High-density polyethylene composition

A technology of high-density polyethylene and composition, applied in the direction of conjugated synthetic polymer artificial filament, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low strength, poor fiber tensile performance, adhesion performance, spinnability Poor performance and other problems, to achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

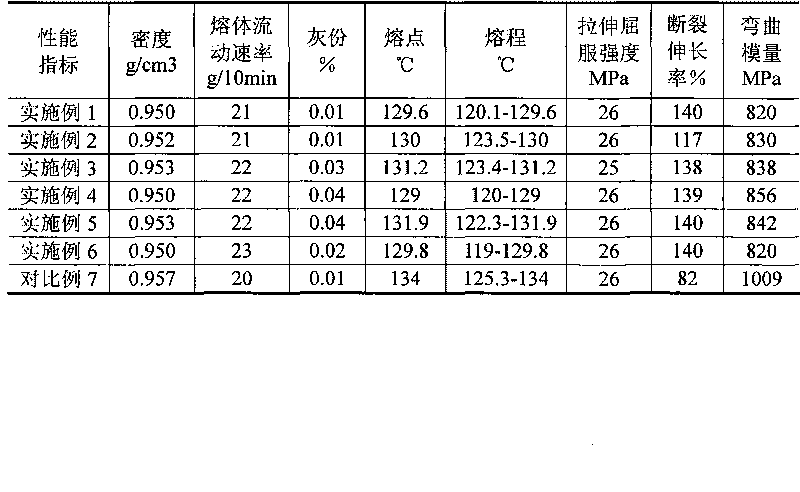

Examples

Embodiment 1

[0034] 100 parts by mass of high-density polyethylene copolymer, melt flow rate 21g / 10min, density 0.950g / cm 3 , wherein the content of 1-butene monomer unit is 0.58mol%; Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester 0.1 mass parts, three ( 2. 0.2 parts by mass of 4-di-tert-butylphenyl) phosphite, and 0.1 parts by mass of stabilizer calcium stearate.

Embodiment 2

[0036] 100 parts by mass of high-density polyethylene copolymer, melt flow rate 21g / 10min, density 0.952g / cm 3 , wherein the content of 1-butene monomer unit is 0.50mol%; antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate 0.1 parts by mass, three ( 2. 0.2 parts by mass of 4-di-tert-butylphenyl) phosphite, and 0.1 parts by mass of stabilizer calcium stearate.

Embodiment 3

[0038] 100 parts by mass of high-density polyethylene copolymer, melt flow rate 22g / 10min, density 0.953g / cm 3 , wherein the content of 1-butene monomer unit is 0.48mol%; antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate 0.1 parts by mass, bis( 2. 0.2 parts by mass of 4-di-tert-butylphenyl) pentaerythritol diphosphite, and 0.2 parts by mass of stabilizer calcium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com