Deodorizing and sterilizing insole and manufacturing method thereof

A technology of insoles and granules, which is applied in the direction of insoles, footwear, non-woven fabrics, etc., can solve the problems of easy wrinkling and wear of the upper surface, easy deformation of the middle layer, complex processing technology of the middle layer, etc., and achieve a strong mixed connection, not easy to deform, and good massage Health care effect, strong anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

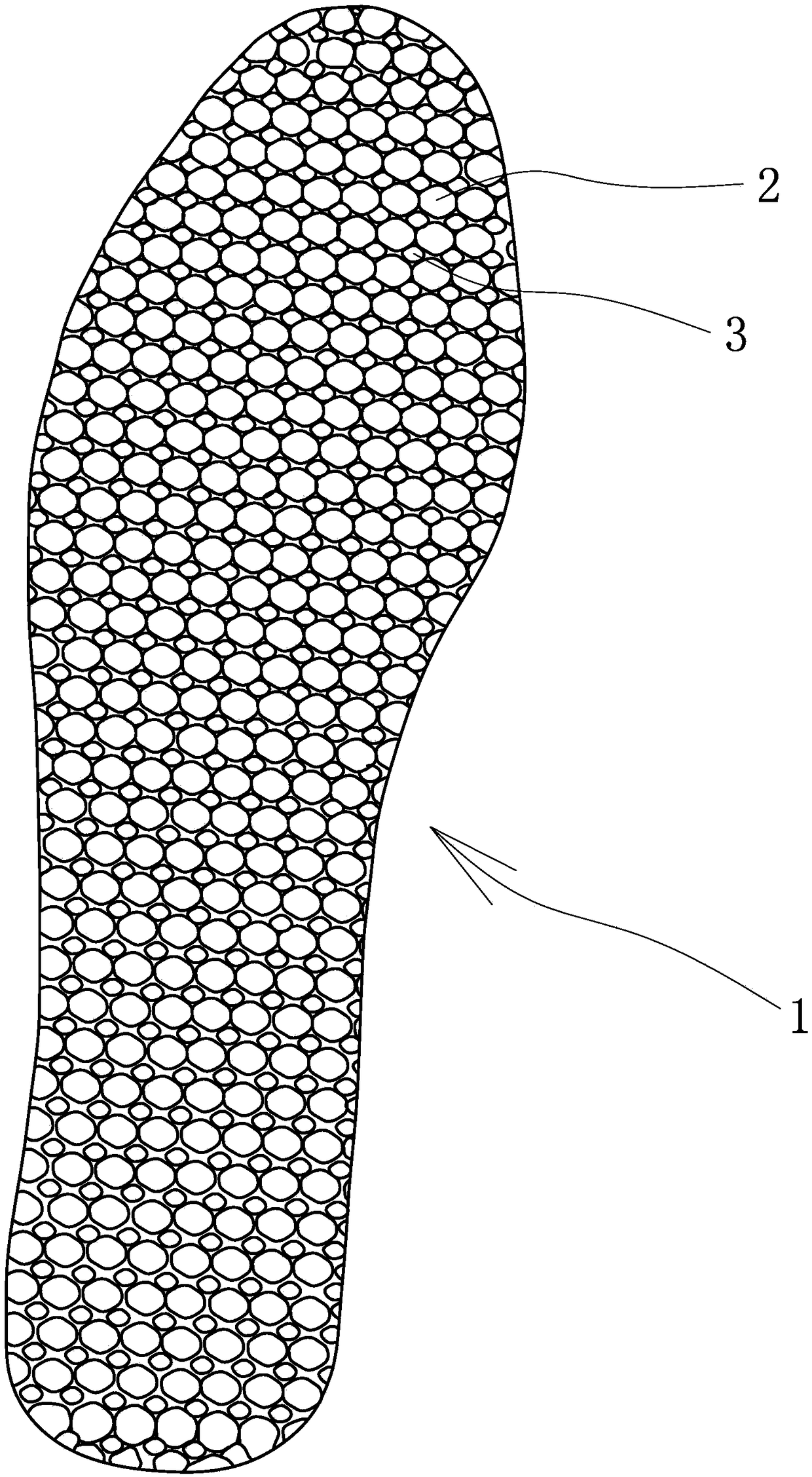

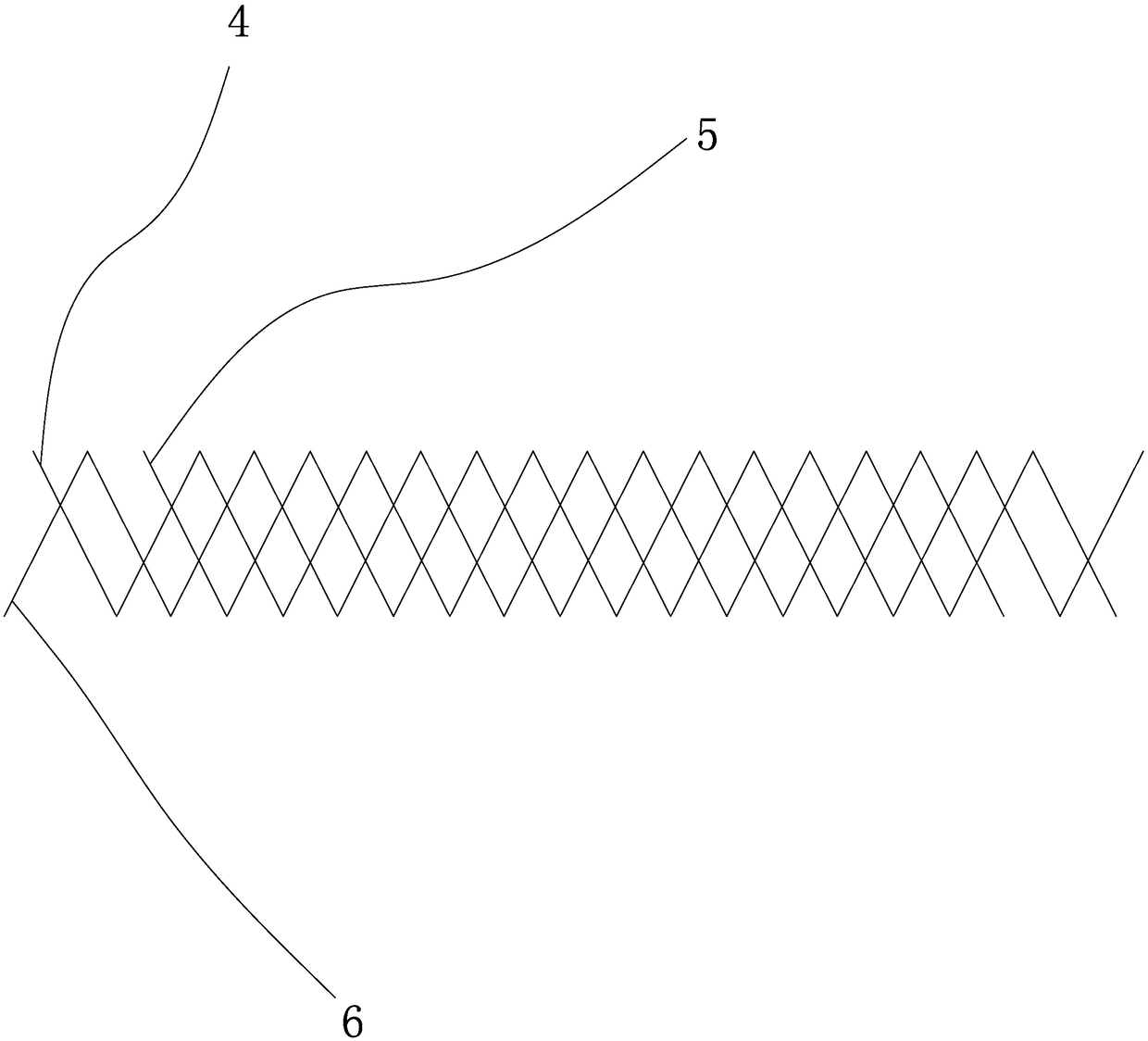

[0024] For convenience of description, at first, with regard to the structure of this deodorizing and sterilizing shoe-pad, as figure 1 , figure 2 As shown, the deodorizing and sterilizing insole includes an insole body 1, the insole body 1 is formed by mixing copper-modified polyester fiber 4, low-melting point fiber 5 and wood pulp fiber 6, and the mixed copper-modified polyester fiber is mixed by a needling machine. The fibers 4, low-melting point fibers 5 and wood pulp fibers 6 are needle-punched into a broken-line intersecting network, and the upper surface of the insole body 1 is evenly distributed with several rows of large raised particles 2 and several rows of small raised particles. Protruding particles 3, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com