Patents

Literature

307results about "Manure distributers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method of dispensing small-scale powders

InactiveUS7316748B2Facilitate depositionIncrease flow rateDispensing apparatusPretreated surfacesUltrasonic vibrationEngineering

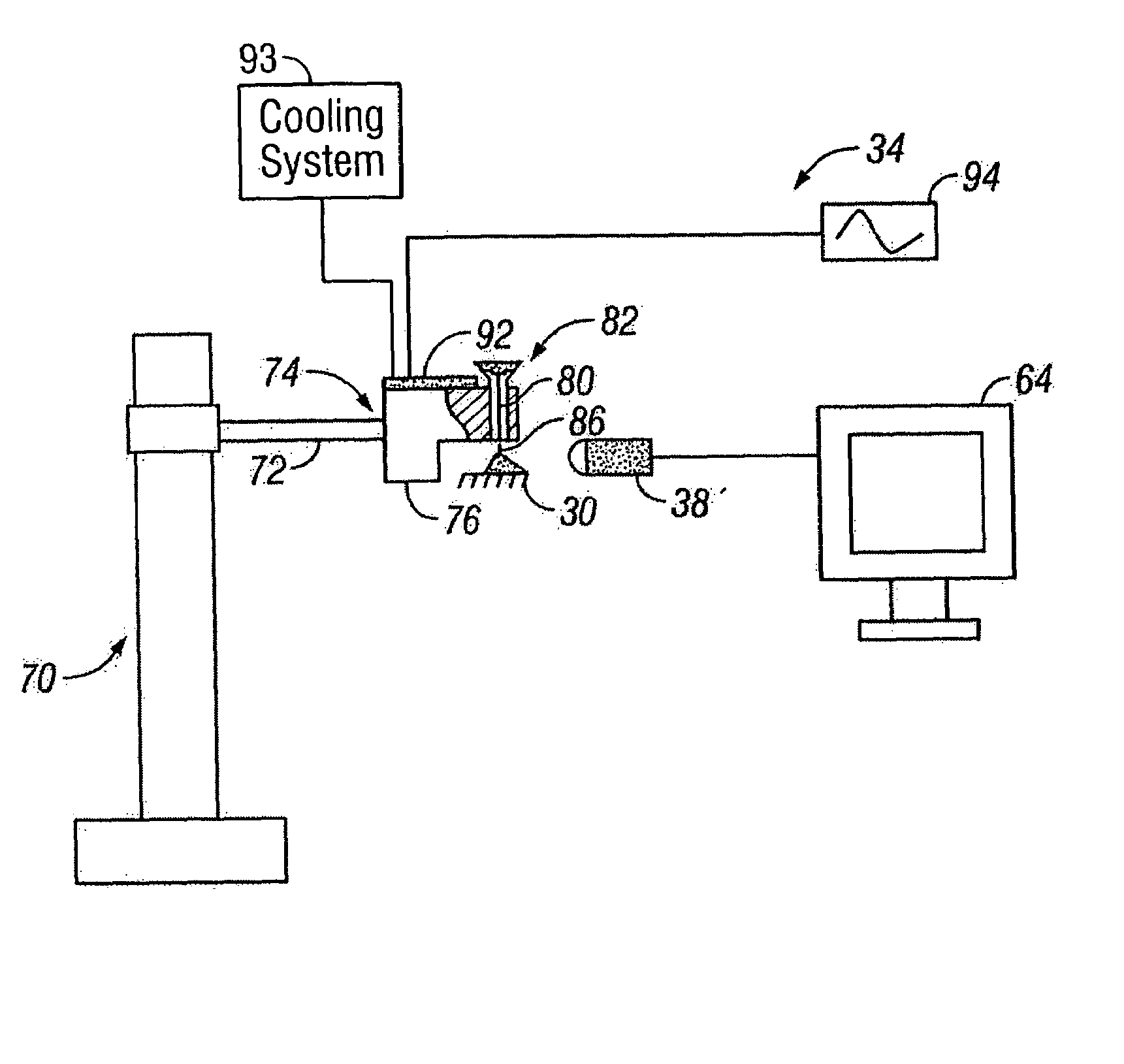

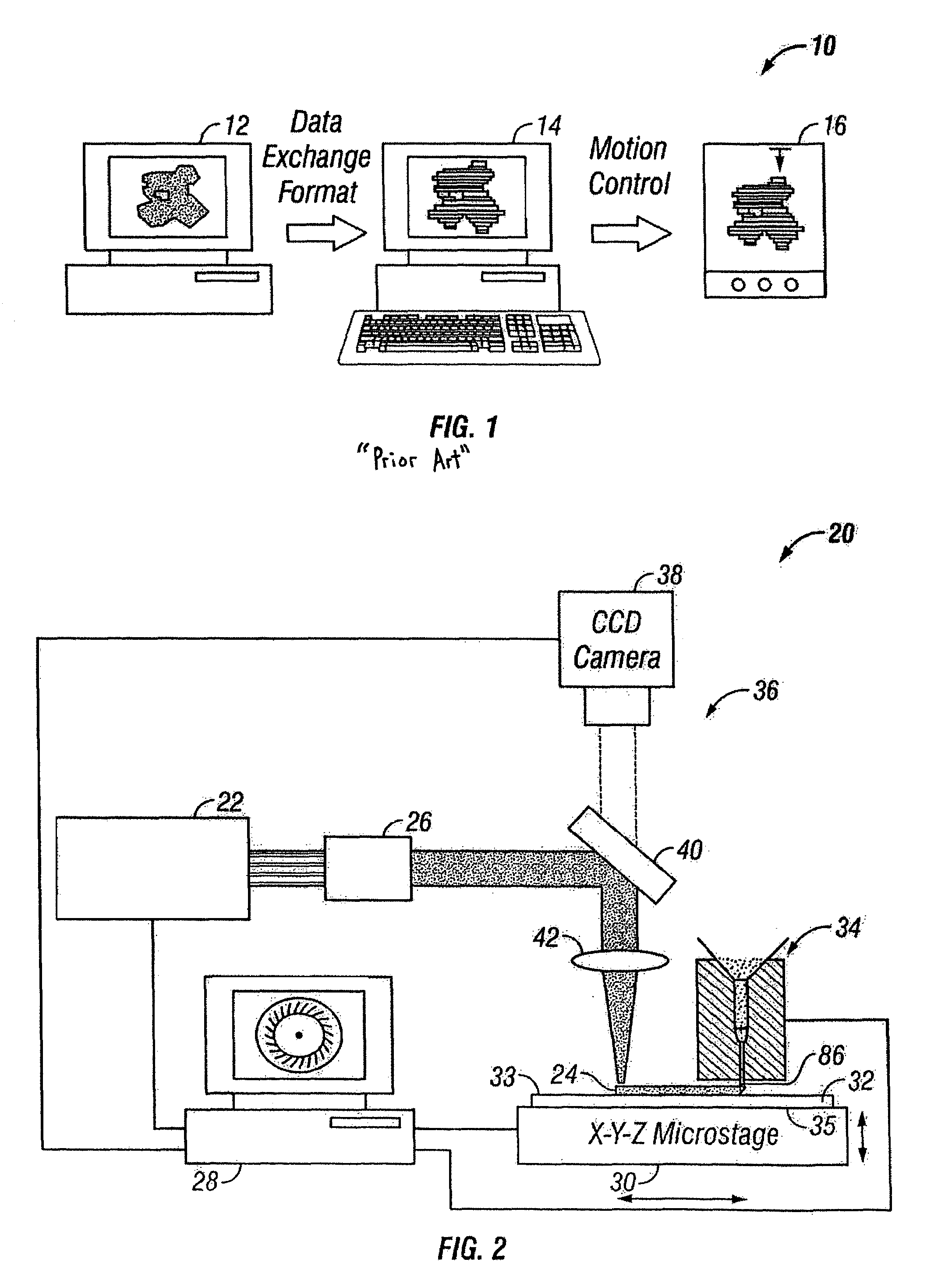

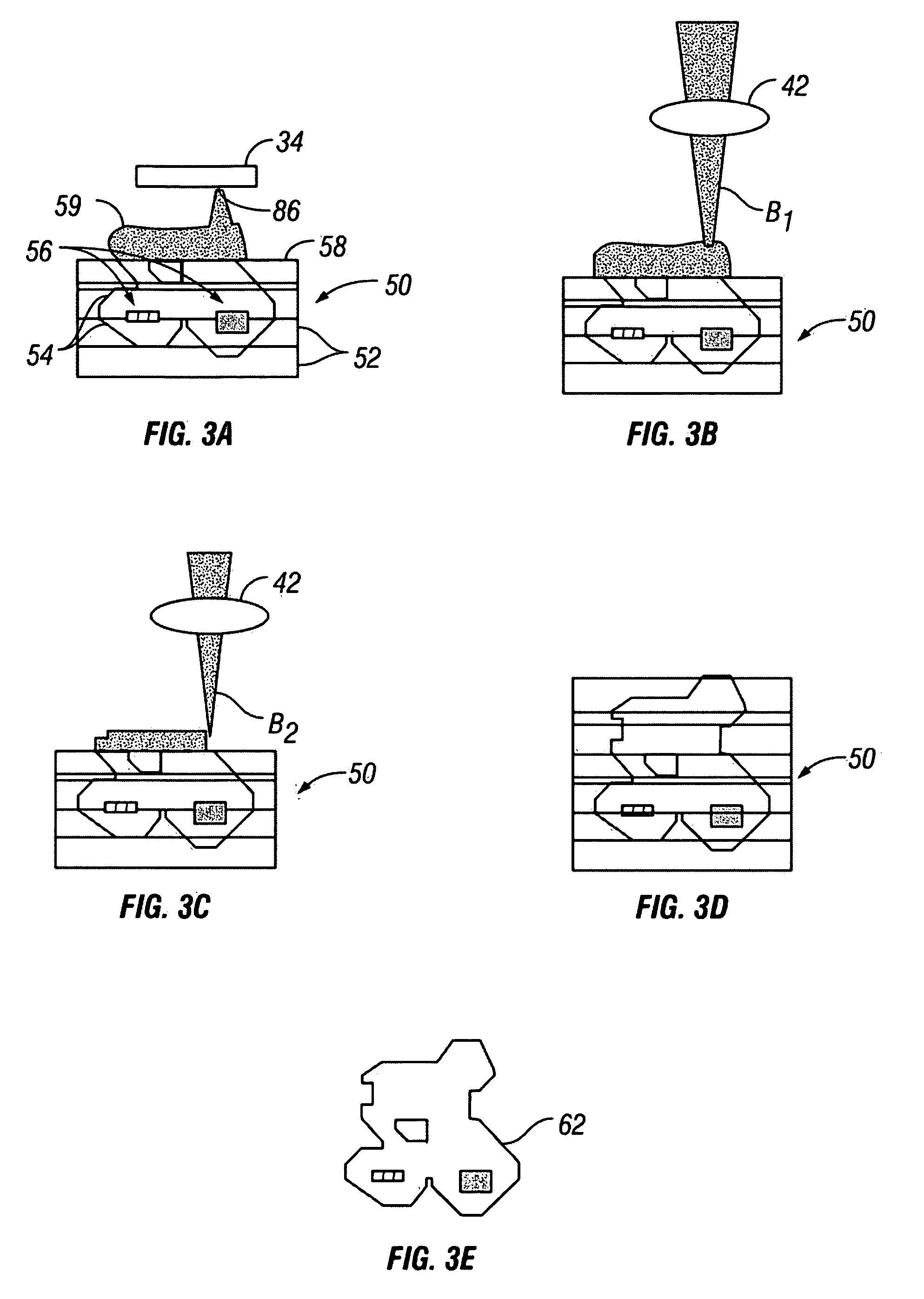

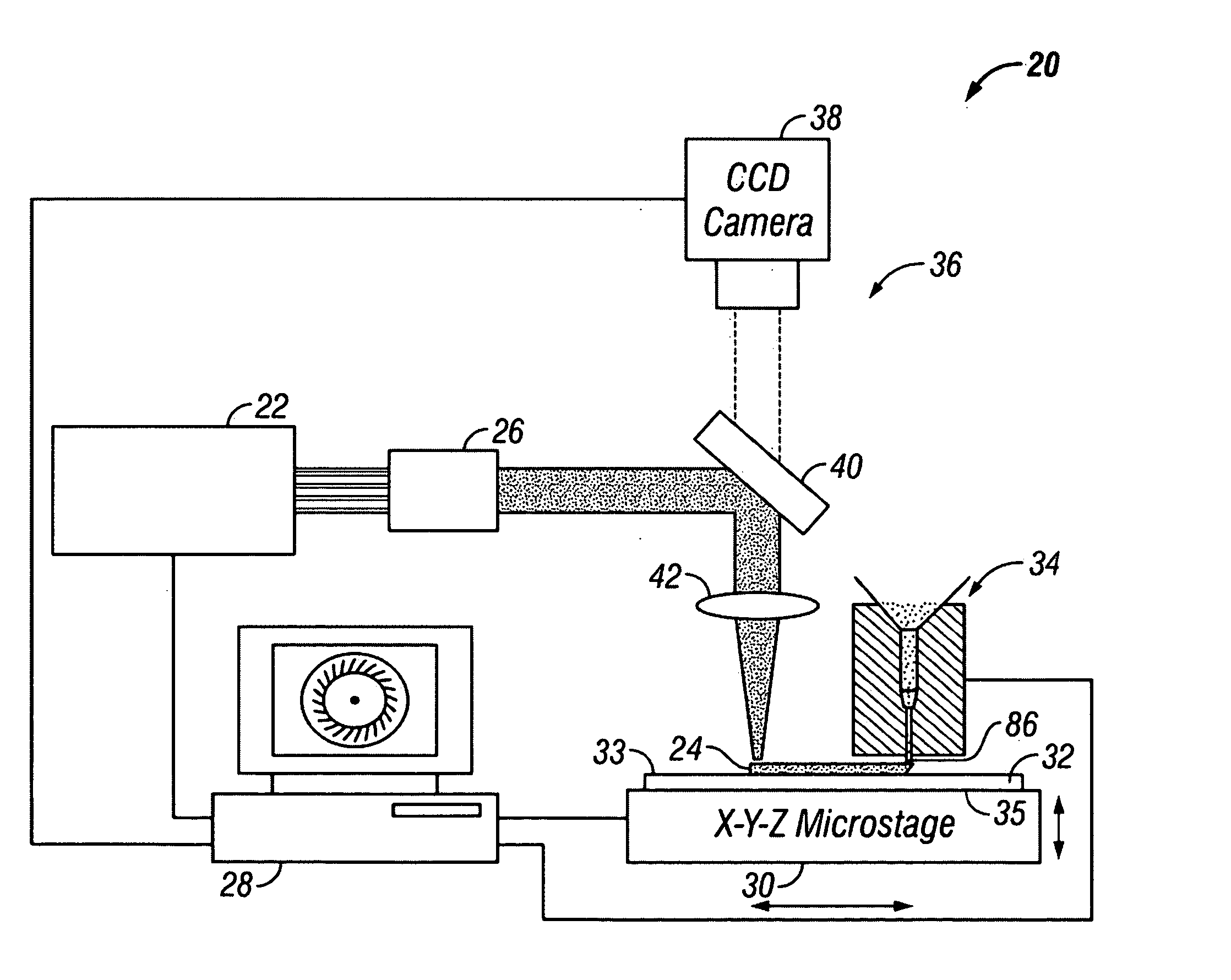

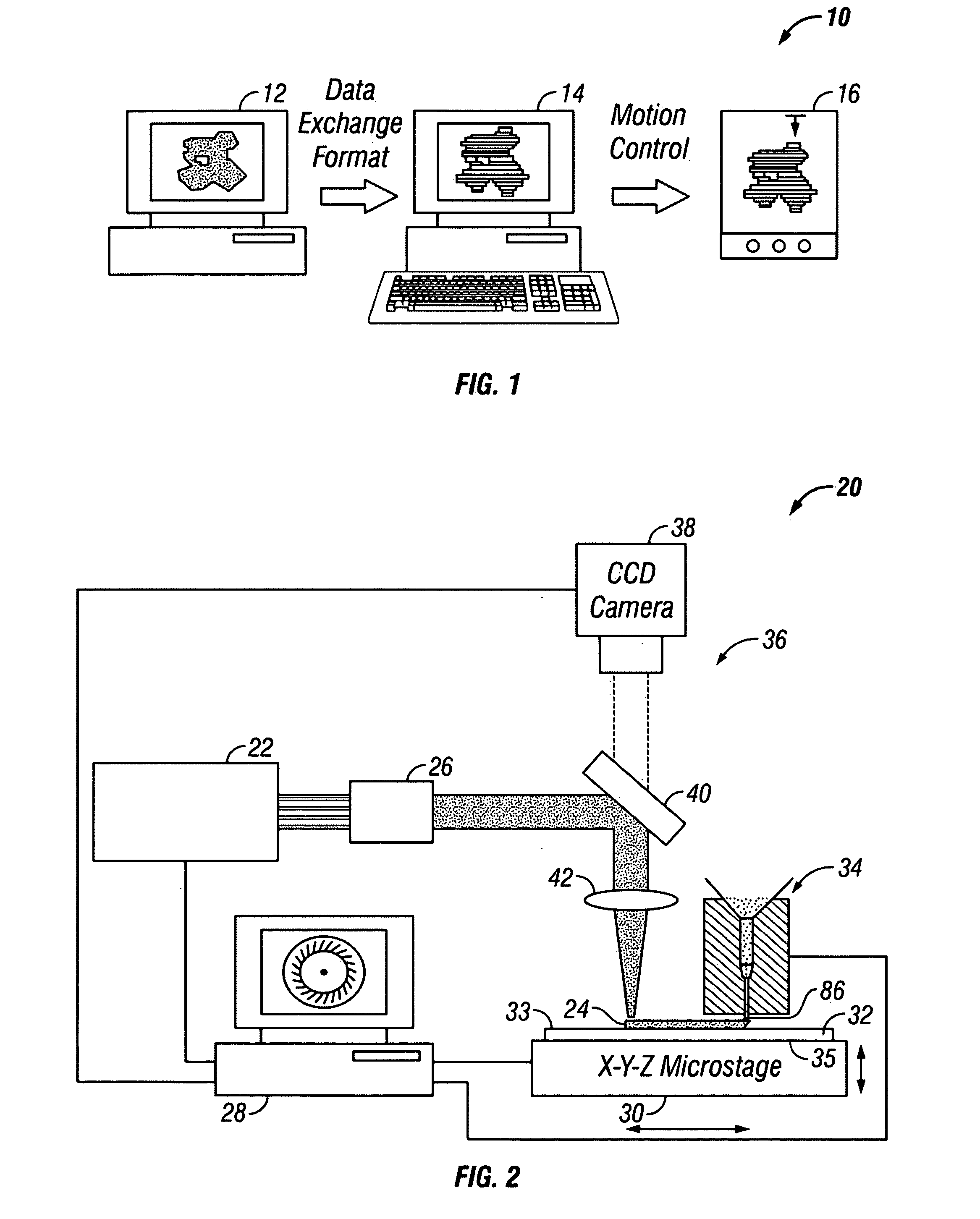

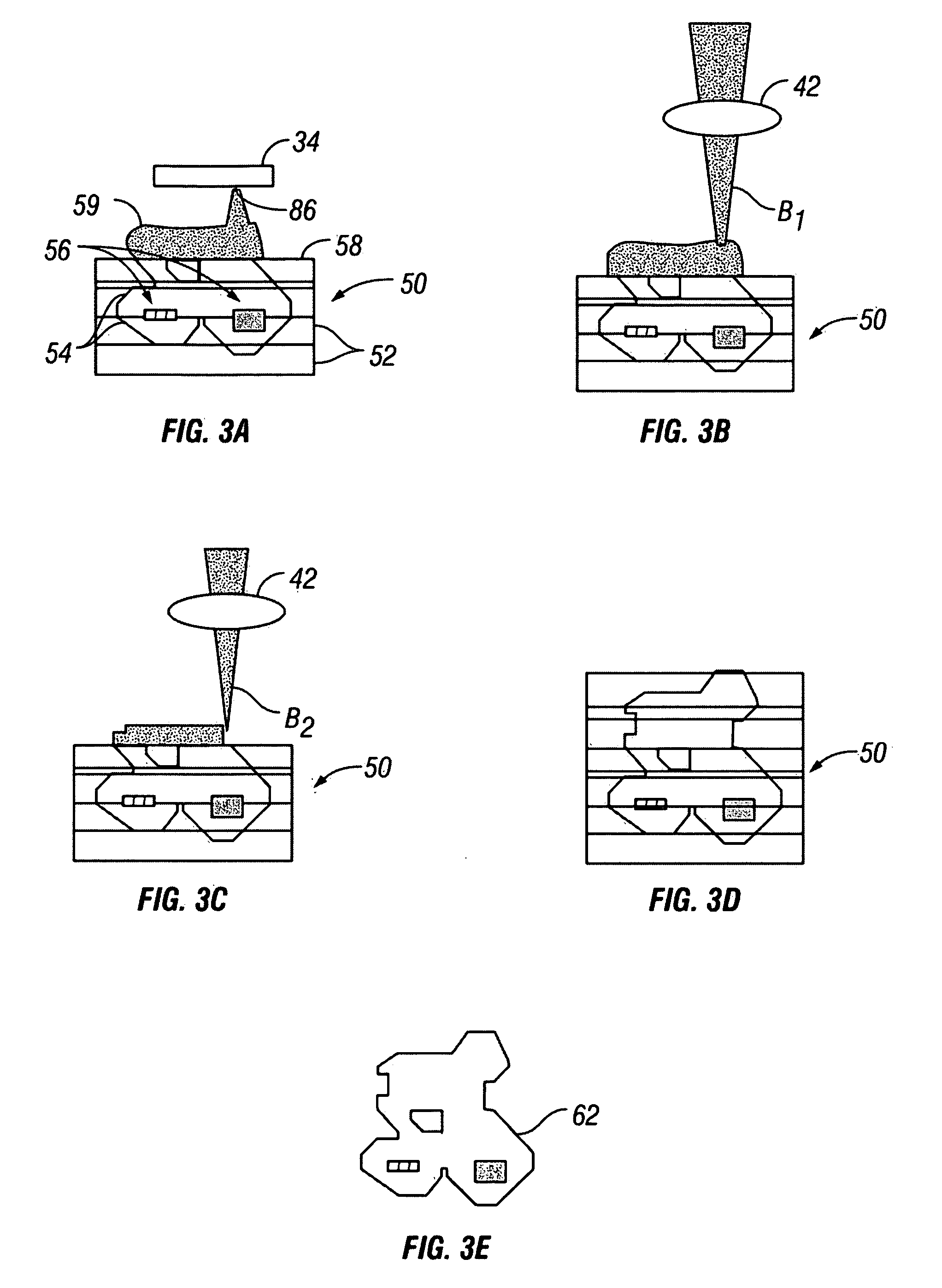

An apparatus and method of dispensing small-scale powders for a variety of applications, including, for example, fabricating a three-dimensional heterogeneous small-scale device, includes using a feed mechanism that causes motion of the powder particles and the steps of depositing fine heterogeneous materials (such as dry powders and biological materials) towards a substrate. The depositing step preferably includes providing a feed mechanism having an input to receive the material, an output, and a source of ultrasonic vibration to impart a torsional force on the material so as to precisely discharge the material from the output. To improve particle flowability, a cooling system is provided to cool the source, generally above a threshold input voltage.

Owner:WISCONSIN ALUMNI RES FOUND

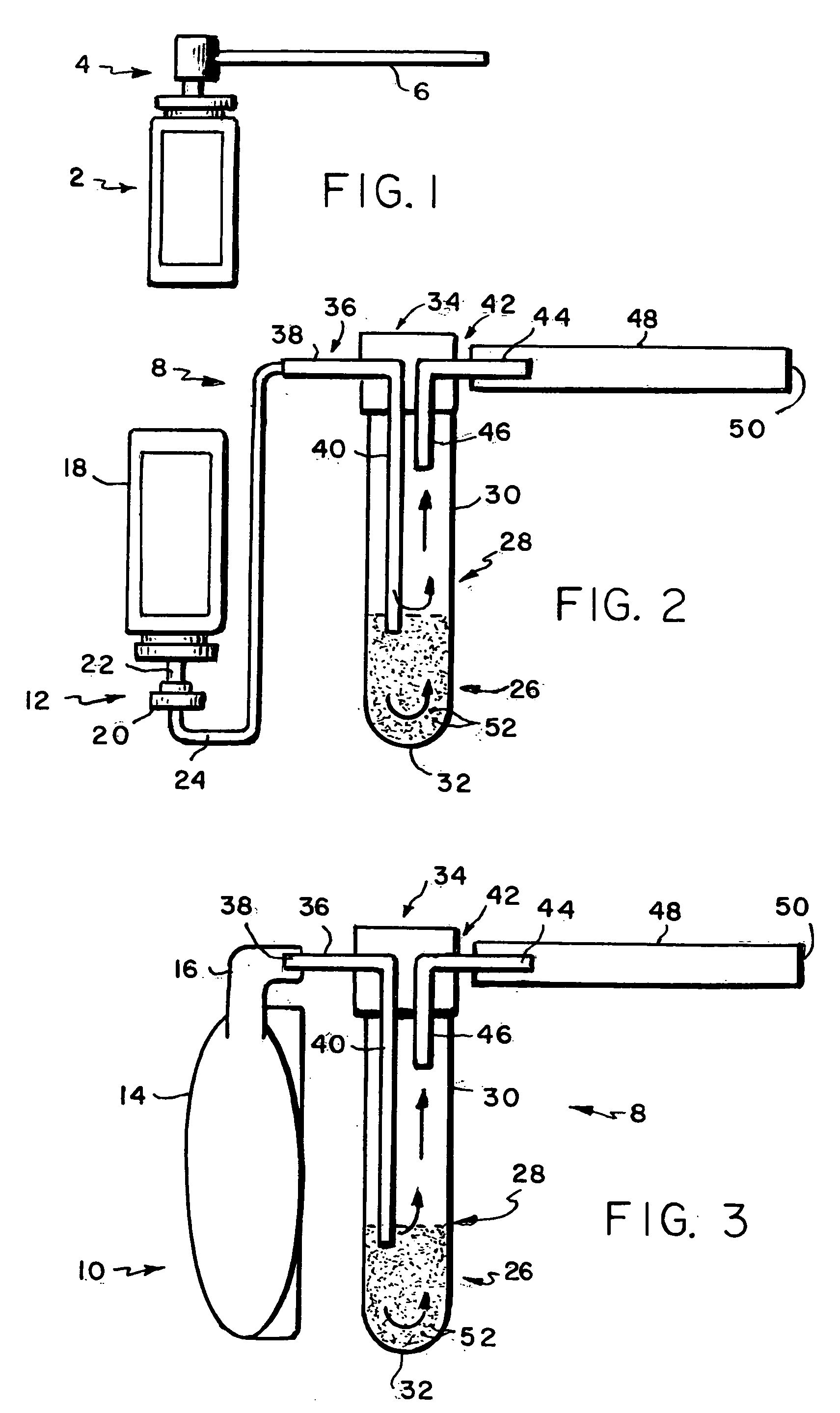

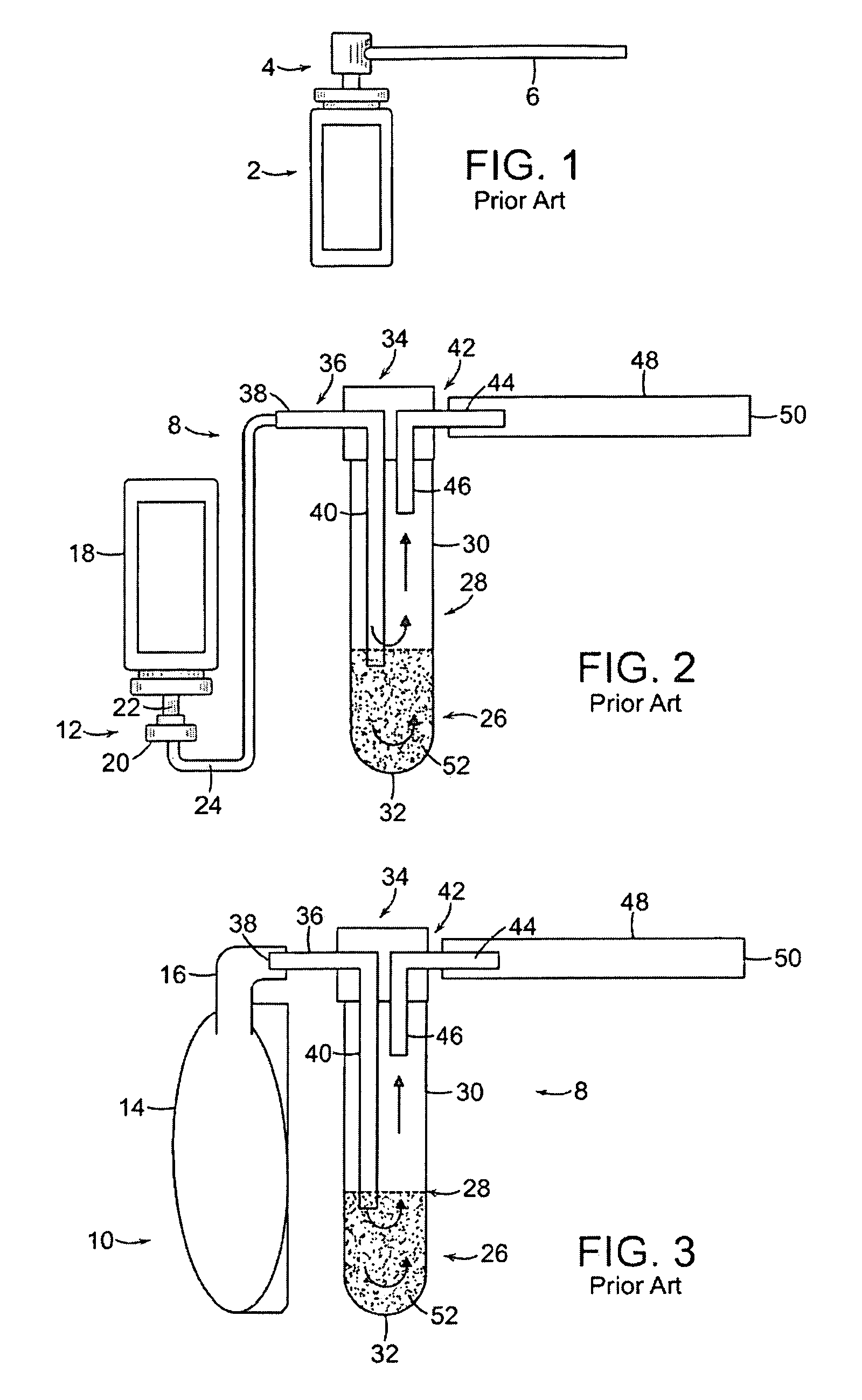

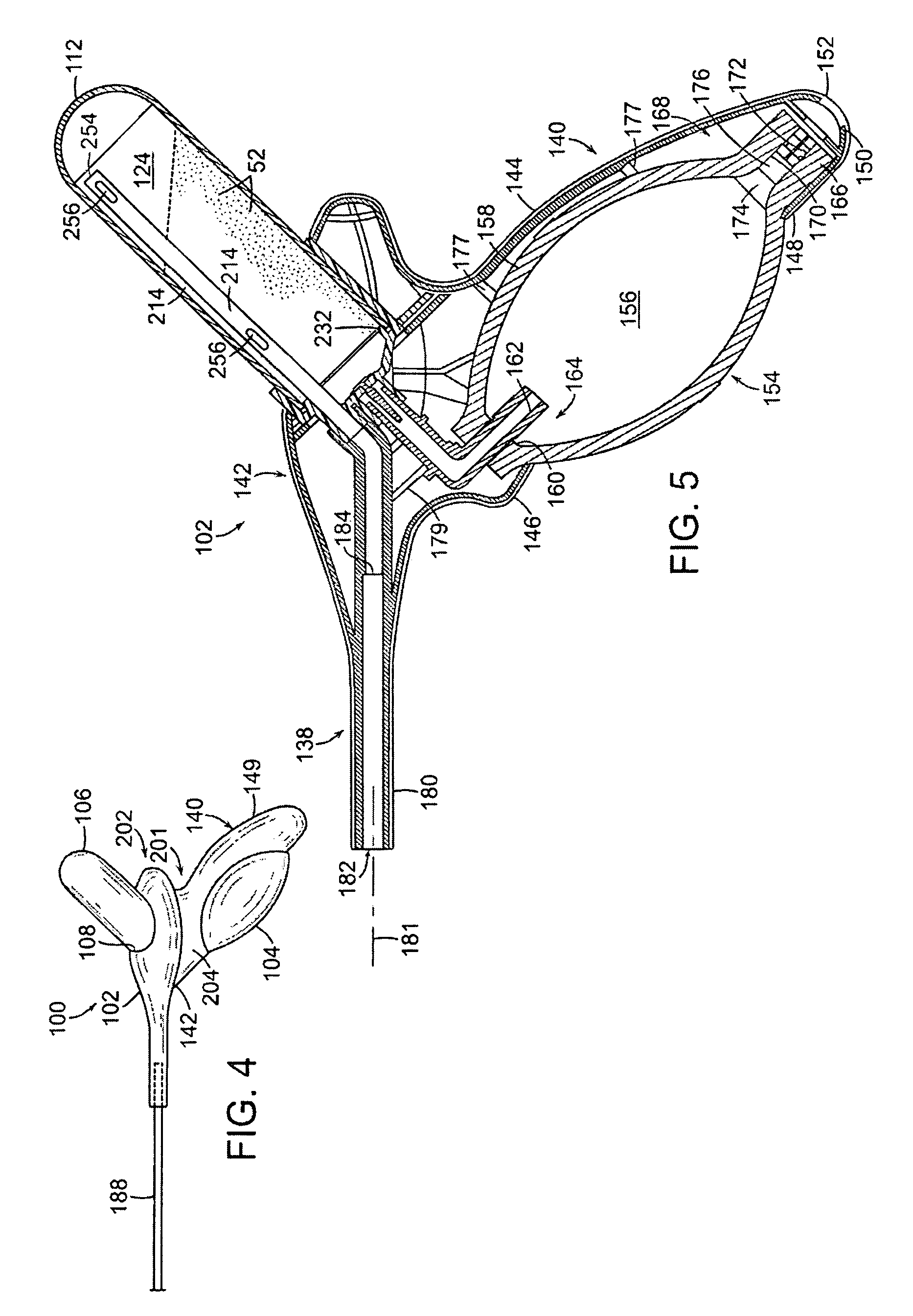

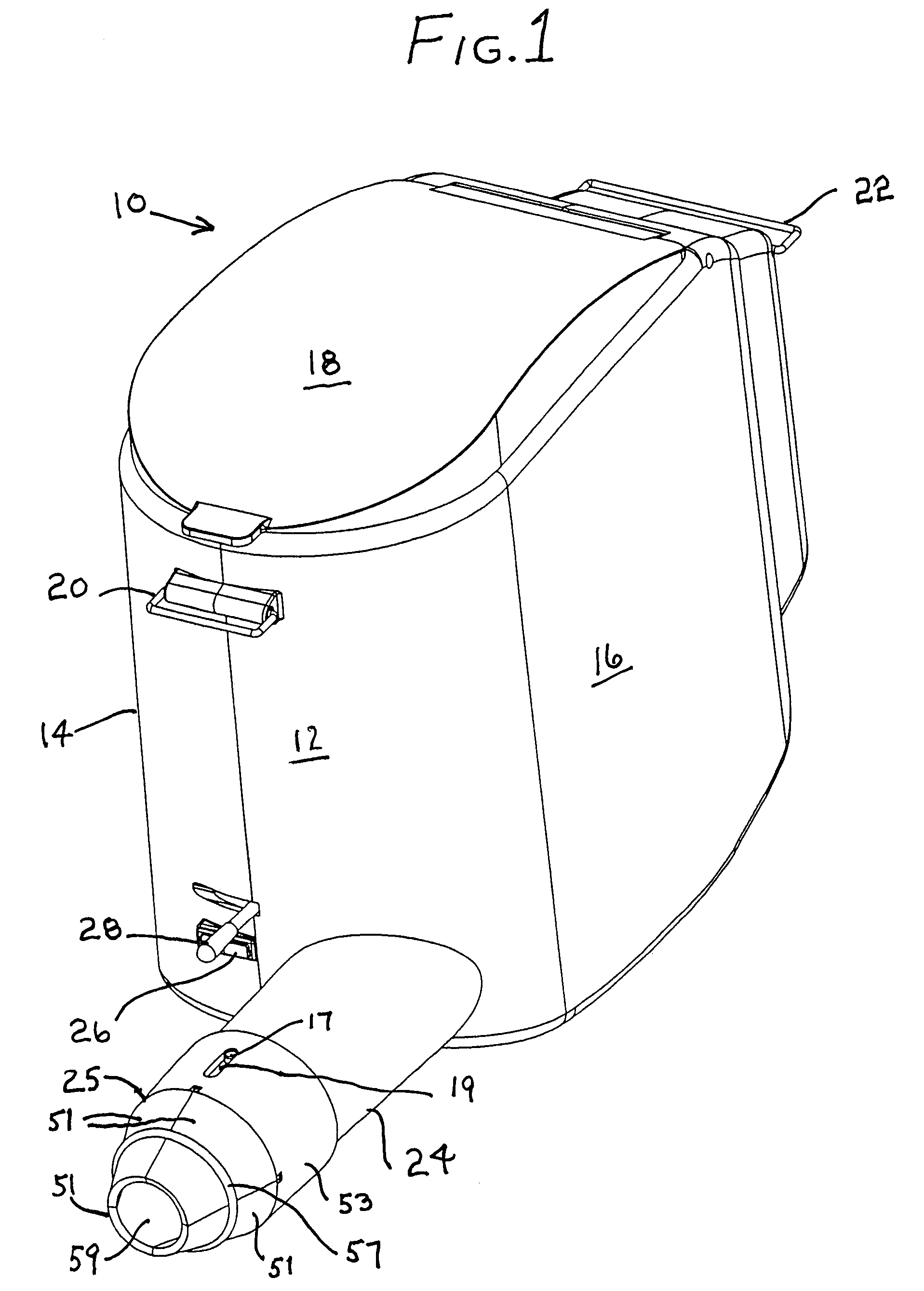

Powder delivery device

ActiveUS20050205087A1Easily and advantageously manufacturedEasily and advantageously and distributedPowder deliverySurgeryHand heldEngineering

A pistol-shaped powder delivery device consolidates propellant pulse creation, powder storage, powder aerosolization and aerolsolized powdered delivery in a single device while providing dose, pattern and coverage control of the output spray. The single-hand-held, single-hand-operated device includes a housing having a handle portion that is selectively collapsed to generate a propellant pulse that is conveyed into and through powder stored in a reservoir mounted at an upward angle to the horizontal in a receptacle provided in the housing. Powder in the reservoir is caused to be aerosolized by the propellant pulse whereupon aerosolized powder exits the reservoir through an open end of, and elongate slots provided in the sidewall of, an elongate hollow member extending from an outlet in the receptacle through the stored powdered material into a head space in the reservoir. The outlet is connected a barrel portion for output of the aerosolized powder spray.

Owner:GENZYME CORP

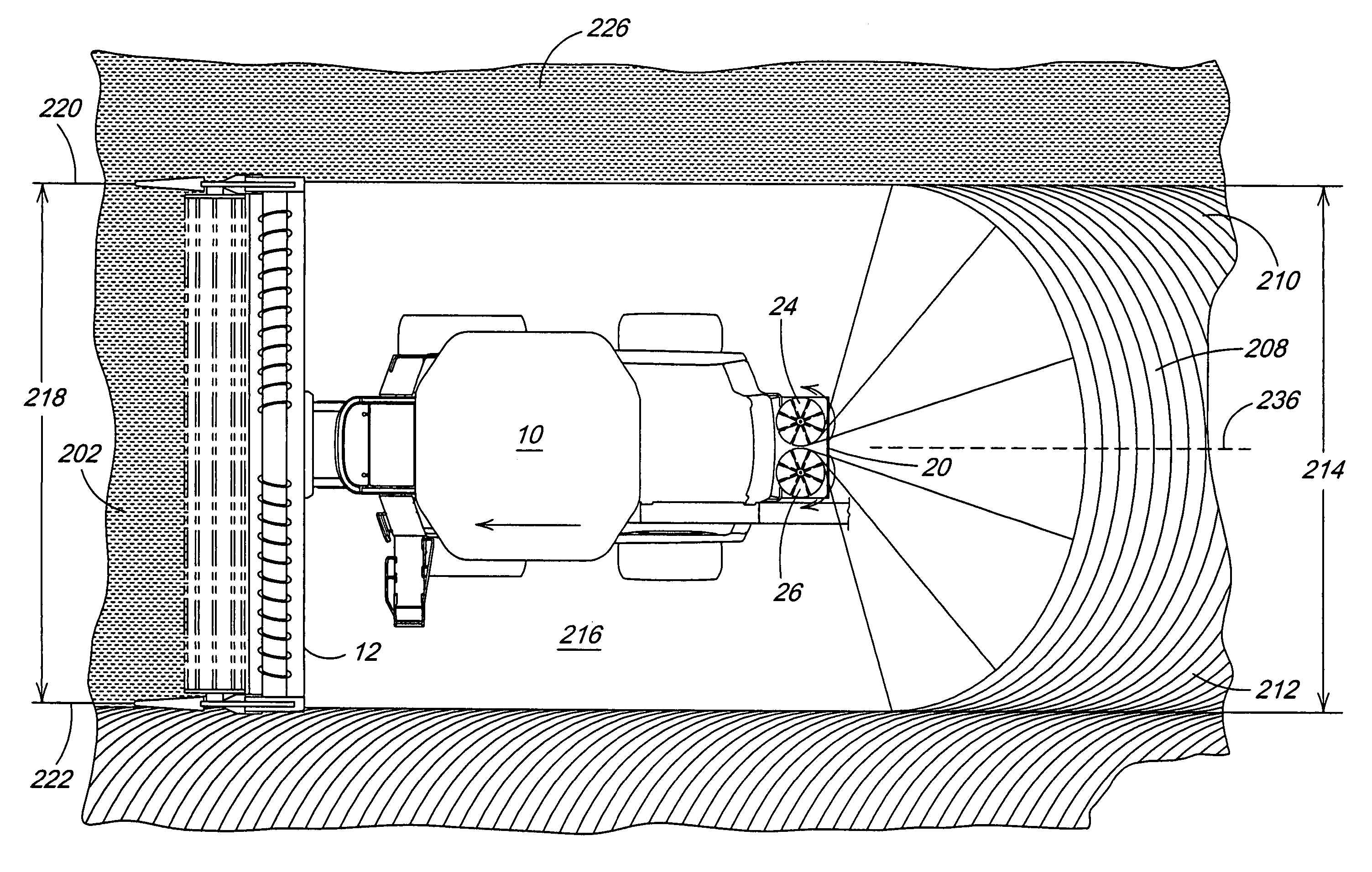

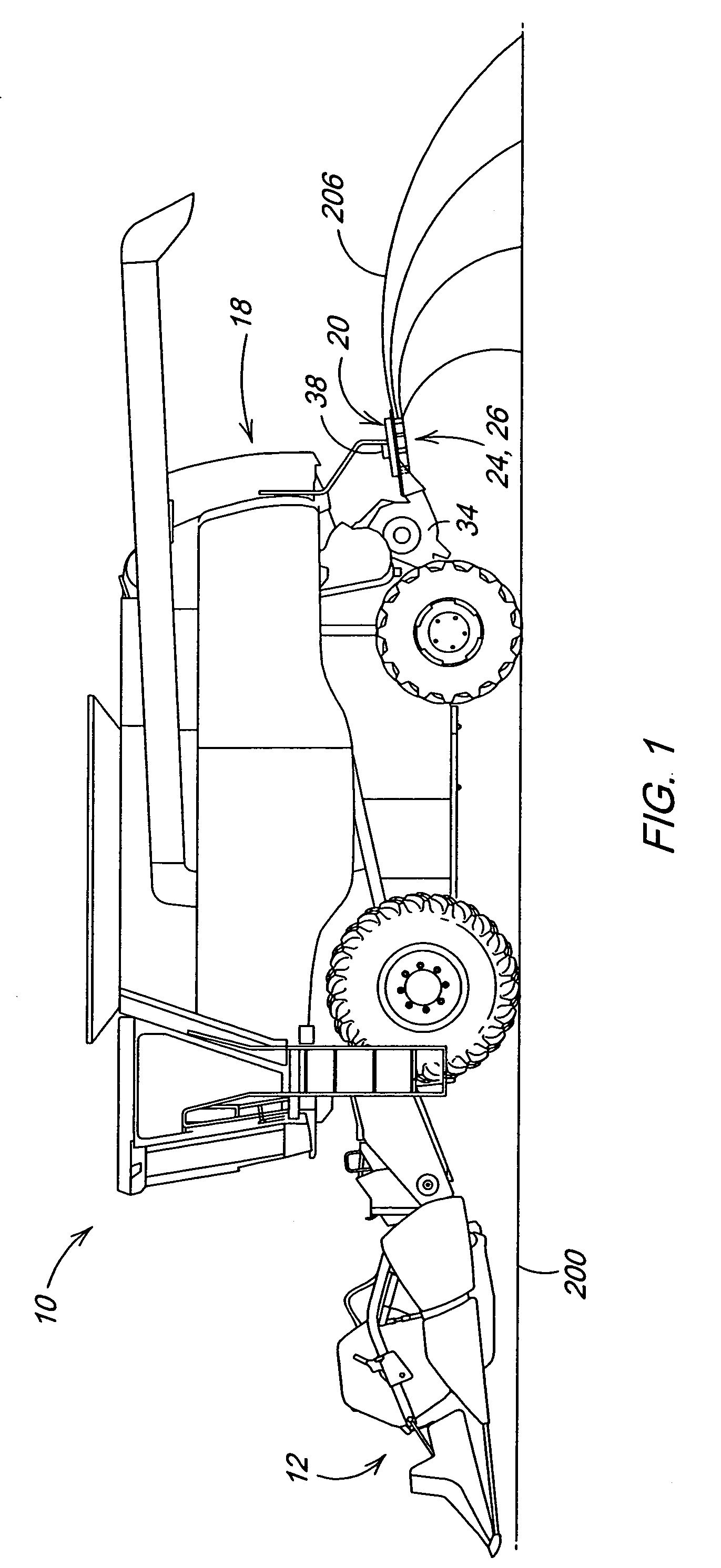

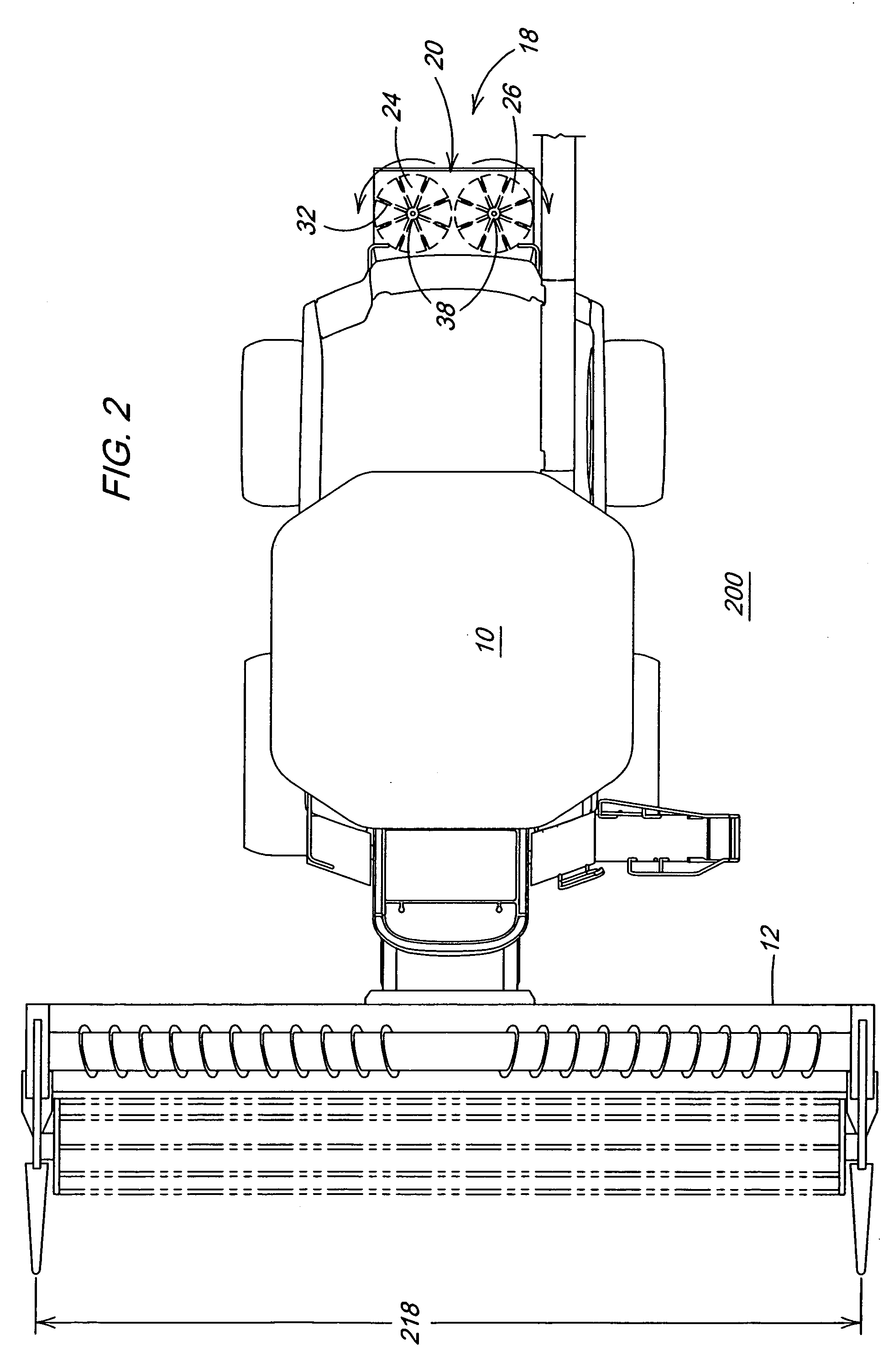

Broadcast width and location control for a combine spreader

Owner:DEERE & CO

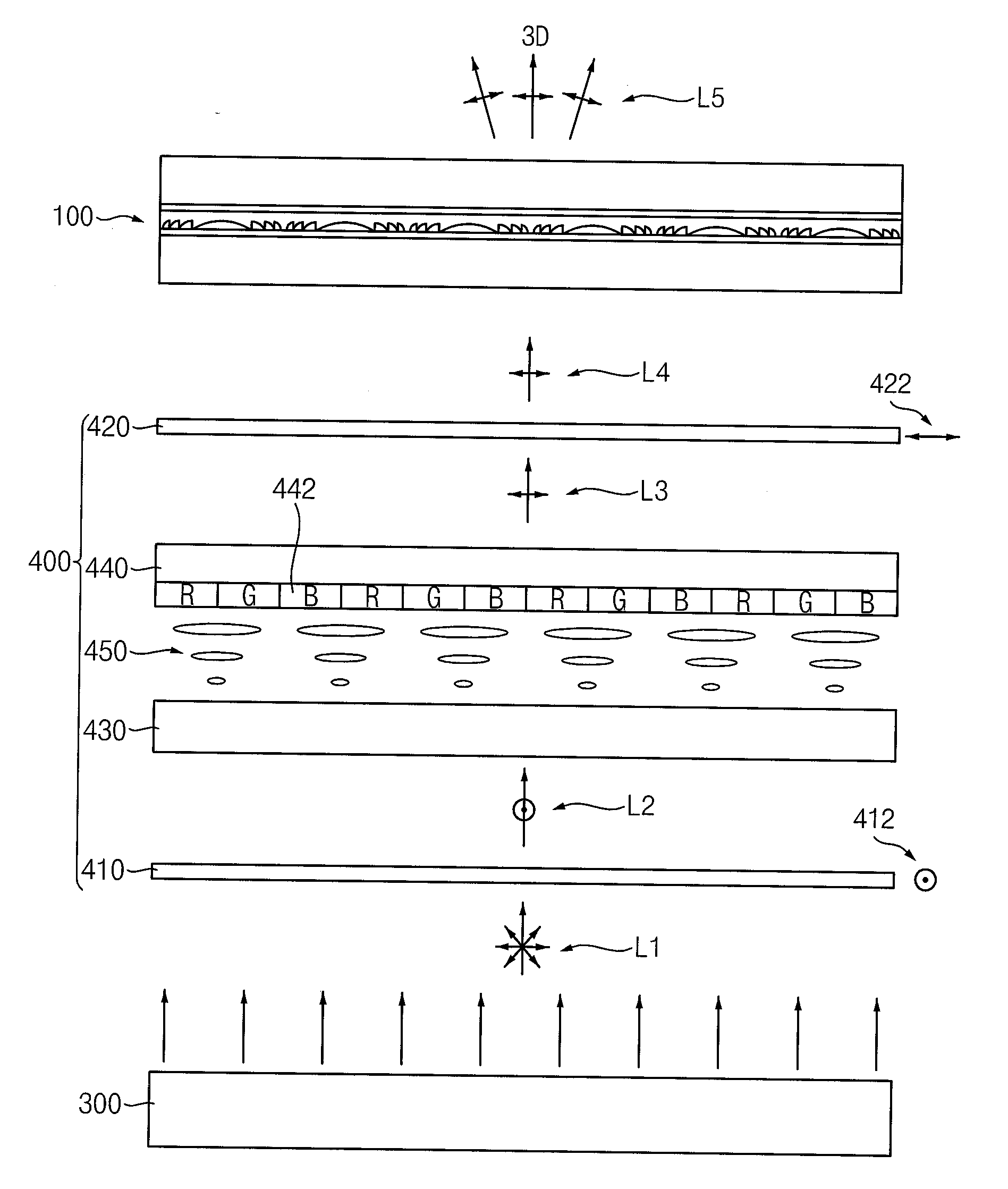

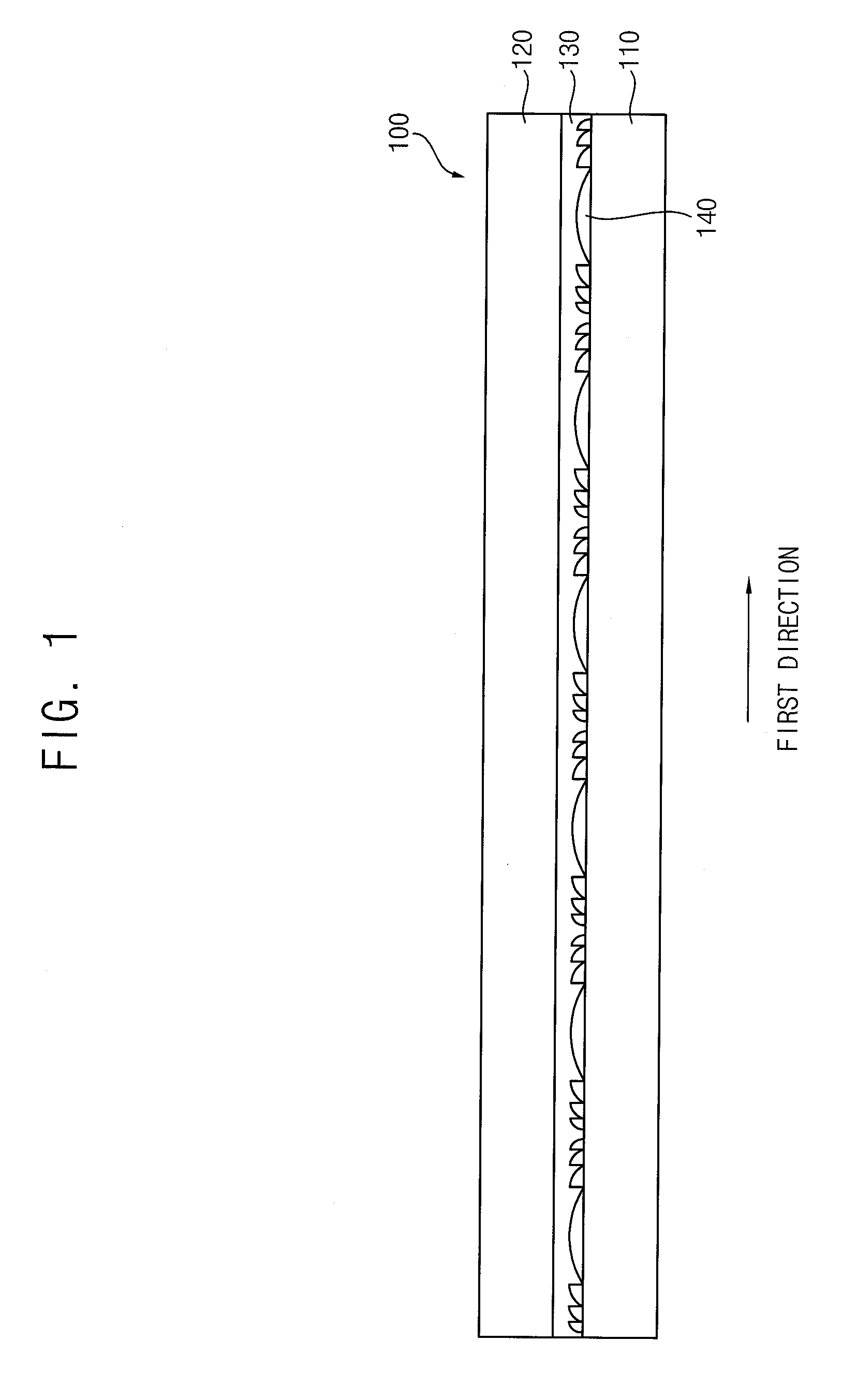

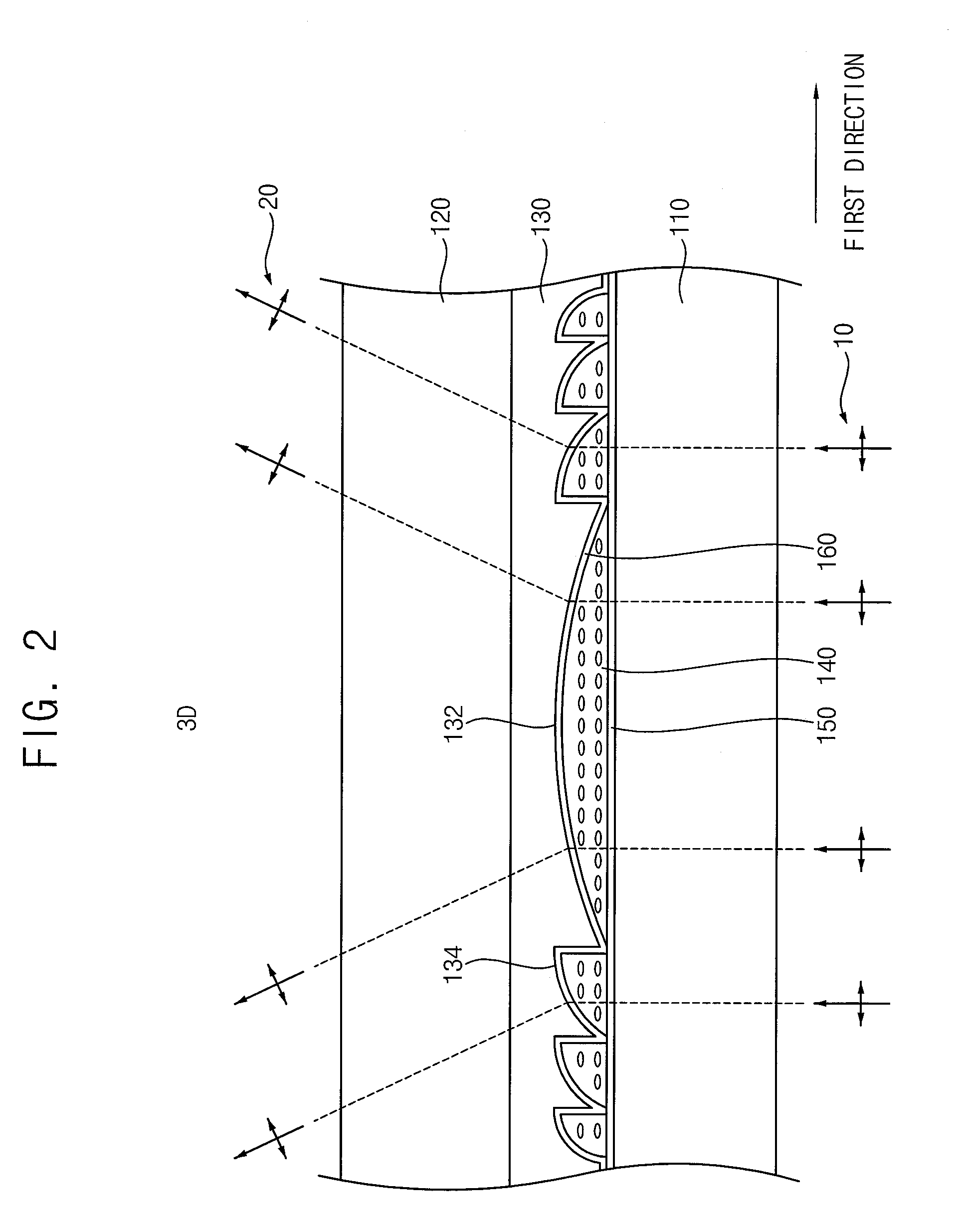

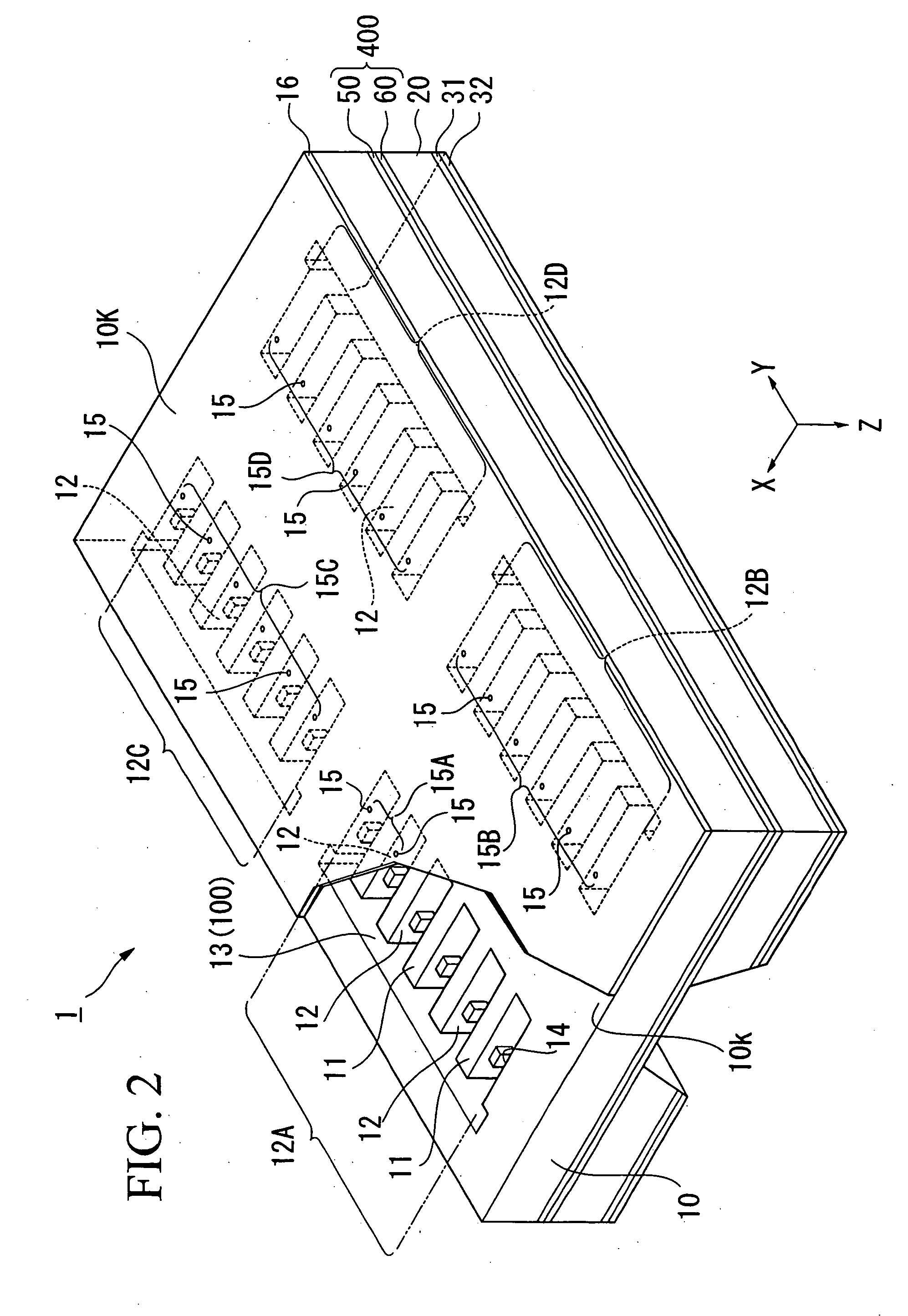

Stereoscopic image conversion panel and stereoscopic image display apparatus having the same

In a stereoscopic image conversion panel and a stereoscopic image display apparatus, the stereoscopic display panel includes a first lens substrate, a second lens substrate, a stereoscopic image lens part and a lens liquid crystal layer. The stereoscopic image lens part is disposed between the first and second substrates, and includes a main lens and sub-lenses with a concave shape. At least one sub-lens is disposed at opposite edge portions of the main lens. The lens liquid crystal layer is received by the main lens and the sub-lenses, is disposed between the first and second lens substrates, and includes liquid crystal molecules having an anisotropic refractive index. The lens liquid crystal layer refracts a polarized light at an interface between the lens liquid crystal layer and the stereoscopic lens part, to convert a flat image into a stereoscopic image. Therefore, the thickness of the stereoscopic image panel can be reduced.

Owner:SAMSUNG DISPLAY CO LTD

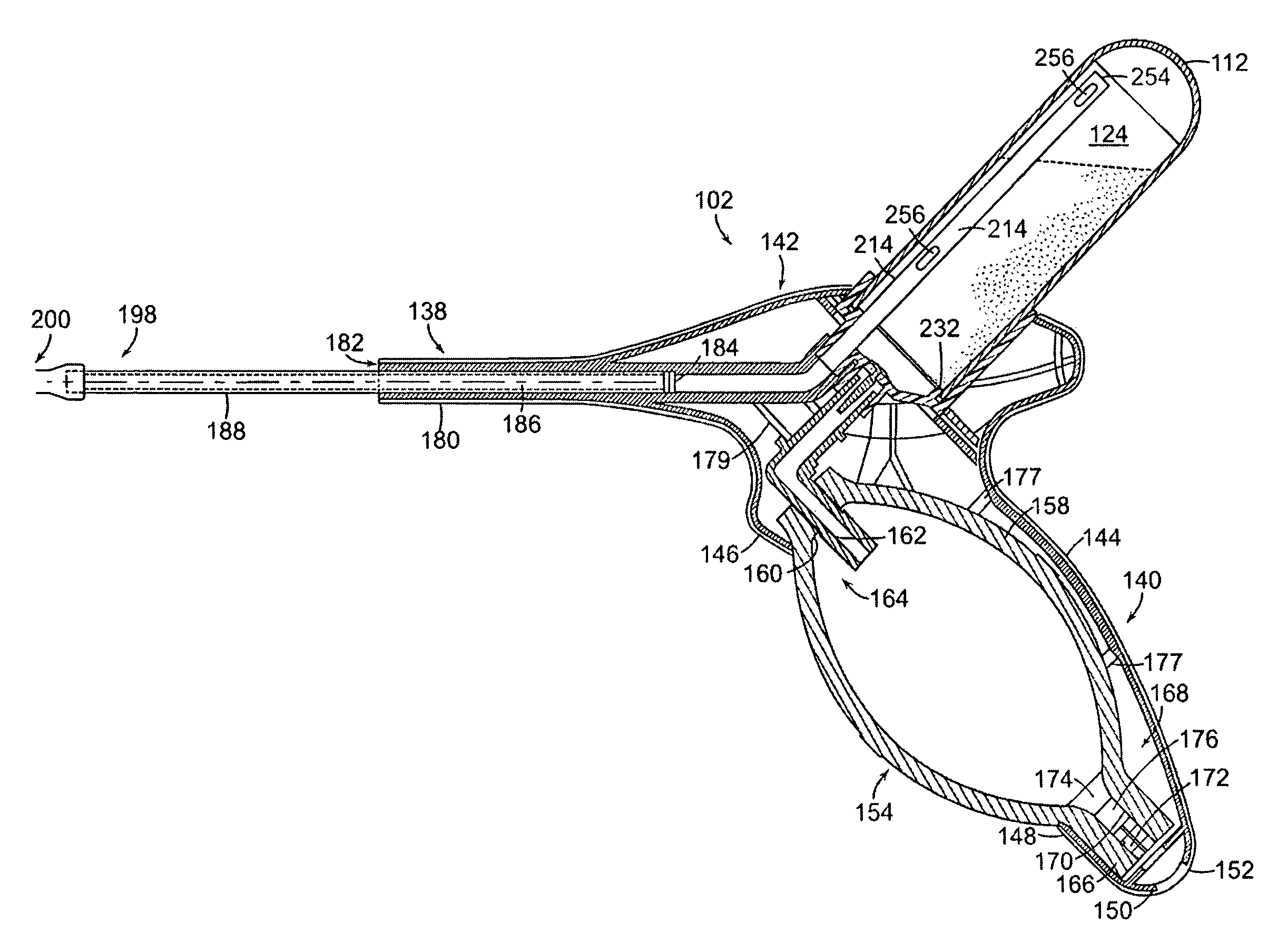

Powder delivery device

ActiveUS7455248B2Efficiently and satisfactorily operablePowder deliverySurgeryHand heldCoverage control

A pistol-shaped powder delivery device consolidates propellant pulse creation, powder storage, powder aerosolization and aerolsolized powdered delivery in a single device while providing dose, pattern and coverage control of the output spray. The single-hand-held, single-hand-operated device includes a housing having a handle portion that is selectively collapsed to generate a propellant pulse that is conveyed into and through powder stored in a reservoir mounted at an upward angle to the horizontal in a receptacle provided in the housing. Powder in the reservoir is caused to be aerosolized by the propellant pulse whereupon aerosolized powder exits the reservoir through an open end of, and elongate slots provided in the sidewall of, an elongate hollow member extending from an outlet in the receptacle through the stored powdered material into a head space in the reservoir. The outlet is connected a barrel portion for output of the aerosolized powder spray.

Owner:GENZYME CORP

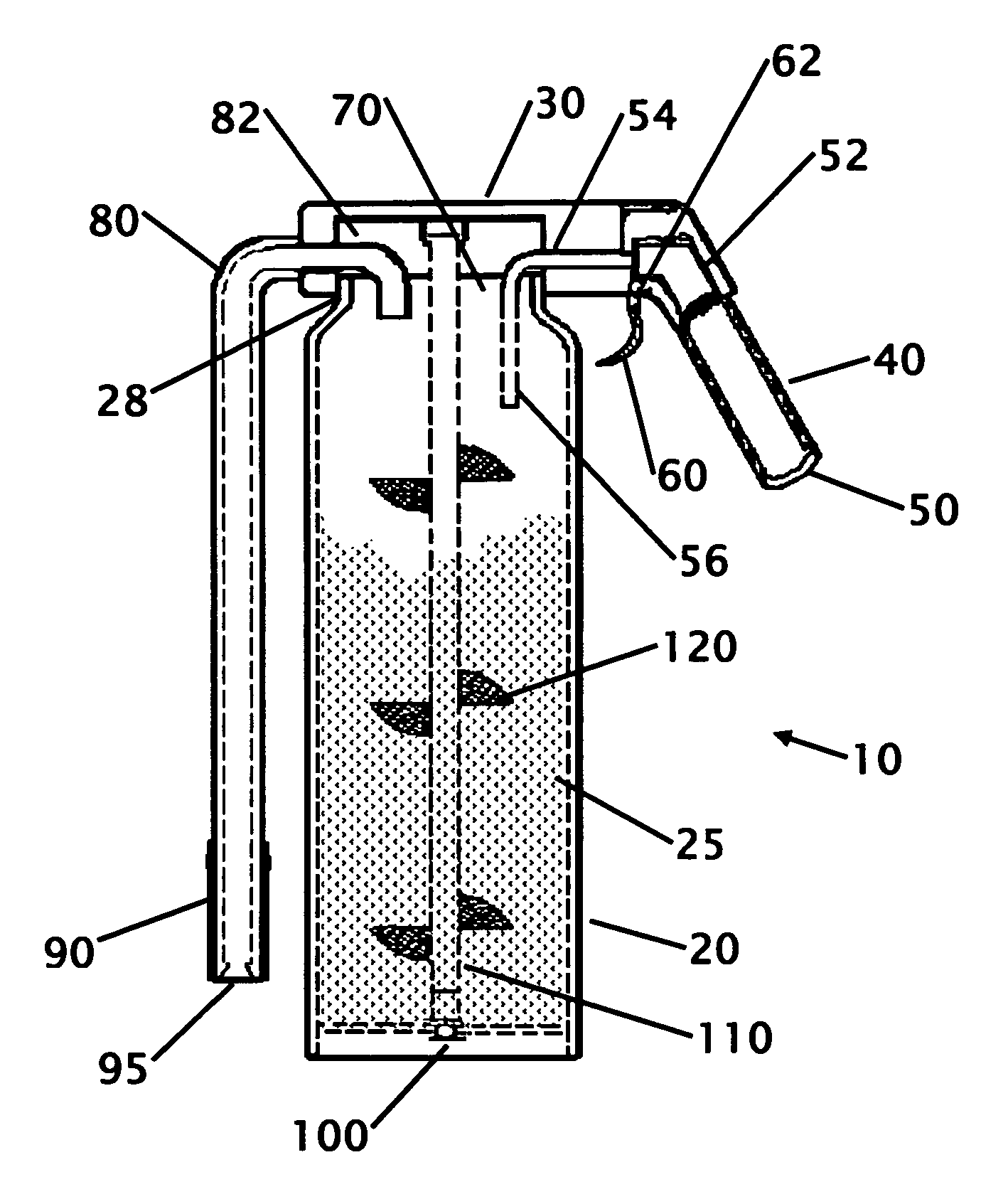

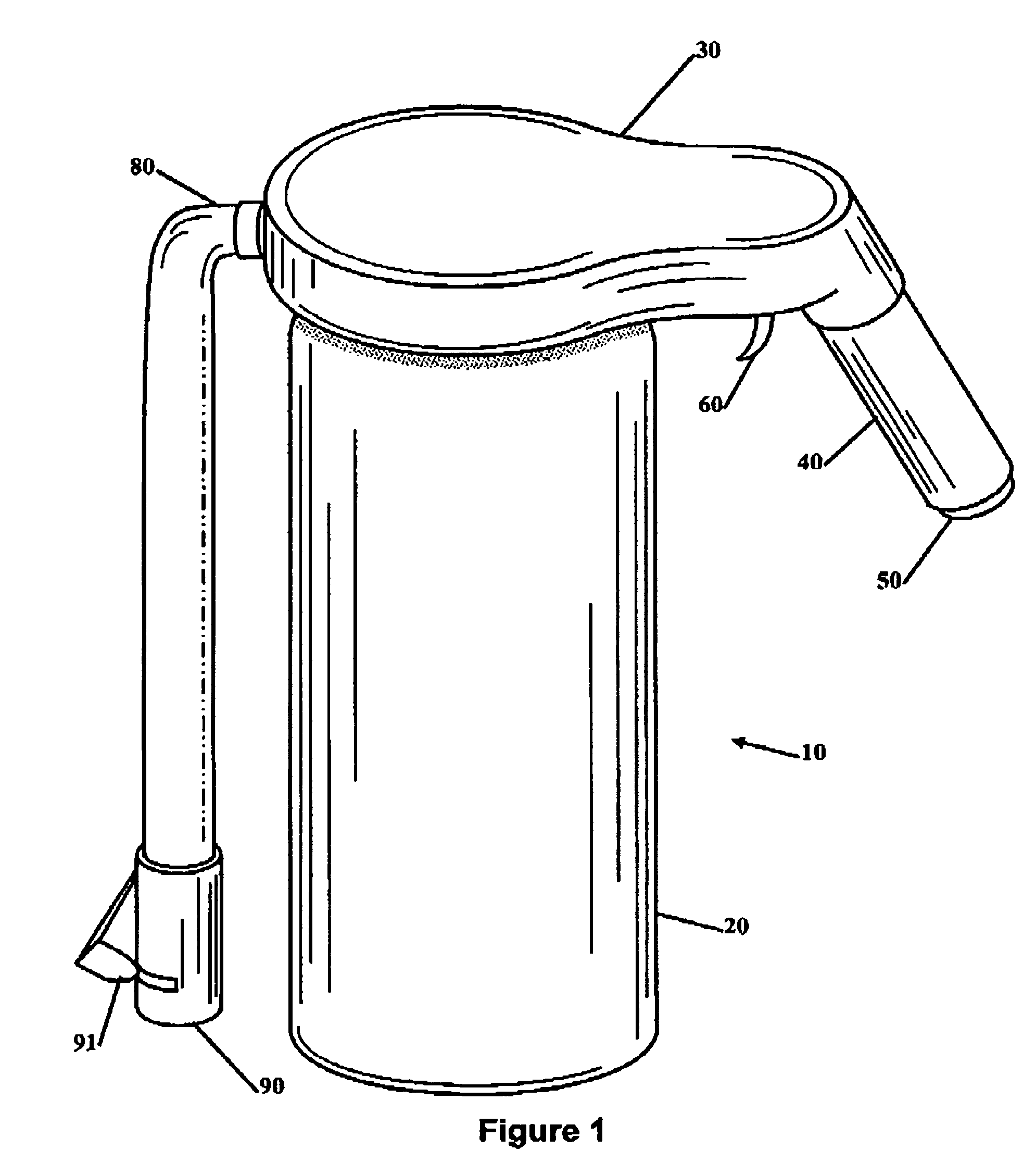

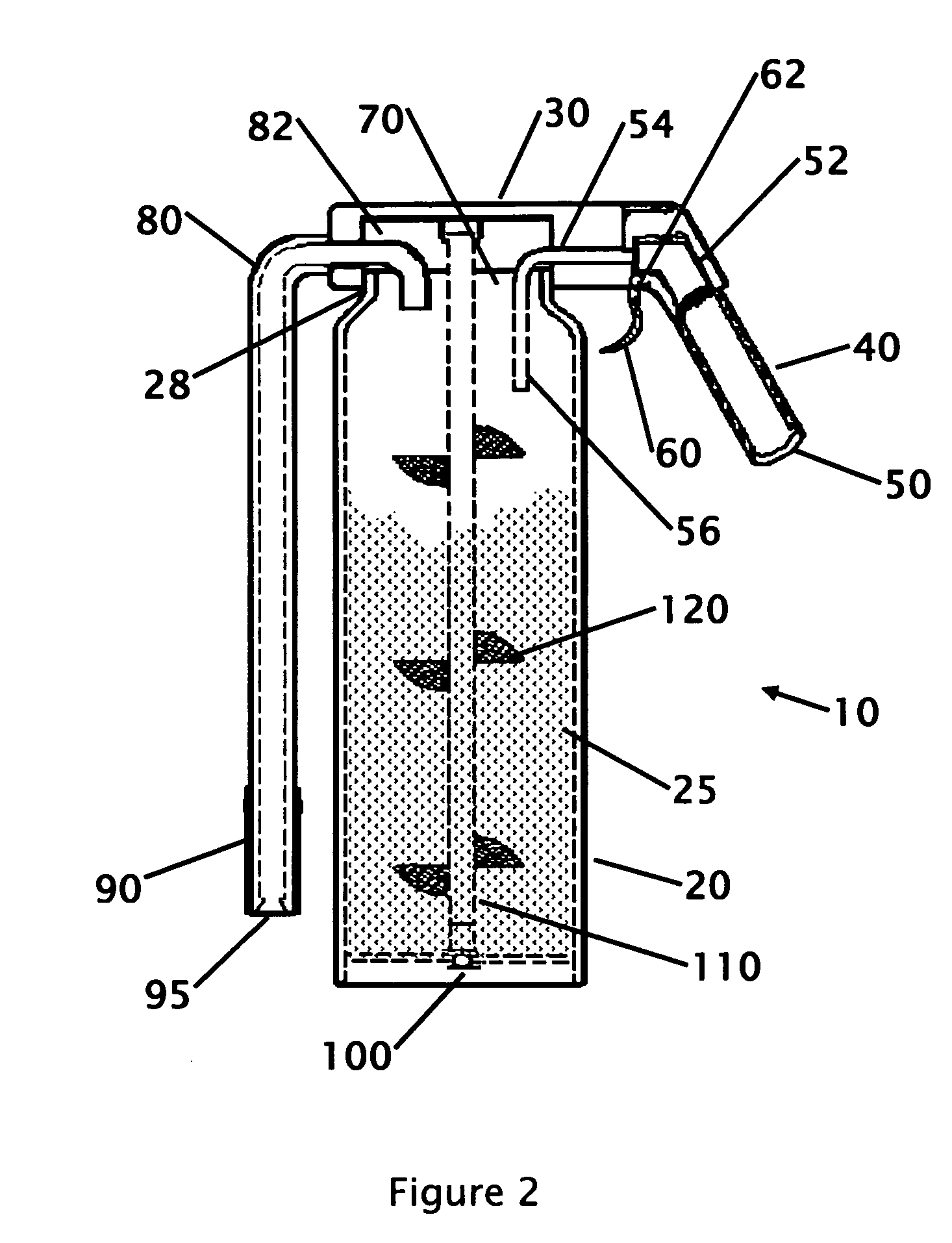

Self servicing fire extinguisher with external operated internal mixing with wide mouth and external CO2 chamber

ActiveUS7128163B1High level of serviceReduce eliminateShaking/oscillating/vibrating mixersRotary stirring mixersWide mouthFire extinguisher

Improvements to a portable fire extinguisher are disclosed. The improvements allow for frequent and simpler untrained and automatic self servicing of a fire extinguisher. The improvements include an anti-bridging mechanism that can be articulated from the exterior of the chamber to fluff, mix or stir the powder within the chamber to keep it in a liquefied state. Additional improvements include a larger opening to more quickly fill and inspect the powder within the chamber. Another improvement includes the use of a CO2 canister located external to the chamber to allow easier servicing or replacement of just the CO2 canister as well as the ability to maintain the chamber in an un-pressurized condition, allows for non-HASMAT shipping. These features will extend the service intervals while maintaining the fire extinguisher in a ready condition.

Owner:RUSOH INC

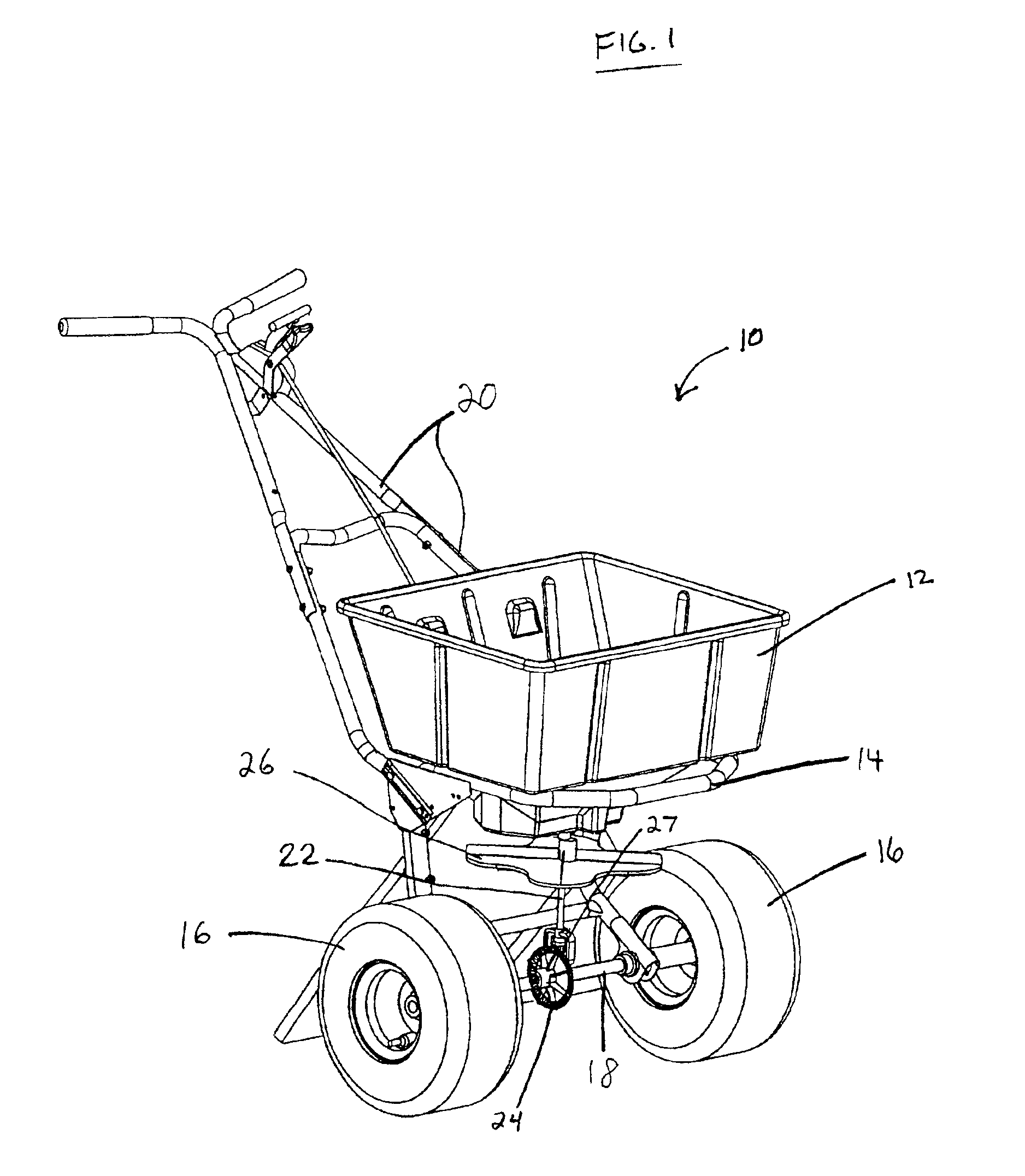

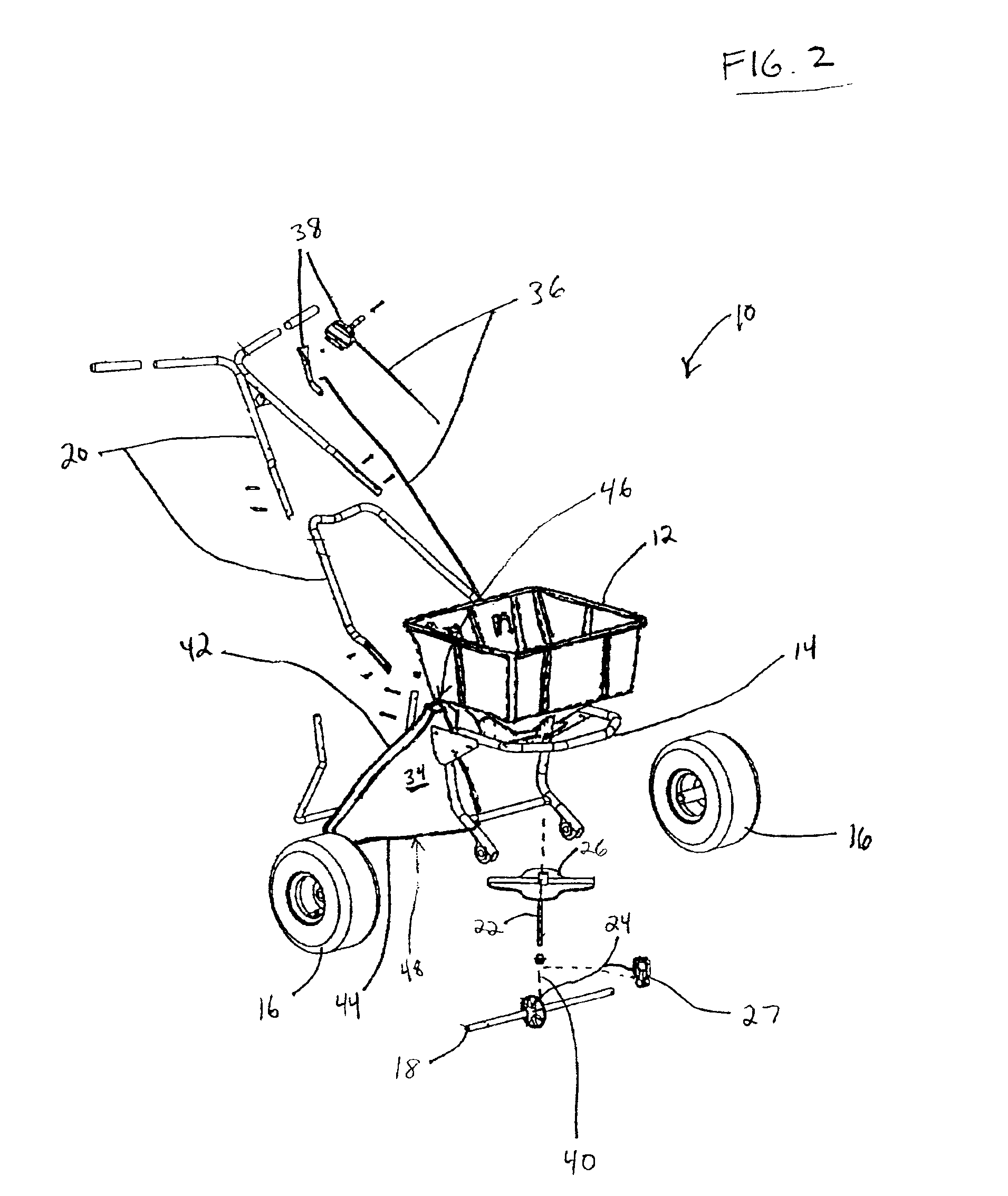

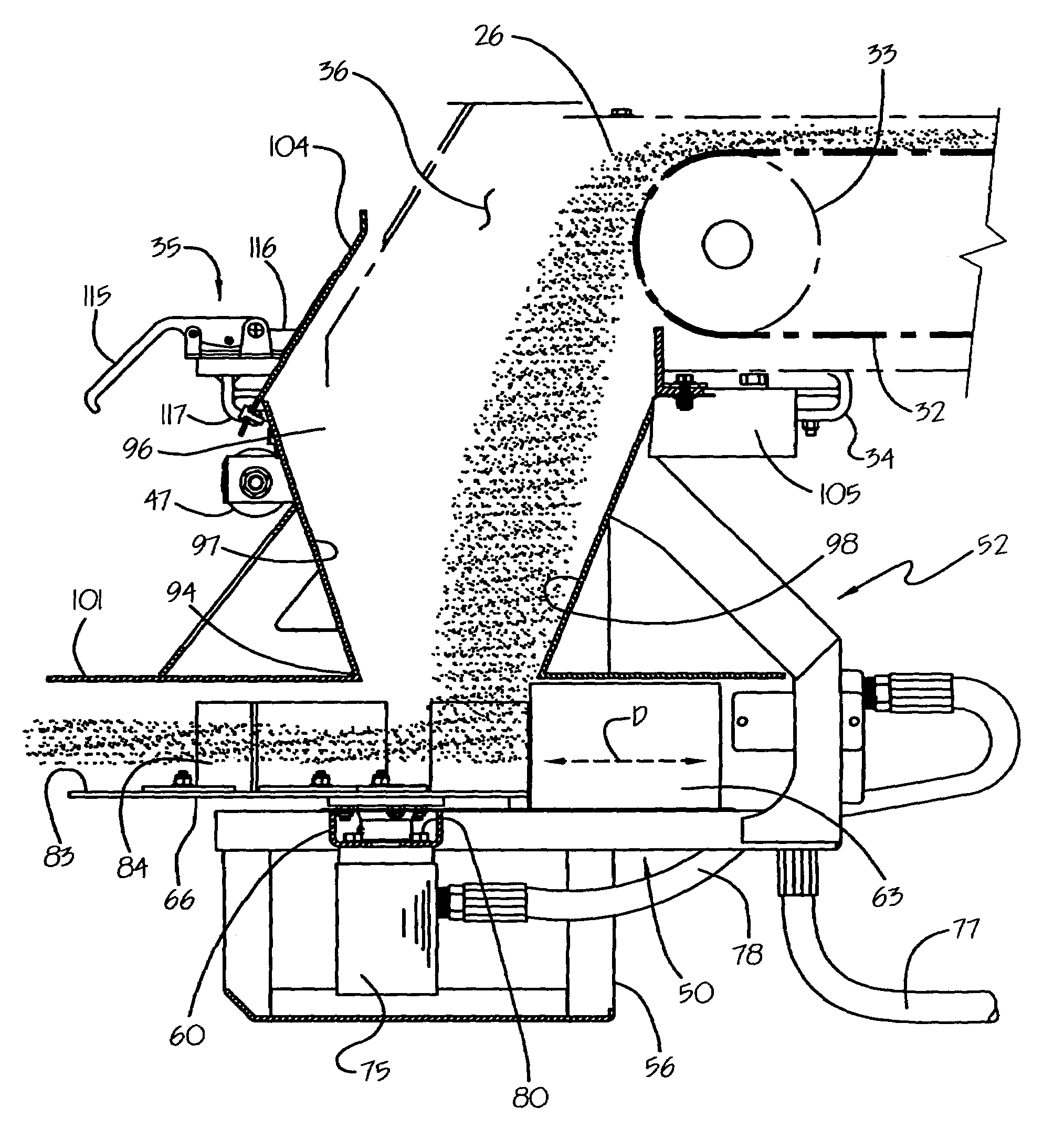

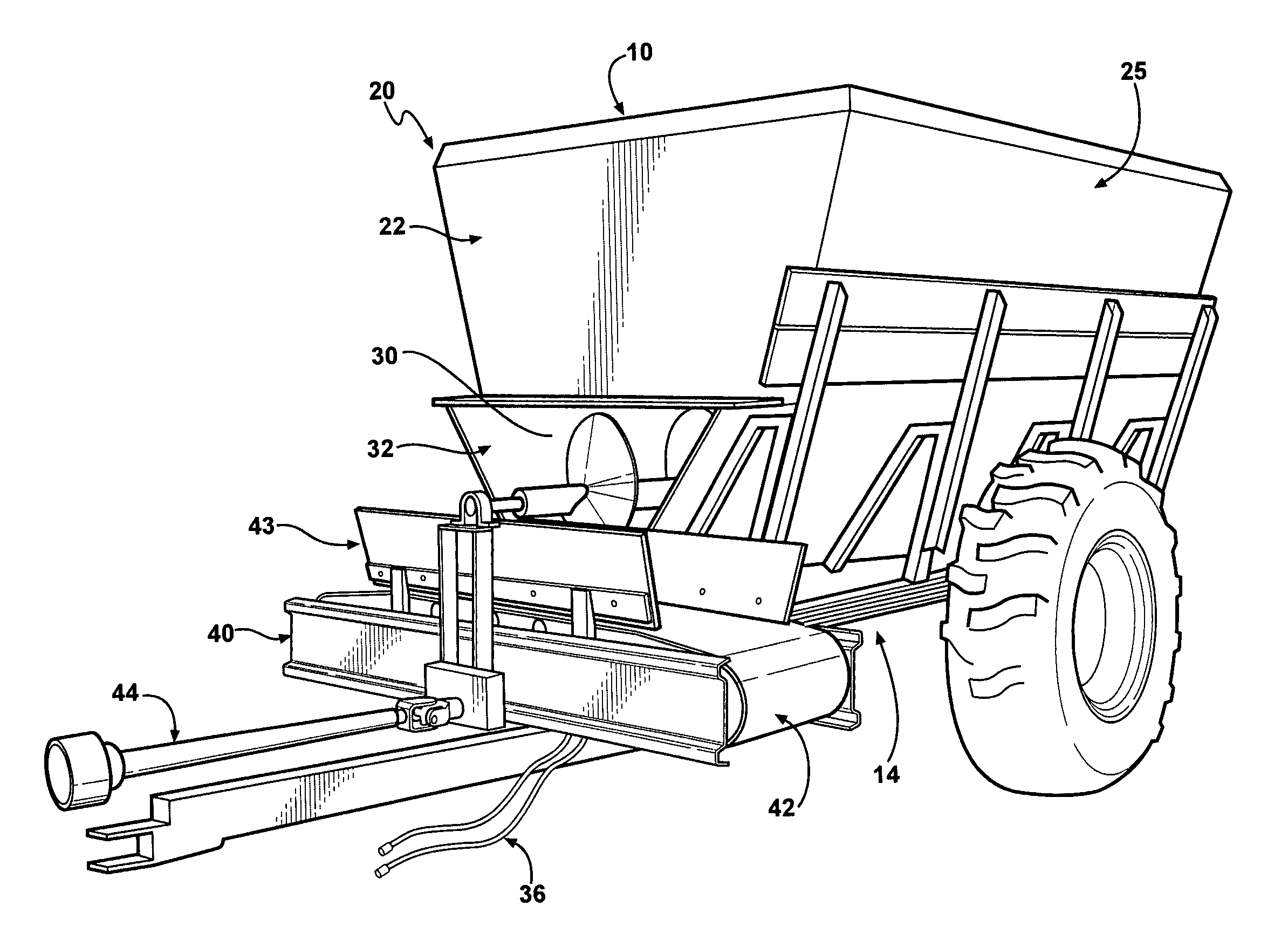

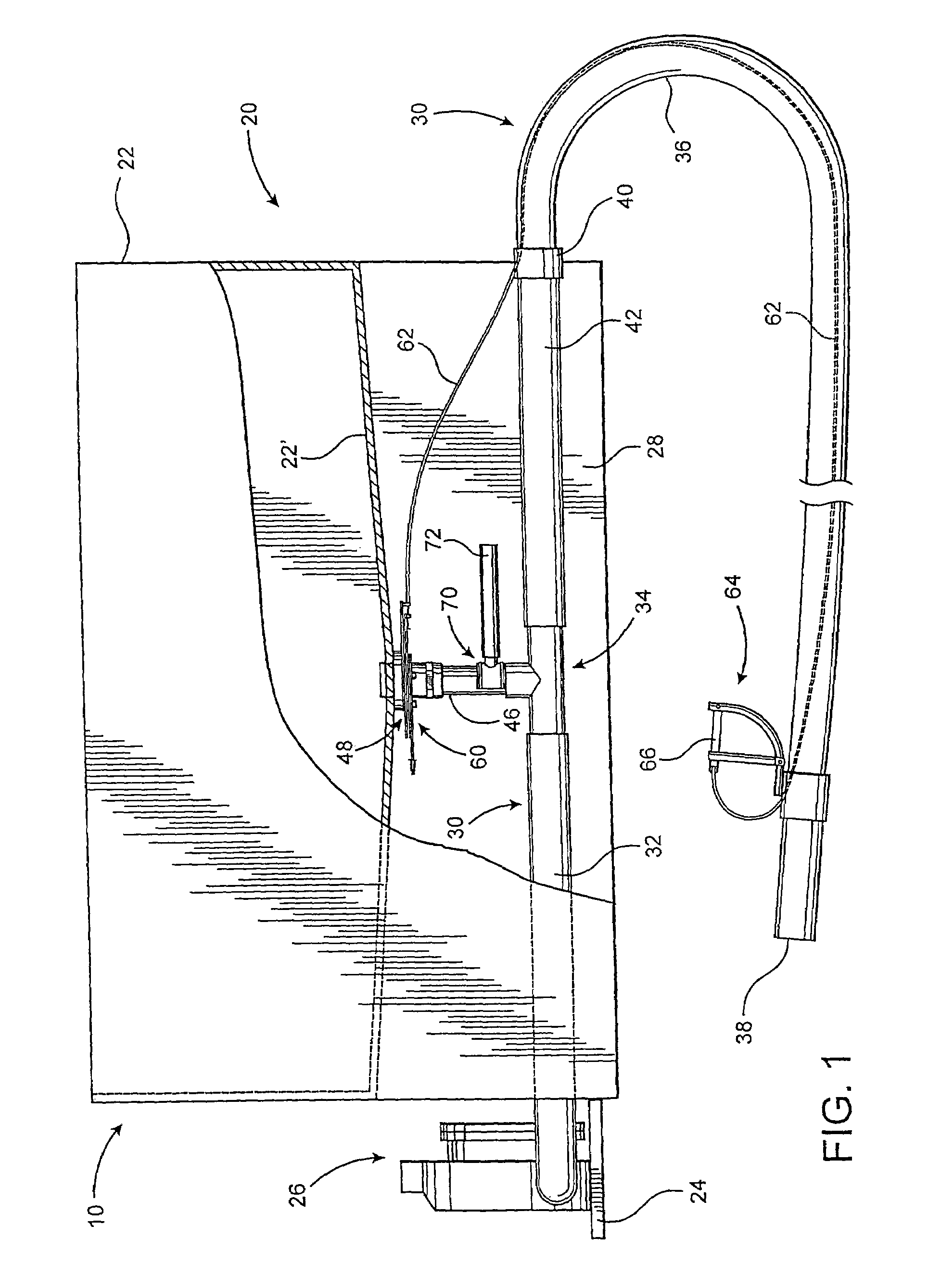

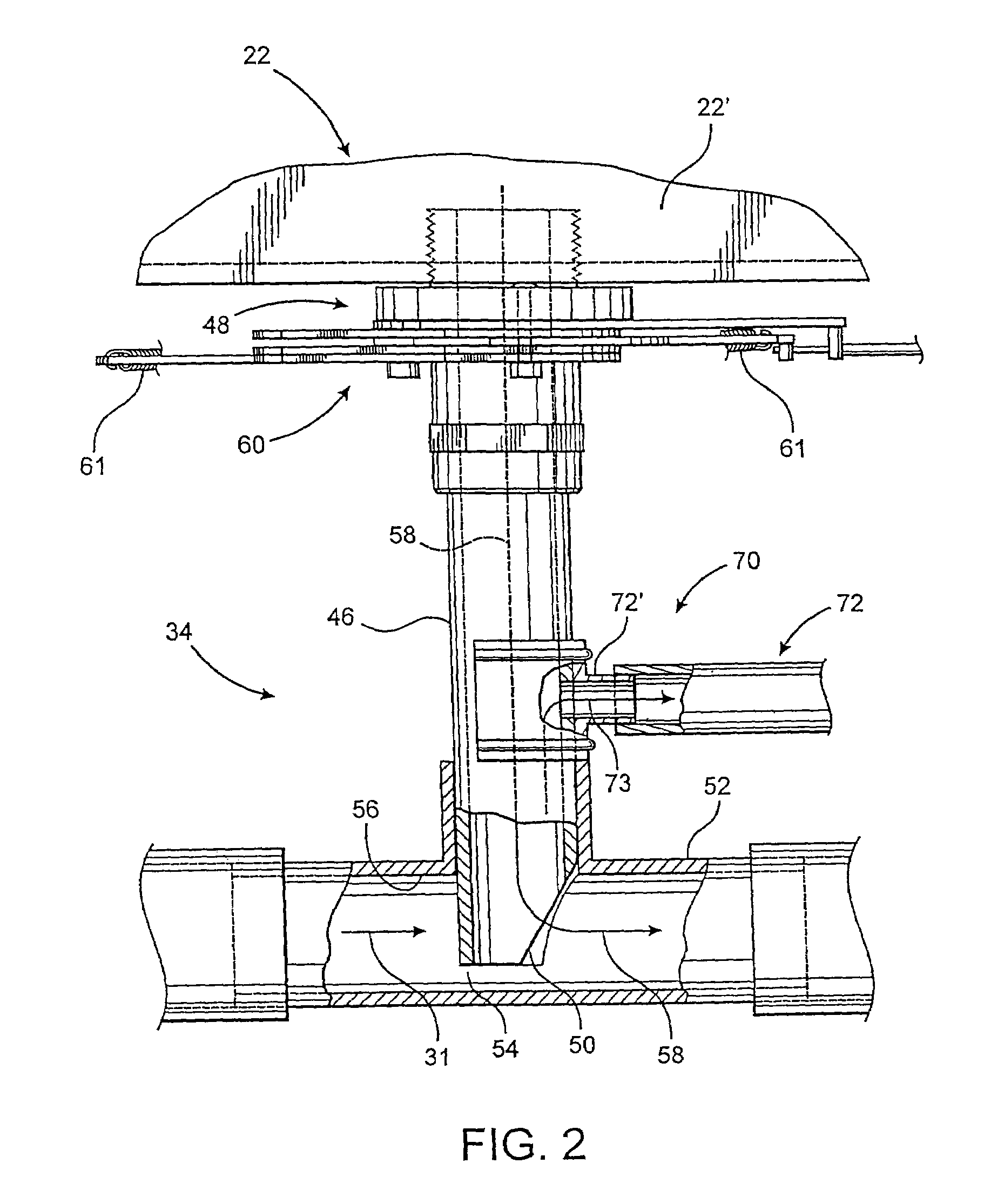

Material spreading apparatus

InactiveUS6202944B1Simple and economical designEasy to modifySowingFertiliser distributersBristleEngineering

A versatile and easily serviceable material spreading apparatus of the type for movement over a ground surface while broadcasting a material along a path on the ground surface. The apparatus includes a belt cartridge which can be slid into or pulled out of a chassis compartment having ledges for supporting the cartridge. The belt cartridge provides an upper flight on which material is carried from a hopper supported on the chassis to a broadcasting unit carried at one end of the chassis. A plurality of broadcasting units each of which has an attachment component, which in combination with a mating attachment component carried by the chassis, permits quick fastening and removal of each unit relative to the chassis. One of the broadcasting units mounts an elongated rotatable member below a drop-offend of the upper flight of the belt cartridge, and the rotatable member is driven in a direction so that the upper rotating periphery of the rotating member propels the material upward and away from the chassis. The rotating member has strips of bristles which spiral around a core of the member towards opposite ends thereof so that the material also has imparted to it from bristles of the rotating member a direction of flight having a side-ways component to thereby increase the width of the path of distribution.

Owner:TORO CO THE

Apparatus and method of dispensing small-scale powders

InactiveUS20050211163A1Facilitate depositionIncrease flow rateDispensing apparatusLarge containersEngineeringUltrasonic vibration

An apparatus and method of dispensing small-scale powders for a variety of applications, including, for example, fabricating a three-dimensional heterogeneous small-scale device, includes using a feed mechanism that causes motion of the powder particles and the steps of depositing fine heterogeneous materials (such as dry powders and biological materials) towards a substrate. The depositing step preferably includes providing a feed mechanism having an input to receive the material, an output, and a source of ultrasonic vibration to impart a torsional force on the material so as to precisely discharge the material from the output. To improve particle flowability, a cooling system is provided to cool the source, generally above a threshold input voltage.

Owner:WISCONSIN ALUMNI RES FOUND

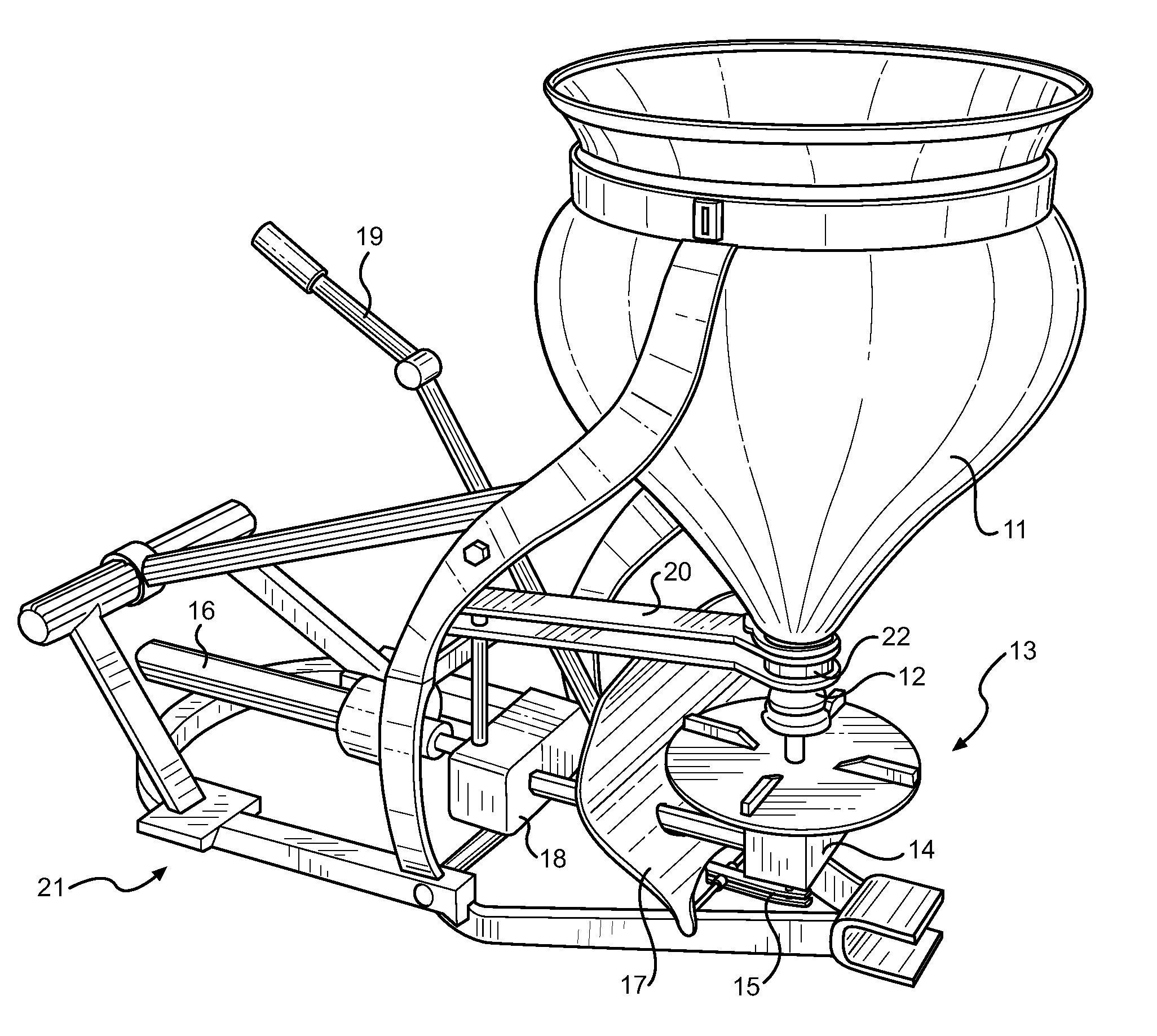

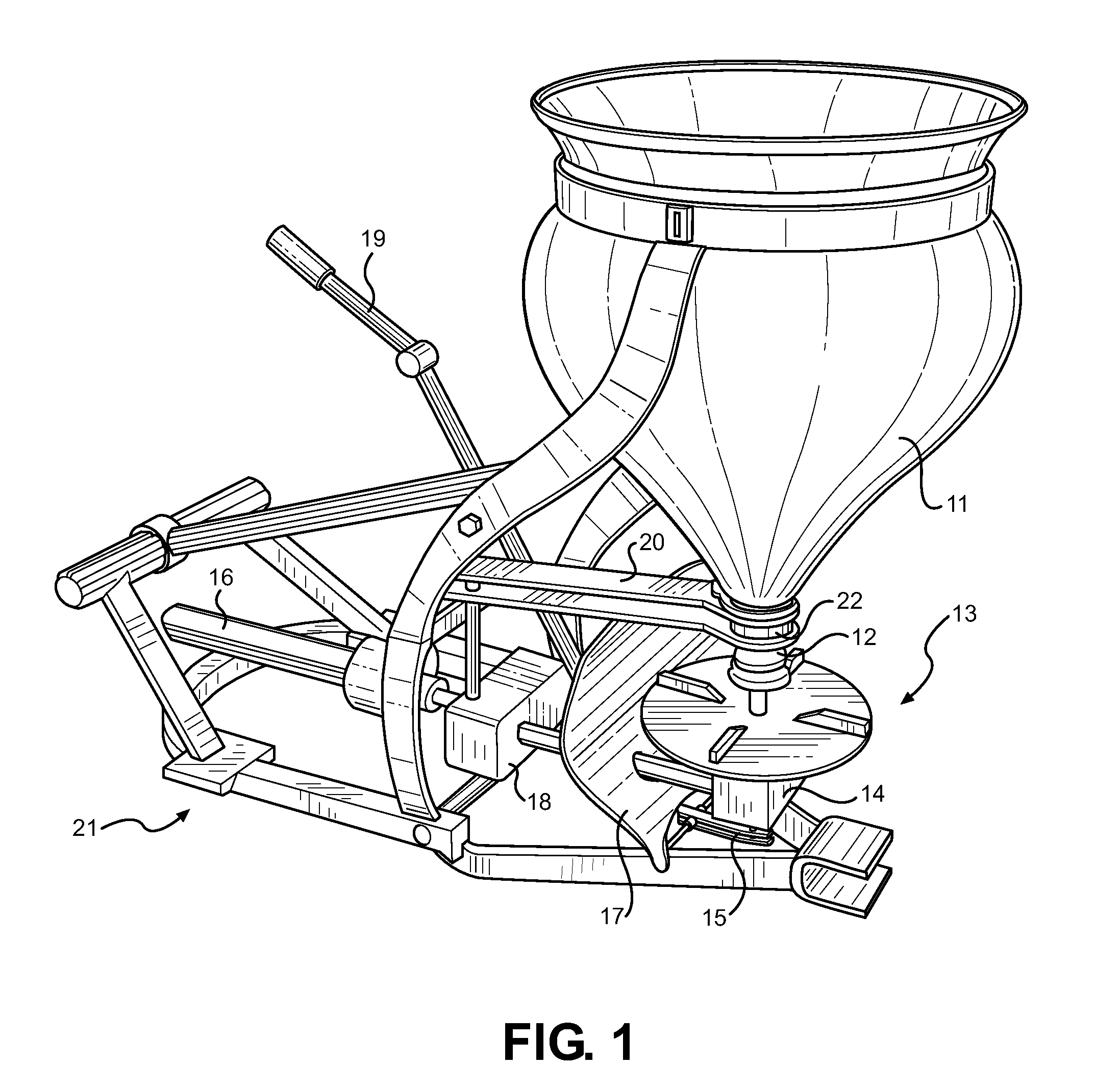

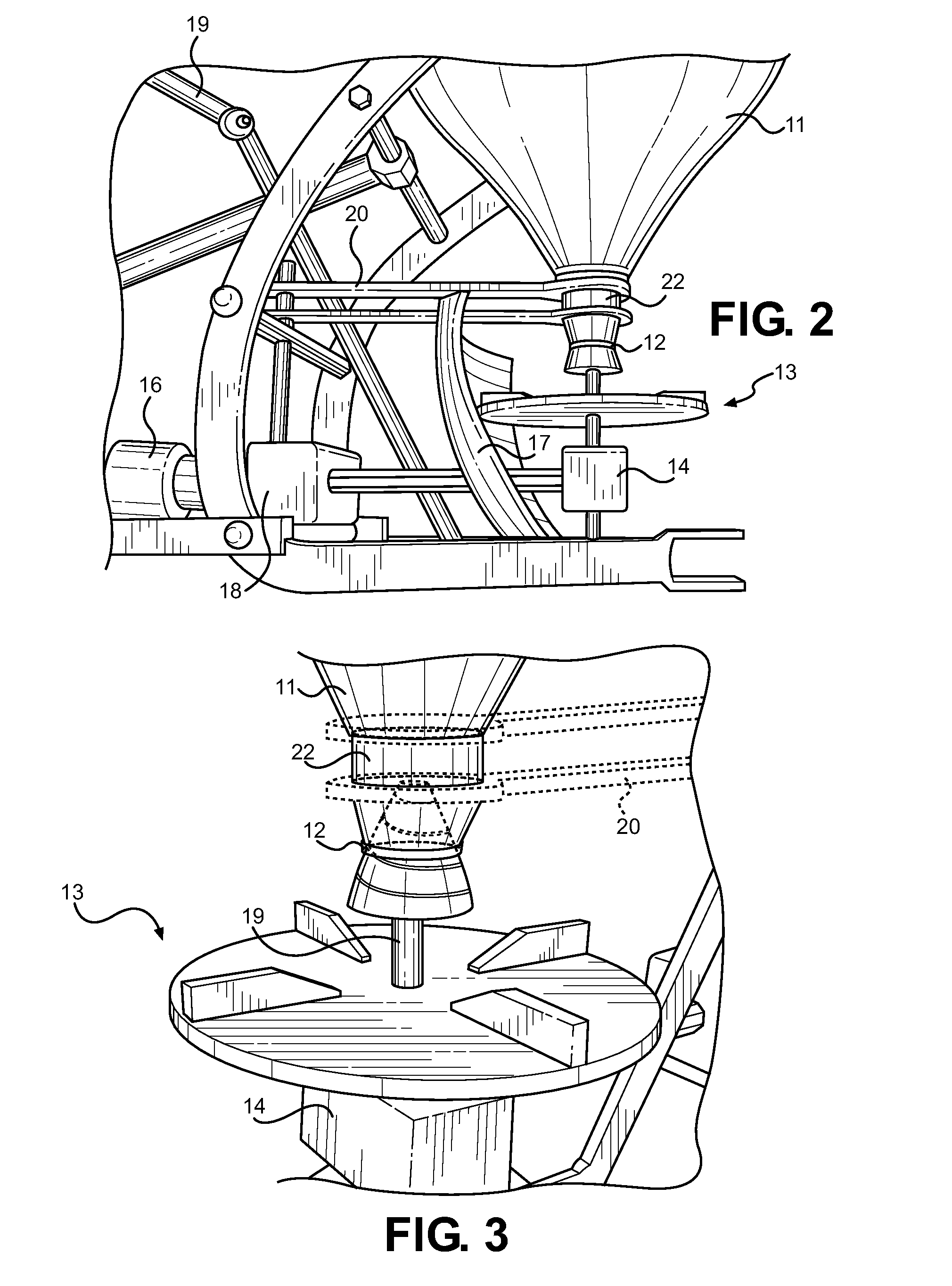

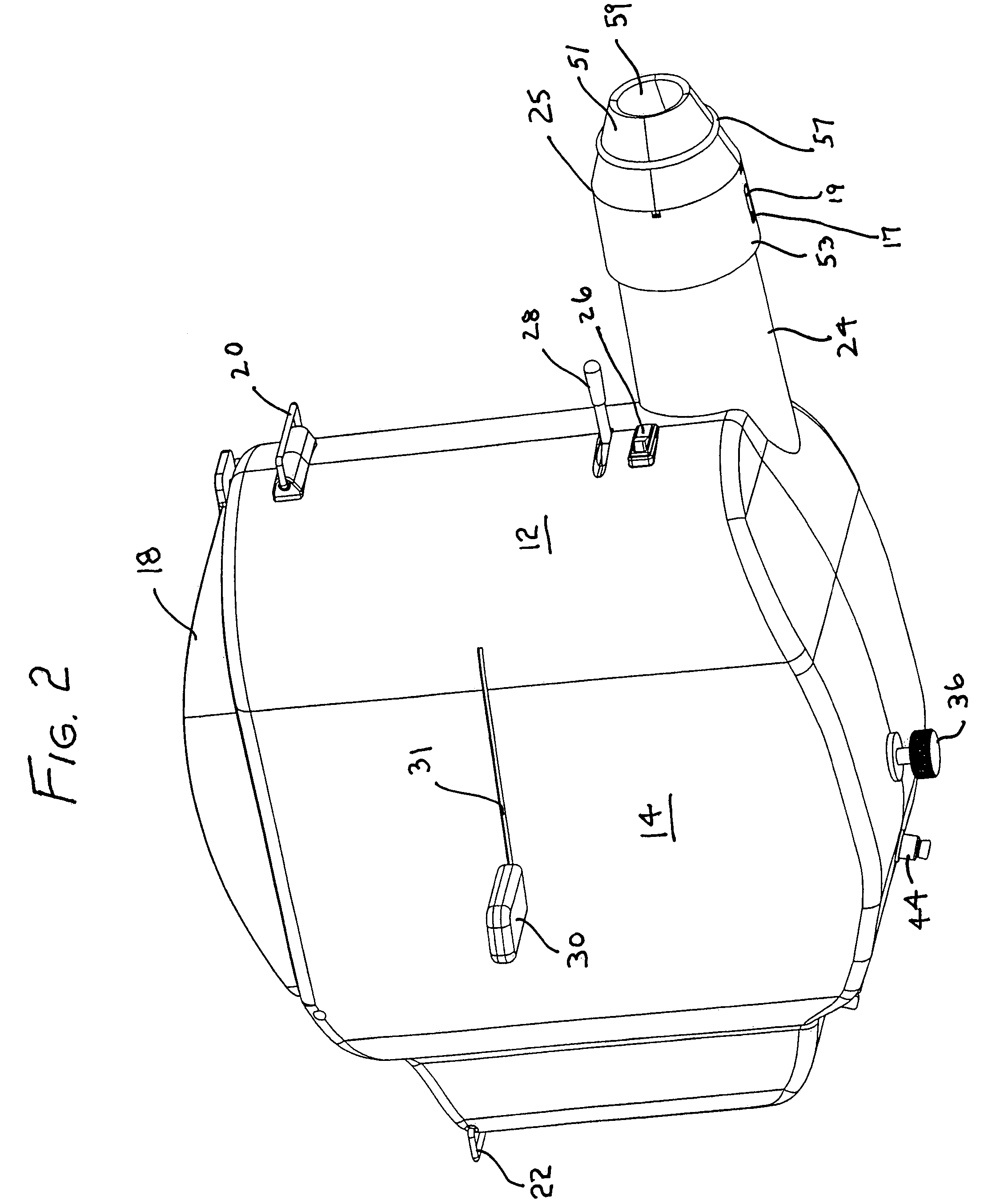

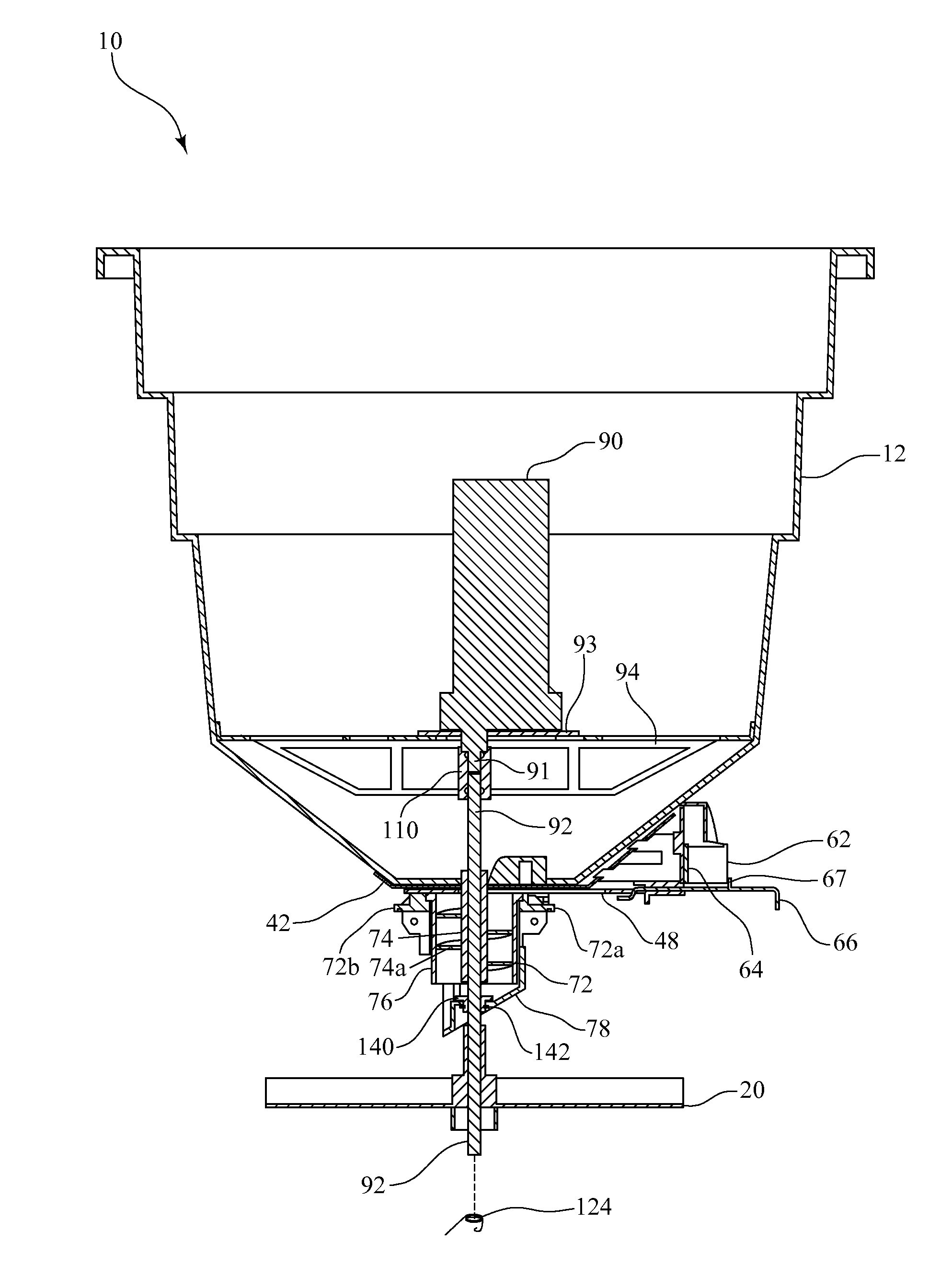

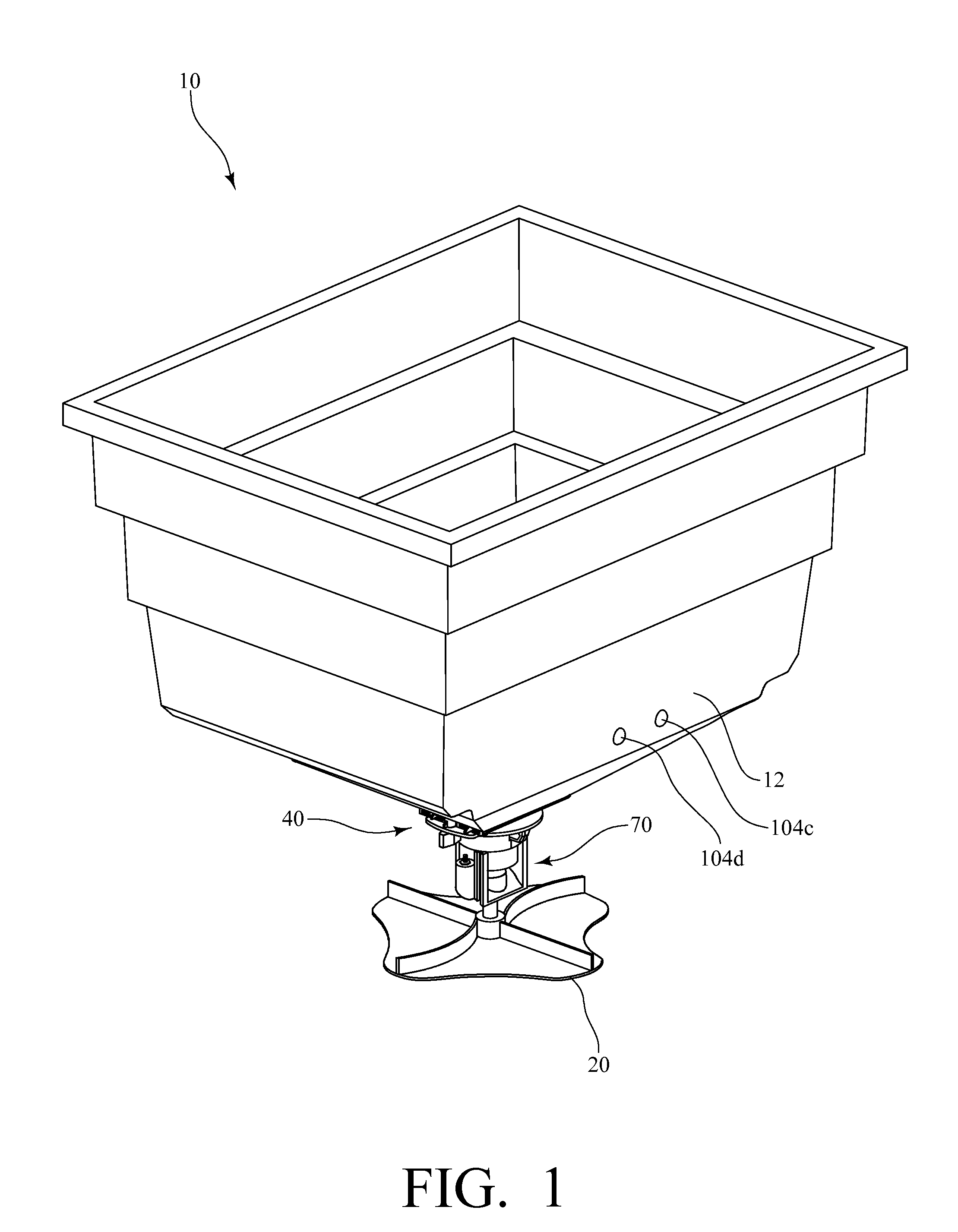

Free Flow Spreader Device

InactiveUS20110309170A1Uniform dispensingAccelerated settlementLiquid fertiliser distributionFertiliser distributersLiquid productImpeller

Disclosed is an improved means for spreading solid or liquid agricultural products, ideally suited for use with a tractor or similar vehicle with an external power takeoff shaft. For solid agricultural products, a specially designed hopper is used in conjunction with a cone-shaped, flow control stopper and an outlet agitator for providing a uniform delivery of product onto a rotating impeller. A plurality of gearboxes provide motive distribution of power for the hopper outlet agitation and impeller, while a user-accessible handle controls the control stopper height within the hopper outlet, and thus controlling the flow rate from the hopper. For liquid products, a cylindrical hopper is provided, along with a pump and a plurality of hoses for drawing or recycling the liquid product. A rear-mounted spray rail is provided for dispensing the liquid product, while an accessory connection is provided for a user to manually distribute the product with an attachable spray gun device.

Owner:WEEKS CHRISTOPHER

Dual mode spreader

InactiveUS6945481B2Accurate identificationFertiliser distributersManure distributersImpellerDual mode

A dual mode spreader for broadcast spreading and drop spreading material comprising a hopper to hold a supply of spreadable material, first and second discharge openings located within the hopper for which spreadable material can flow therethrough, an impeller mounted in a position below the hopper for rotational movement about an upright axis, wherein the first discharge opening leads to impeller to enable the spreadable material in the hopper to exit therefrom onto the impeller to be distributed in a path outwardly therefrom onto the surface to be treated; and a diffuser defining an inlet opening and an outlet opening, wherein the second discharge opening is in communication with the inlet opening to enable the spreadable material in the hopper to enter the diffuser and exit therefrom through the outlet opening to be distributed in a path downwardly therefrom onto the surface to be treated.

Owner:USG STAMFORD BRANCH +1

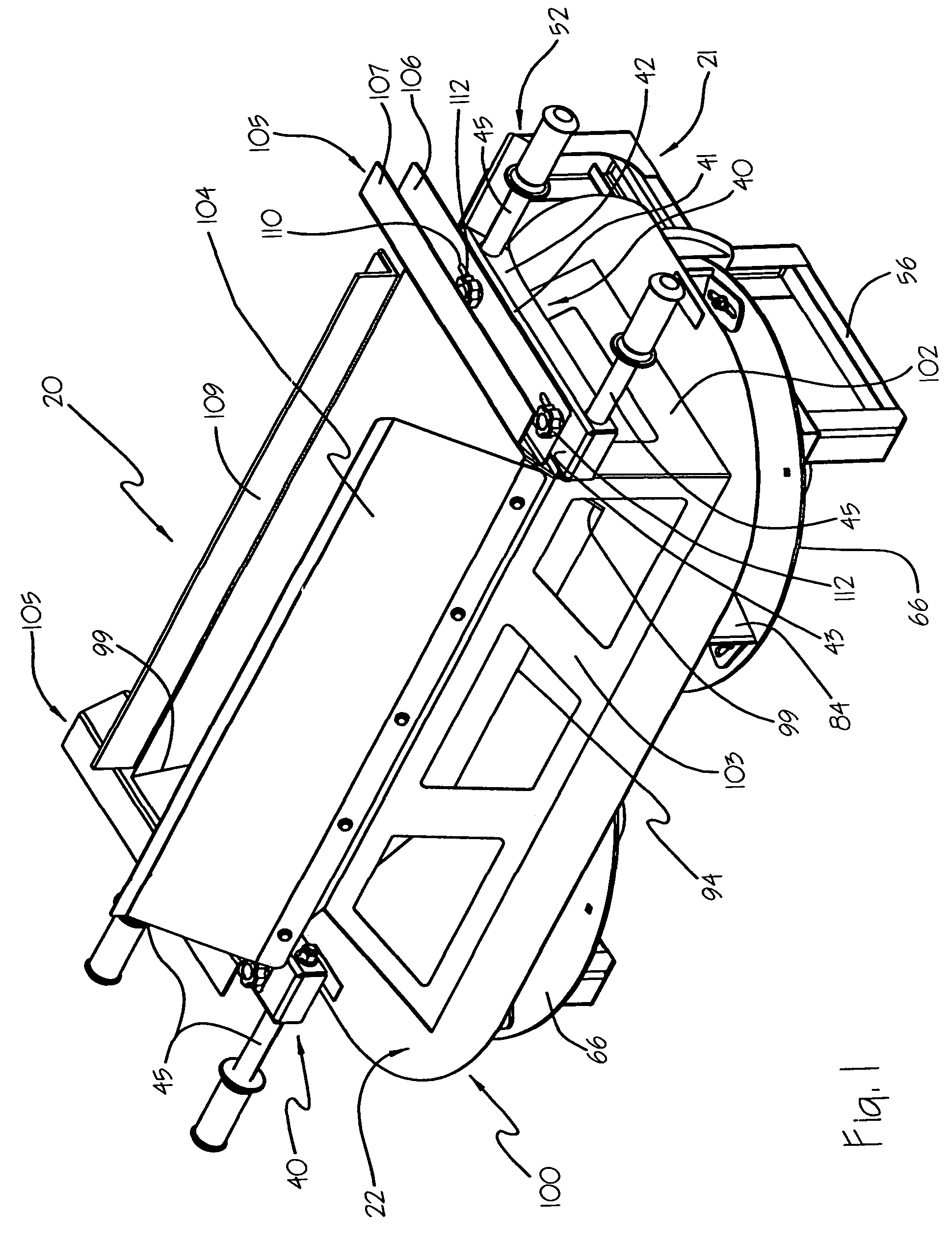

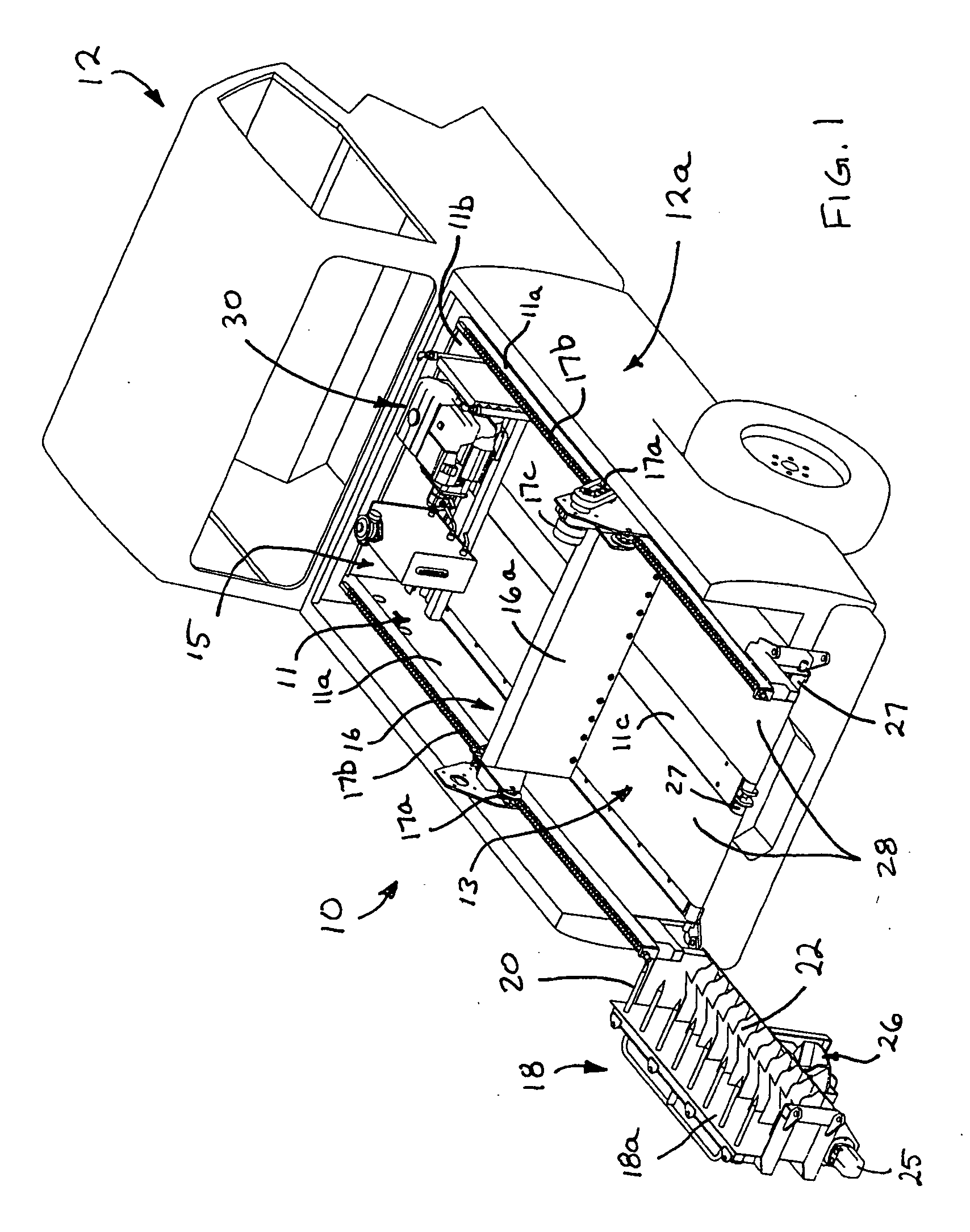

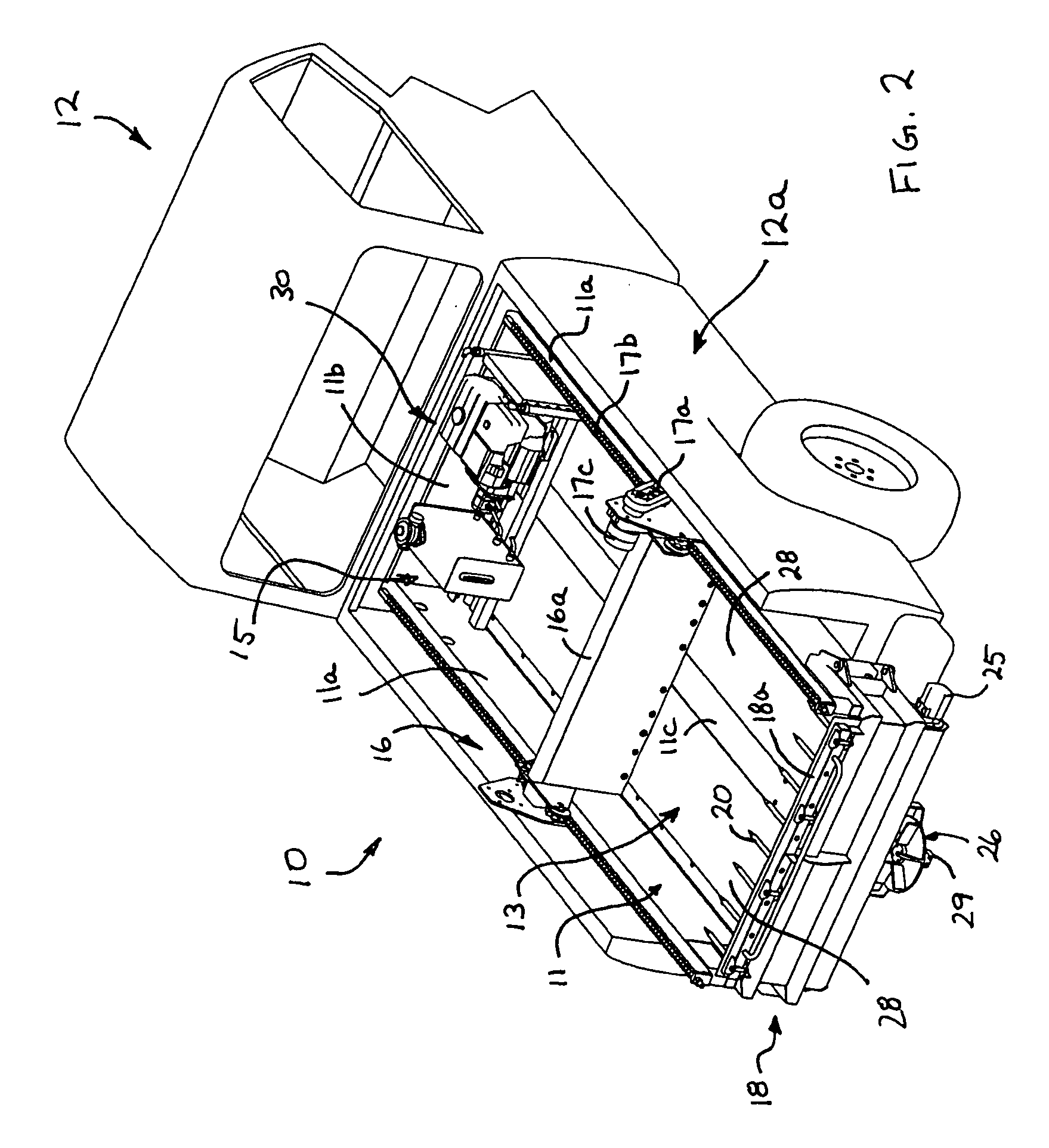

Twin spinner spreading apparatus

ActiveUS7044408B2Efficient disseminationFertiliser distributersSowingElectrical and Electronics engineeringChassis

Owner:TORO CO THE

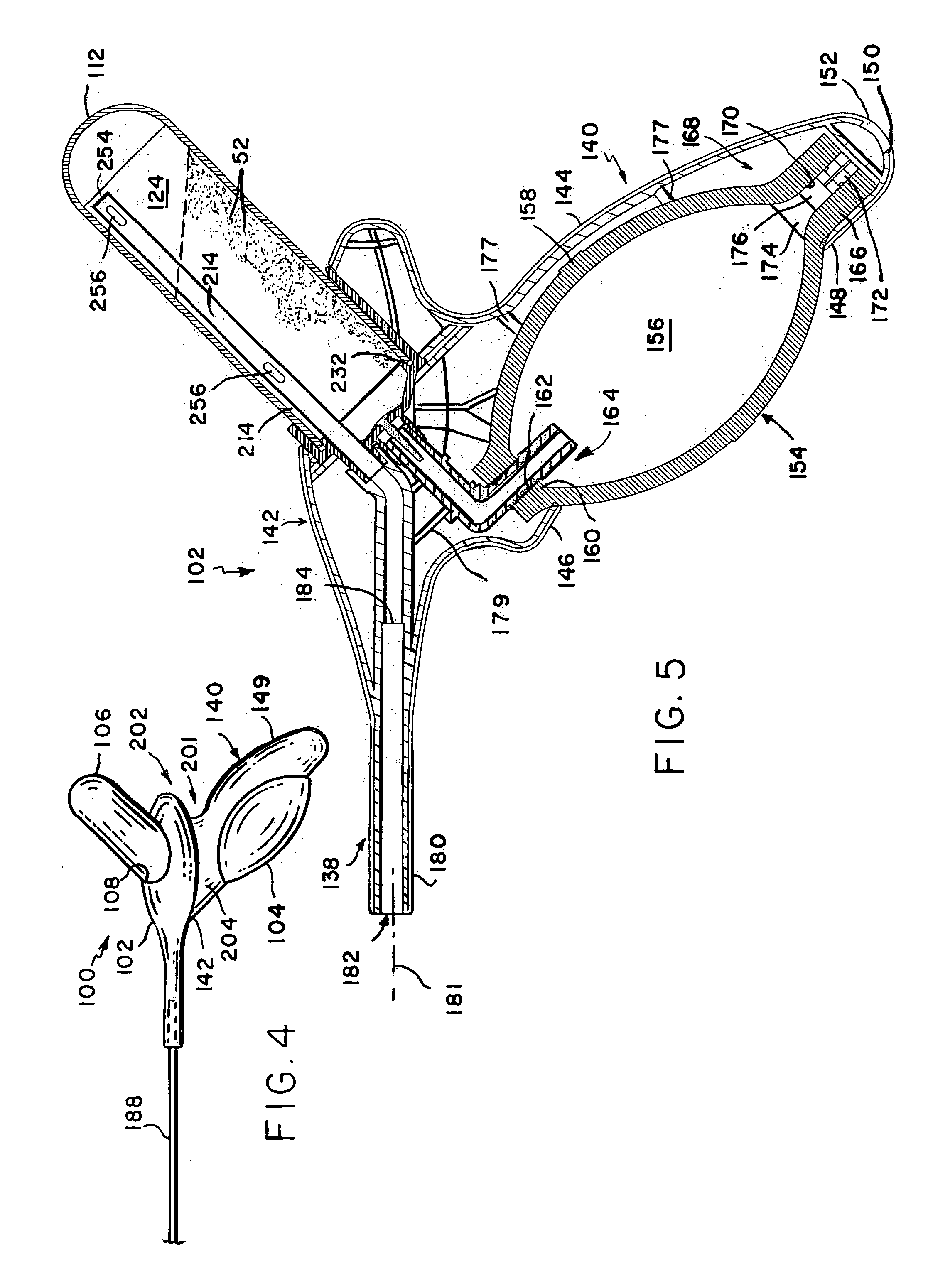

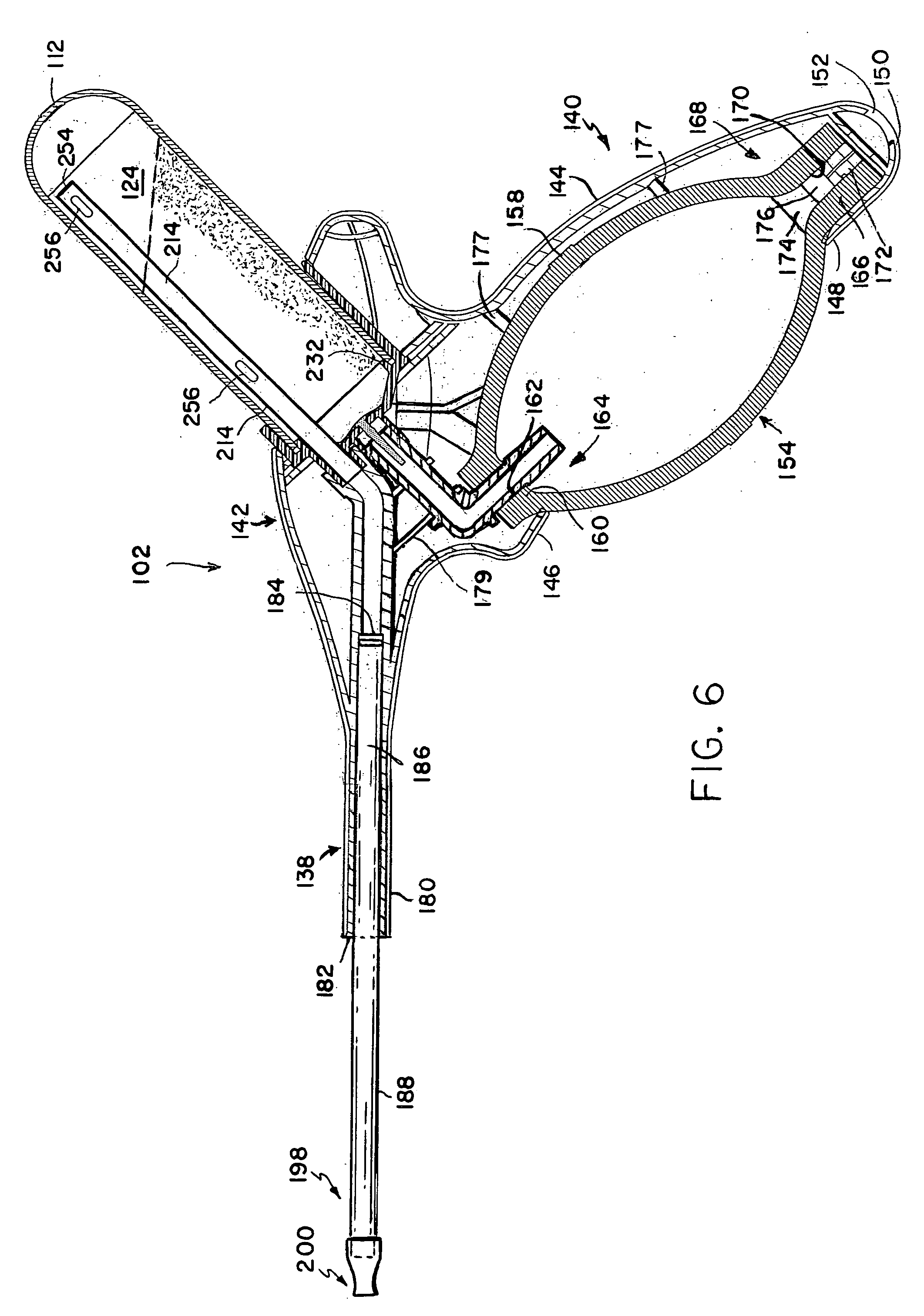

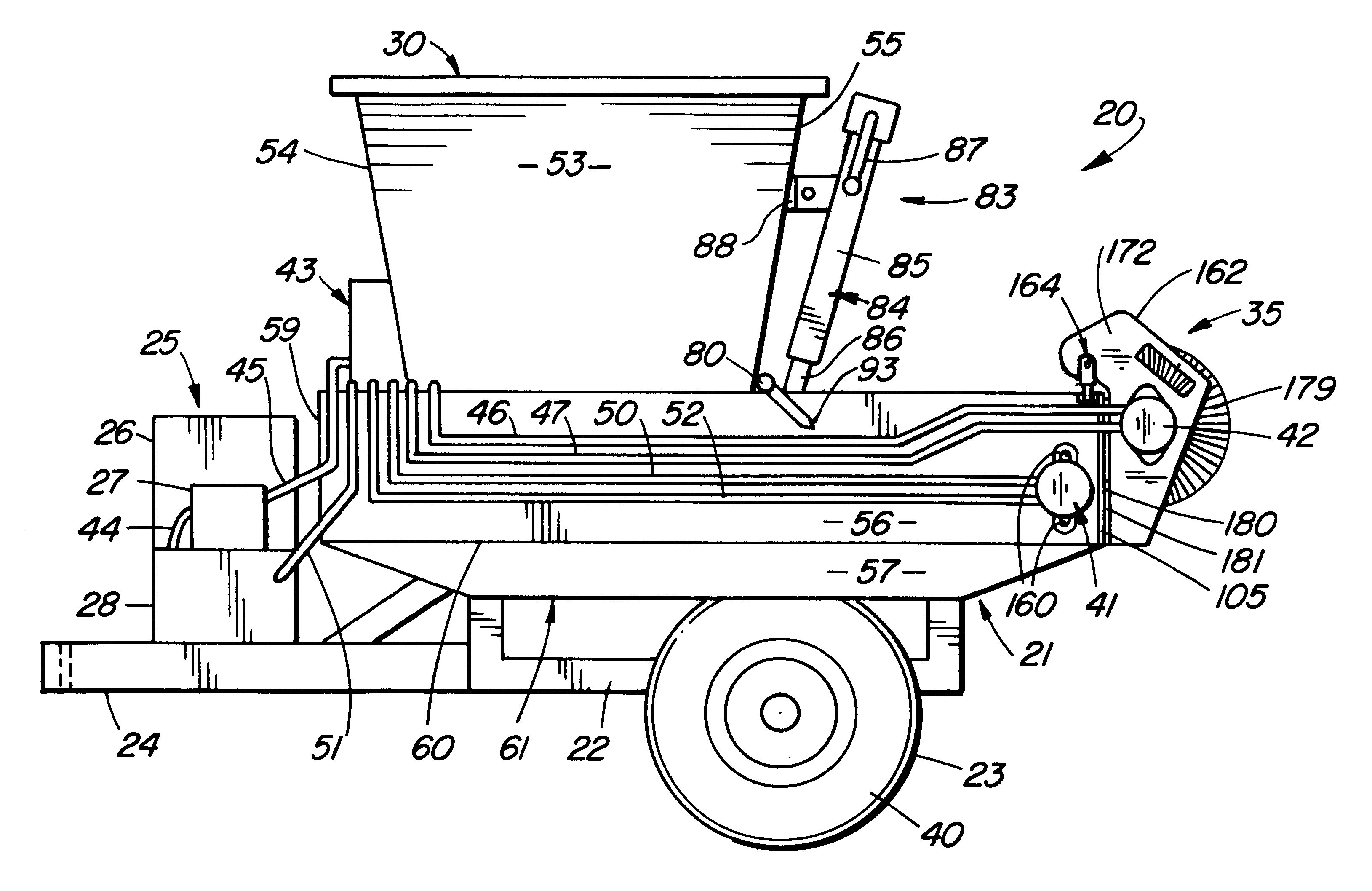

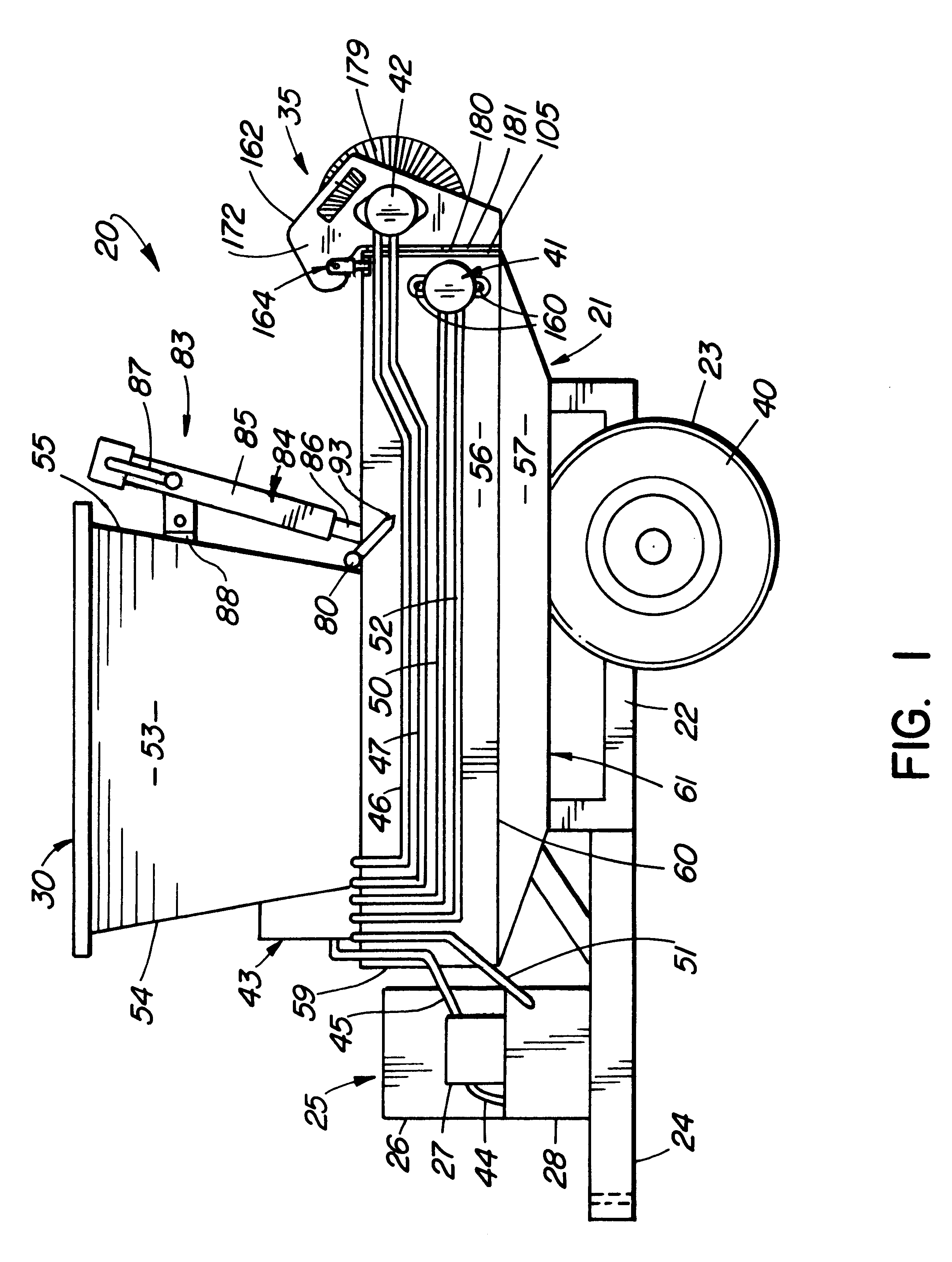

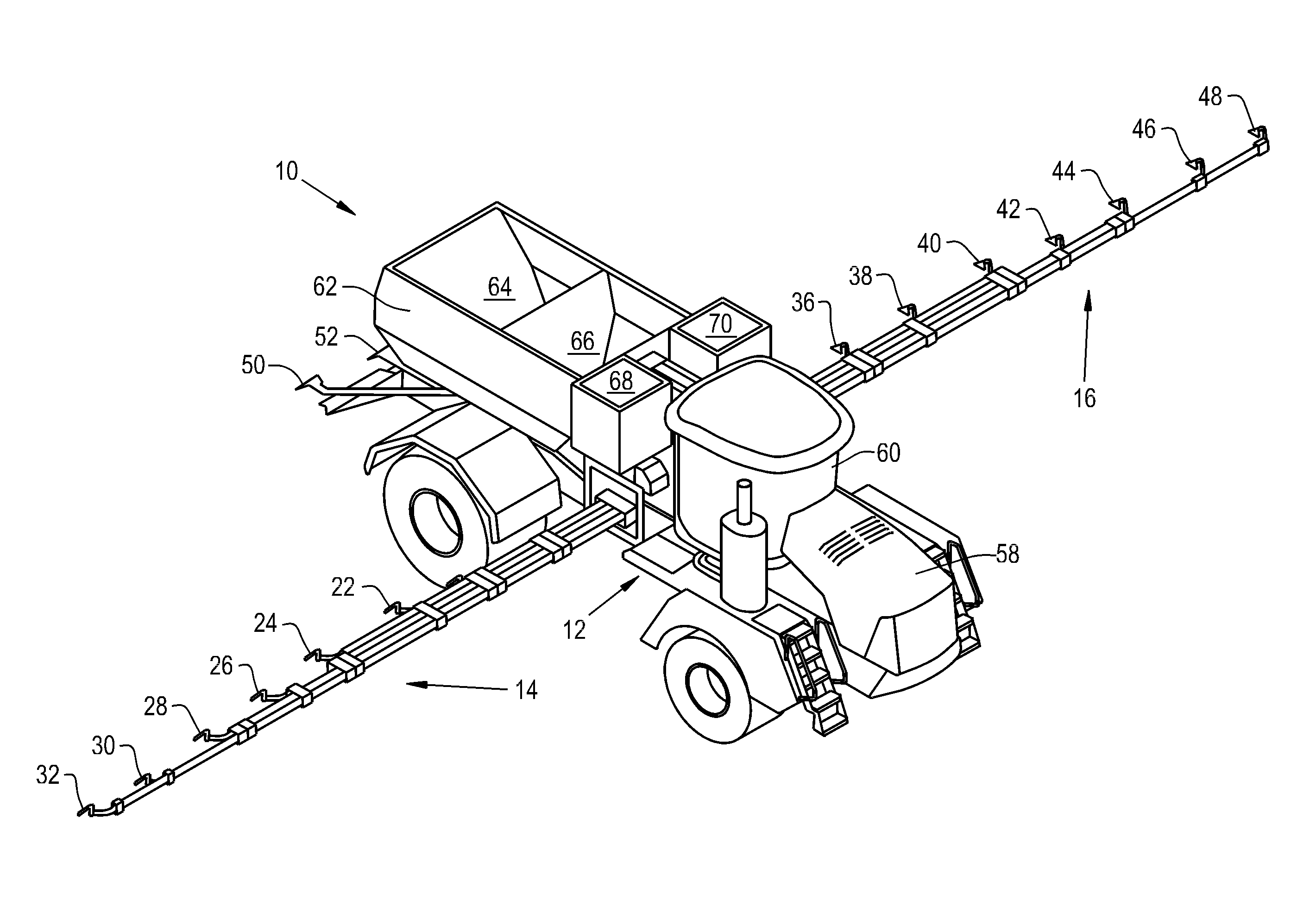

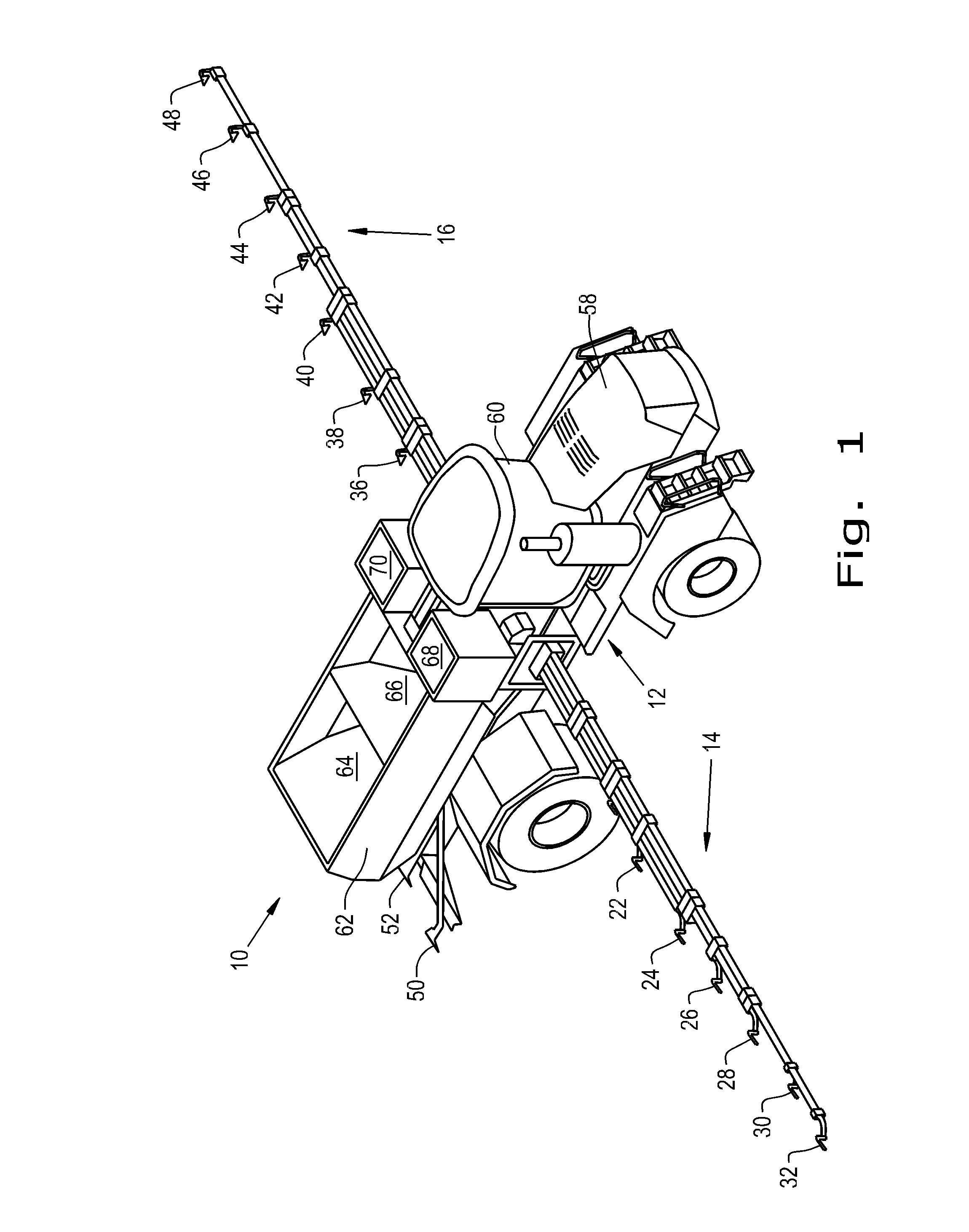

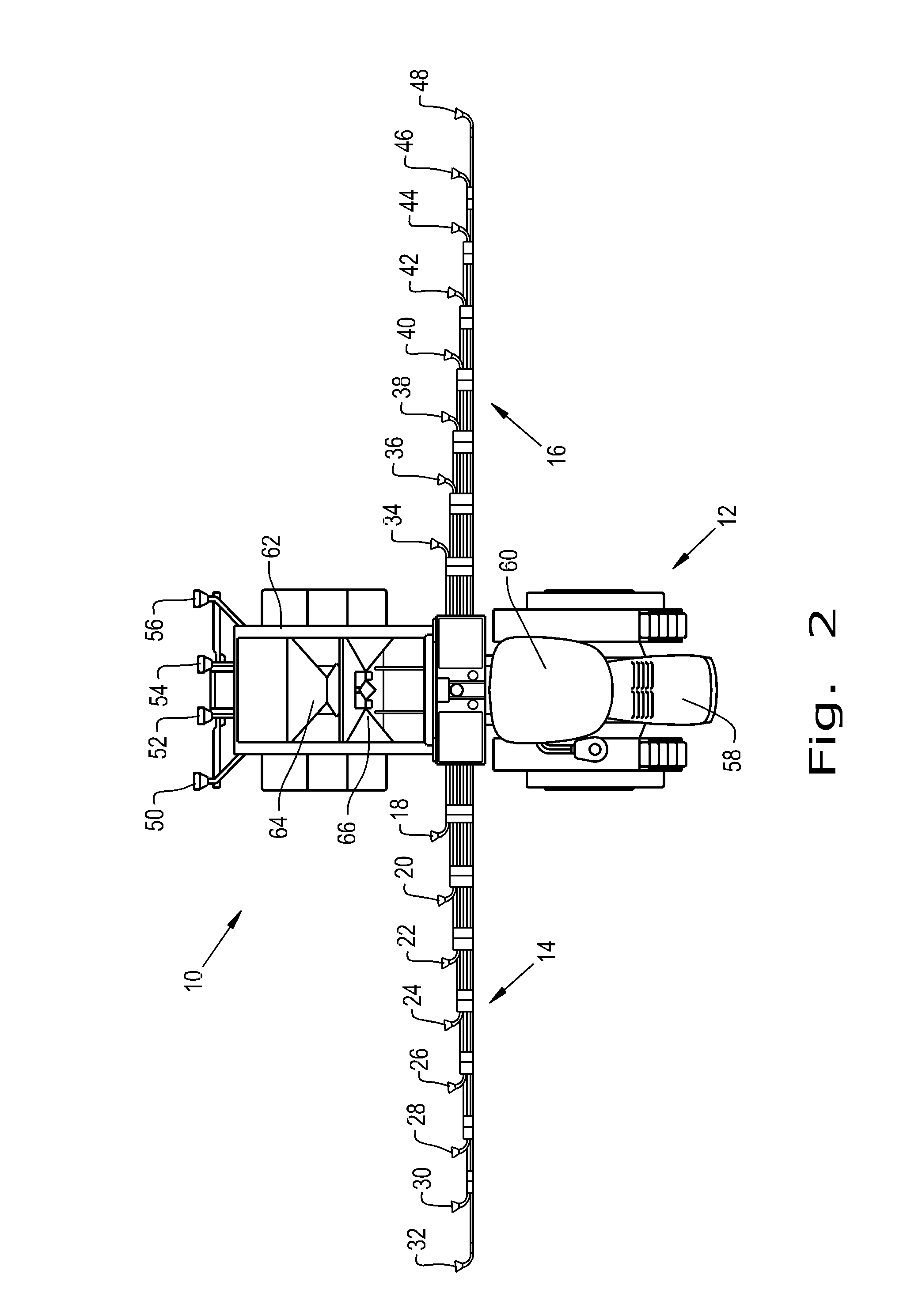

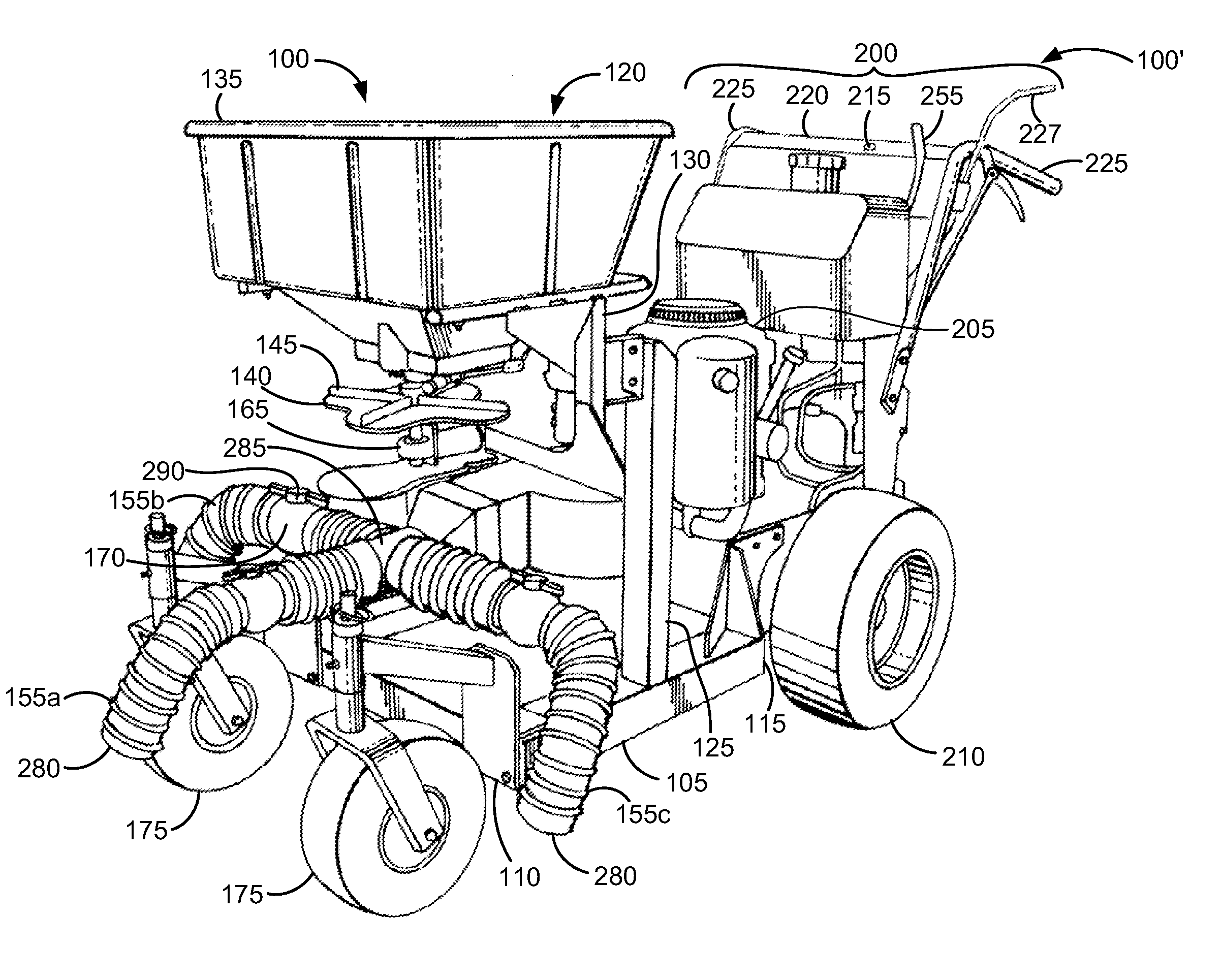

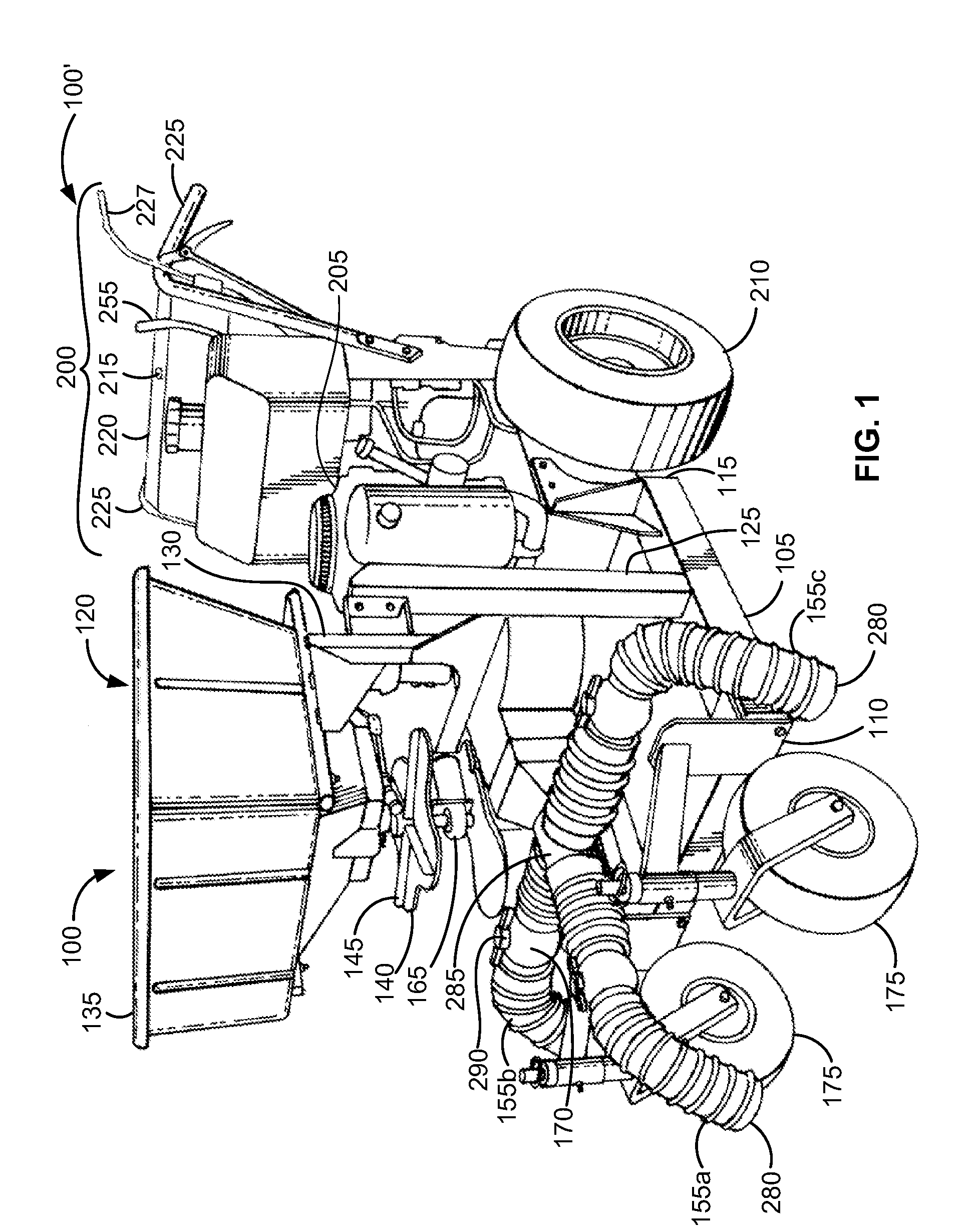

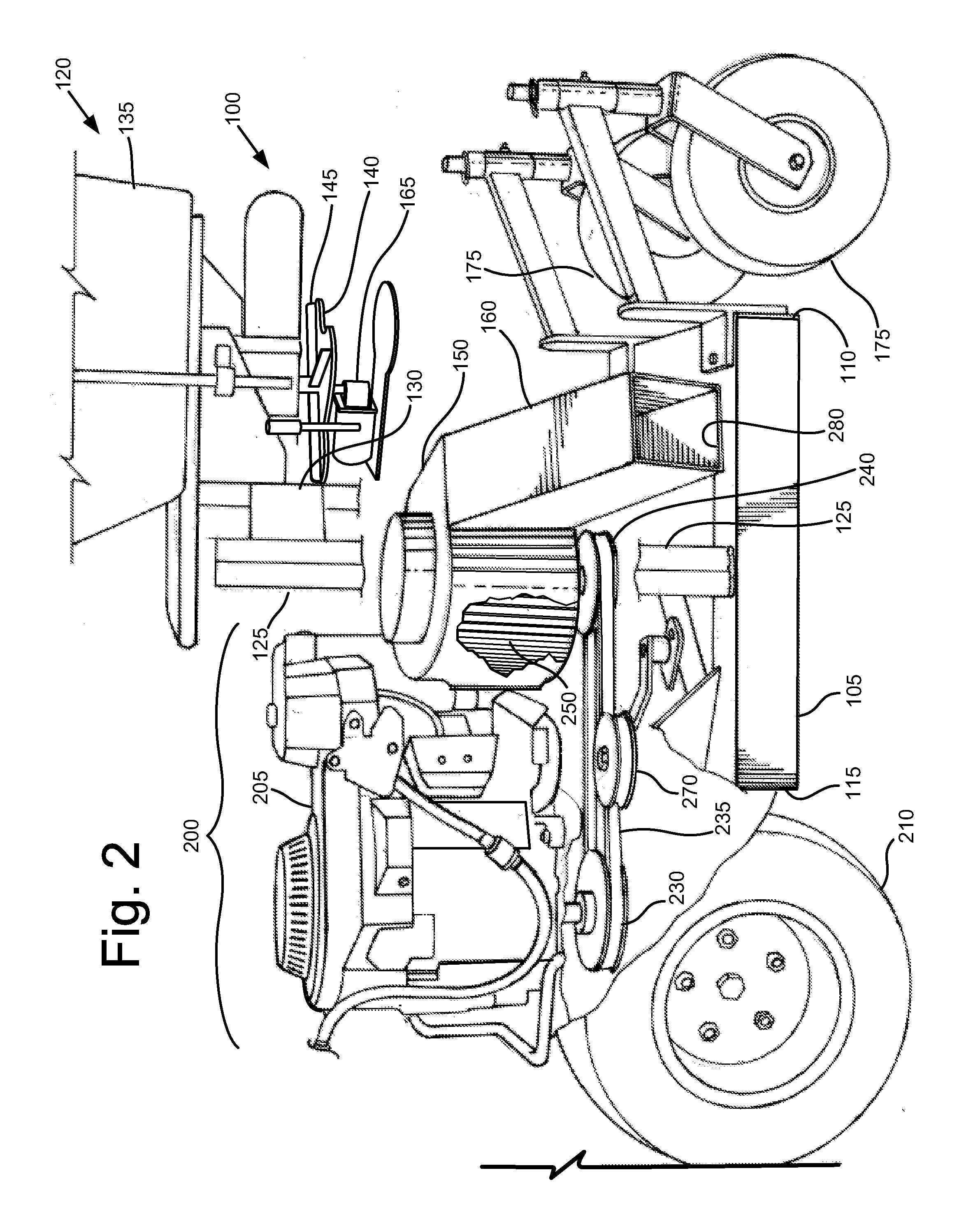

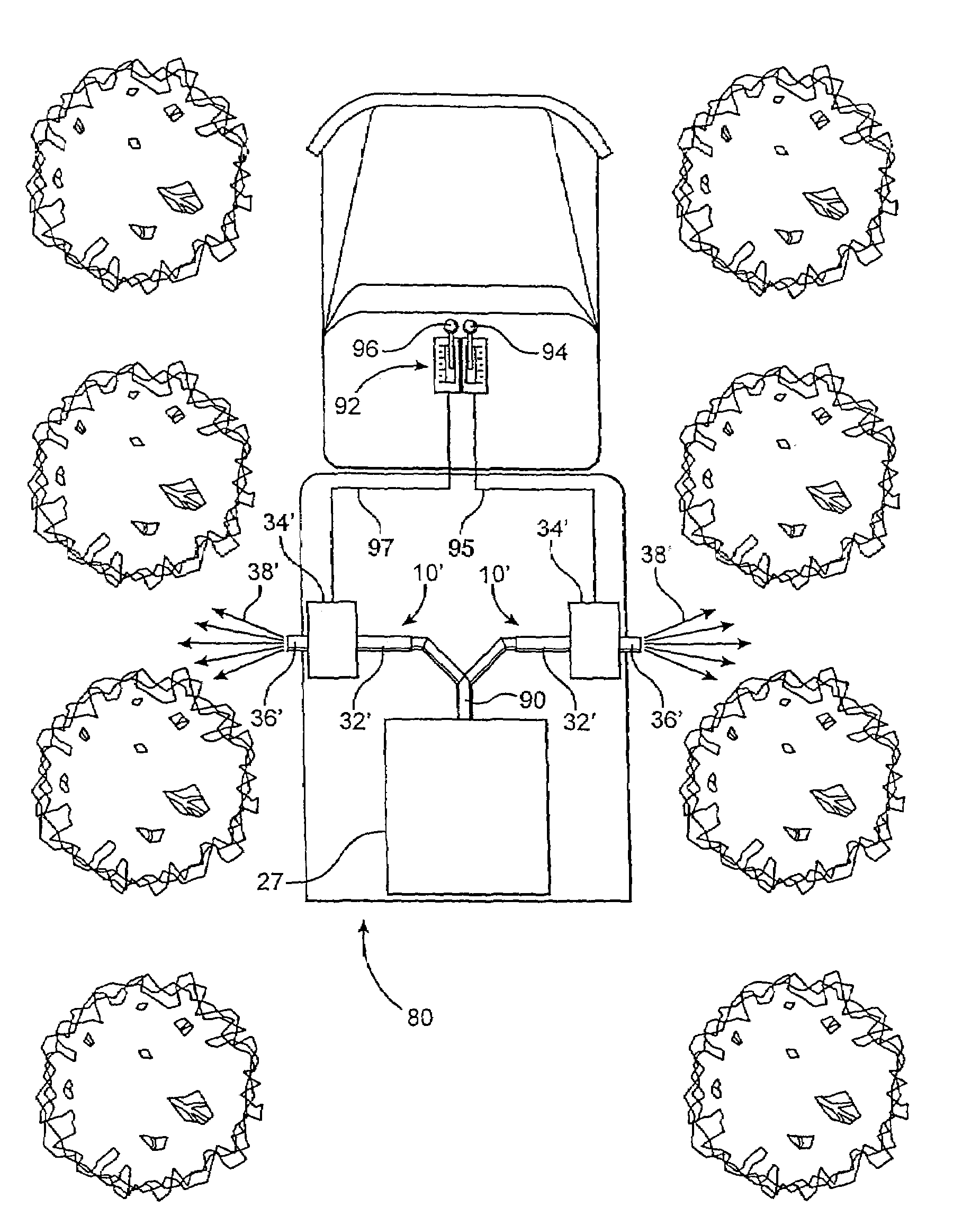

Pheumatic delivery system for application implement using multiple metering devices

ActiveUS20160095276A1Minimize complicationsLess-prone to adverse impactFertiliser distributersManure distributersParticulatesInductor

A pneumatic delivery system for particulate agricultural products includes one or more compartment for containing and supplying one or more particulate product. An inductor assembly separately receives and fluidizes the particulate products and conveys the fluidized products to a metering assembly. The metering assembly separately meters each of the product flows and transfers the metered flows to one or more delivery units for applying the products. The pneumatic delivery system can be used on various implements, including planters and applicators for applying seeds, fertilizer, pesticides and other products.

Owner:CNH IND CANADA

Material spreading device

InactiveUS7104478B2Improve transmission efficiencyEasy and safe to loadGrain huskingGrain polishingMechanical engineeringEngineering

A material spreading device for spreading material over a targeted area includes a receiving portion for receiving a plurality of bags of material, a hopper assembly and a material moving device. The material spreading device is configured for use on a vehicle. The hopper assembly has a bag holding portion and a material dispensing bin. The bag holding portion receives at least some of the bags and retains the bags at or near the material dispensing bin. The hopper assembly includes at least one opening device for opening the bags such that material within the opened bags is deposited into the material dispensing bin. The material dispensing bin is operable to dispense or broadcast the material over the targeted area. The material moving device is operable to move the bags of material along the receiving portion and toward the hopper assembly.

Owner:ROCKIT

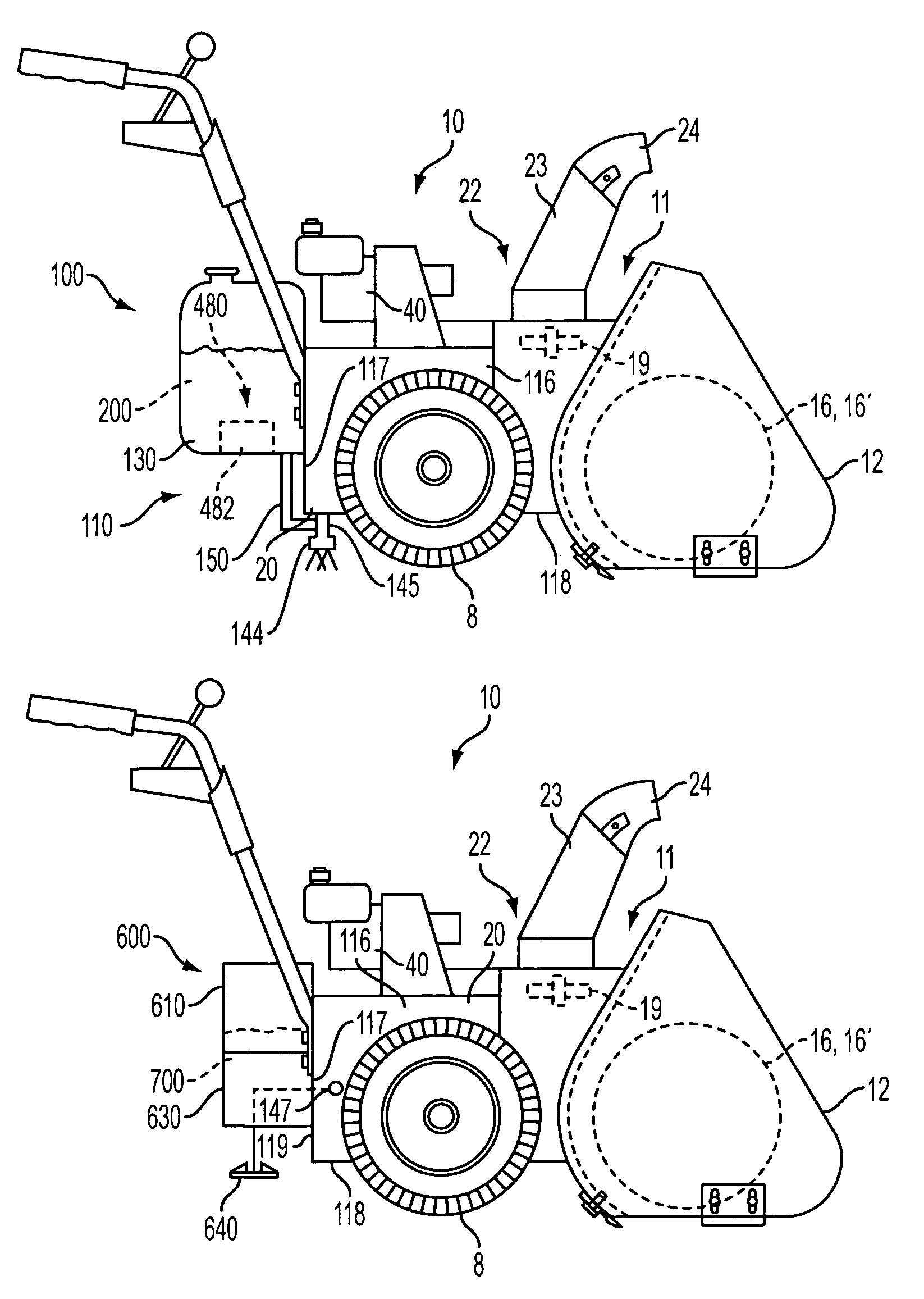

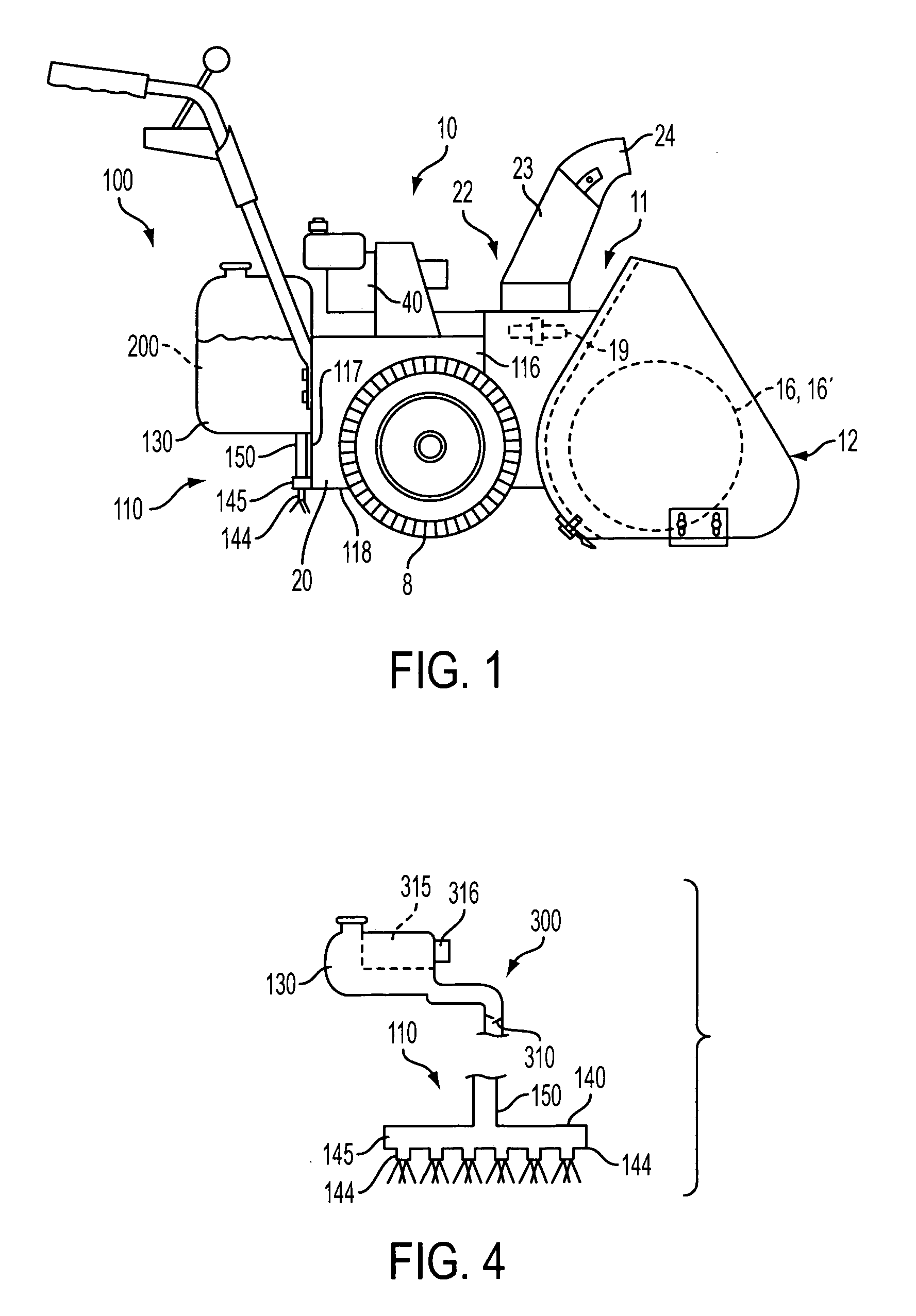

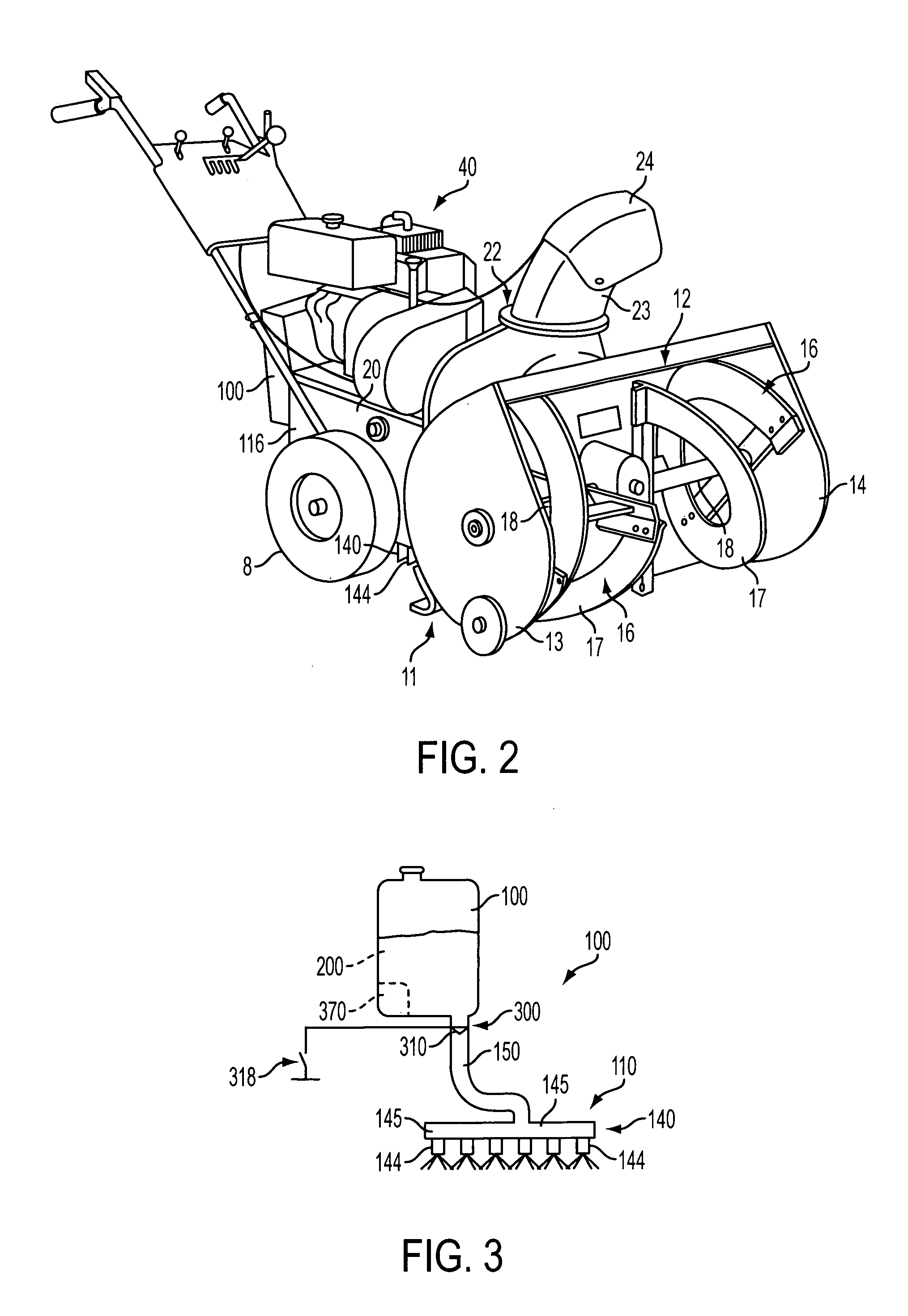

Snow removal machine with system for applying a surface treatment material

InactiveUS7137214B2Minimize adhesionLow costSki bindingsFertiliser distributersSnow removalEngineering

A snow removal machine including a housing with a forward opening through which snow enters the snow removal machine. At least one rotatable member is positioned and rotatably secured within the housing for engaging and eliminating the snow from within said housing. The snow removal machine also includes a surface treatment application system with a treatment material dispensing system connected to the housing for dispensing a liquid or solid deicer and / or anti-icing treatment material over an area from which snow has been removed.

Owner:CARGILL INC

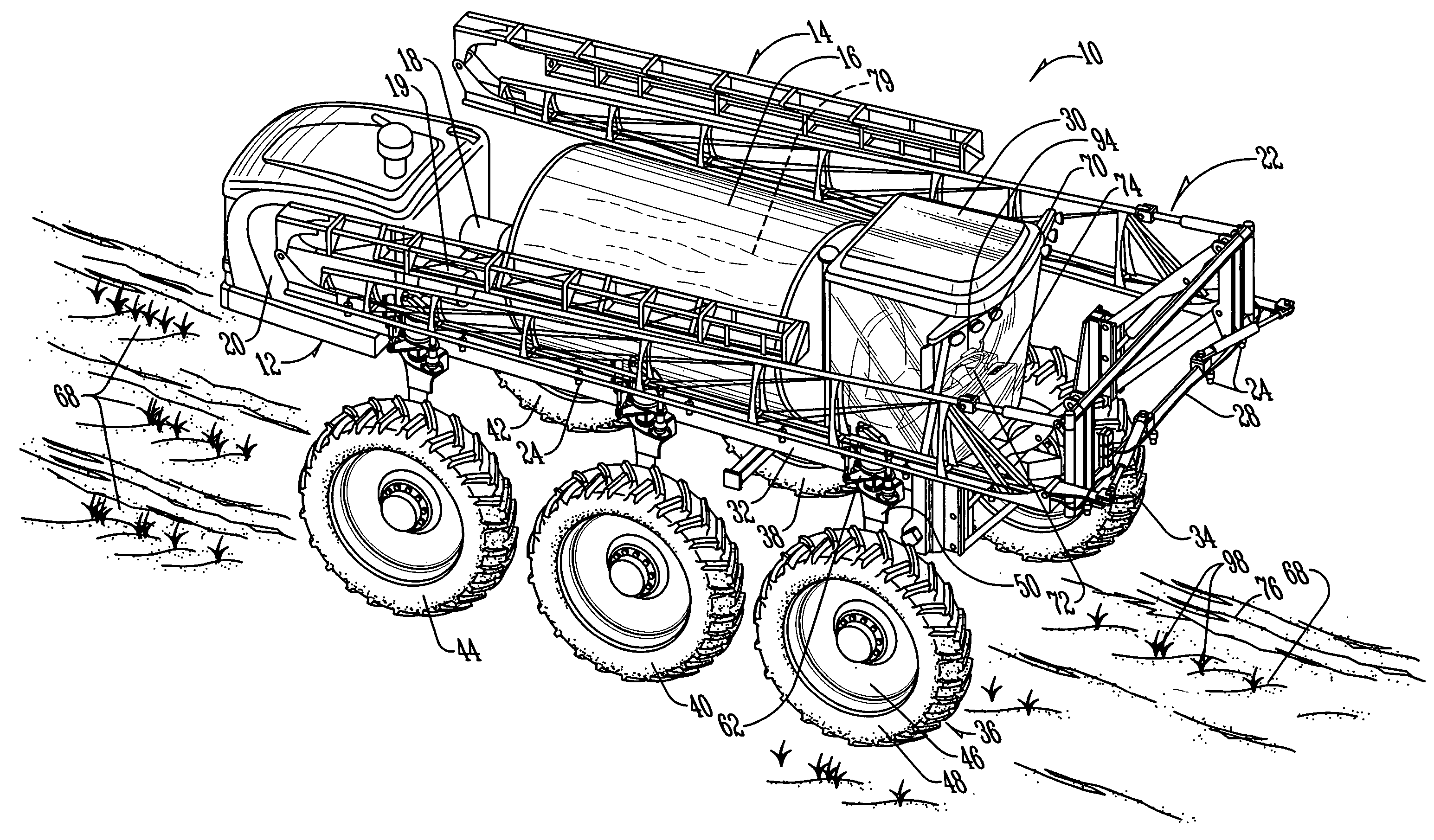

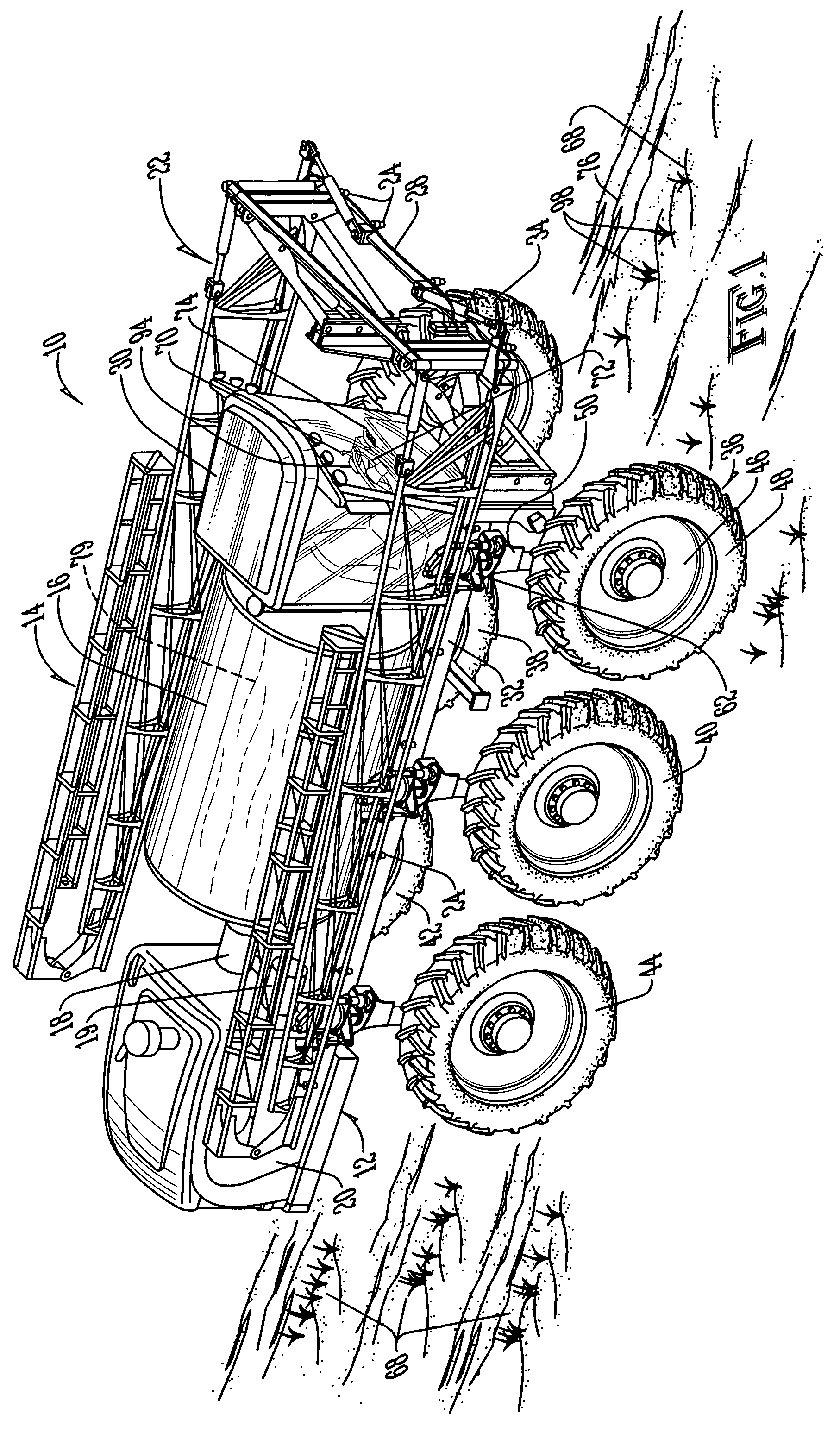

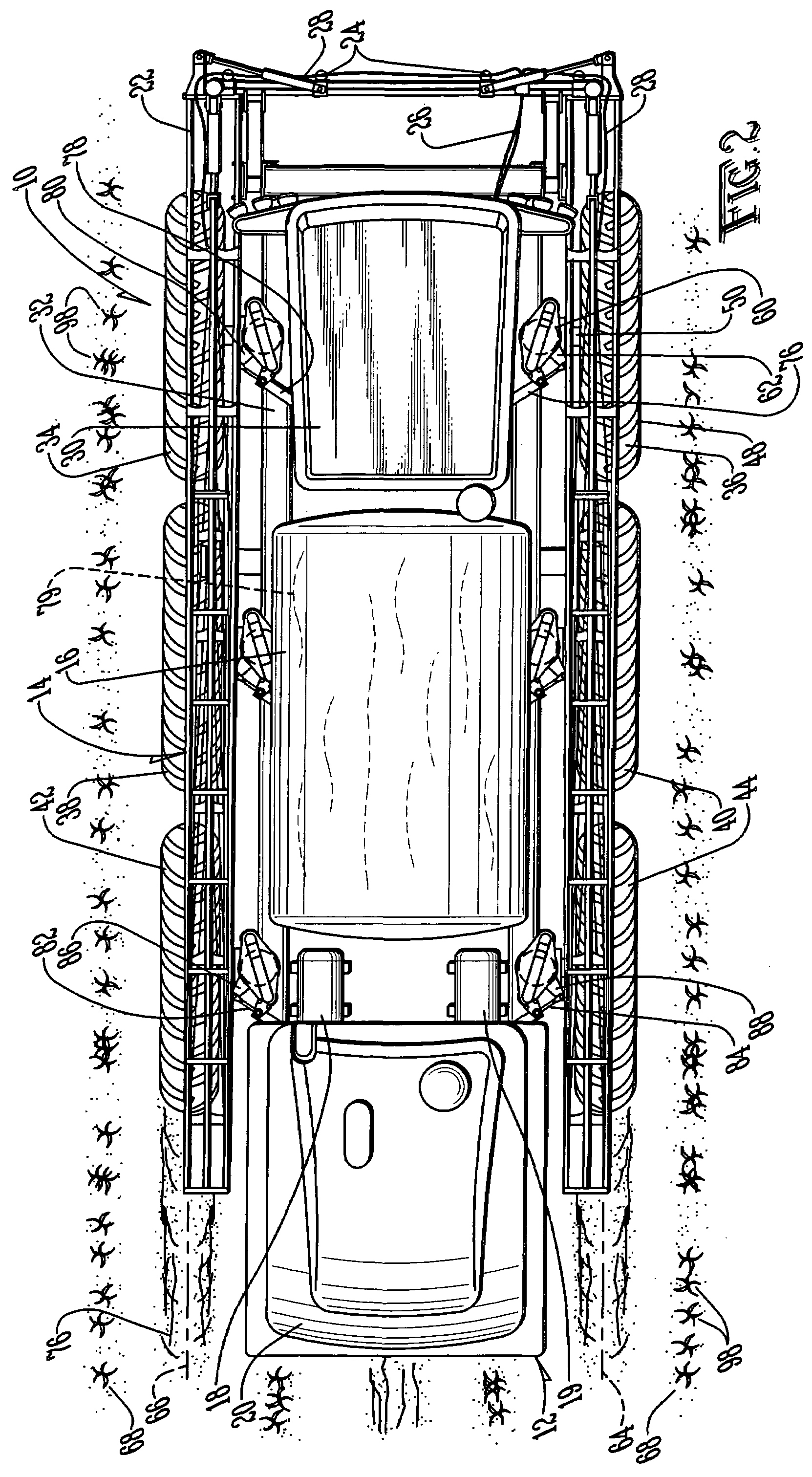

Agricultural sprayer

ActiveUS7669675B2Increase capacityRelieve pressureTank vehiclesLiquid fertiliser distributionSprayerAgricultural engineering

An agricultural sprayer is provided, having a plurality of wheels. By providing six wheels, a narrow overall wheel width may be maintained to allow for use of the sprayer in post-emergent crop spray applications. By providing six wheels, a greater amount of fluid may be provided on the vehicle without increasing soil compaction. By providing low soil compaction and a high fluid capacity, the applicator may be utilized in both pre-emergent and post-emergent situations, and may be utilized on wet or soft ground, where standard applicators may not be utilized.

Owner:HAGIE MFG

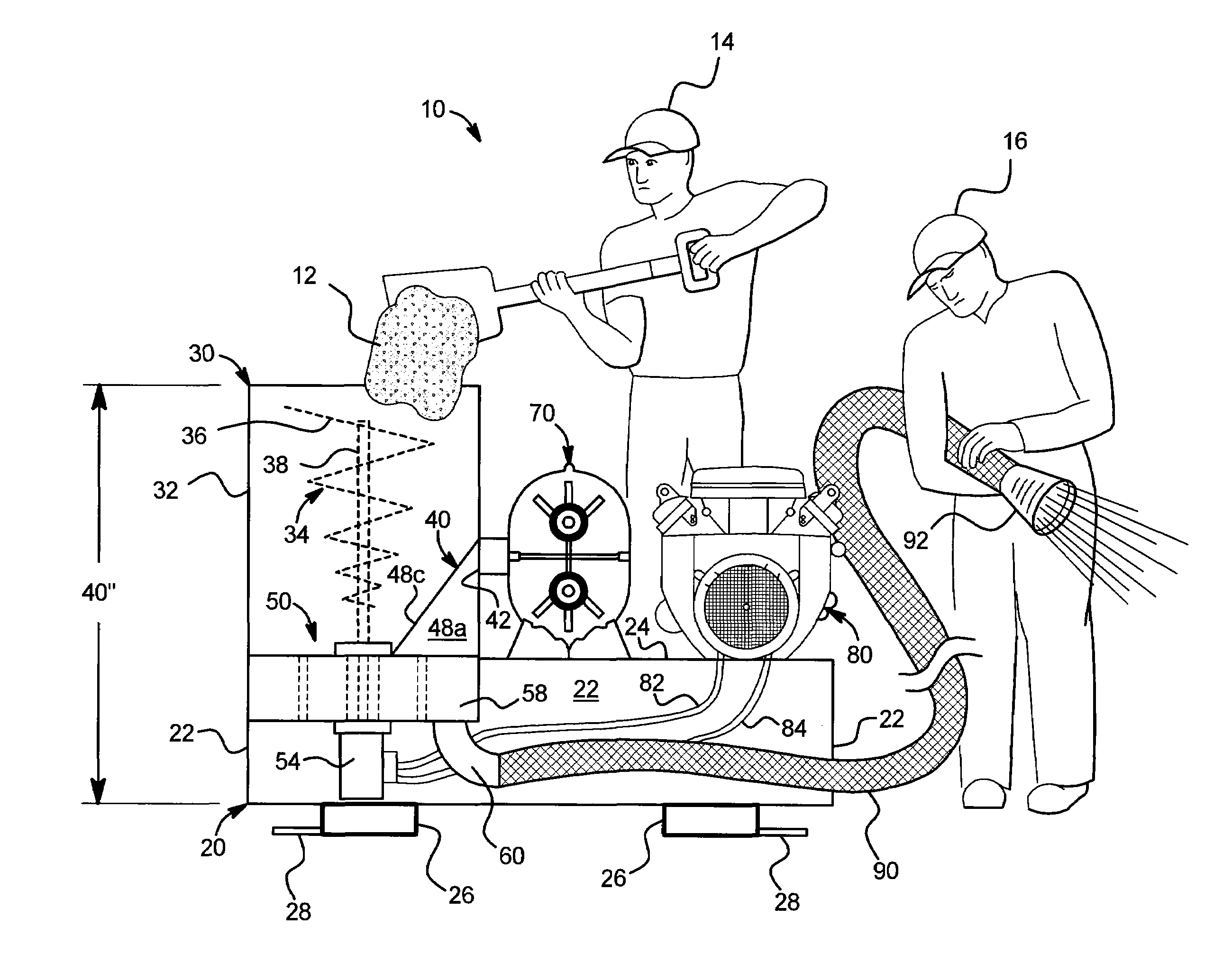

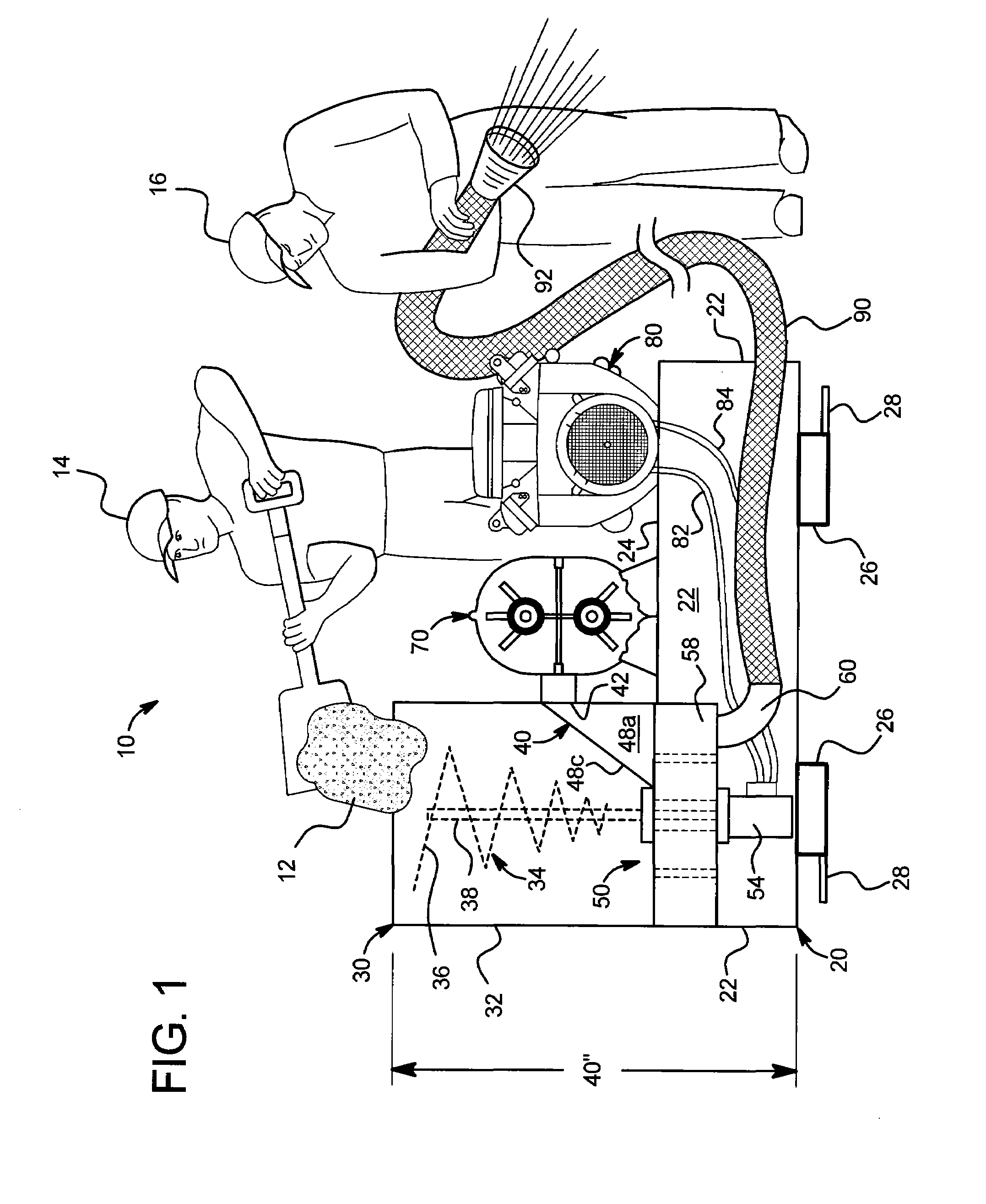

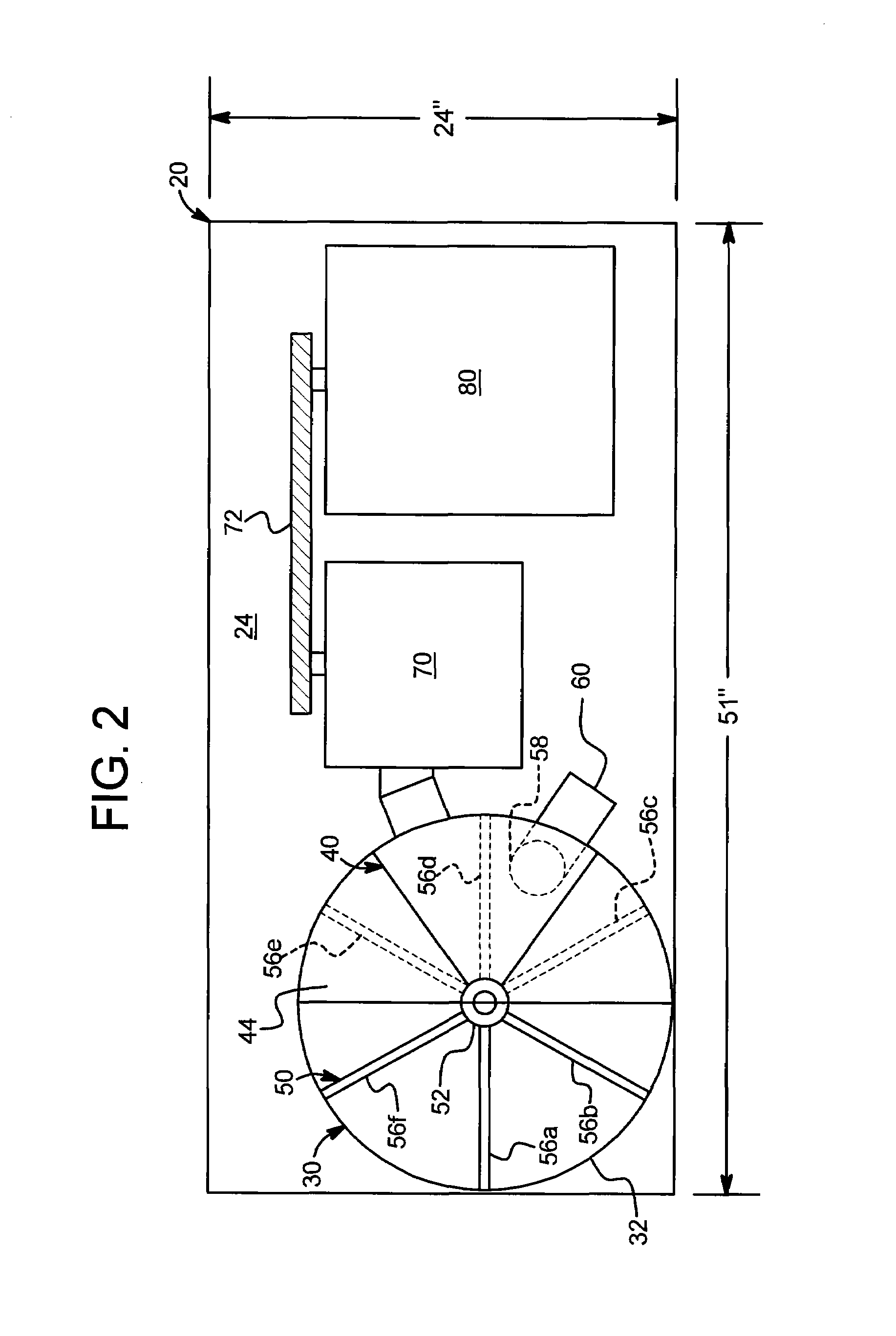

Portable pneumatic blower

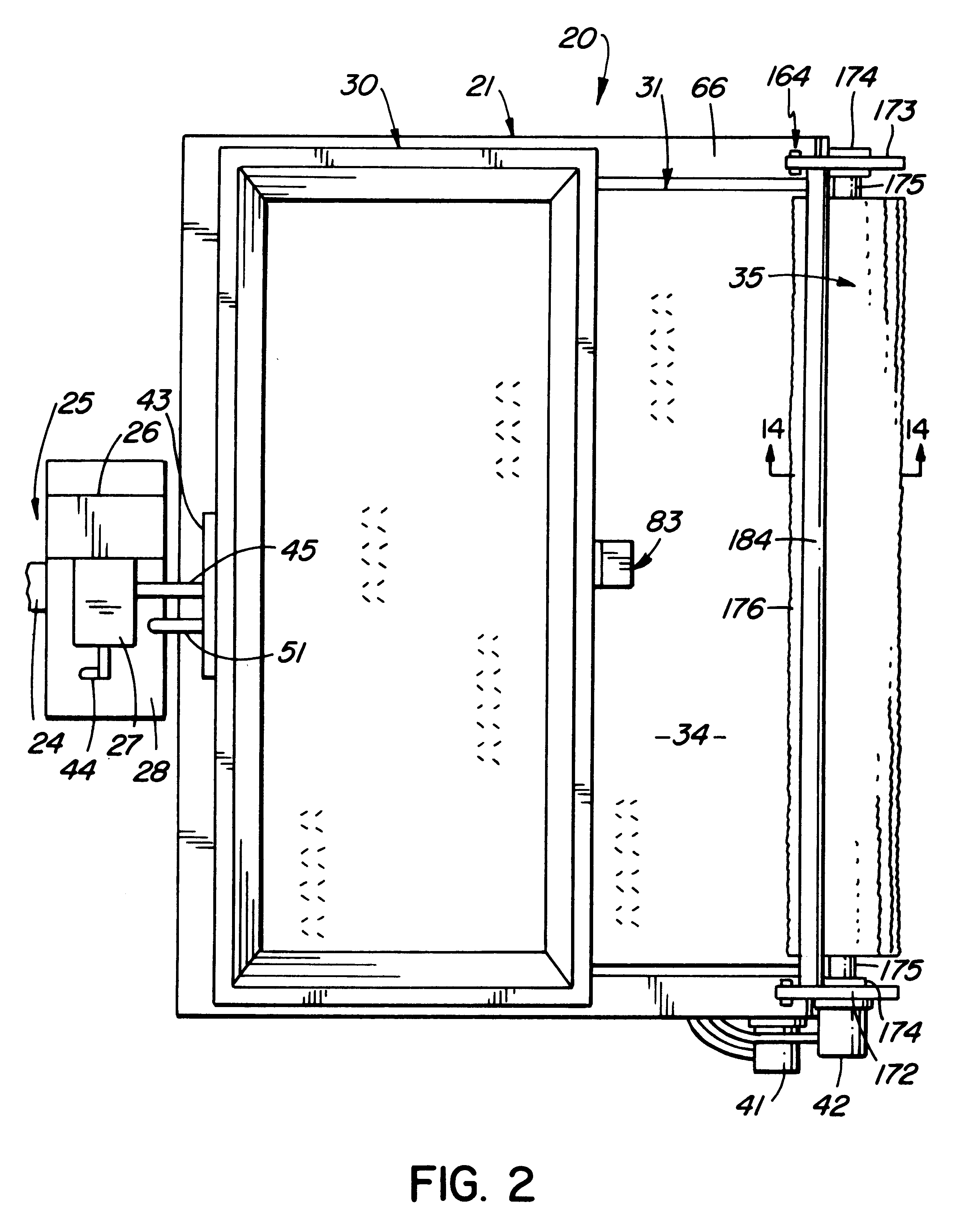

A portable unit for pneumatically blowing landscaping and / or building materials, such as bark, mulch, fertilizer, compost, wood chips, grass clippings, leaves, gravel / stone, straw, hay, sawdust and combinations thereof is provided. The unit is transportable by: a car trailer, truck trailer, garden tractor trailer; on stakes of a stake bed truck; by a three point hitch; by a forklift and any combination thereof. The unit includes a hopper having an integral airlock feeder in one preferred embodiment. The unit either includes an on-board power supply device, such as an engine, or provides connections for receiving power remotely.

Owner:FINN CORP

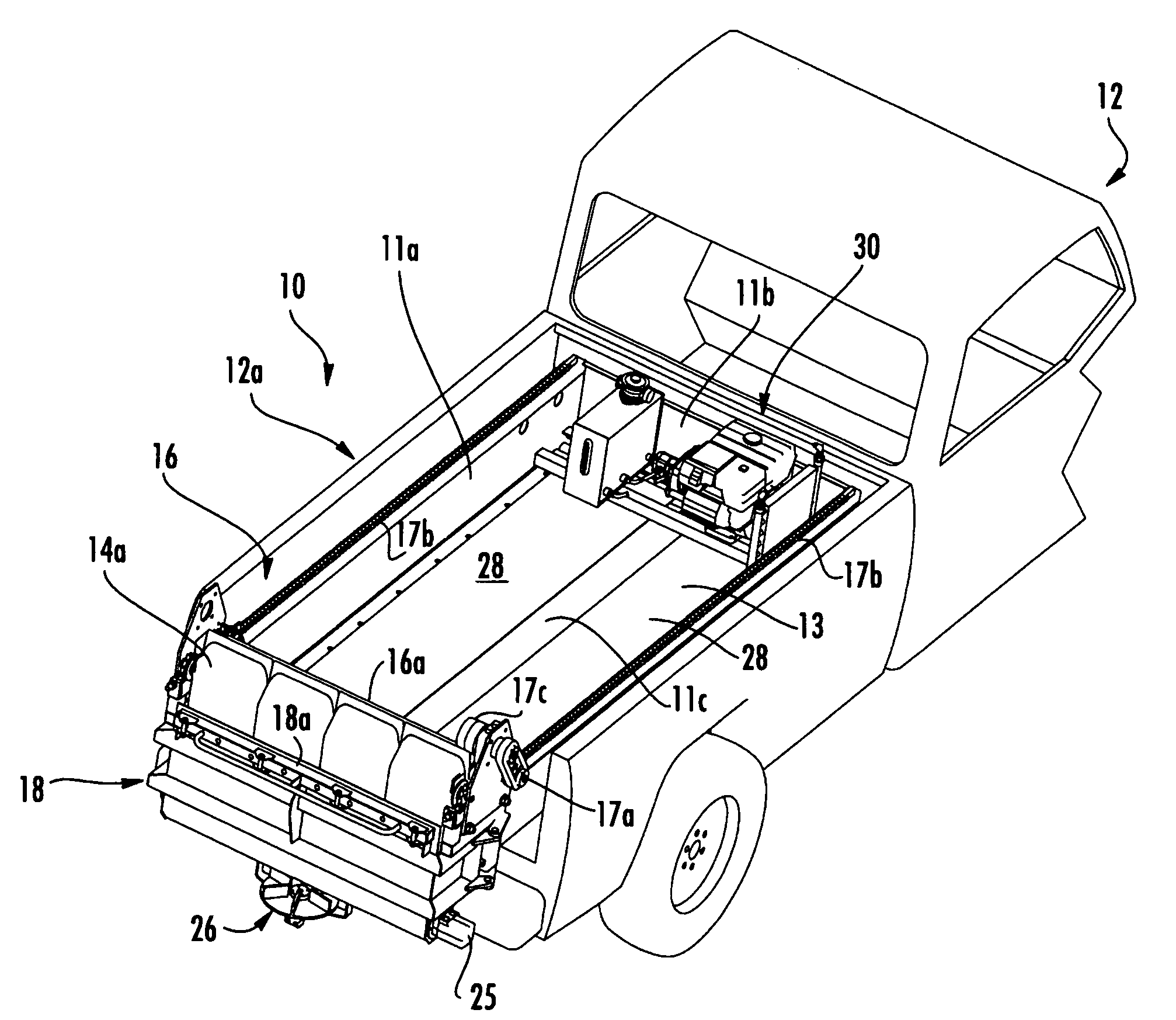

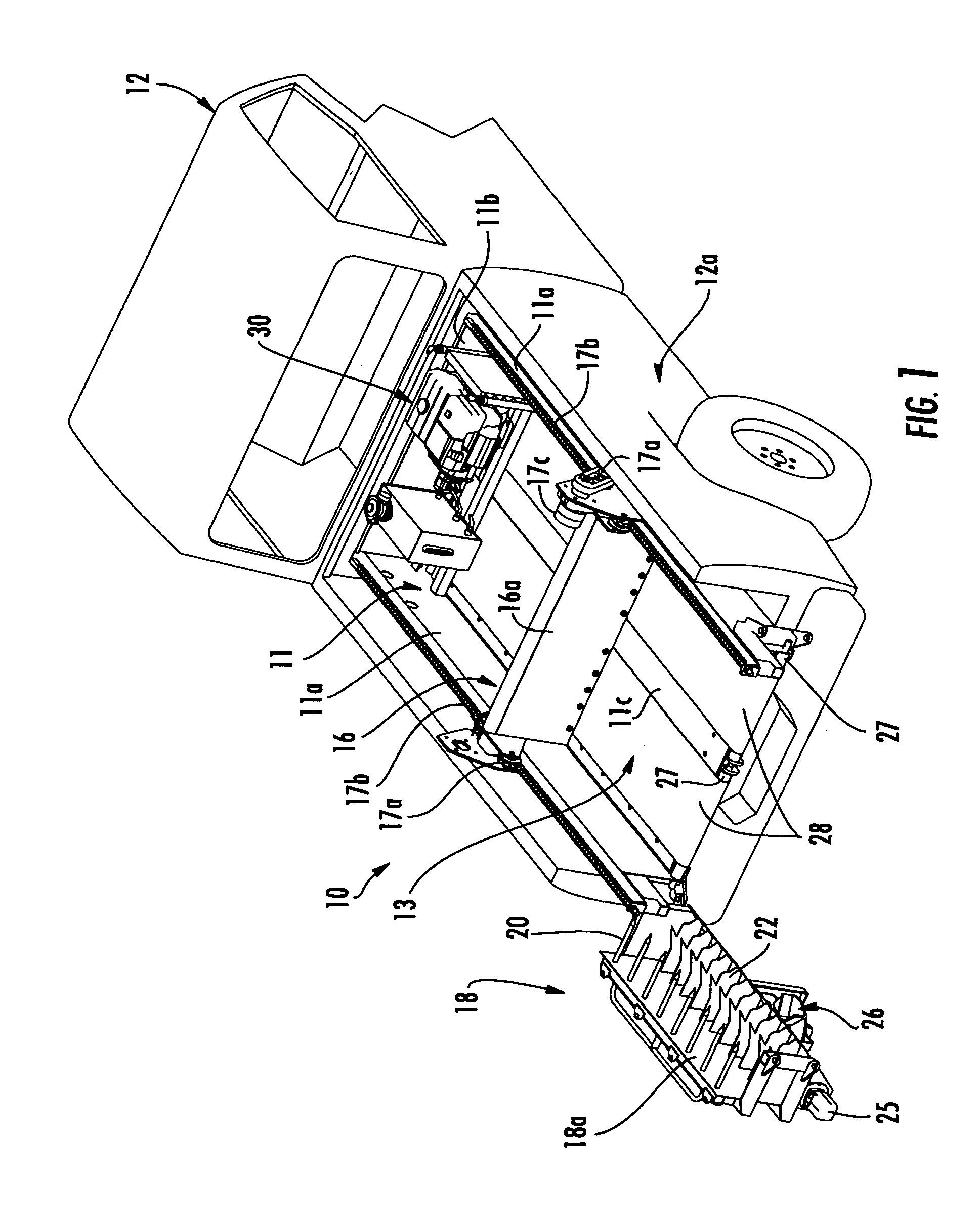

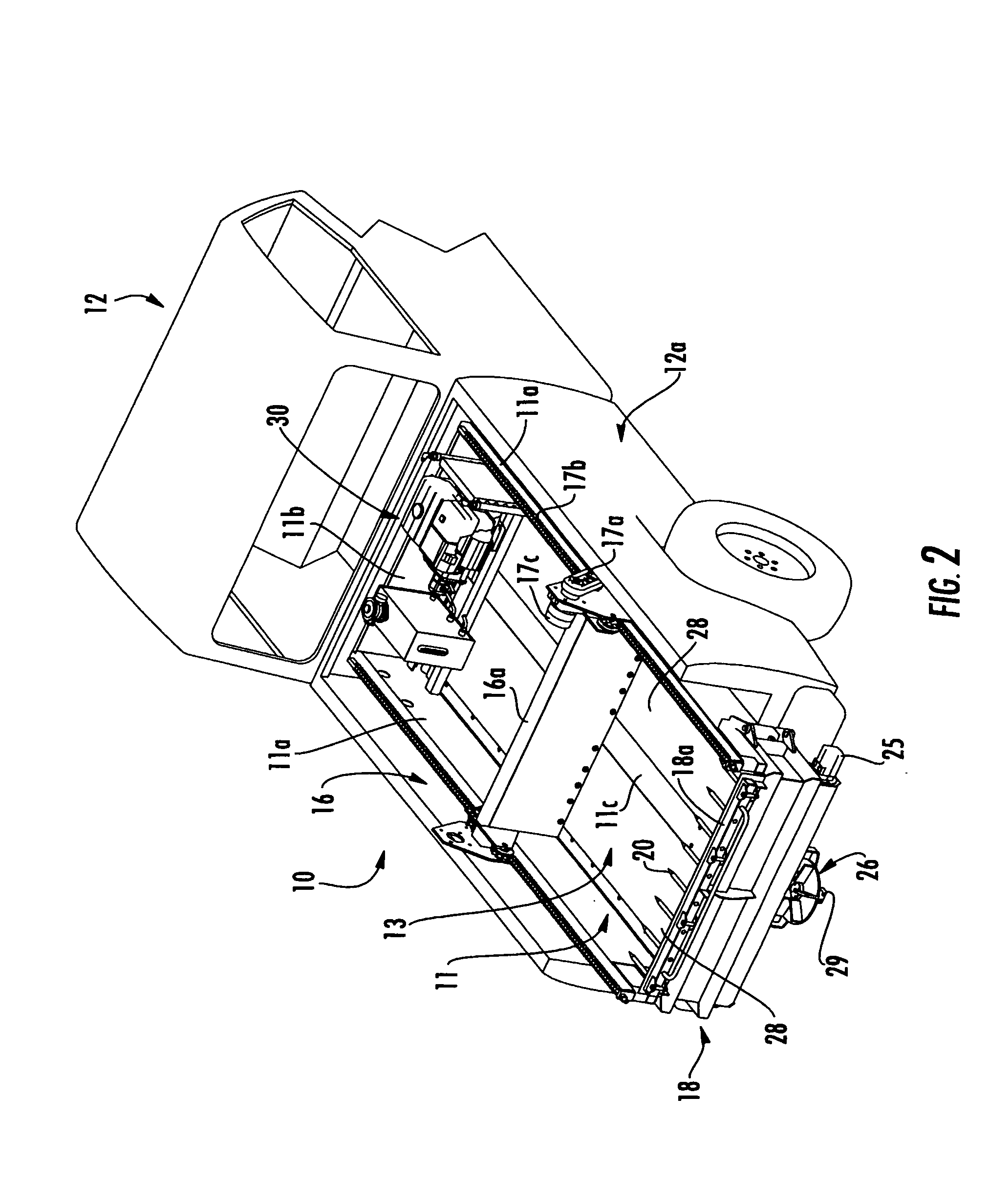

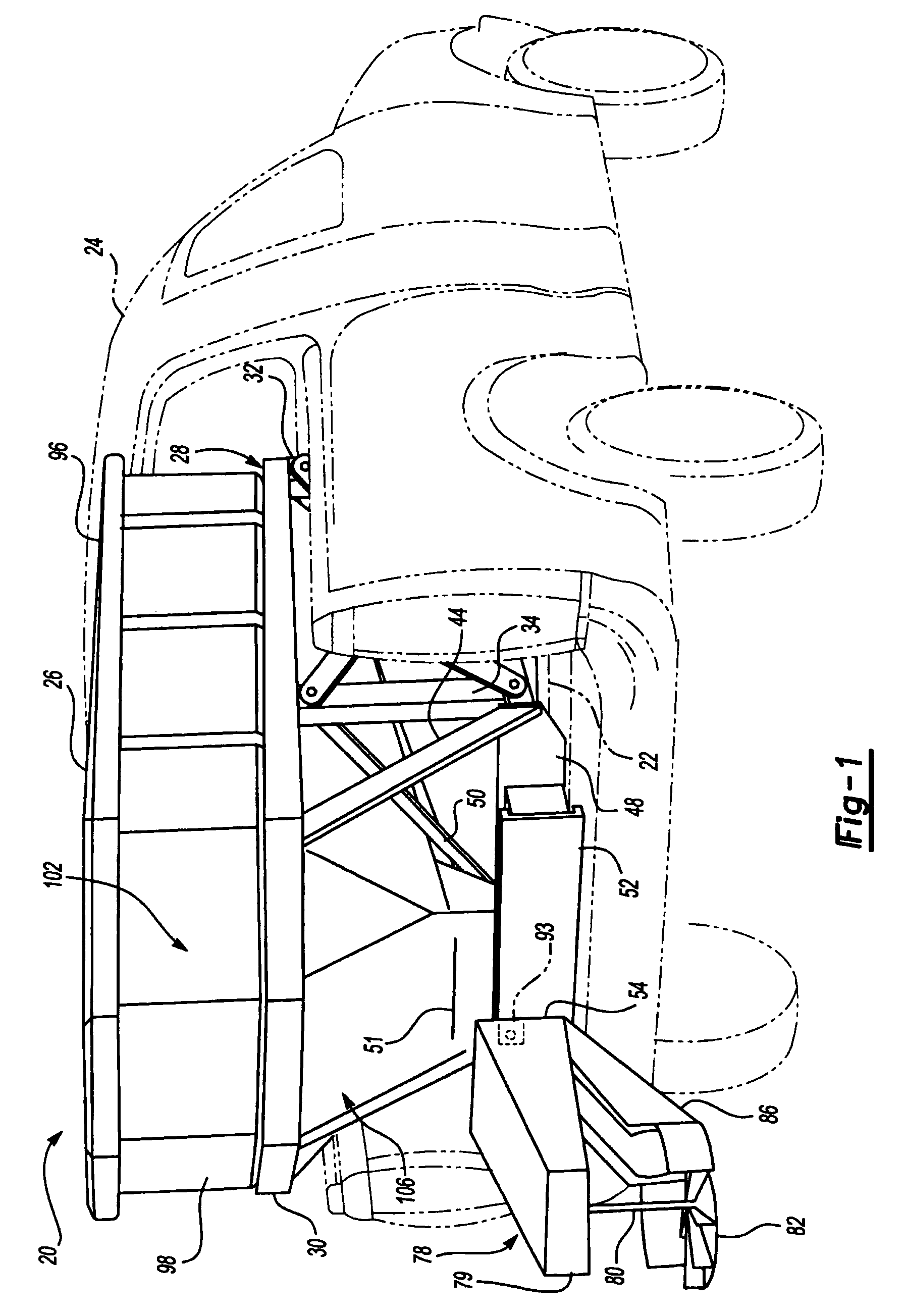

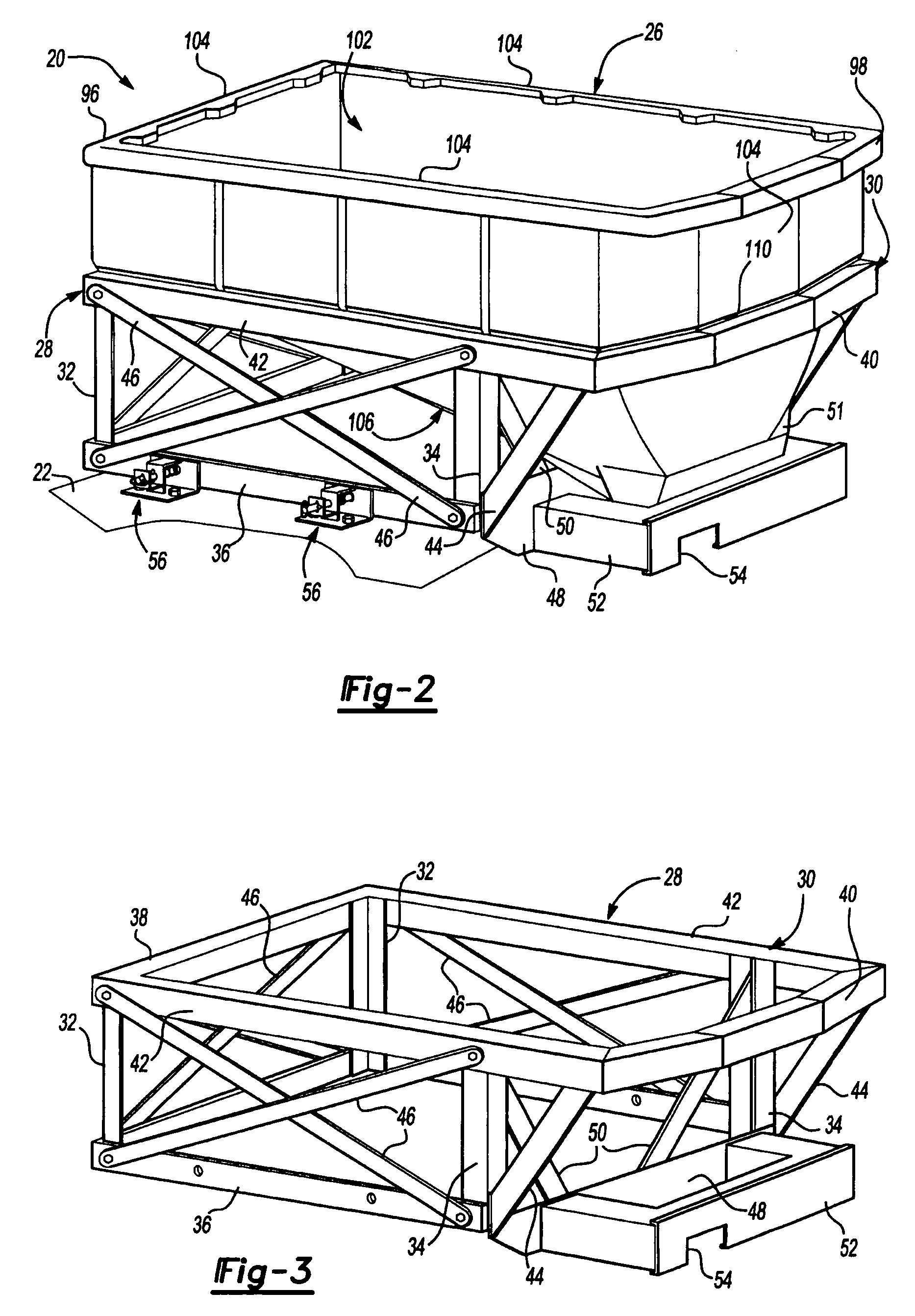

Combination dump and spreader apparatus

A vehicle is disclosed which includes a chassis and a combination body for selectively dumping and spreading materials. A hoist is provided which extends between the body and the chassis for pivoting the body. A conveyor assembly for selectively conveying materials from the body is also included. A tailgate is pivotally connected to the body and has an opening therein to permit material to be transported therethrough. A rear feed gate assembly for selectively covering the opening of the tailgate is provided. The vehicle includes a rear diverter chute that is operably arranged with the conveyor assembly to direct the materials to a rear spreader. A front feed gate assembly for selectively covering an opening of a front end of the body is provided. First and second side chutes are operably arranged with the conveyor assembly to direct materials to a side spreader and a surface, respectively.

Owner:HENDERSON PRODS

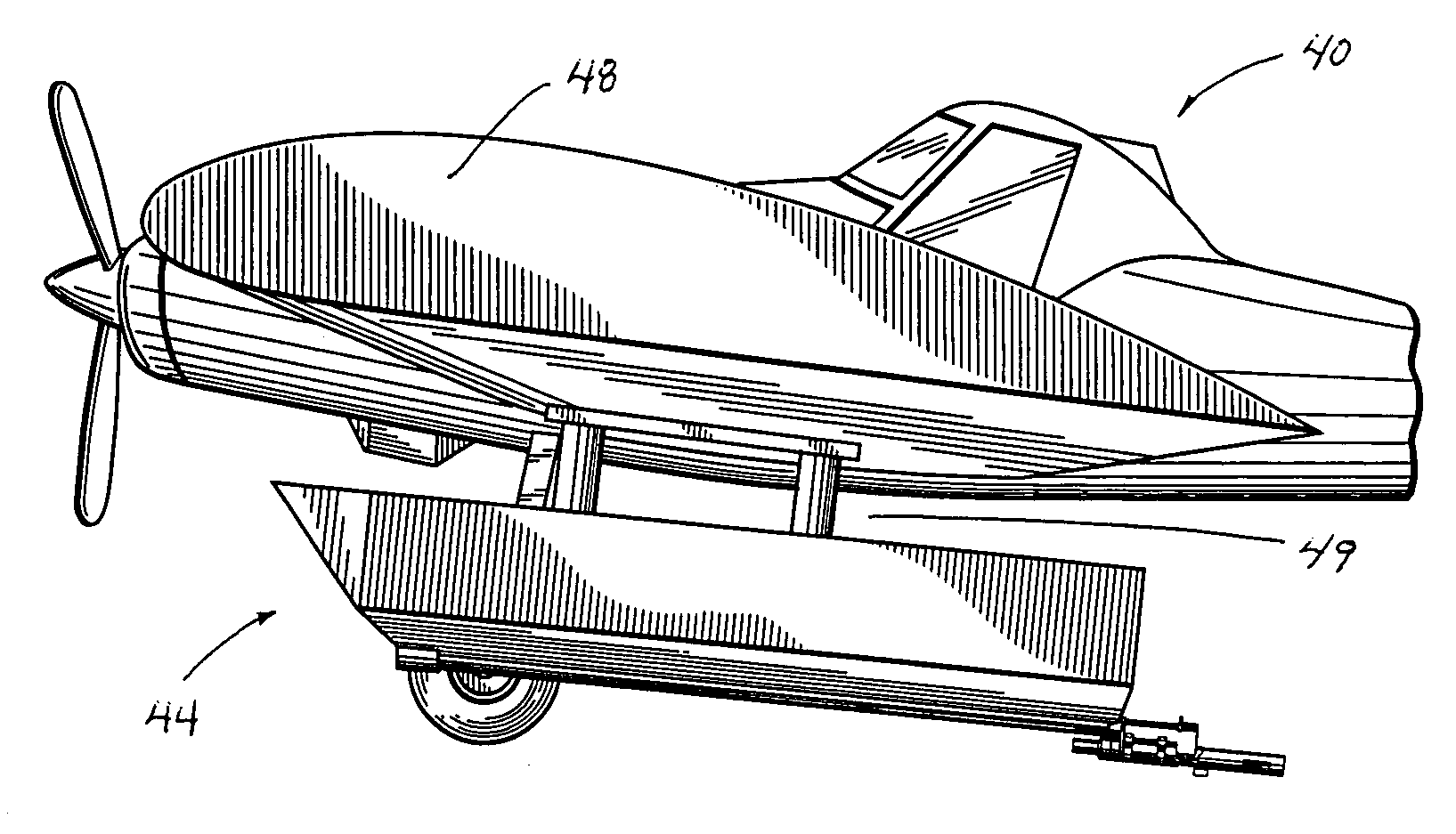

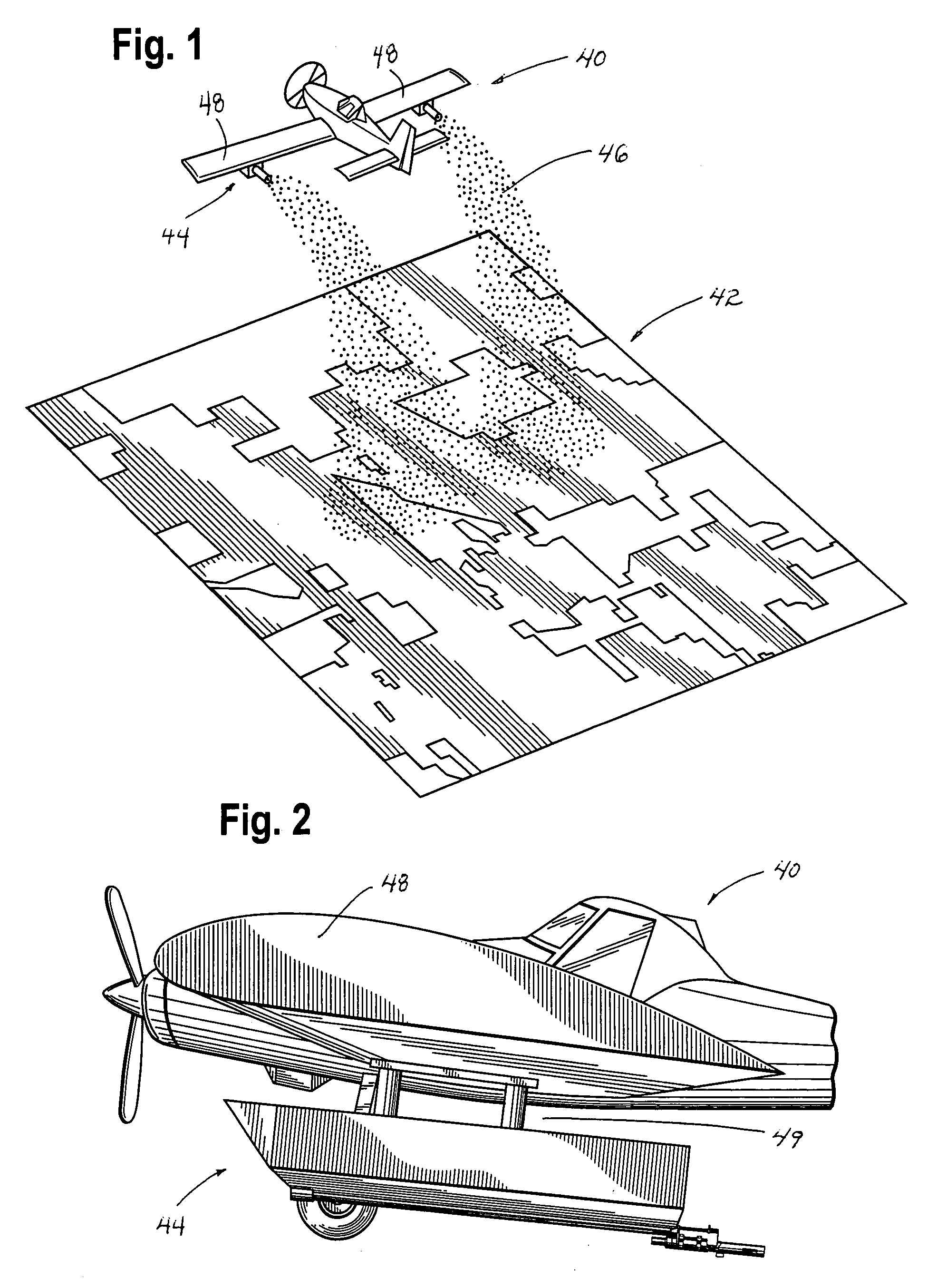

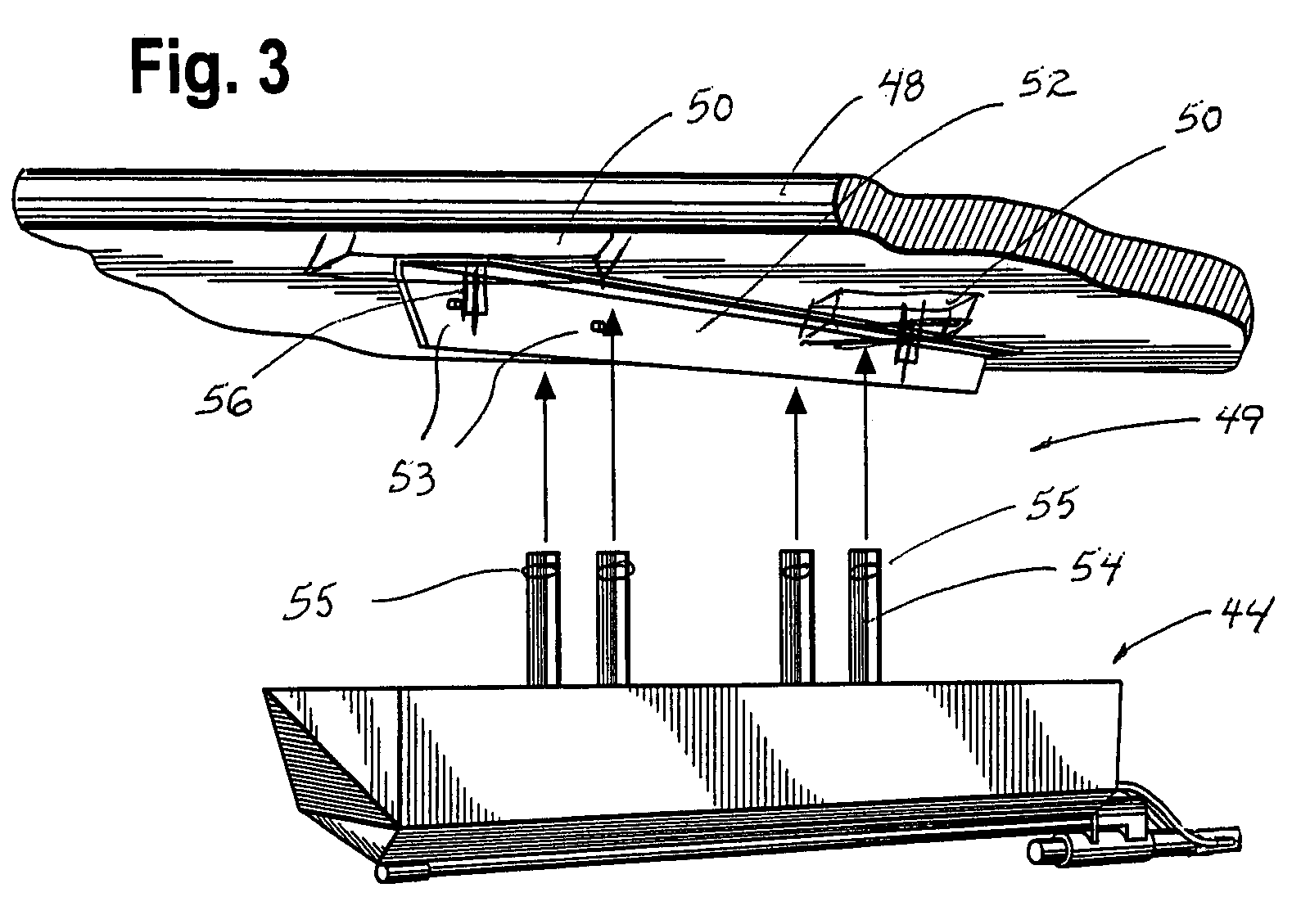

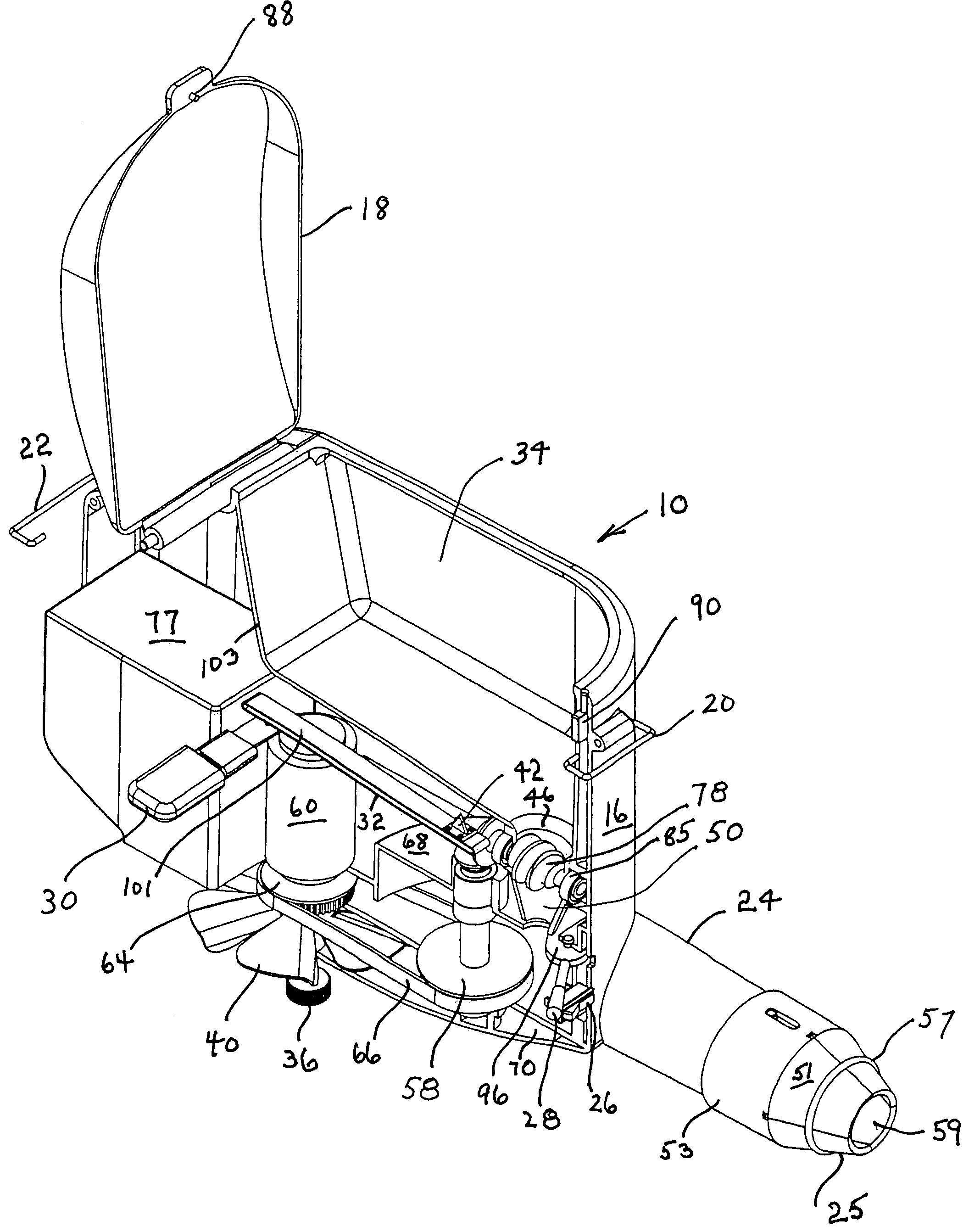

Aerial application dispersal system

An aerial application dispersal system that comprises an aerial vehicle and an aerial dispersal unit. The aerial dispersal unit provides an insect control substance, a flake auger, and a motor to drive the flake auger for transporting the insect control substance to a dispensing chamber. The aerial dispersal unit also provides a glue substance, a pump, and a motor to drive the pump for transporting the glue substance from a storage container to the dispensing chamber for mixing with the insect control substance. The dispensing chamber is provided with a motor for forcing the insect control substance mixed with the glue substance out an exit portal for disbursement over the designated area. A control box, control switches, global positioning satellite system, and dispersal unit operator interface are also provided for automatically regulating the mixing and dispensing rate of the insect control substance and glue substance in relation to the ground speed of the aerial vehicle for maintaining a constant, uniform disbursement of a bonded substance over a designated area.

Owner:PETERSEN SCOTT

Portable particle spreader/blower

InactiveUS7281675B2Convenient and comfortable and efficient useMost effective immediate use of materialHops/wine cultivationWatering devicesImpellerCommon space

Owner:ELROD MARCOS +1

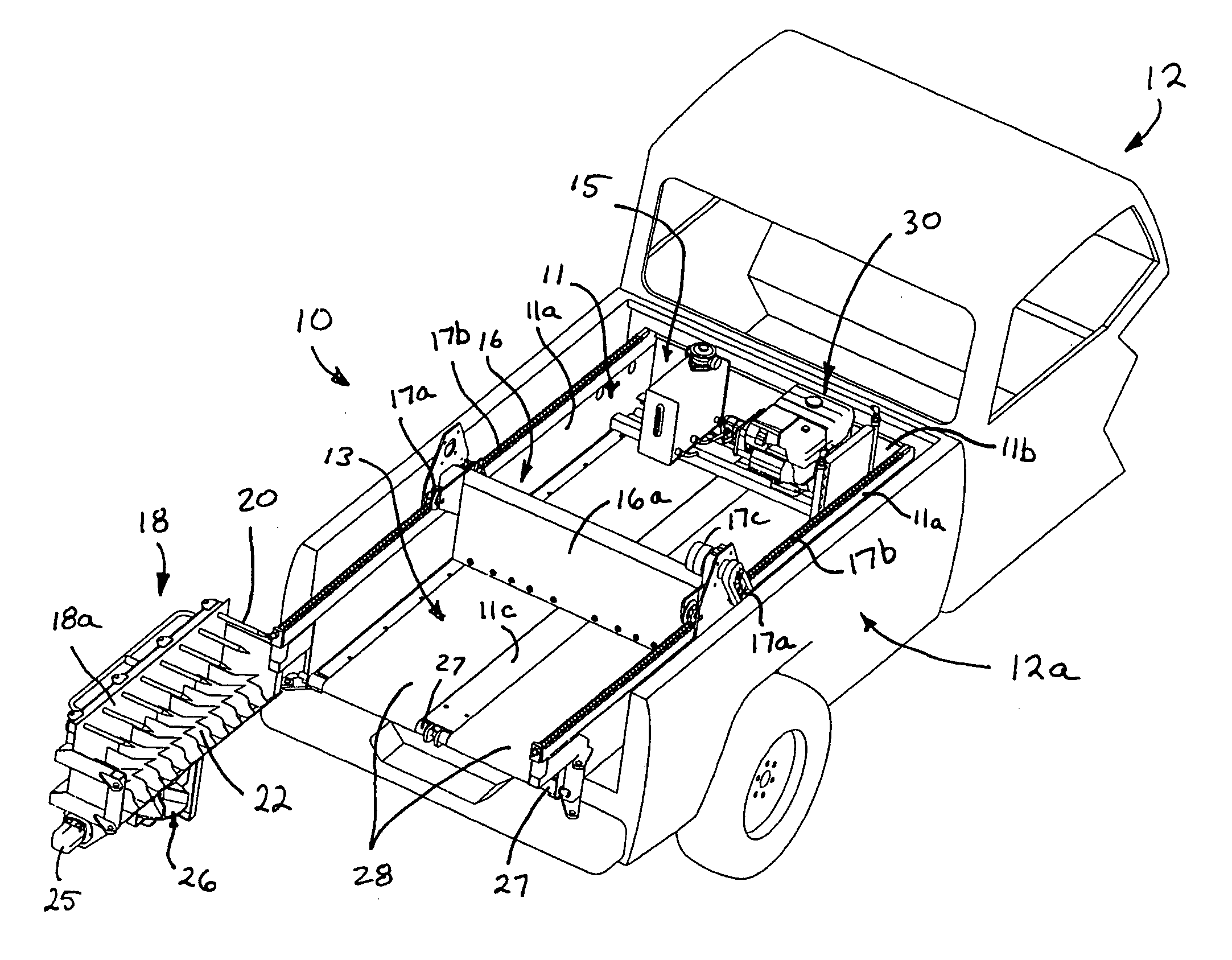

Self unloading pull-type trailer

An improved self-unloading spreader has a front end, a back end, and sides defining walls of a container for holding material. The container has at least one opening in one of the walls through which material can move. Inside of the container, longitudinally disposed between the front end and the rear end, is an auger that can move material in the container to and through the opening. Also inside of the container, adjustably positioned above the auger, is an adjustable height baffle to control the amount of material the auger has available to move. Outside of the container, adjacent to the opening, is a transversely mounted conveyer belt for spreading material that flows through the opening. An hydraulic system powers the auger and allows the hydraulically powered auger to either move material towards the opening or away from the opening. The auger, in combination with the adjustable height baffle, controls the rate at which material is provided to the conveyer system. A power-take-off system transfers power to a gear box system that allows bi-directional movement of the transversely mounted conveyer belt so the conveyer system can spread material to either side of the spreader. The speed of the power-take-off system controls the distance to which the conveyer system throws the material to be spread.

Owner:ELLING BRAD

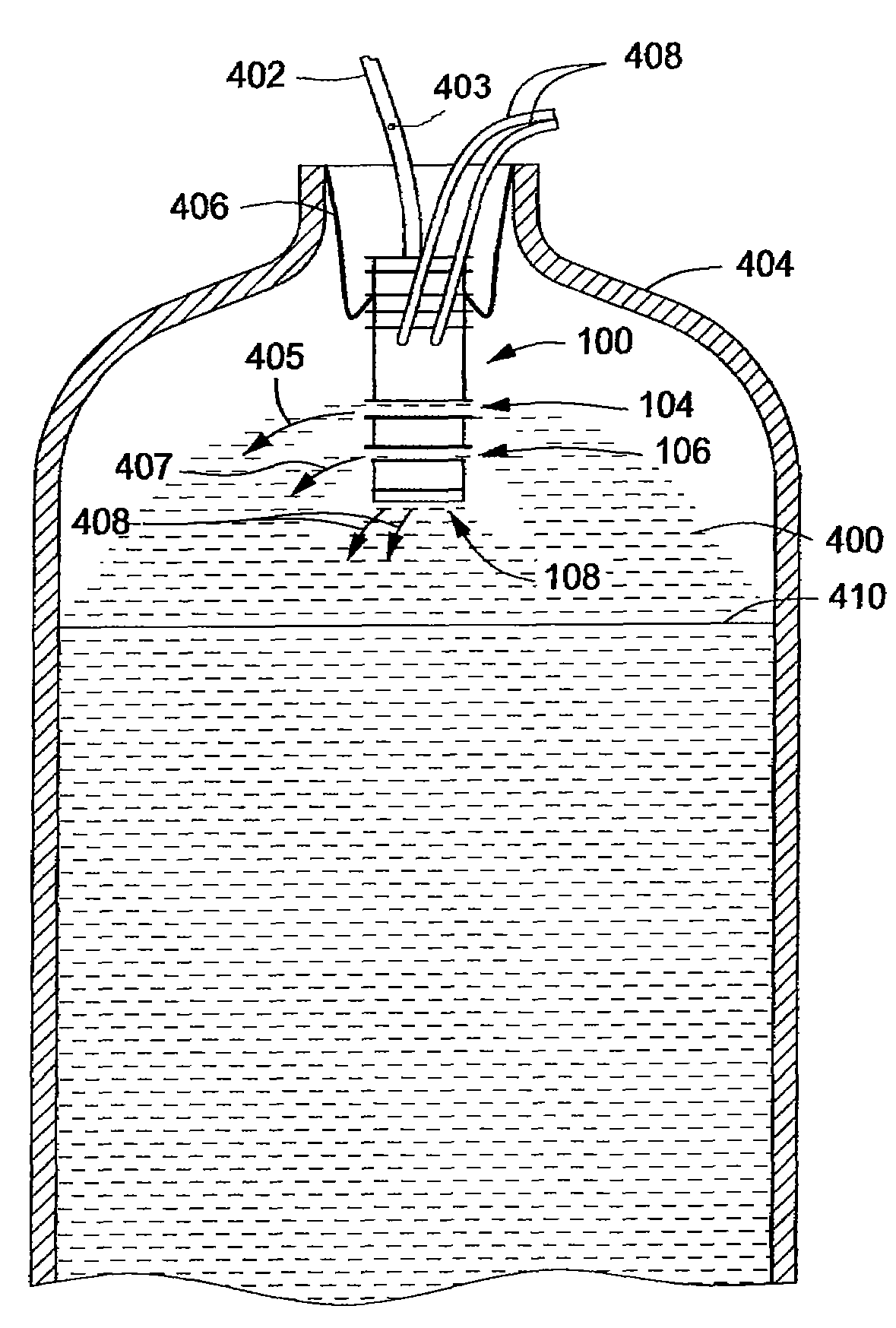

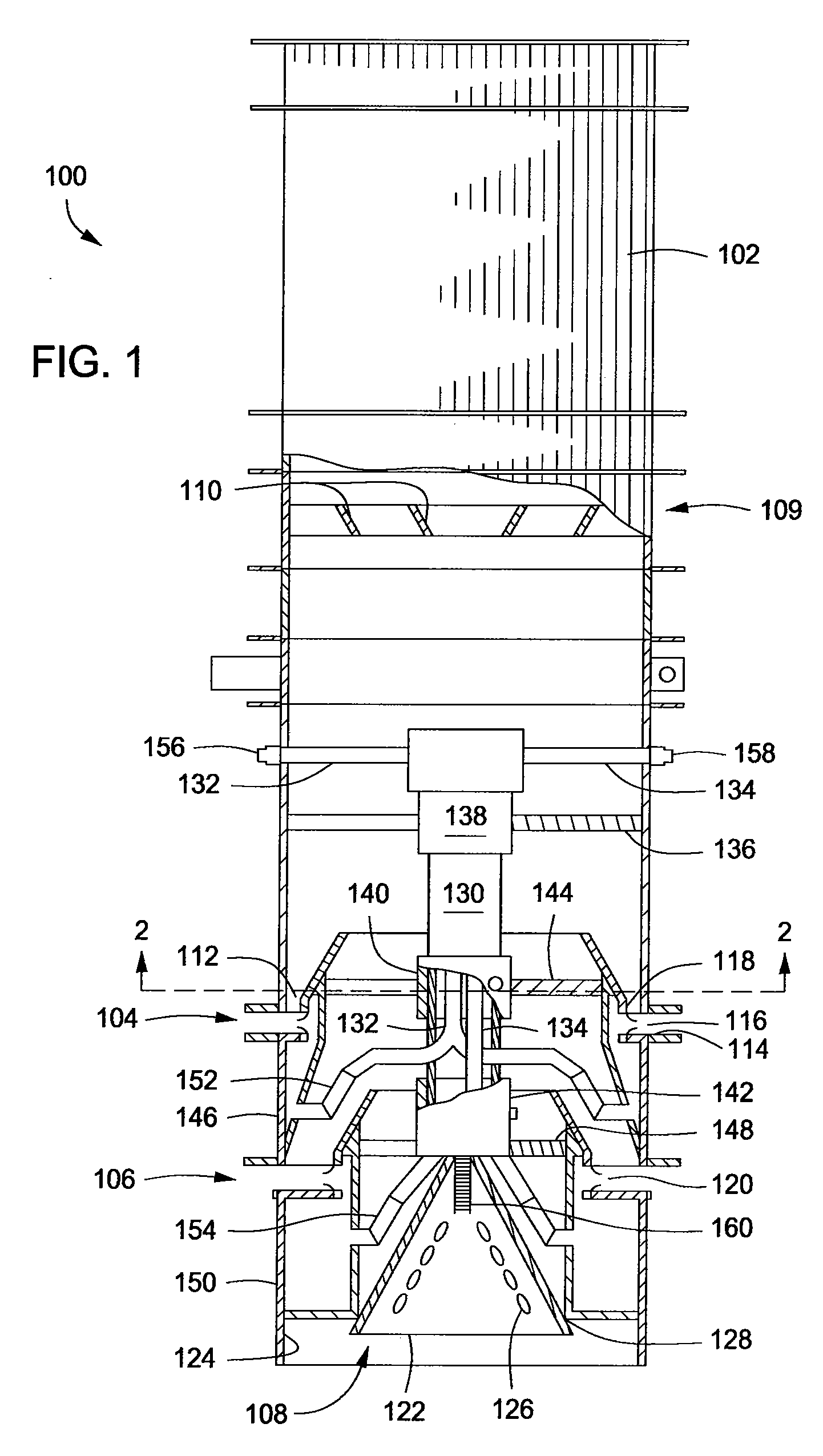

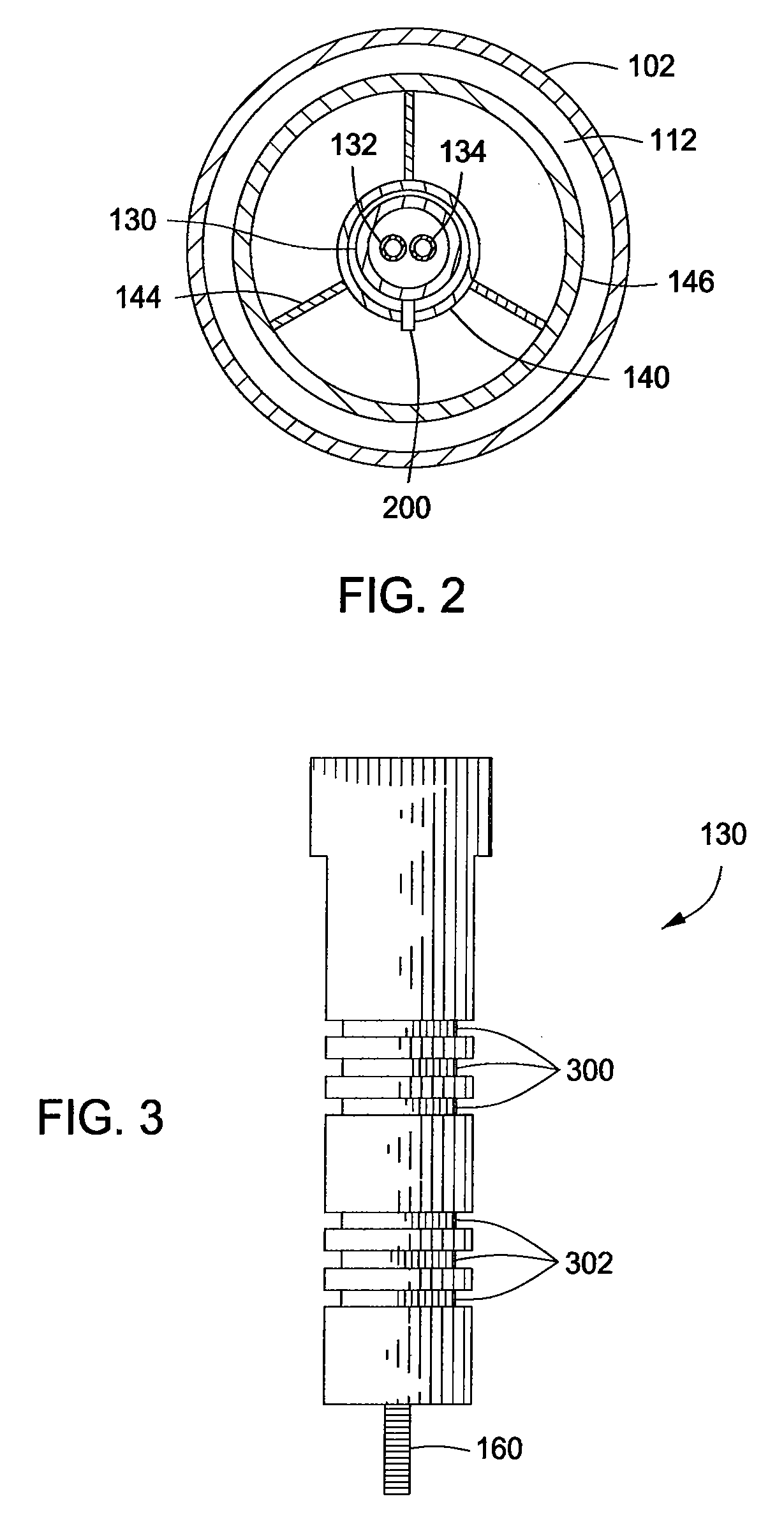

Methods and apparatus for dense particle loading

Methods and apparatus enable filling a receptacle with solid particles introduced into the receptacle with a controlled flow rate and pattern of distribution of the particles. A pneumatic loader may dispense the particles into the receptacle with ability to adjust the flow rate and pattern of distribution of the particles. Further, a laser sensor may enable detecting a topographic level of the particles loaded by movement of the laser sensor around a point to make linear measurements across the reactor at multiple angularly offset orientations.

Owner:WINDLASS METALWORKS +1

Truck bed mounted spreader

InactiveUS7540436B2More responsiveLight-weightSelf-acting watering devicesFertiliser distributersEngineeringTruck

A spreader assembly for spreading a material and for mounting in a bed of a truck is disclosed. The assembly includes a hopper and a frame for supporting the hopper in the bed of the truck. The hopper has a length extending between a front end and a rear end sized for placing in the bed of the truck to hold material for spreading and has an outlet spout with an opening for discharging material therefrom. The hopper and the frame are each formed from a thermoplastic material.

Owner:TRYNEX INT

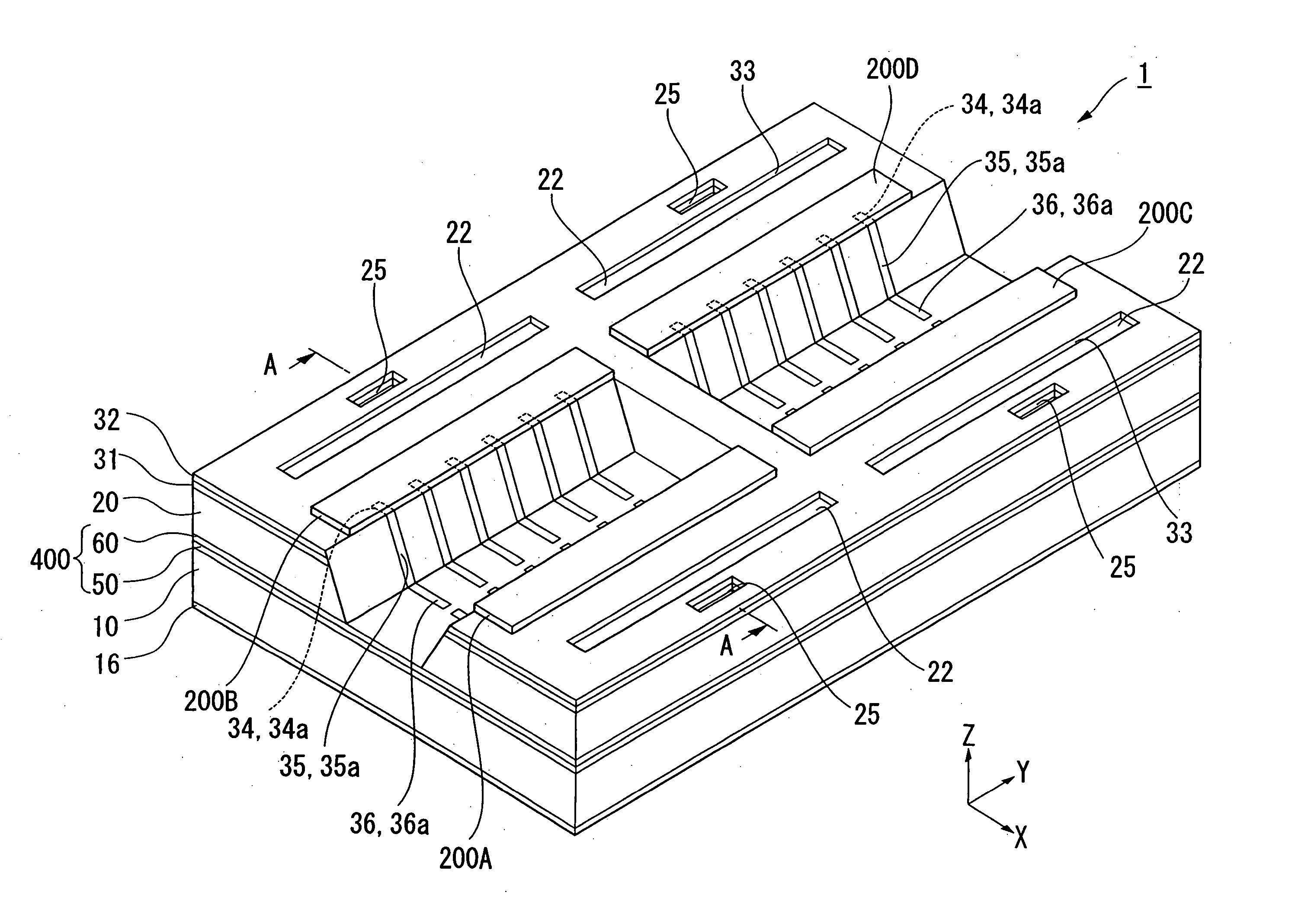

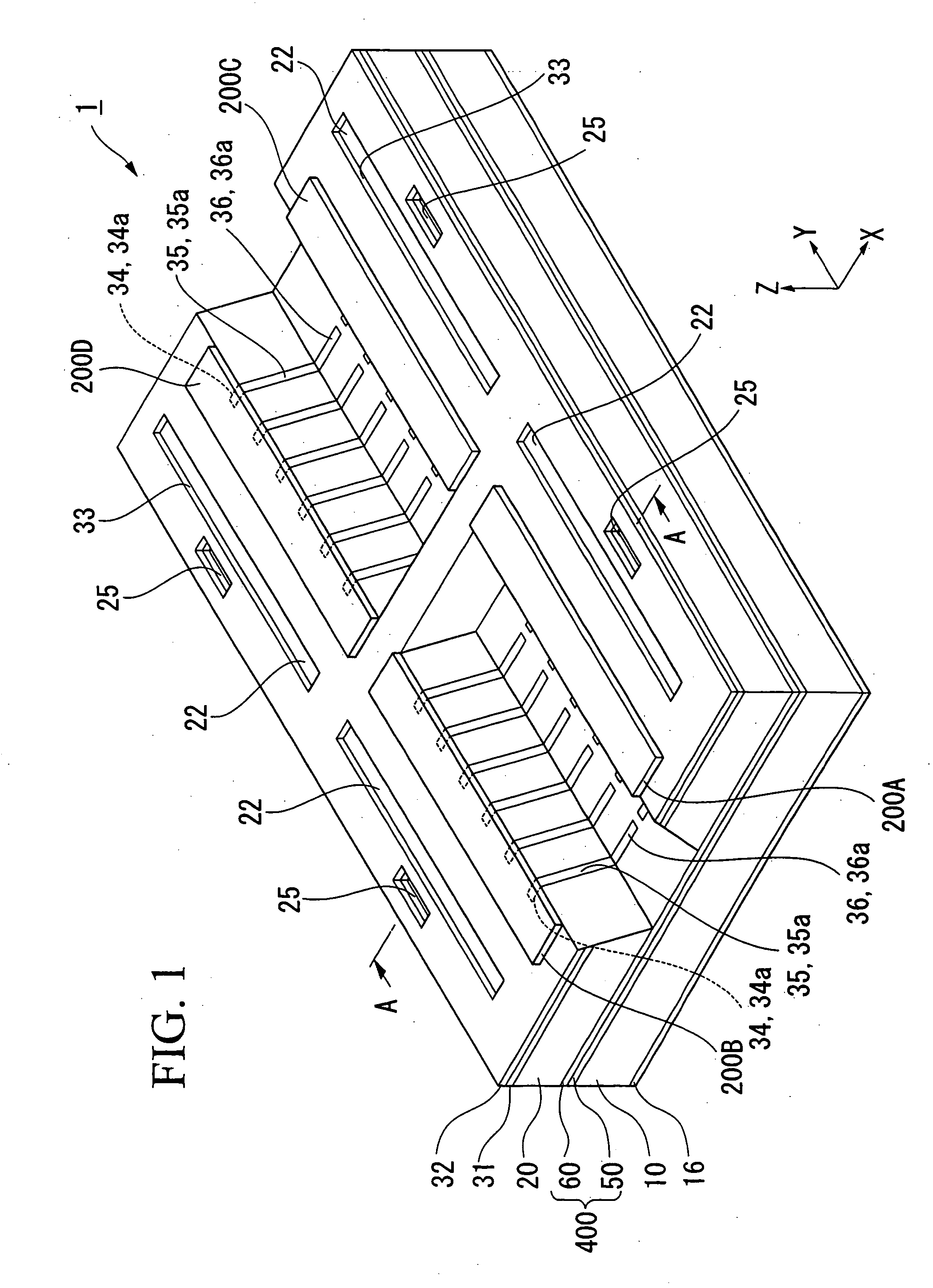

Mounted structure, liquid droplet ejection head, liquid droplet ejection apparatus and manufacturing method

A liquid droplet ejection head that ejects liquid droplets through deformation of a driven element, includes: a first substrate having a pressurizing chamber with a nozzle aperture that ejects liquid droplets, and a first surface on which is formed a first wiring electrically connected to the drive element; a second substrate disposed on the first surface of the first substrate and covering the driven element, the second substrate having a second surface and a side surface, the second surface facing in a same direction as the first surface of the first substrate and on which is formed a second wiring, the side surface on which is formed a third wiring that combines the first wiring and the second wiring; a semiconductor element disposed on the second surface of the second substrate, and which drives the driven element; and plating that electrically connects the first wiring, the second wiring, the third wiring, and a connection terminal of the semiconductor element.

Owner:SEIKO EPSON CORP

Spreader assembly with surface-clearing blower

InactiveUS20100133365A1Easy to useLess operator forceFertiliser distributersSowingForced-airIce melt

A spreader assembly with surface-clearing blower includes a rotary or broadcast spreader mounted on a frame for distribution and deposition of granular material in an area proximate the spreader assembly, a blower also mounted on the frame and with one or more ducts or hoses for conveying forced air to a surface proximate the spreader assembly to be cleared of deposited material. Granular material may include seed, ice-melt compound or salt, or fertilizer or other lawn or garden amendment or additive. The frame is mounted on the powered drive unit of a walk-behind mower to replace the mower deck.

Owner:MASTER MFG

Distribution assembly for particulate material

InactiveUS6883736B1Rapidly and efficiently distributeOvercome disadvantagesWatering devicesFertiliser distributersForced-airEngineering

An assembly for distributing particulate material comprising a blower assembly which is preferably removably mounted on a mobile platform and structured to generate a forced flow of air along a flow path and through a manifold assembly connected to a supply of material being distributed. The manifold assembly includes a receiving segment incorporating a Venturi section facilitating the entrainment of the material into the forced air flow passing through a discharge conduit preferably having an extended length to facilitate distribution of the material to a plurality of locations in a variety of different environments. A vent assembly is provided to relieve back pressure from within the discharge conduit, which may be created due to its extended length.

Owner:BLATT MICHAEL SCOTT

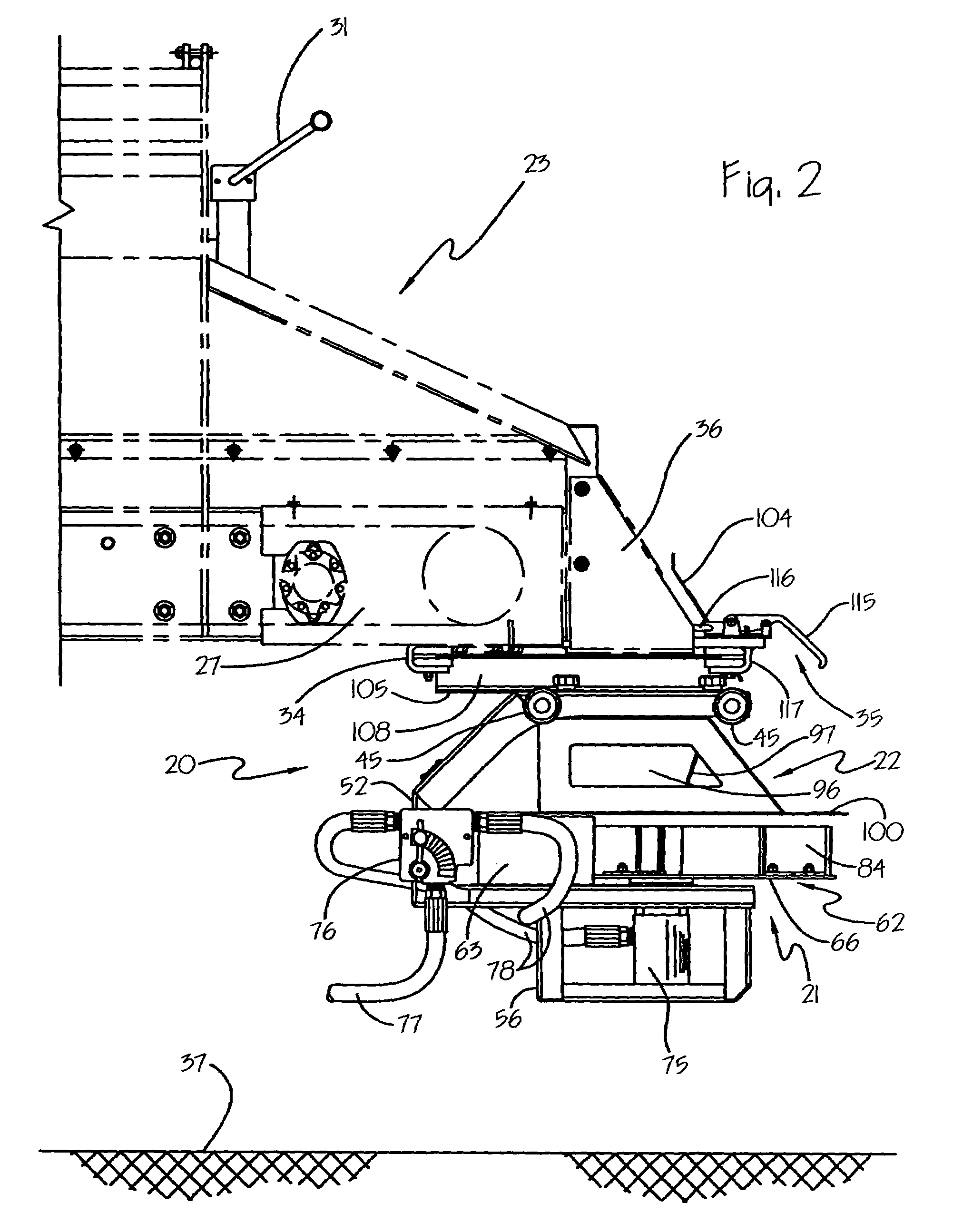

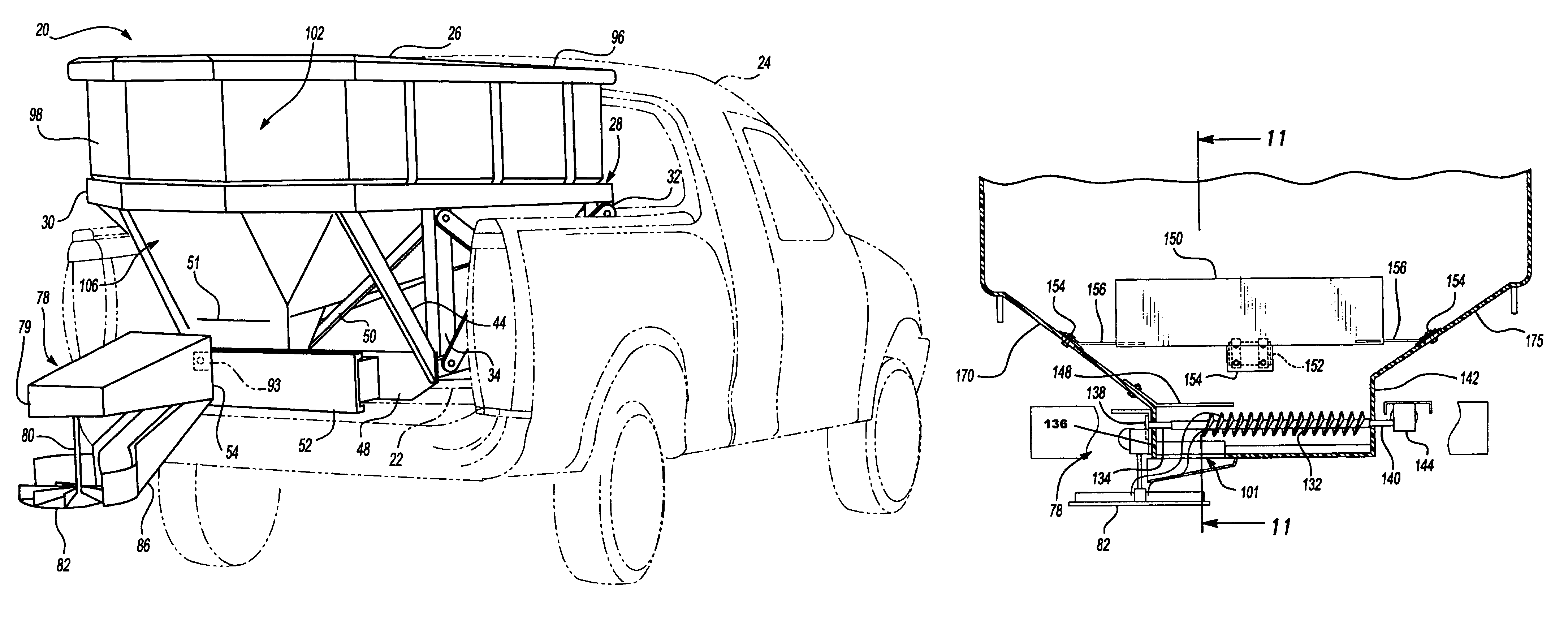

Material handling device for vehicle

InactiveUS20060255189A1Easy loadingFacilitate handling of materialVehicle with living accommodationRoads maintainenceEngineeringMaterials processing

A material handling device for a vehicle includes a receiving portion for receiving material, a material moving system operable to move material along the receiving portion, a material processing device attachable at a rear of the receiving portion, and a power source. The receiving portion is configured to fit at a vehicle bed, and is removably positioned at a vehicle bed. The material handling device may be movably supported at a support surface to ease installation and removal of said material handling device at the vehicle. The material processing device is operable to dispense material from within the receiving portion to a location external the receiving portion and / or collect material from a location external the receiving portion and dispense the collected material into the receiving portion. The power source may provide power to the material processing device and / or the material moving device.

Owner:ROCKIT

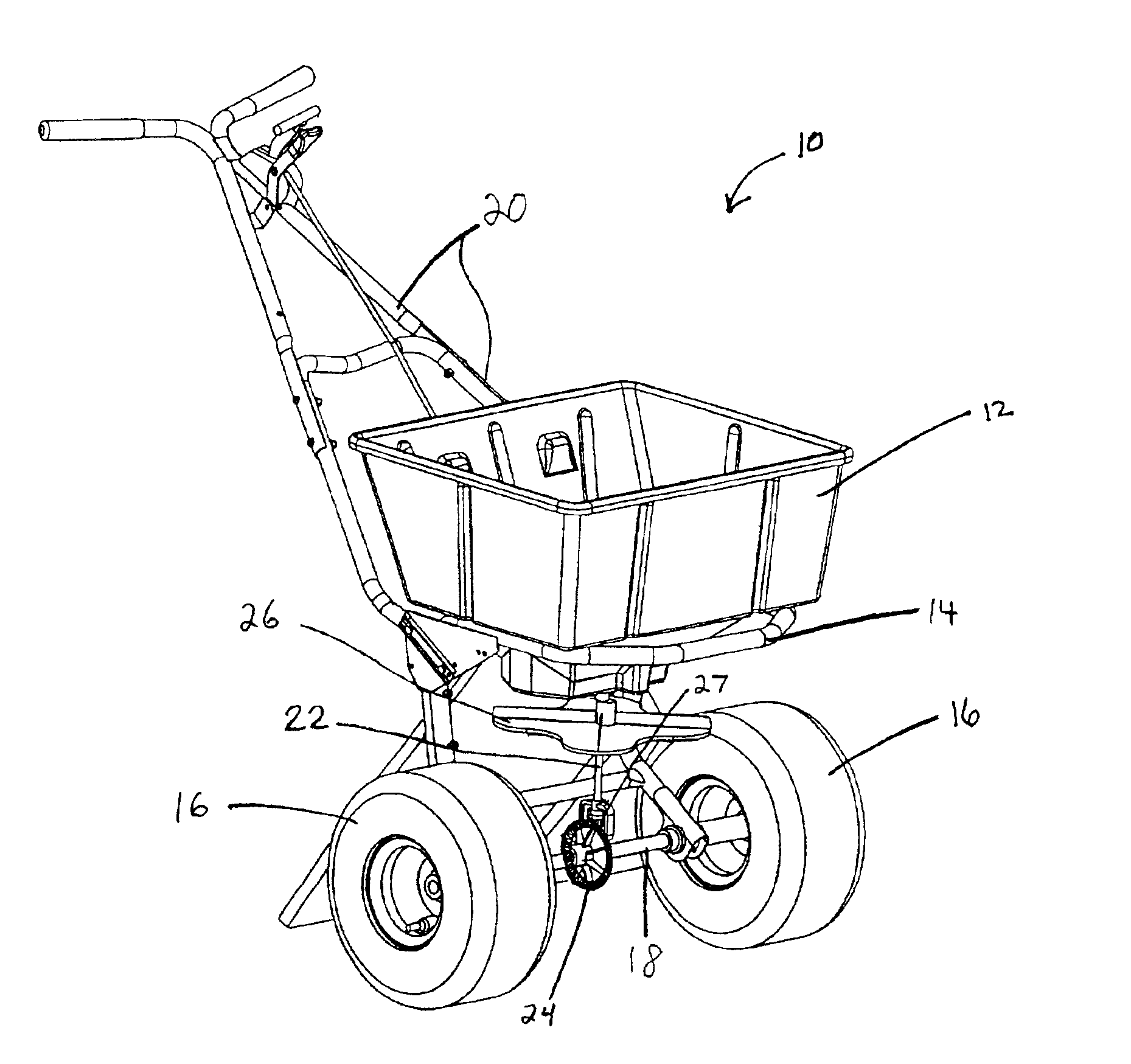

Broadcast spreader

InactiveUS8474735B2Effective controlSliding movement of the gateFertiliser distributersCentrifugal wheel fertilisersDistribution patternEngineering

A broadcast spreader provides for effective control of the flow of granular material to a rotating fan through use of a gate assembly in combination with an auger assembly. The broadcast spreader further includes a means for directing the granular material onto the fan, thus allowing for the shifting of the distribution pattern of the granular material from side to side.

Owner:BRINLY-HARDY COMPANY

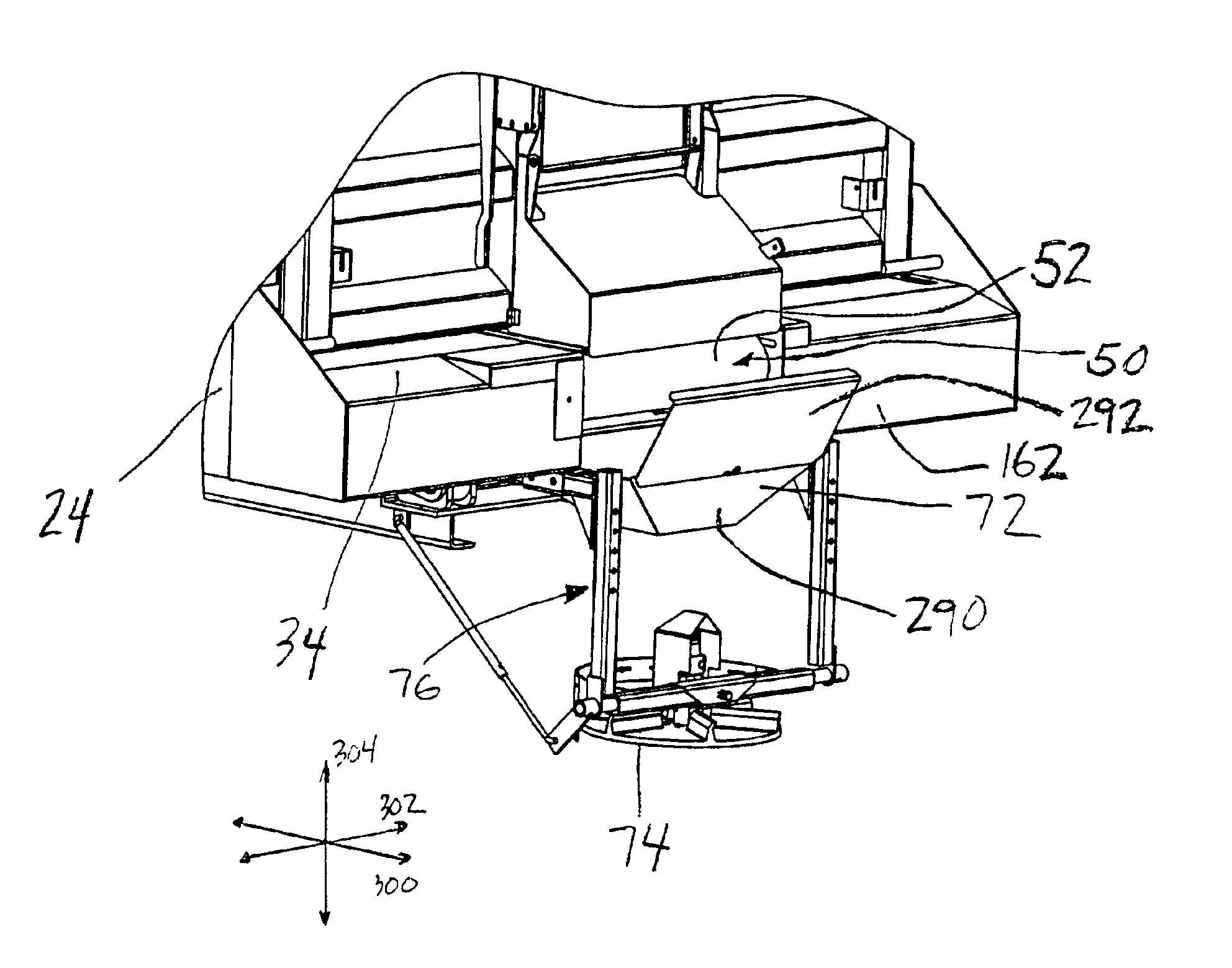

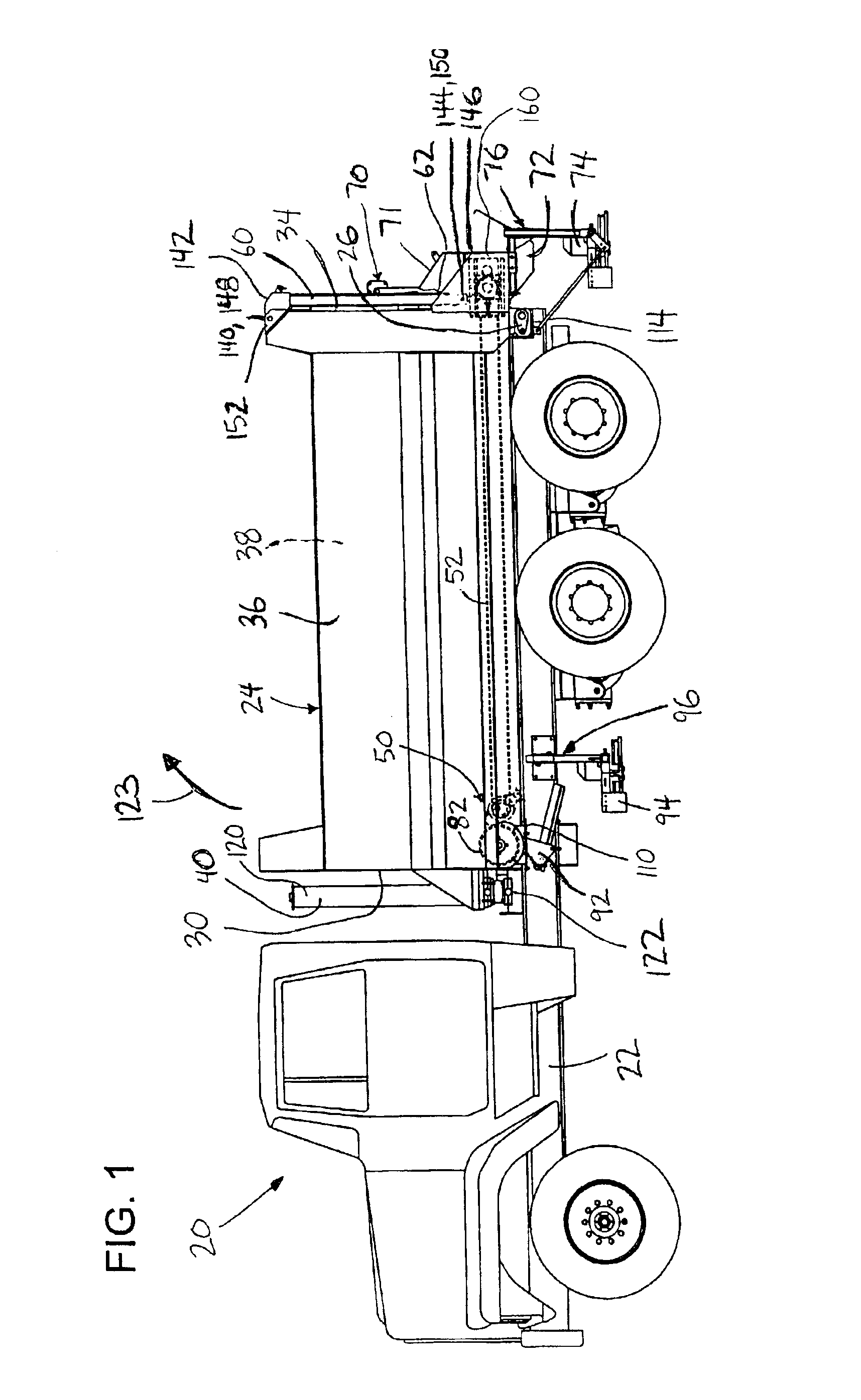

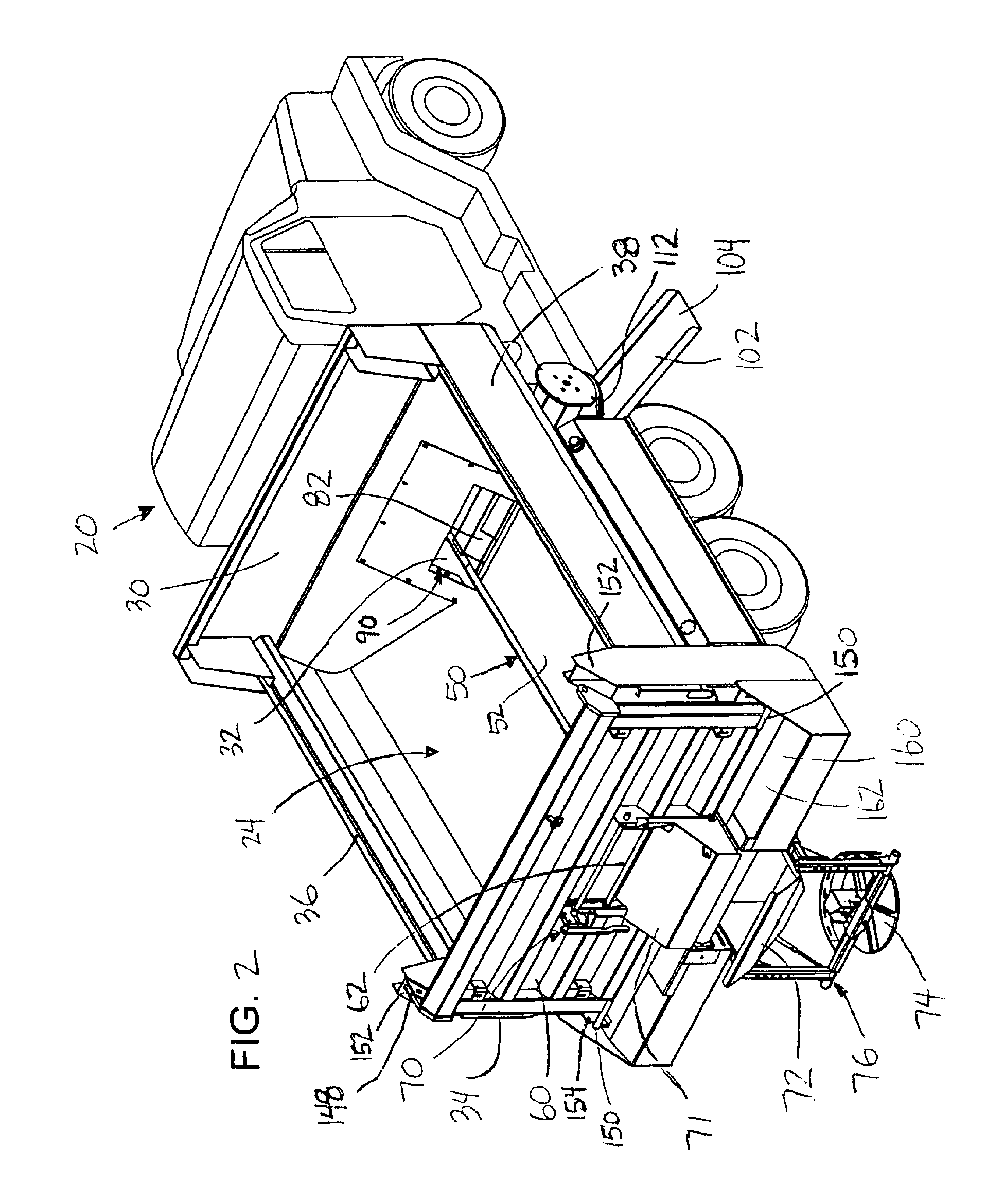

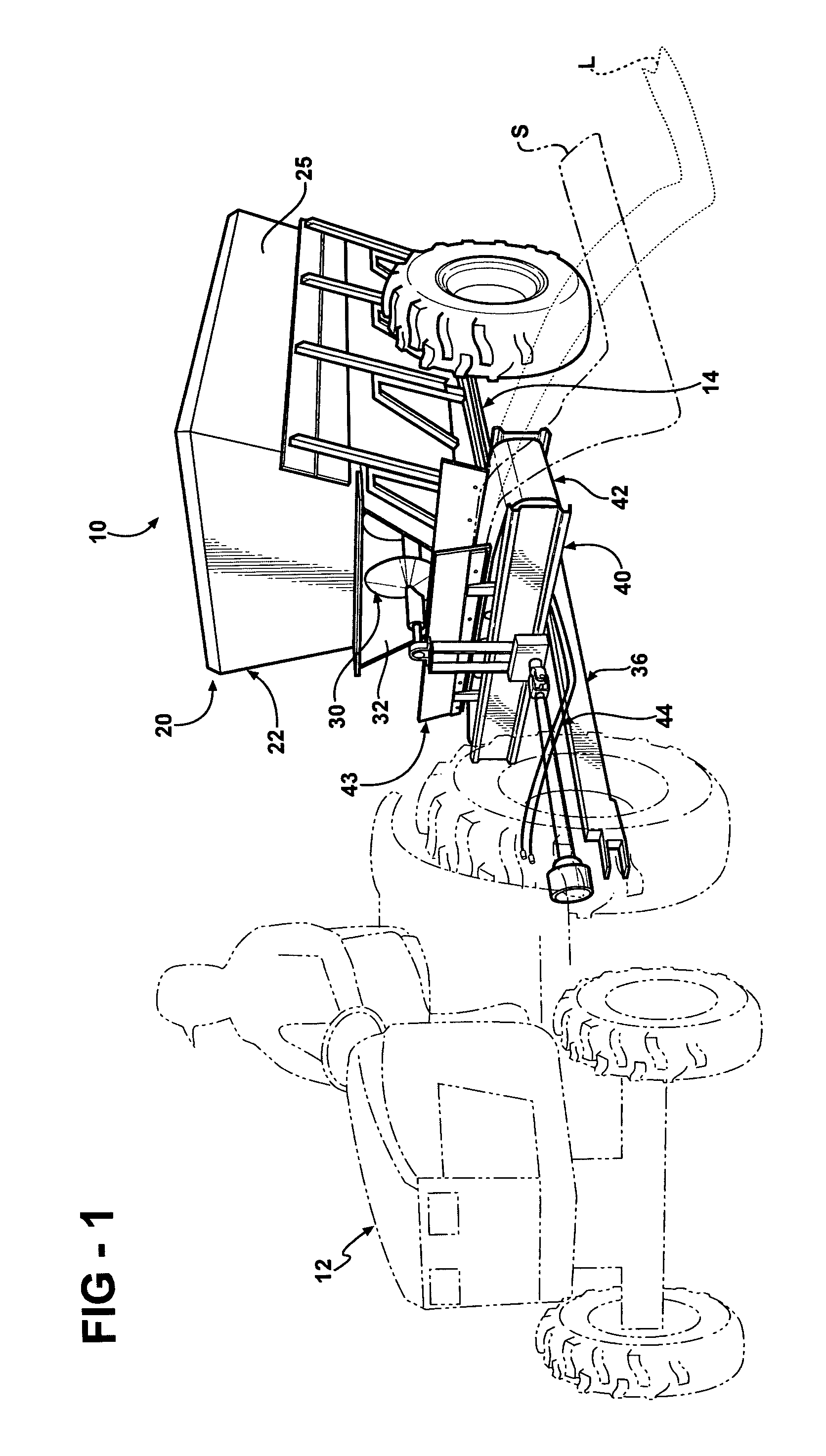

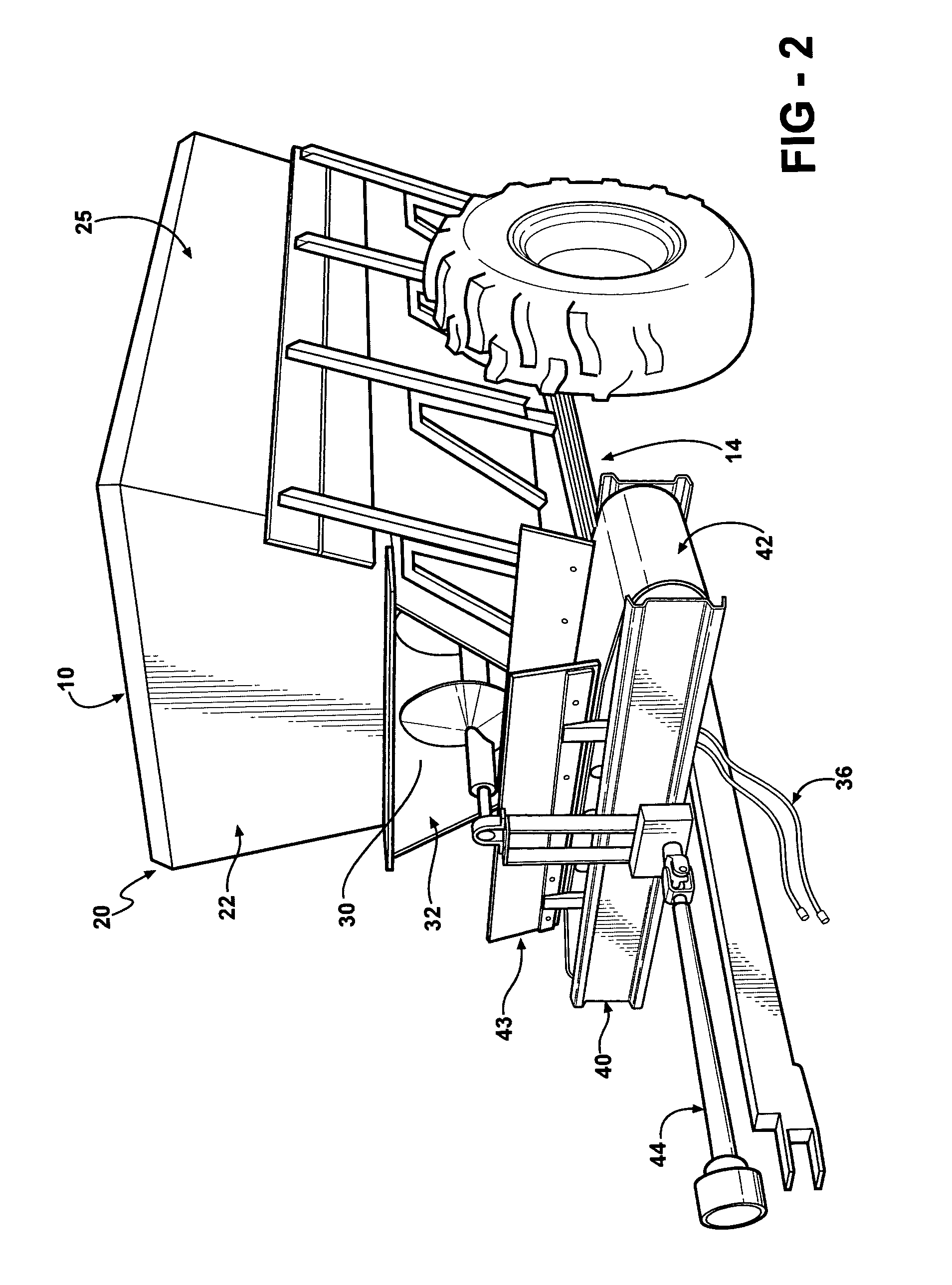

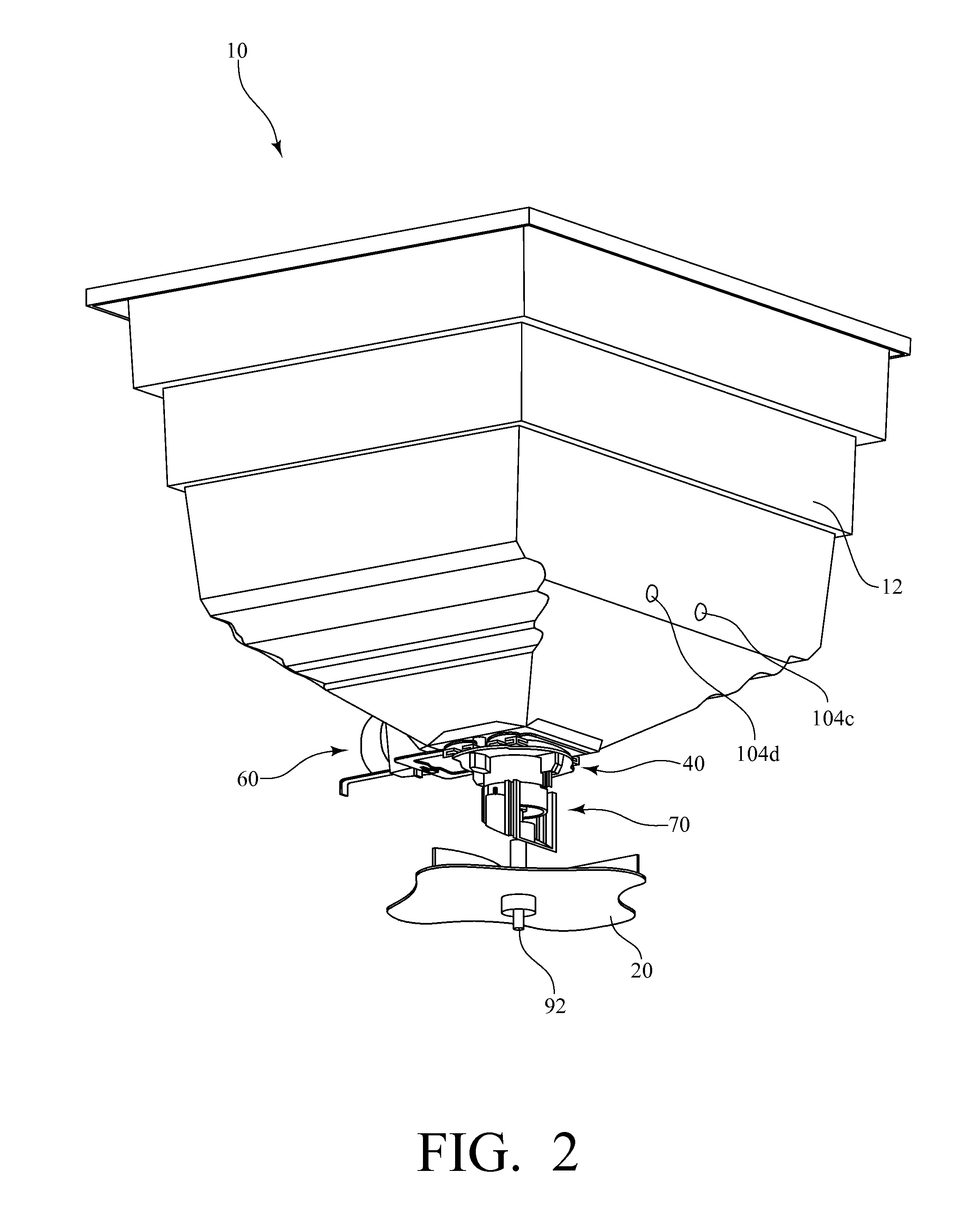

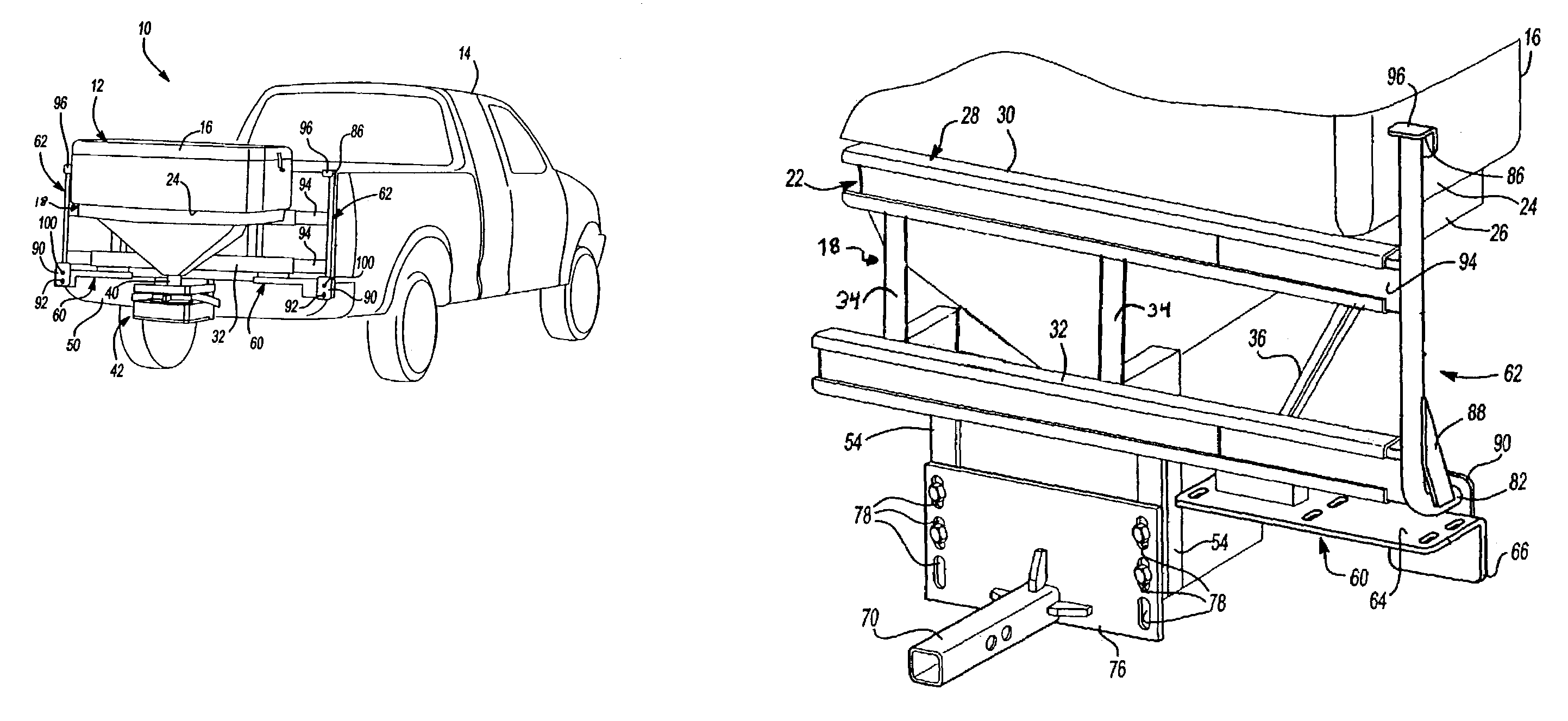

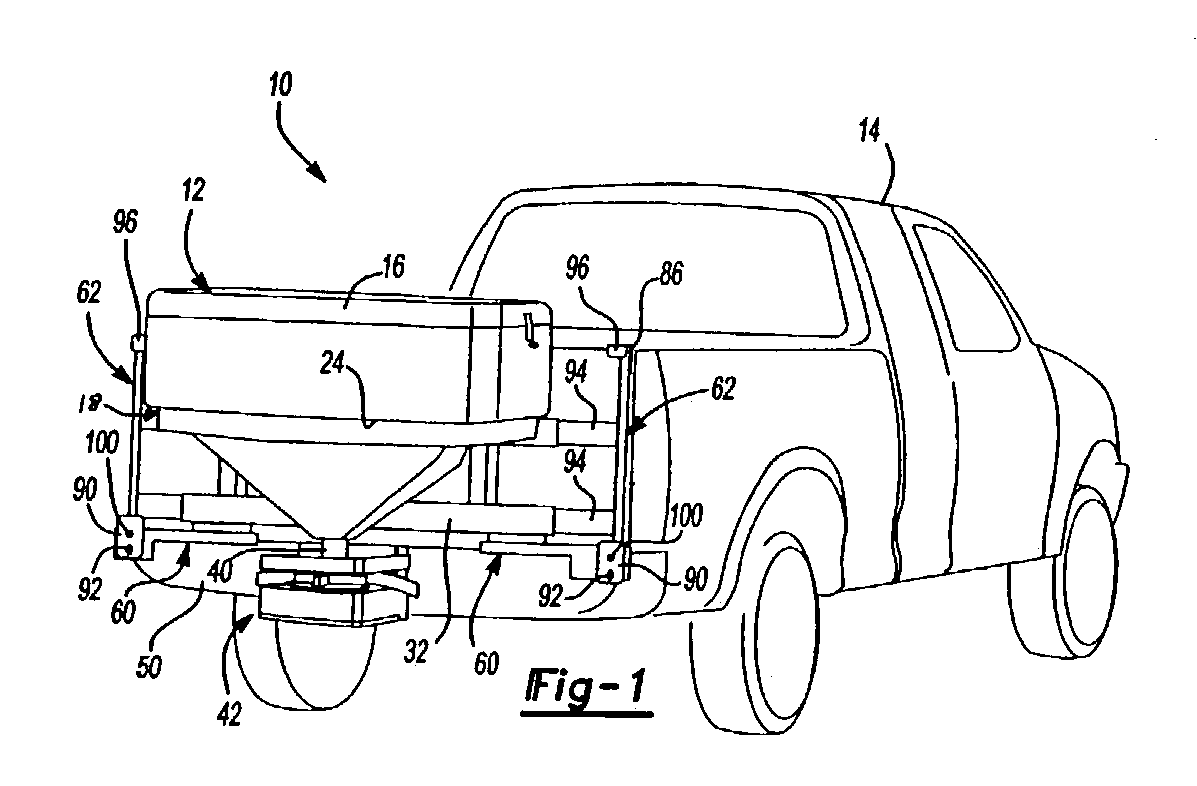

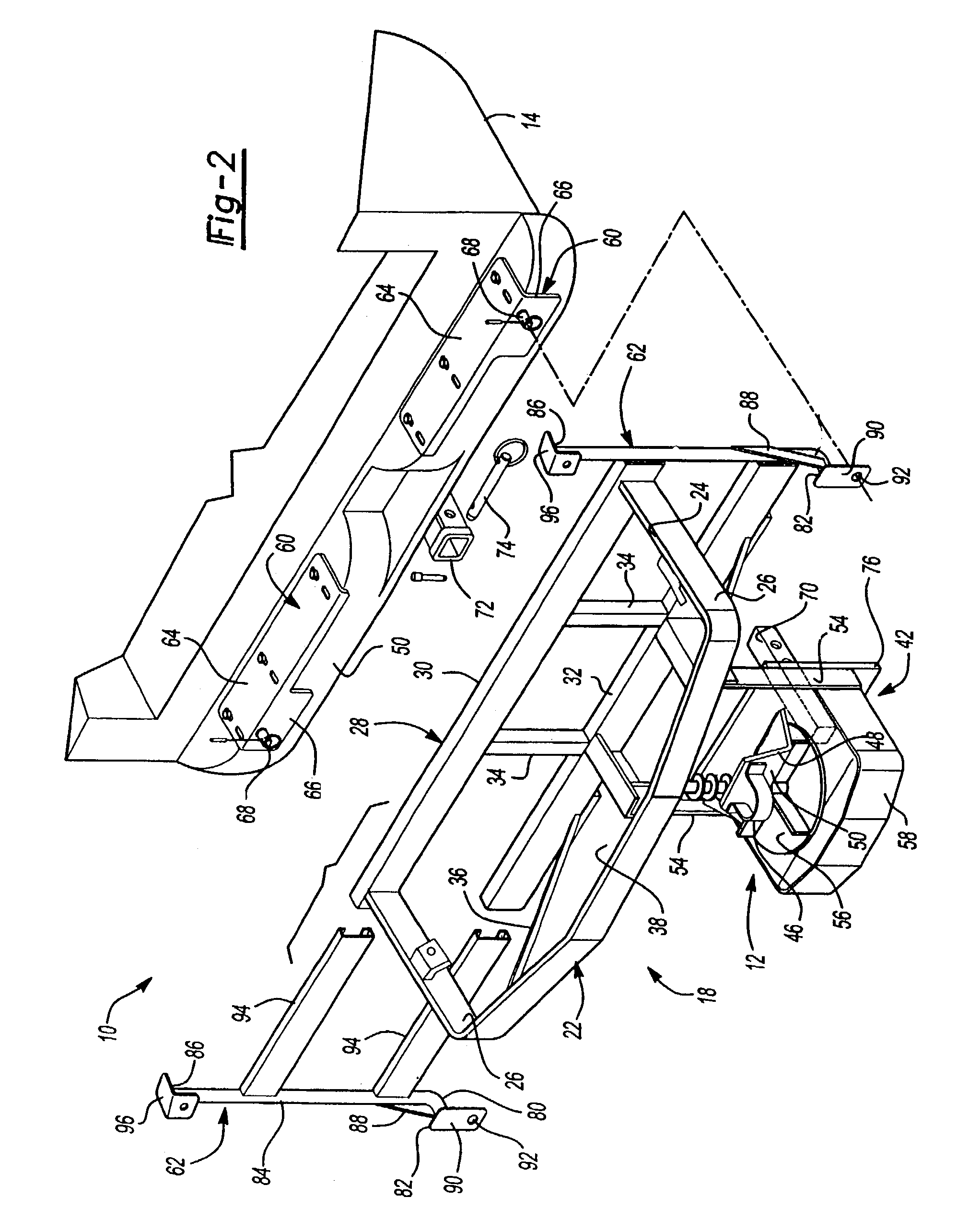

Mounting assembly for supporting a hopper and a spreading mechanism on a vehicle

InactiveUS7118053B2Tailgate of the vehicle to be loweredQuick installationWatering devicesFertiliser distributersEngineeringMechanical engineering

The subject invention provides a mounting assembly (10) for supporting a hopper (16) and a spreading mechanism (12) on a vehicle (14) for carrying and spreading a material. A spreader frame (18) supports the hopper (16) and a bumper bracket (60) is mounted to a bumper of the vehicle (14) for attaching the spreader frame (18) to a bumper. The mounting assembly (10) further includes a hitch support (70) for supporting the spreader frame (18) on a hitch receiver (72) of the vehicle (14). A plate (76) interconnects the hitch support (70) to the spreader frame (18) for adjusting a height of the hitch support (70) relative to the spreader frame (18). A pair of vertical supports (62) extend vertically from the spreader frame (18) for attachment to the bed of the vehicle (14) at an upper end (86) thereof. A coupler (90) interconnects the vertical supports (62) and the bumper brackets (60) for allowing removal of the vertical supports (62) and spreader frame (18), while the bumper brackets (60) remain mounted to the vehicle (14).

Owner:TRYNEX INT

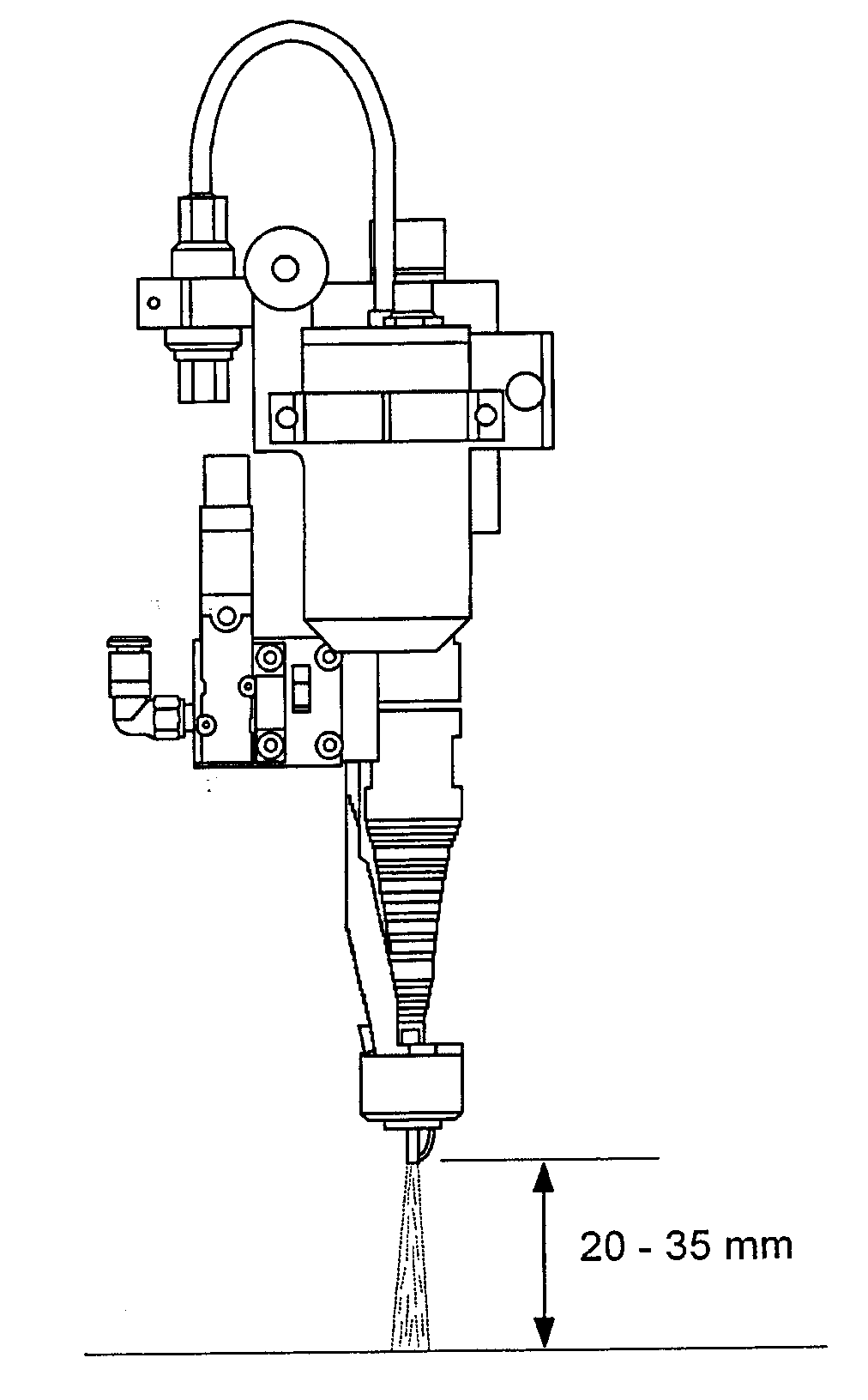

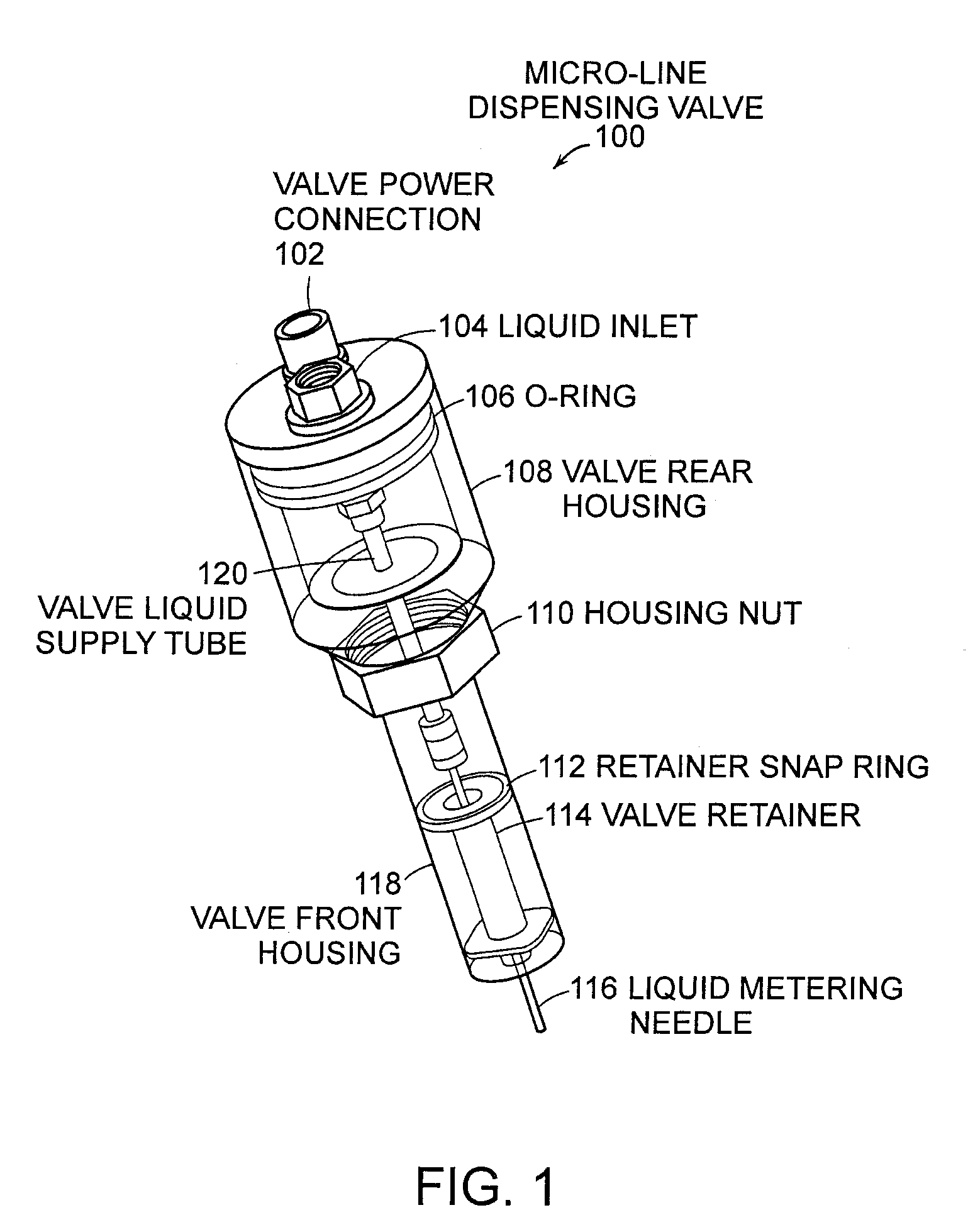

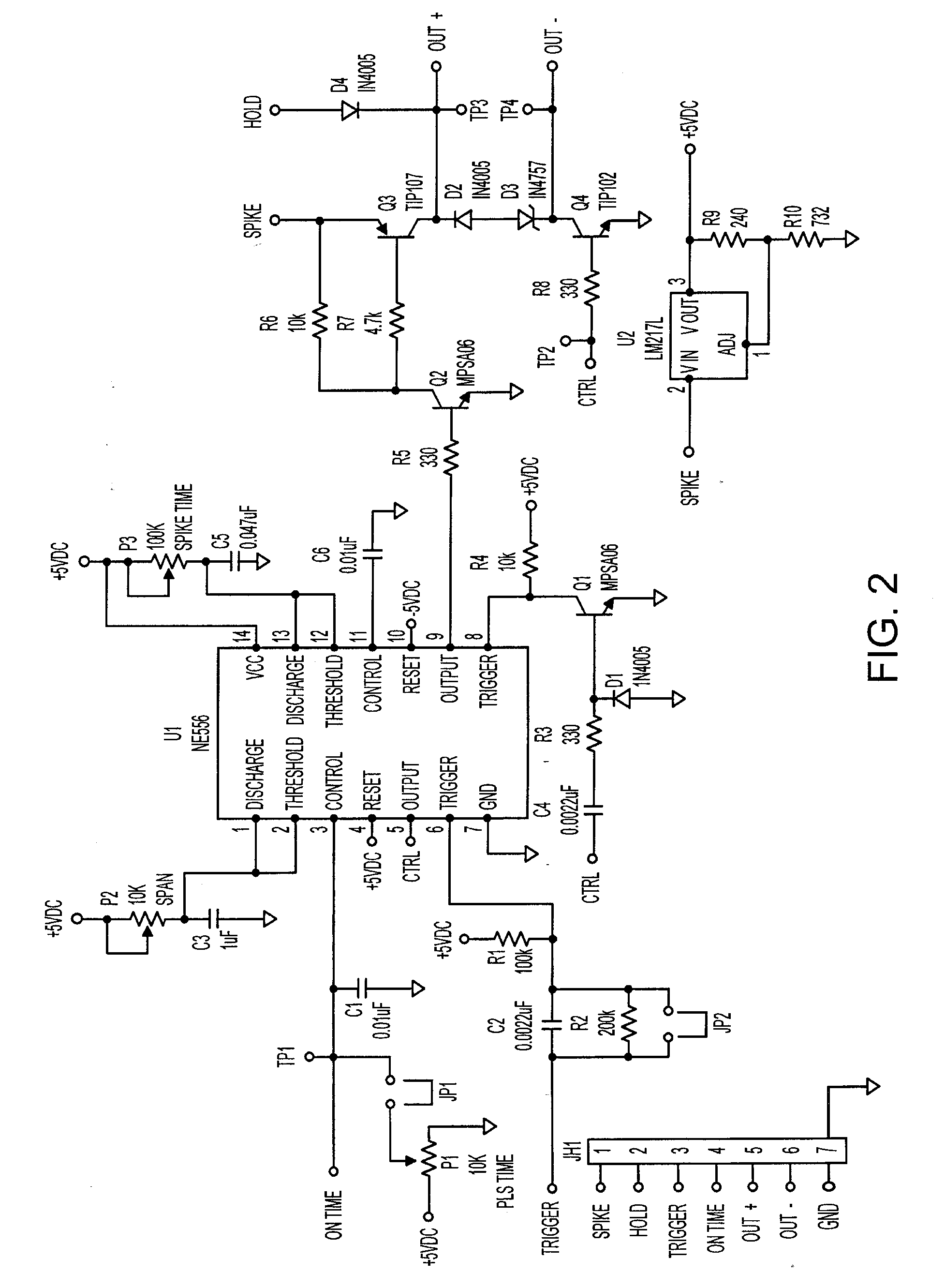

Coating system

Disclosed is a coating system for the selective application of coatings to substrates to apply a uniform coating to selected areas of the substrate without the need for masking. The system comprises a first coating applicator for coating large areas of the substrate, a second coating applicator for coating small areas of the substrate, a motion and positioning system for both coating applicators and a system controller. Also disclosed is an ultrasonic spray coating system comprising an ultrasonic transducer with spray forming head, integrated fluid delivery device with air and liquid supply passage ways, support brackets and an ultrasonic power generator.

Owner:ULTRASONIC SYST GMBH

Apparatus for increasing the density of blown insulation materials

A dispenser for a blown fibrous insulation delivery system which is attached to a fibrous material delivery conduit of the system. The dispenser includes a pipe having a first end which is attachable to the delivery conduit and second end which carries a deflector for compressing a flow of fibrous insulation discharged through the outlet of the pipe and for changing the direction of flow of fibrous insulation compressed thereby. The deflector includes a substantially planar portion disposed at an acute angle with respect to the pipe outlet. The dispenser may also include a second deflector for changing the direction of flow of the compressed fibrous insulation.

Owner:CERTAINTEED CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com