Polyphenylene sulfide fibers and nonwoven fabric

A technology of polyphenylene sulfide fiber and polyphenylene sulfide, applied in fiber treatment, fiber chemical characteristics, textiles, etc., can solve the problems of poor thermal adhesion and no proposal, and achieve excellent thermal adhesion and mechanical strength excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

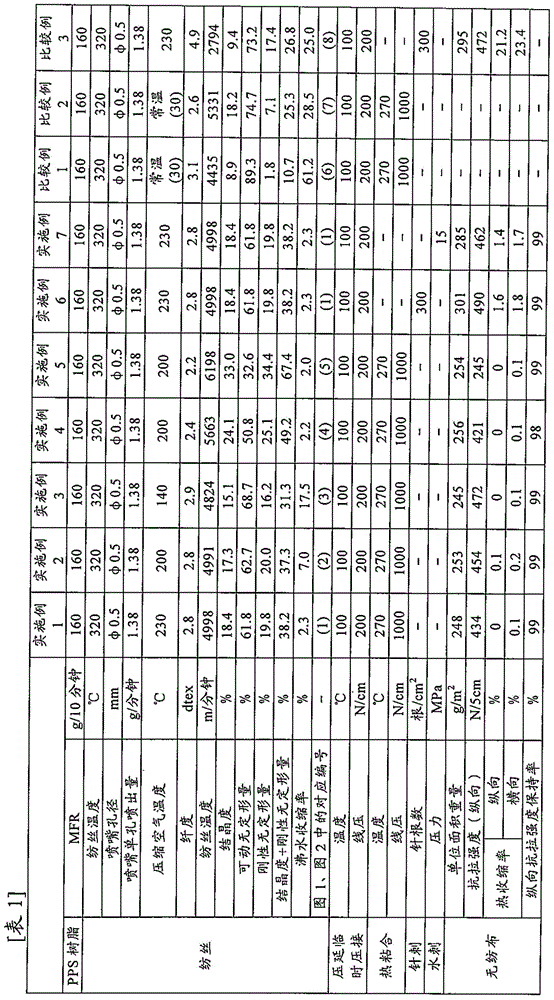

Embodiment 1

[0105] (PPS resin)

[0106] 100 mol% linear polyphenylene sulfide resin (manufactured by Toray Co., Ltd., product number: E2280, MFR: 160 g / 10 minutes) in which trichlorobenzene was intentionally not copolymerized was dried in a nitrogen atmosphere at a temperature of 160° C. for 10 minutes. hours to use.

[0107] (spinning and non-woven reticulation)

[0108] Melt the above PPS resin with an extruder, and at a spinning temperature of 320°C, It was spun at a single-hole discharge rate of 1.38 g / min in a rectangular spinning nozzle. The distance from the rectangular spinning nozzle to the rectangular injector was set at 55 cm, and the spun filaments were cooled and solidified in an atmosphere at a room temperature of 20°C. The cooled and solidified filaments are passed through a rectangular injector, and compressed air is sprayed from the injector, and the compressed air is heated to a temperature of 230°C with an air heater and the pressure of the injector is 0.15MPa, to d...

Embodiment 2

[0114] (PPS resin · spinning · nonwoven reticulation)

[0115] A nonwoven web was formed by spinning in the same manner as in Example 1, except that the same PPS resin as that used in Example 1 was used, and the temperature of the compressed air was set to 200°C.

[0116] The average single fiber fineness of the obtained long fiber is 2.8dtex, the crystallinity is 17.3%, the sum of rigid amorphous and crystallinity is 37.3%, and the boiling water shrinkage is 7.0%. In addition, the spinning speed was 4,991 m / min, and there were no yarn interruptions in one hour of spinning, and the spinnability was good.

[0117] (Temporary Bonding · Thermal Bonding)

[0118] Next, the above-mentioned nonwoven web was temporarily bonded and thermally bonded in the same manner as in Example 1 to obtain the long-fiber nonwoven fabric of Example 2.

[0119] When the obtained nonwoven fabric was thermally bonded using an embossing roll, it did not have a large width shrinkage caused by thermal s...

Embodiment 3

[0121] (PPS resin · spinning · nonwoven reticulation)

[0122] The same PPS resin as the resin used in Example 1 was used, except that the temperature of the compressed air was 140° C., and spinning was carried out in the same manner as in Example 1 to form a nonwoven web.

[0123] The average single fiber fineness of the obtained long fiber is 2.9dtex, the crystallinity is 15.1%, the sum of rigid amorphous and crystallinity is 31.3%, and the boiling water shrinkage is 17.5%. In addition, the spinning speed was 4,824 m / min, and there were 0 interruptions in spinning for 1 hour, and the spinnability was good.

[0124] (Temporary Bonding · Thermal Bonding)

[0125] Next, the above-mentioned nonwoven web was temporarily bonded and thermally bonded in the same manner as in Example 1 to obtain the long-fiber nonwoven fabric of Example 3.

[0126] The obtained nonwoven fabric did not suffer from large width shrinkage due to heat shrinkage even when heat-compression bonding was perfo...

PUM

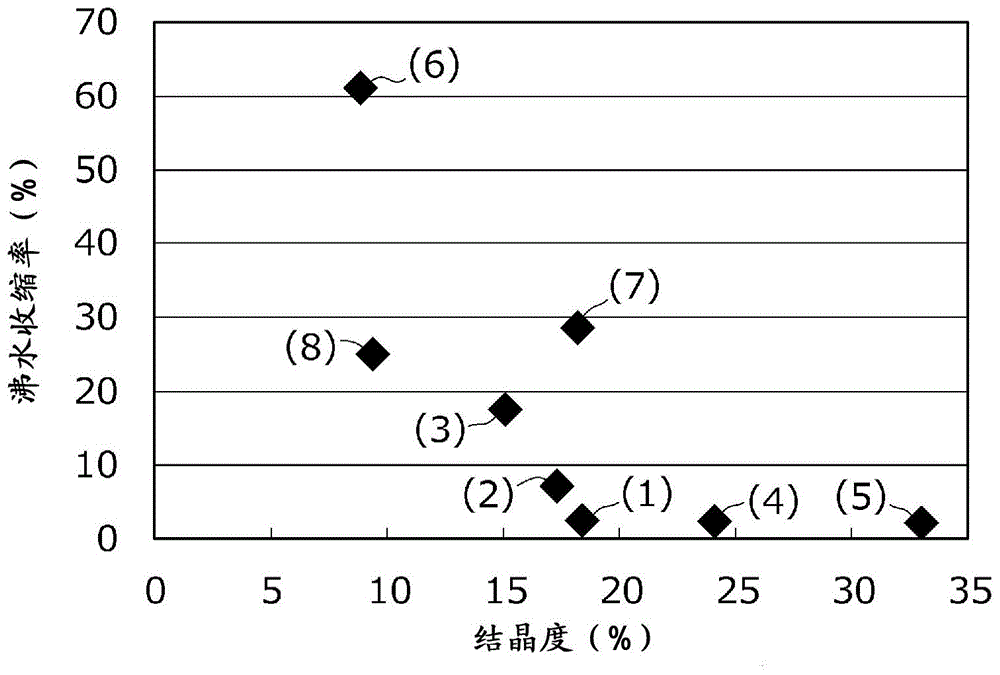

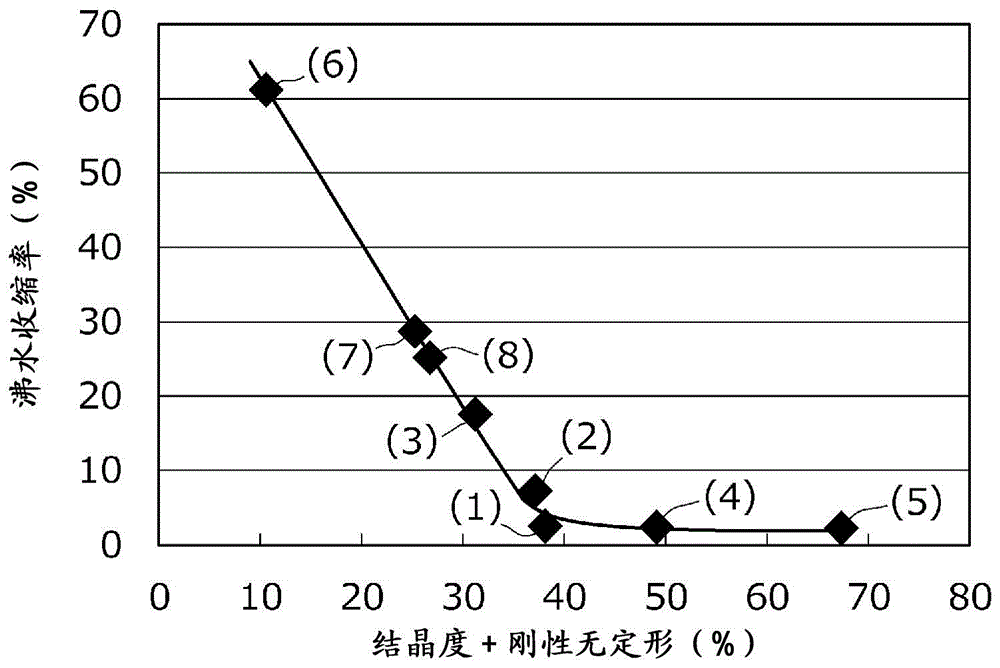

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com