Air compressor with pipeline air tightness detection

An air compressor and pipeline gas technology, which is applied in liquid tightness measurement using liquid/vacuum degree, mechanical equipment, machine/engine, etc. It can solve the inconvenient disassembly, inconvenient cleaning and replacement of filter screen, poor shock absorption effect, etc. problem, to achieve good heat dissipation effect, improve shock absorption effect, and reduce vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

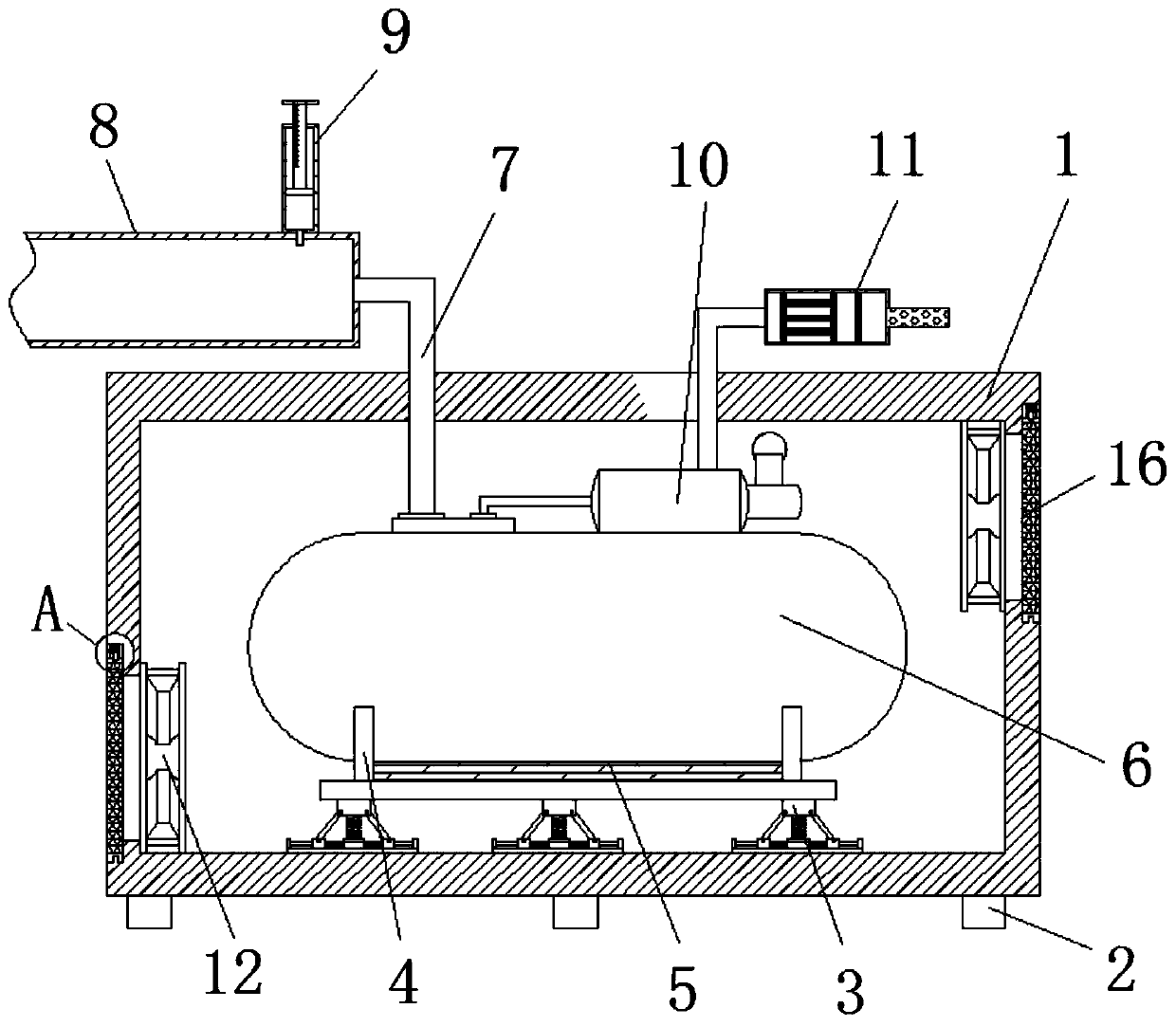

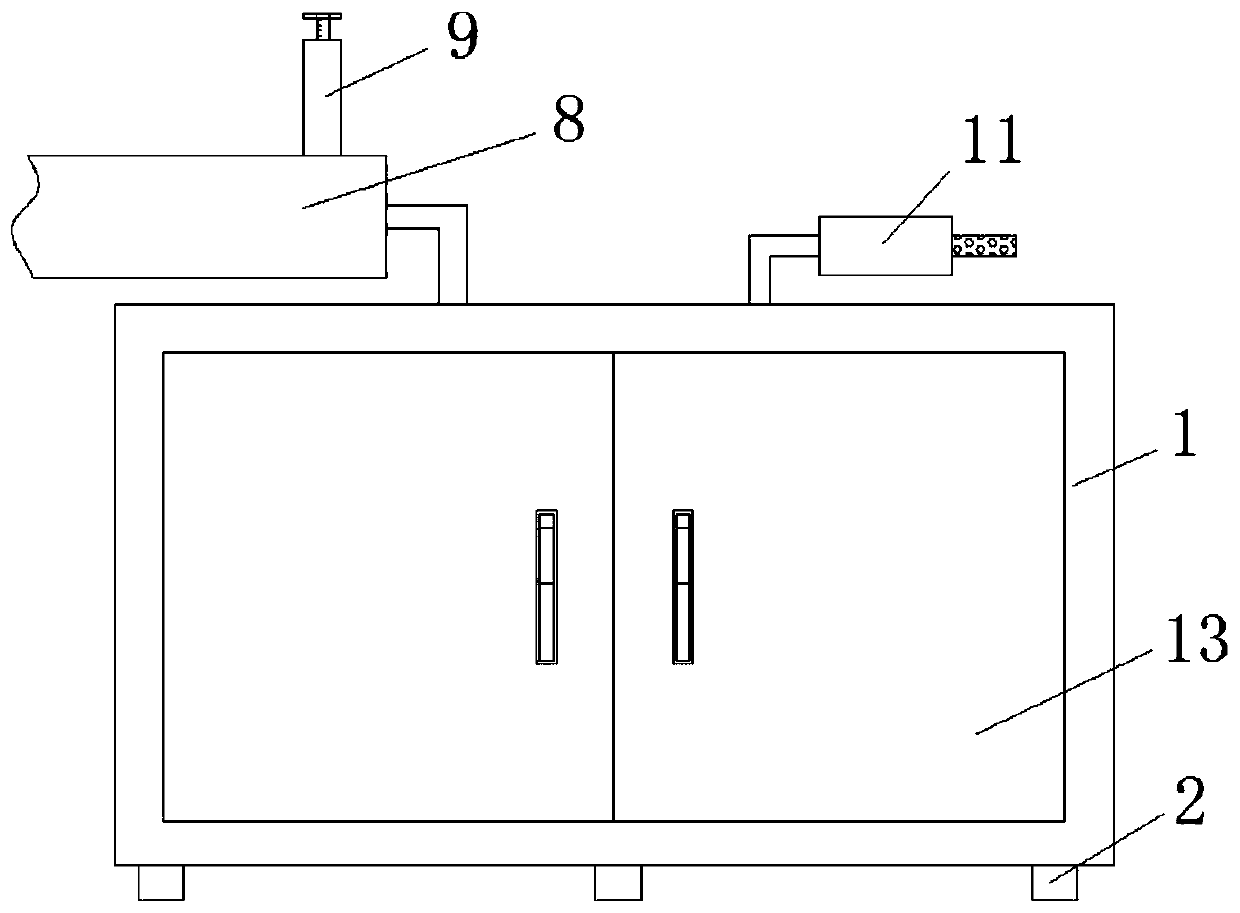

[0033] see Figure 1-6 , this embodiment provides an air compressor with pipeline air tightness detection, including a box body 1, the lower surface of the box body 1 is fixedly connected with a bottom column 2, and the front surface of the box body 1 is hinged with a box door 13, The inner lower surface of the box body 1 is fixedly connected with a shock absorbing assembly 3, the shock absorbing assembly 3 is fixedly connected with a fixed frame 4, the fixed frame 4 is fixedly connected with a gas storage tank 6, and the upper surface of the gas storage tank 6 is fixedly connected with an output The pipe 7 and the output pipe 7 run through the box body 1 longitudinally, the other end of the output pipe 7 is fixedly connected to the pipe 8, the top of the pipe 8 is fixedly connected to the air tightness detection assembly 9, and the top of the gas storage tank 6 corresponds to the outlet pipe 7. One side is fixedly connected with an air compressor 10, the output end of the air...

Embodiment 2

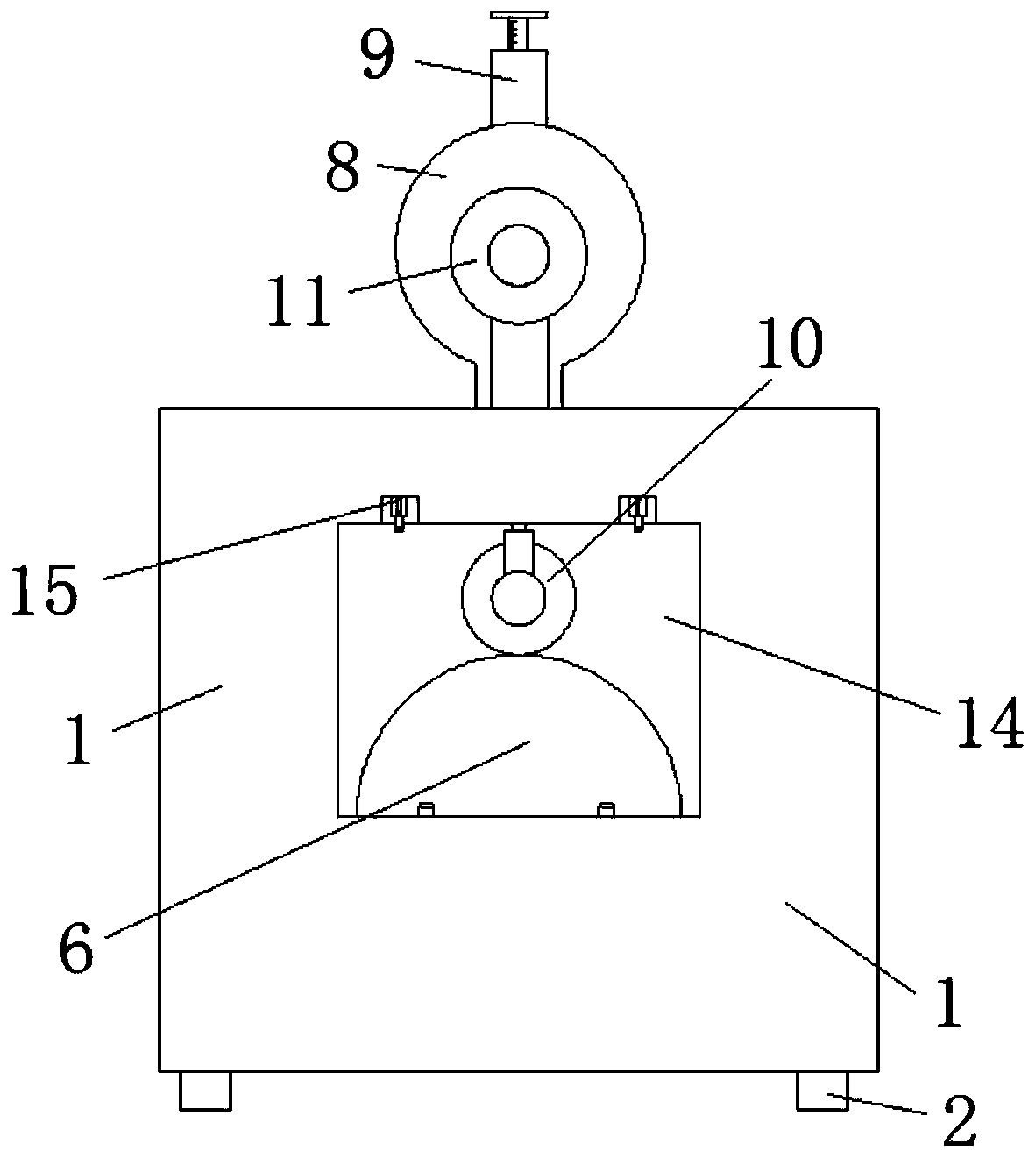

[0036] see Figure 1-7 , On the basis of Embodiment 1, a further improvement has been made: the air intake device 11 includes an air intake sleeve 1101, an air intake cylinder 1102, a first filter screen 1103, a radial muffler plate 1104 and an axial muffler plate 1105, and the air intake sleeve The output end of 1101 is connected with the air storage tank 6 through the air pipe, the input end of the air intake sleeve 1101 is fixedly connected with an air intake cylinder 1102, and several through holes are provided on the air intake sleeve 1102, and the inside of the air intake sleeve 1101 is fixedly connected with a second A filter screen 1103, the inside of the intake sleeve 1101 corresponding to the side of the first filter screen 1103 is fixedly connected with two radial sound-absorbing plates 1104, and an axial sound-absorbing plate 1105 is fixedly connected between the two radial sound-absorbing plates 1104, The external air is inhaled through the air intake device 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com