Method and device for detecting draught fan insufficient output fault

A technology for fan output and fault detection, applied in mechanical equipment, machines/engines, non-variable-capacity pumps, etc., can solve problems such as data distortion, affecting the accuracy of fault sources, and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

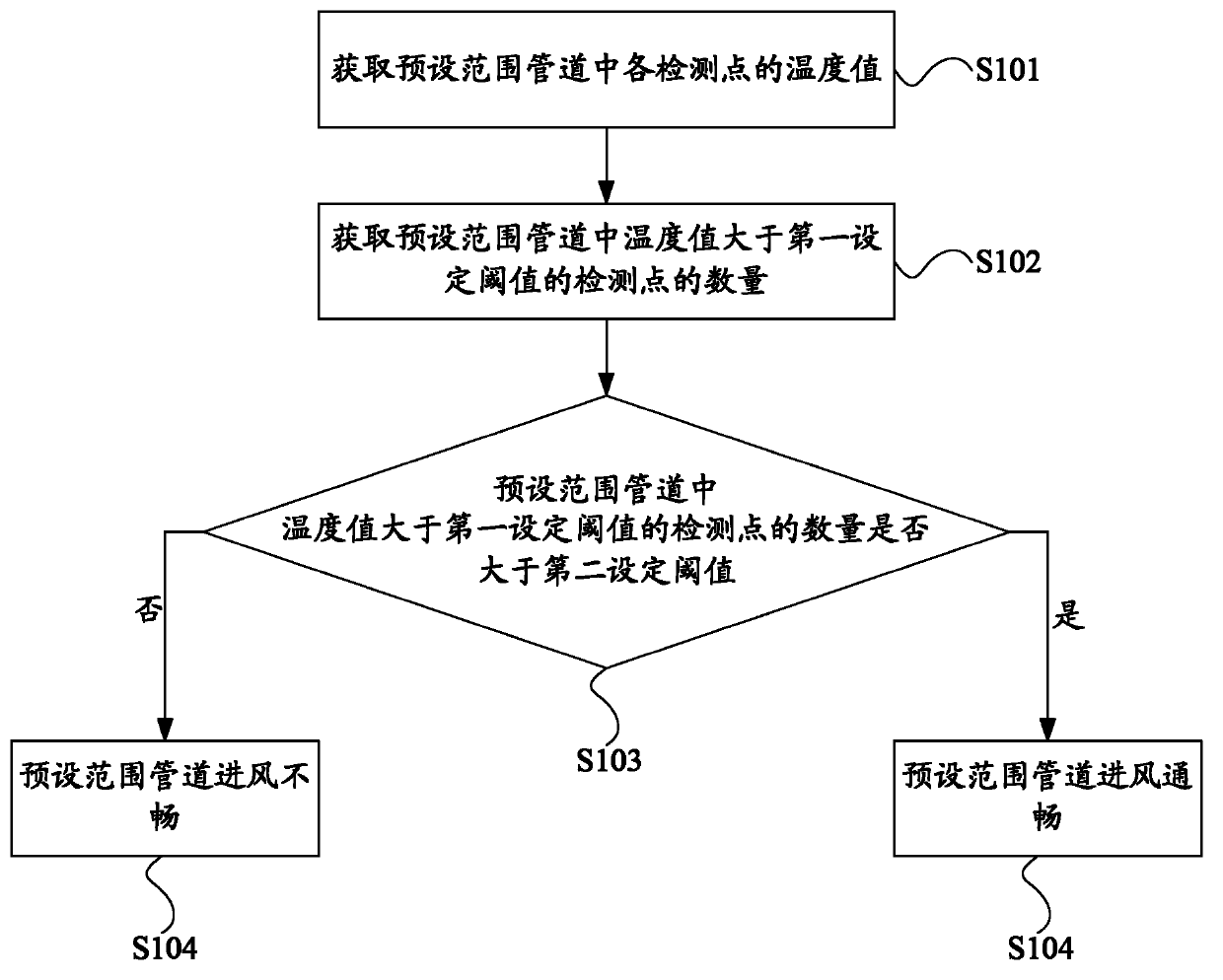

[0031] Because the flue gas in the casthouse has a certain temperature, the temperature of the dust suction hood can reach more than 200°C, which belongs to high-temperature flue gas, and the temperature before entering the dust collector is also about 80°C. The present invention utilizes the temperature characteristics of the flue gas in the casthouse , providing a fault detection method for insufficient fan output, figure 1 It is a schematic flowchart of the method provided in Embodiment 1 of the present invention, the method may include:

[0032] S101: Obtain the temperature values of each detection point in the pipeline in a preset range.

[0033] S102: Obtain the number of detection points in the pipeline with a preset range whose temperature value is greater than a first set threshold.

[0034] S103: Determine whether the number of detection points whose temperature values are greater than the first set threshold in the pipeline in the preset range is greater than t...

Embodiment 2

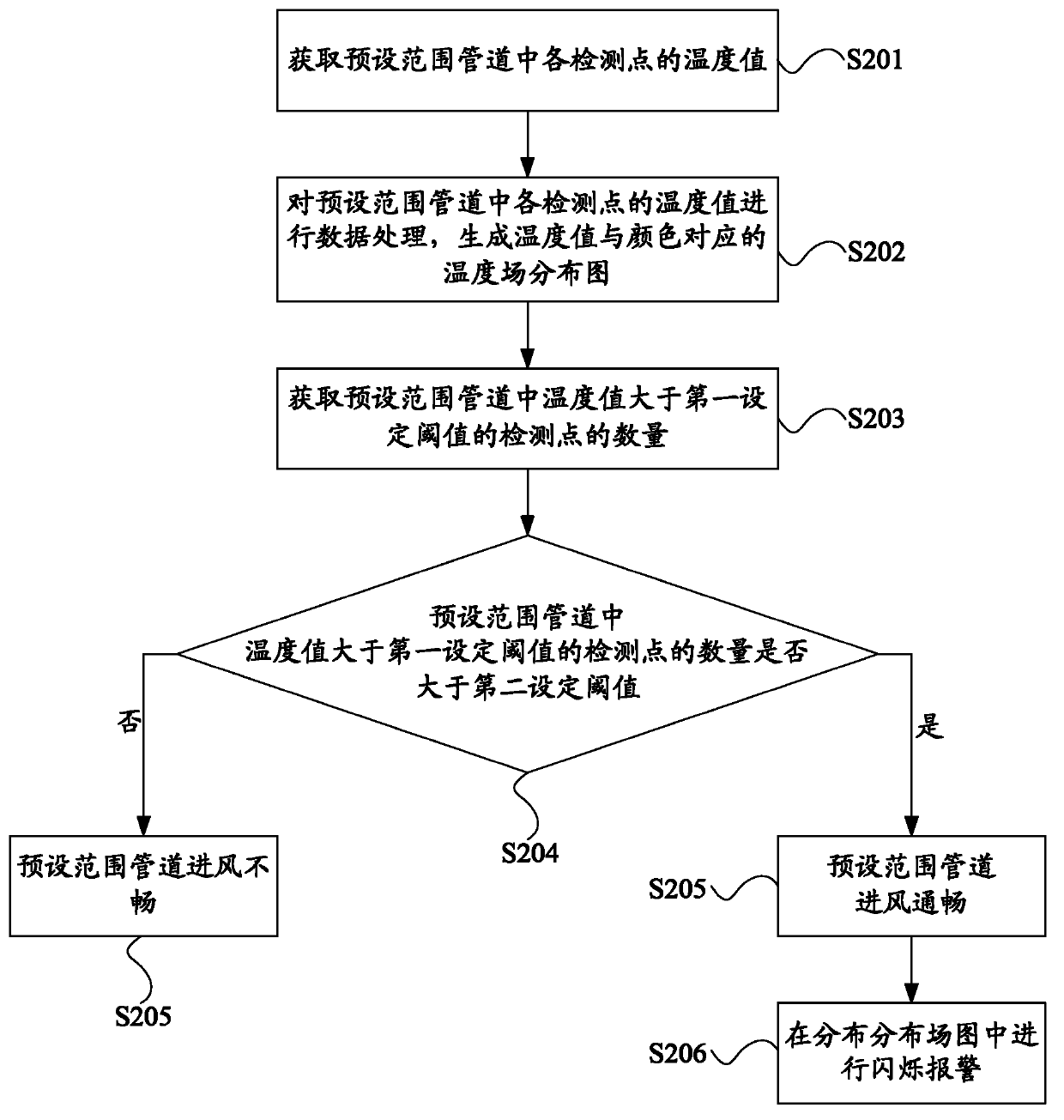

[0039] Embodiment 2 of the present invention provides a fault detection method for insufficient fan output, figure 2 A schematic flow chart of the method, the method may include:

[0040] S201: Obtain the temperature values of each detection point in the pipeline within a preset range.

[0041] S202: Perform data processing on the temperature values of each detection point in the pipeline in the preset range, and generate a temperature field distribution map corresponding to the temperature values and colors.

[0042] S203: Obtain the number of detection points in the pipeline with a preset range whose temperature value is greater than a first set threshold.

[0043] S204: Determine whether the number of detection points whose temperature values are greater than the first set threshold in the pipeline in the preset range is greater than the second set threshold.

[0044] S205: If the number of detection points whose temperature value is greater than the first set th...

Embodiment 3

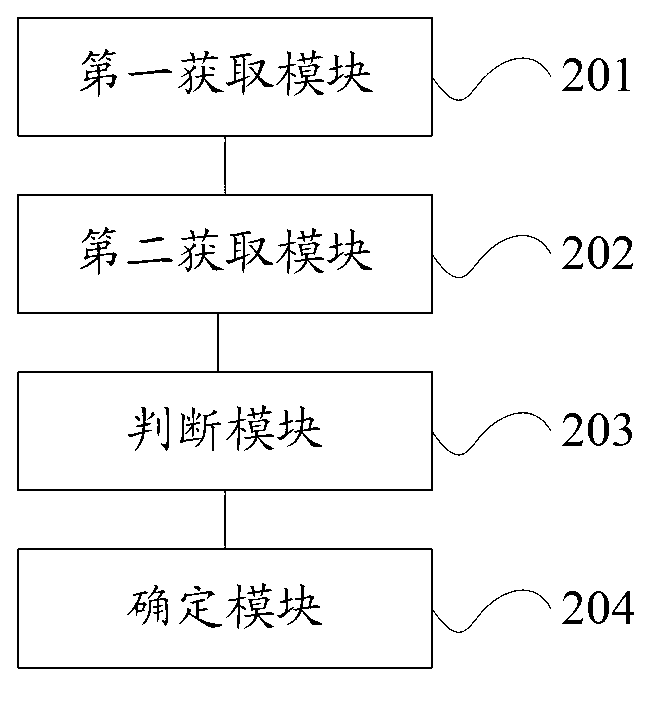

[0052] Embodiment 3 of the present invention provides a fault detection device for insufficient fan output, image 3 It is a schematic structural diagram of the device, and the fault detection device includes: a first acquisition module 101 , a second acquisition module 102 , a judgment module 103 and a determination module 104 .

[0053] The first acquisition module 101 is configured to acquire the temperature values of each detection point in the pipeline within a preset range.

[0054] The second acquiring module 102 is configured to acquire the number of detection points whose temperature values are greater than the first set threshold in the pipeline within the preset range.

[0055] The judging module 103 is configured to judge whether the number of detection points whose temperature values acquired by the second acquiring module 102 are greater than the first set threshold is greater than the second set threshold.

[0056] The determination module 104 is configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com