Composite waterproof roll as well as preparation method and application thereof

A waterproof roll material and roll material technology, which is applied in the direction of chemical instruments and methods, building insulation materials, synthetic resin layered products, etc., can solve the problems of polypropylene fiber strength decrease, longitudinal tensile strength, transverse tensile strength, peeling strength decrease, The problems of low three-strength of the coiled material can achieve the effect of increasing the depth of the core layer pressed into the coiled material, increasing the temperature of the composite process, and improving the environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

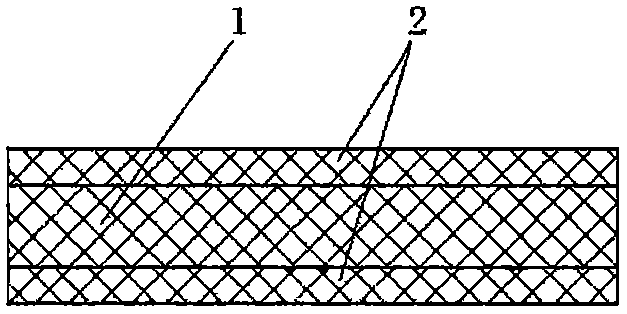

[0056] Coil core material: linear low density polyethylene, core thickness 0.5mm.

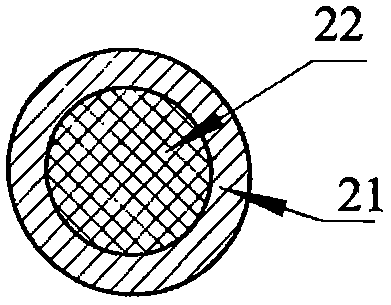

[0057] Non-woven fabric: bicomponent fiber with skin-core structure, fiber skin material polyethylene; fiber core material polyester (PET), fiber length 51mm.

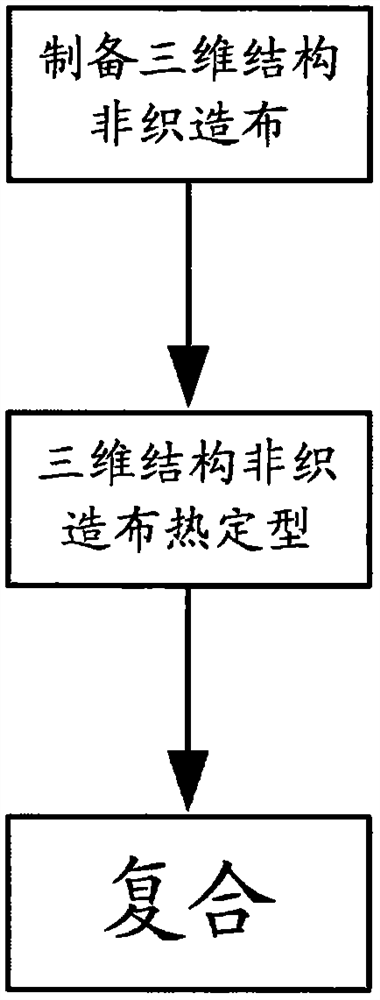

[0058] The production of the nonwoven fabric in this embodiment adopts the controllable two-dimensional fiber arrangement direction to lay the net. The two-dimensional structure has 40-45% of the X-axis fiber arrangement quantity and 55-60% of the Y-axis fiber arrangement quantity. In a three-dimensional direction, the needling density determines the number of fibers arranged in the Z-axis direction, and the number is 360-390 fibers / cm 2 (The number of X-axis fibers + the number of Y-axis fibers = 100. The X-axis fibers and Y-axis fibers are punctured into 4 90-degree bends by needle punching. After needle punching, the fibers are concave-convex, and the length of the non-woven fabric in the Z-axis direction is only the fiber length. 5...

Embodiment 2

[0067] The coil core layer 1 is made of (EVA from Mitsui Polymer Chemicals Co., Ltd., model P-2805, with a melt index of 2), and the nonwoven fabric 2 is made of two-component (PE / PET) polyester with a polyethylene skin core structure. ) fibers are made by needle punching process.

[0068] Coil core material: EVA (ethylene-vinyl acetate copolymer core layer, core layer thickness 0.5mm.

[0069] Non-woven fabric: bicomponent fiber with skin-core structure, fiber skin material polyethylene; fiber core material polyester (PET), fiber length 51mm.

[0070] The preparation of the nonwoven fabric in this example is as in Example 1.

[0071] In the coil preparation process of this embodiment, the composite temperature is 160-190° C.; the pressure is 4.5-5 MPa, the composite gap is 0.6-0.65 mm, and the non-woven fabric is pressed into the core layer of the coil to a depth of 0.08-0.12 mm.

[0072] Present embodiment coil inspection result:

[0073] Longitudinal tensile strength: 79...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com