Composite membrane with high barrier property

A high-barrier, composite film technology, applied in household appliances, flexible coverings, packaging items, etc., can solve the problems of changing the properties of medicines and potential safety hazards, and achieve high use temperature, low cost, and thermal adhesion. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

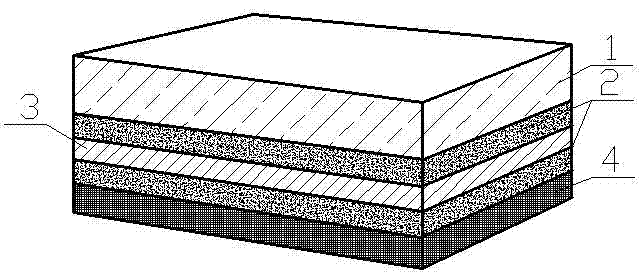

[0016] As shown in Figure 1, the composite film with high barrier properties of the present invention includes an outer surface layer 1, an intermediate layer 3 and an inner layer 4. The outer surface layer 1 is paper, the intermediate layer 3 is aluminum foil, and the inner layer 4 is polyethylene. An adhesive layer 2 is provided between the outer surface layer 1 and the middle layer 3, and the middle layer 3 and the inner layer 4.

[0017] The outer surface layer 1 set as paper has good printing effect and low cost; the middle layer 3 set as aluminum foil has excellent high resistance to light, moisture, oxygen and other gases, and has a beautiful luster; the inner layer 4 is polyethylene, which It has stable chemical properties, good heat resistance and thermal adhesion, and is directly thermally bonded to the packaging substrate material. Compared with the existing viscose that meets the adhesiveness and retort resistance, the composite film of the present invention is heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com