Aromatic melt-blown non-woven fabric having low ventilation resistance, planar mask with melt-blown non-woven fabric and manufacturing method of planar mask

A melt-blown non-woven fabric and low-ventilation technology, which is applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of poor filtering effect, skin allergies, and large ventilation resistance of flat masks, and achieve excellent storage performance , good filtering effect and low ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

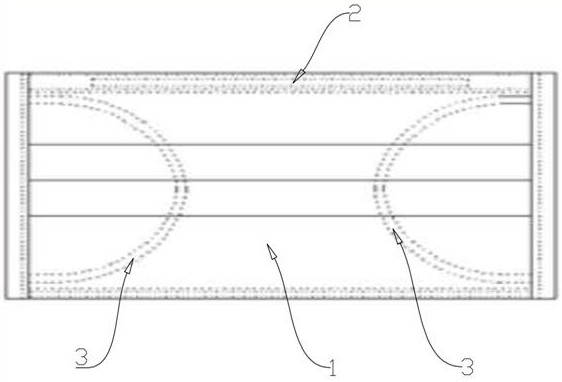

Image

Examples

Embodiment 1

[0057] An aromatic melt-blown non-woven fabric with low ventilation resistance, made of raw materials comprising the following parts by weight:

[0058] 80-90 slices of polypropylene melt-blown non-woven fabric,

[0059] 10-13 parts of maleic anhydride grafted polypropylene,

[0060] 5-7 parts of metallocene-catalyzed linear low-density polyethylene,

[0061] 1.8-2.2 parts of mesoporous silica,

[0062] 2.5-3 parts of nano bismuth stearate,

[0063] 1.5-1.8 parts of methyl 3-[3-(benzotriazol-2-yl)-5-tert-butyl-4-hydroxyphenyl]propionate,

[0064] 3-3.8 parts of N-(2,6-dimethylphenyl)phthalimide,

[0065] 2 to 2.5 parts of oleic acid amide,

[0066] 0.6-0.9 parts of erucamide.

[0067] In this embodiment, the aromatic melt-blown non-woven fabric with low ventilation resistance is preferably, but not limited to, made of raw materials including the following parts by weight:

[0068] 85 slices of polypropylene melt-blown non-woven fabric,

[0069] 11.5 parts of maleic anh...

Embodiment 2

[0131] An aromatic melt-blown non-woven fabric with low ventilation resistance, made of raw materials comprising the following parts by weight:

[0132] 80 slices of polypropylene melt-blown non-woven fabric,

[0133] 10 parts of maleic anhydride grafted polypropylene,

[0134] Metallocene catalyzed linear low density polyethylene 5 parts,

[0135] Mesoporous silica 1.8 parts,

[0136] 2.5 parts of nano bismuth stearate,

[0137] 1.5 parts of methyl 3-[3-(benzotriazol-2-yl)-5-tert-butyl-4-hydroxyphenyl]propionate,

[0138] 3 parts of N-(2,6-dimethylphenyl)phthalimide,

[0139] 2 parts of oleic acid amide,

[0140] 0.6 parts of erucamide.

[0141] In this embodiment, the aromatic melt-blown nonwoven fabric with low ventilation resistance further includes the following raw materials in parts by weight: 3 parts of polypropylene cooling masterbatch.

[0142] In this embodiment, the low ventilation resistance aromatic melt-blown nonwoven fabric further includes the following...

Embodiment 3

[0155] An aromatic melt-blown non-woven fabric with low ventilation resistance, made of raw materials comprising the following parts by weight:

[0156] 90 slices of polypropylene melt-blown non-woven fabric,

[0157] 13 parts of maleic anhydride grafted polypropylene,

[0158] Metallocene catalyzed linear low density polyethylene 7 parts,

[0159] Mesoporous silica 2.2 parts,

[0160] 3 parts of nano bismuth stearate,

[0161] 1.8 parts of methyl 3-[3-(benzotriazol-2-yl)-5-tert-butyl-4-hydroxyphenyl]propionate,

[0162] 3.8 parts of N-(2,6-dimethylphenyl)phthalimide,

[0163] 2.5 parts of oleic acid amide,

[0164] 0.9 parts of erucamide.

[0165] In this embodiment, the aromatic melt-blown nonwoven fabric with low ventilation resistance also includes the following raw materials in parts by weight: 4 parts of polypropylene cooling masterbatch.

[0166] In this embodiment, the aromatic melt-blown nonwoven fabric with low ventilation resistance further includes the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com