, and then observe whether there is any air leakage in each place of the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com